Abstract

The possibilities of control of the electrophysical and mechanical properties of amorphous diamond-like silicon-carbon films by means of structural, chemical and structural-chemical modification are considered. The magnitude of the bias voltage and its frequency during the process of film synthesis, argon pressure in working chamber and precursors with different molecular structures are used as factors of structural modification. Introduction of transition metals with the concentration up to 30–35 at % into the film is used for chemical and structural-chemical modification. The high efficiency of control of the physical properties of films by the considered methods is shown.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 INTRODUCTION

From the material science point of view, the success in creating instruments and devices is largely determined by the ability to control of the properties of the source material. It is the presence of the method of controlled property management in microvolumes of crystalline semiconductors by doping with substitutional impurities (donors and acceptors) has provided modern development of micro-and nanoelectronics.

At the same time, immediately after the discovery of non-crystalline semiconductors [1], the weak sensitivity of these materials to substitution impurities was found, which became a significant barrier to their practical application. Therefore, a number of alternative methods have been developed for control of the properties of non-crystalline semiconductors. These include methods for producing hydrogenated amorphous silicon with a low density of localized states [2], method of chemical modification of properties of multi-component chalcogenide glassy semiconductors consisting in the introduction of a significant amount of impurity (fractions and units of atomic percentages) under certain conditions [3], method of structural modification of properties of non-crystalline semiconductors based on changing the structure of the material at a constant chemical composition [4, 5]. In this paper, we consider the possibility of applying chemical and structural modification methods for control of the properties of a relatively new class of materials—amorphous diamond-like silicon-carbon films.

Amorphous diamond-like silicon-carbon films obtained by plasma-chemical decomposition of silicon-organic compounds have the advantages of diamond-like films of amorphous carbon and at the same time are free from many disadvantages of the latter [6], which opens up the possibility of their use as protective and antifriction coatings in various areas of technology [7–10]. In this regard, the development of methods for control of the properties of these materials is a task of current interest.

2 SAMPLE PREPARATION AND RESEARCH METHODS

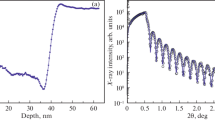

The scheme of the setup for the synthesis of silicon-carbon films is shown in Fig. 1 [11]. The silicon-organic precursor is fed to the working chamber via a ceramic disperser located at a distance of 20–30 mm from the tungsten thermocathode (the temperature of the cathode is approximately 2500°C). Thermal radiation of the cathode heats ceramic to a temperature of 300–400°C thus ensuring the transition of the precursor to a vapor-like state. The plasma discharge is generated in a criss-cross constant (radial) and variable (axial) fields. The magnetron located in the upper part of the figure is used for introducing metals into the growing film (see Section 4) and leak 2 serves for introducing the inert gas into the chamber.

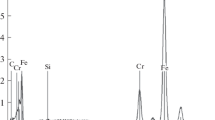

The elemental composition of the films was studied by X-ray spectral microanalysis using the energy dispersive spectrometer Inca x-Act. Morphology of the film surface was studied by atomic force microscope NteGRA Prima. Frequency dependences of electrical conductivity and dielectric properties at different temperatures were measured on a device for complex measurement of the dielectric properties of materials Novocontrol Alpha-A. Studies of electrophysical properties were carried out on the automated system for electrophysical measurements ASEC-03E. Mechanical properties were studied by the method of nanoindentation with a Berkovich pyramid on the nanoindentor NHT2-TTX.

3 STRUCTURAL MODIFICATION OF THE PROPERTIES

Structural modification of the properties of amorphous silicon-carbon films is carried out by influencing the material by various external factors in the process of their production. The setup described above allows structural modification of the film during its synthesis by changing:

—bias voltage magnitudes on the substrate holder;

—argon pressure in the working chamber;

—type, and therefore, the structure of the molecules of the silicon-organic precursor;

—frequency of the alternating voltage that creates the axial field.

These factors determine the structure of the particles forming the plasma, their kinetic energy at deposition on the substrate and influence the structure of the formed film.

The magnitude of bias potential on the substrate holder determines the kinetic energy of the particles depositing on the substrate during film growth. An increase in the potential leads to higher mobility of the particles at the surface of the growing film, increasing the probability of forming sp3 bonds on carbon atoms. As a result, denser films are formed. Thus, when the bias voltage on the substrate holder is –200 V, the nanohardness of the films is 22 GPa and their elastic modulus is 135 GPa, and when the bias voltage is ‒400 V, the specified characteristics become equal to 28 and 190 GPa, respectively. The height of the surface relief of the films decreases from 0.9 to 0.35 nm when the voltage on the substrate holder changes from –100 to –1000 V. In addition, as noted in [8], the specific electrical conductivity of the material is simultaneously reduced by about an order of magnitude.

Argon ions in the working chamber bombard the surface of the growing film at negative bias on the substrate holder and the intensity of their bombardment depends on the partial pressure of argon. As a result of the bombardment two competing processes can occur: an increase in the effective temperature of the growth surface due to the transfer of ion energy to it (which contributes to the formation of more ordered structure) and the creation of additional defects during the interaction of ions with the growing film (which disorders the structure). The experiments on the effect of partial pressure on silicon-carbon films showed [8] that an increase in the partial pressure of argon leads to an increase in density of the localized states in the tails of permitted zones. Since the studied materials are characterized by a hopping mechanism of conductivity [10], this fact leads to a significant increase in electrical conductivity: from 3 × 10–12 Ω–1 cm–1 at the absence of argon in the chamber, up to 1 × 10–6 Ω–1 cm–1 at argon pressure 7 × 10–4 Torr [8]. Thus, experimental data show that bombarding the growing film with argon ions leads to the formation of a more disordered structure under the implemented experimental conditions.

Structure and properties of silicon-carbon films depend on the structure of the original silicon-carbon precursor. To assess this effect, the studies of films produced by plasma-chemical decomposition of polyphenylmethylsiloxane (PPMS) with chemical formula (CH3)3Si[CH3C6H5SiO]nOSi(CH3)3, and of polymethylsiloxane (PMS) with chemical formula (CH3)3Si[(CH3)2SiO]nOSi(CH3)3 were carried out. The first of them (PPMS) consists of atomic chains with asymmetric structure, containing branches in the form of phenyl rings and CH3 groups. In contrast, PMS consists of linear molecules containing symmetrically arranged CH3 groups. The chemical compositions of precursors are quite close to each other. PPMS has slightly higher carbon content due to the presence of phenyl rings. The results of X-ray spectral microanalysis show chemical compositions of the films obtained by plasma chemical decomposition of both PPMS and PMS to be close to the chemical composition of the corresponding precursors. The ratio of concentrations of carbon and silicon atoms in the films based on PPMS is 3.9 ± 0.4 and in films based on PMS is 2.7 ± 0.3.

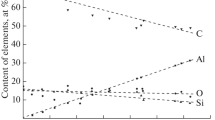

The influence of technological regimes on the properties of films of both types has a similar character. Figure 2 shows the temperature dependences of electrical conductivity of the films obtained at different bias potentials on the substrate holder (Fig. 2a) and different argon partial pressure in the working chamber (Fig. 2b). It can be seen that for both types of the films an increase of bias potential on the substrate holder leads to a decrease of the film electrical conductivity, and an increase of argon partial pressure in the working chamber leads to an increase of their electrical conductivity. Moreover, if changes in the bias potential on the substrate holder cause changes in the absolute values of electrical conductivity within the same order of magnitude, then the degree of influence of argon pressure in the working chamber on the electrical conductivity for two types of the films is much higher.

In the case of films obtained by decomposition of polymethylsiloxane, changes in the partial pressure of argon from 0 to 8 × 10–3 Torr cause a change in the electrical conductivity of the films by two orders of magnitude.

In the films based on polymethylphenylsiloxane with similar changes in the partial pressure of argon, the changes in electrical conductivity reached 6 orders of magnitude.

This fact can probably be due to the more diverse content of particles that are generated in plasma during defragmentation of complex PPMS molecules. The process of deposition of these particles on the growth surface under conditions of its bombardment by argon ions leads to an increase in the concentration of defects and, accordingly, increases the density of localized states in the tails of the permitted zones.

The results described above were obtained using alternating voltage of 1.76 MHz. However, as was noted above, one of the possibilities of structural modification is to change the frequency of the electric field. It should be mentioned that there are very few studies of the effect of the frequency of the electric field on the properties of films obtained by plasma deposition methods. Typically, standard megahertz frequencies are used. In [12, 13] the films a-Si : H and a-Si1 − xGex : H were obtained by the method of low-frequency (55 kHz) plasma-chemical deposition. It was shown that in this case, the film growth rate increases by an order of magnitude compared to the standard method of high-frequency deposition, while maintaining a low density of localized states and “high electronic properties”.

In this work, we fabricated PPMS-based silicon-carbon films using an alternating voltage source with a frequency of 100 kHz while keeping other technological parameters unchanged. The results on the electrical conductivity of films obtained by high-frequency (1.76 MHz) and low-frequency (100 kHz) methods at different argon pressures in the working chamber are shown in the Table 1.

As can be seen from the table, in the absence of argon in the chamber, the electrical conductivity of the films fabricated at low frequency of the electric field is two orders of magnitude higher than of the films fabricated at high frequency method. But the main difference is that the introduction of argon into the working chamber leads to a decrease in electrical conductivity by an order of magnitude, while in films fabricated at high frequency, at close partial argon pressures, the electrical conductivity increases by three orders of magnitude. In addition, it should be noted that the introduction of argon into the working chamber in the low-frequency method of films fabrication reduces the value of the tangent of the dielectric loss angle in the low-frequency region by several times (Fig. 3), which indicates a decrease in through-conduction currents in these samples.

A change in the frequency of the axial electric field during the fabrication of films by plasma-chemical decomposition of organosilicon compounds leads to significant changes in the electron and ion subsystems of the plasma, to the change in the magnitude of the negative self-bias of the substrate holder, which, in turn, changes the intensity of the ion bombardment of the growing film and the effective temperature of the growth surface.

At present, it is difficult to make concrete conclusions, based on the above mentioned experimental data, about the mechanisms of the observed changes in properties. However, it is obvious that changing the frequency of the electric field during the plasma-chemical decomposition is an effective method for control of the properties of diamond-like silicon-carbon films.

4 CHEMICAL MODIFICATION OF THE PROPERTIES

Due to the high stability of the silicon-carbon structural lattice, the materials under consideration allow the introduction of a large amount of impurities (up to several tens of atomic percent of transition metals [6]) without breaking the amorphous state of the matrix. This makes it possible to control of the properties of diamond-like silicon-carbon films in a wide range by chemical modification.

The introduction of metals into a silicon-carbon matrix, as a rule, leads to the formation of a two-phase system—amorphic silicon–carbon matrix with nanocrystals with dimensions of units of nanometers embedded in it. In this case, the latter are either a metal (when platinum [14] or silver [15] are introduced), or metal carbide MeC (when the transition metals [16] are introduced). Figure 4 shows the dependence of the specific electrical conductivity of tantalum-containing film on the concentration of tantalum. The value of electrical conductivity increases by 9 orders of magnitude from 10–6 to 103 Ω–1 cm–1 when tantalum up to 30 at % is introduced. As it is seen from the picture, the dependency has three distinct areas. In the first area, at low concentrations of metal, the electrical conductivity increases smoothly by about two orders of magnitude. In the second area, the sharp increase of electrical conductivity by 6 orders of magnitude takes place. Finally, in the third area, when the metal concentration exceeds 22 at %, a weak dependence of the electrical conductivity on the metal concentration is observed. Such type of the dependency is typical for percolation systems.

The results of calculating the concentration dependence of the electrical conductivity of a tantalum-containing film in accordance with the self-consistent Bruggeman field approximation used for such systems [17] are shown in Fig. 4 by dotted line. When calculating the electrical conductivity of the silicon-carbon matrix was taken equal to 1.2 × 10–6 Ω–1 cm–1 (the value for zero metal concentration in the figure), electrical conductivity of tantalum carbide was 2 × 103 Ω–1 cm–1 [18], the concentration of the conducting phase in accordance with the TaC chemical formula was assumed to be twice as high as the concentration of the metal. The figure shows a good correspondence between experimental and calculated results in the area of high metal concentrations. Satisfactory agreement is also observed in the area of a sharp change in electrical conductivity. At the same time, in the first area, the experimental points lie significantly higher than the calculated curve.

Along with the electrical properties, there is a change in the mechanical properties of the material. The concentration dependences of the nanohardness of the films containing tungsten and molybdenum are shown in Fig. 5 [19].

Concentration dependences of the nanohardness of molybdenum- and tungsten-containing silicon–carbon films (the dashed line is the illustration of the contribution of the amorphous matrix, and the dashed curves are the illustration of the contribution of nanocrystalline phase into the nano-hardness of the material).

An increase in the metal content in the film leads to an increase in the concentration of metal carbide nanocrystals [10]. Since transition metal carbides have high mechanical characteristics, an increase in the concentration of their nanocrystals should lead to an increase in the nanohardness of the nanocomposite material. It is this dependence that is observed in the case of tungsten-containing samples. However, for molybdenum-containing films, the dependence has a different character. With an increase in the metal concentration, the nanohardness first decreases to a minimum value at 9 at % of molybdenum, and then increases, reaching the value for an unmodified sample at 15–16 at % of molybdenum. At the metal concentration of 17–18 at %, the nanohardness of the molybdenum-containing film begins to exceed the values for the tungsten-containing nanocomposite.

5 STRUCTURAL–CHEMICAL MODIFICATION OF THE PROPERTIES

As follows from the data presented, structural and chemical modification methods allow control of the properties of diamond-like silicon-carbon films within a wide range. However, a number of experimental results been obtained cannot be explained in terms of chemical or structural modification models. These include the concentration dependences of electrophysical and mechanical properties in the area of metal concentrations up to 15–17 at %, described above.

Let us return to the concentration dependence of the electrical conductivity of tantalum-containing films (Fig. 4). As is indicated above, at low values of the metal concentration (up to 15 at %), the experimental points lie above the calculated curve, and with an increase in the metal concentration, the difference in their values increases from zero to more than an order of magnitude. Such a discrepancy can occur in the case if the formation of nanocrystals of metal carbide not only reduces the fraction of the dielectric phase of the silicon-carbon matrix, but also changes its electrical conductivity. To understand the reasons for the change in the properties of the silicon-carbon matrix at the introducing the transition metals into the material, it is necessary to take into account that during the formation of metal carbides, carbon is borrowed from the silicon-carbon matrix, which leads to a change in the structure and properties of the last. The removal of carbon atoms leads to an increase in the concentration of broken bonds and to an increase in the density of localized states in the tails of the permitted zones. This results in the appearance of hopping conductivity in the dielectric matrix. Thus, during chemical modification of diamond-like silicon-carbon films by the transition metals, in addition to the formation of a new phase (metal carbide nanocrystals), the structure of the initial silicon-carbon matrix is modified due to removal of carbon atoms from it at the constant total carbon content in the material.

The situation is more complicated in the case of concentration dependences of mechanical properties (Fig. 5). The redistribution of carbon between the nanocrystalline carbide phase and the amorphous silicon-carbon matrix leads to the appearance of two competing processes: on the one hand, an increase in the volume of the carbide phase increases its contribution to the mechanical properties of the nanocomposite, on the other hand, the depletion of the amorphous matrix with carbon causes a decrease in its contribution. These processes can cause the appearance of an extremum in the concentration dependences of mechanical properties, which is observed on the concentration dependence of the nanohardness of molybdenum-containing films. However, as can be seen from Fig. 5, the minimum on the concentration dependence of nanohardness is absent in the films with tungsten.

To explain this fact, it is necessary to take into account that the sizes of nanocrystals of molybdenum and tungsten carbides differ significantly even at close metal concentrations in silicon-carbon films (the average size of MoC nanocrystals is 2.5 nm and of WC nanocrystals is about 1 nm) [19]. Since at a constant amount of metal, the concentration of nanocrystals is inversely proportional to their volume, and the distance between them is proportional to the size of the particles, then the number of tungsten carbide nanocrystals in tungsten-containing films will be greater and the distance between them will be less than in the films with nanocrystals of molybdenum carbide. Taking into account the same chemical formula of tungsten and molybdenum carbides and close volumes of their unit cells (WC — 62.3 Å3, MoC — 60.5 Å3), the number of carbide nanocrystals falling in the area of the identified region was evaluated during studying mechanical properties with the Berkovich indenter [19]. At a metal concentration of 10 at %, the number of tungsten carbide nanocrystals in the identified region is in the range (1.1–1.7) × 106, and the number of molybdenum carbide nanocrystals is in the range (0.4–1.4) × 105. Thus, the number of nanocrystals located in the identification region is an order of magnitude higher in the case of the tungsten-containing nanocomposite than in the films of the molybdenum-containing nanocomposite. This leads to different degrees of influence of the carbide phase being of the same content in tungsten- and molybdenum-containing films on the mechanical properties of the material.

The contributions of an amorphous silicon-carbon matrix and a nanocrystalline carbide phase to the nanohardness of the material at different metal concentrations are shown in Fig. 5 by dashed and dotted lines. As it is seen from the figure, the contribution of the carbide phase to the nanohardness increases significantly faster with increasing metal concentration in the case of tungsten-containing films than in the case of molybdenum-containing ones, so that the minimum in the experimental dependence is not observed.

6 CONCLUSIONS

Structural and chemical modifications of amorphous diamond-like silicon-carbon films are found to be an effective method for control of the electrophysical and mechanical properties of these materials. The combined usage of these two methods allows changing the electrical conductivity by more than 16 orders of magnitude. However, when using chemical modification, it is necessary to take into account the influence of the introduced impurities on the structure of the silicon-carbon matrix for predictable changes in properties. Taking this influence into account (of structural-chemical modification) allows describing quantitatively the dependence of films properties on the concentration of introducing metal.

REFERENCES

N. A. Goryunova and B. T. Kolomiets, Izv. Akad. Nauk SSS, Ser. Fiz. 20, 1496 (1956).

W. E. Spear and P. G. le Comber, Solid State Commun. 17, 1193 (1975).

S. R. Ovshinsky, in Amorphous and Liquid Semiconductors, Ed. by W. E. Spear (Univ. Edinburgh, UK, 1977), p. 519.

A. Popov, N. Mikhalev, and V. Shemetova, Philos. Mag., B 47, 73 (1983).

A. I. Popov, V. A. Vorontsov, and I. A. Popov, Semiconductors 35, 637 (2001).

Š. Meškinis and A. Tamulevičiené, Mater. Sci. (Medžiagotyra) 17, 358 (2011).

F. Mangolini, B. A. Krick, T. D. B. Jacobs, S. R. Khanal, F. Streller, J. B. McClimon, J. Hilbert, S. V. Prasad, T. W. Scharf, J. A. Ohlhausen, J. R. Lukes, W. G. Sawyer, and R. W. Carpick, Carbon 130, 127 (2018).

A. I. Popov, A. D. Barinov, and M. Y. Presniakov, J. Nanoelectron. Optoelectron. 9, 787 (2014).

E. V. Zavedeev, O. S. Zilova, M. L. Shupegin, A. D. Barinov, N. R. Arutyunyan, T. Roch, and S. M. Pimenov, Appl. Phys. A 122, 961 (2016). https://doi.org/10.1007/s00339-016-0508-7

A. Popov, Disordered Semiconductors: Physics and Applications, 2nd ed. (Pan Stanford, Singapore, 2018).

M. L. Shupegin, Zavod. Lab. Diagn. Mater. 79, 28 (2013).

B. G. Budagyan, A. A. Sherchenkov, A. E. Berdnikov, and V. D. Chernomordik, Russ. Microelectron. 29, 391 (2000).

A. A. Sherchenkov, Mater. Elektron. Tekh., No. 1, 48 (2003).

M. D. Malinkovich, Yu. N. Parkhomenko, D. S. Polyakov, and M. L. Shupegin, Mater. Elektron. Tekh., No. 1, 41 (2010).

T. Tamulevičius, D. Tamulevičiené, A. Virganavičius, V. Vasiliauskas, Š. Kopustinskas, and S. Meškinis, Nucl. Instrum. Methods Phys. Res., Sect. B 341, 1 (2014).

M. Yu. Presnyakov, A. I. Popov, D. S. Usol’tseva, M. L. Shupegin, and A. L. Vasiliev, Nanotechnol. Russ. 9, 518 (2014).

A. A. Snarskii, I. V. Bezsudnov, and V. A. Sevryukov, Transport Processes in Macroscopically Disordered Media. From Mean Field Theory to Percolation (LKI, Moscow, 2007) [in Russian].

Ya. M. Kolotyrin and V. M. Knyazheva, Itogi Nauki Tekh., No. 3, 5 (1974).

A. D. Barinov, A. I. Popov, and M. Yu. Presnyakov, Inorg. Mater. 53, 690 (2017).

Funding

This study was performed with financial support of the Russian Foundation for Basic Research (grant no. 19-07-00021).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by S. Rostovtseva

Rights and permissions

About this article

Cite this article

Popov, A.I., Barinov, A.D., Emets, V.M. et al. Control of Properties of Diamond-Like Silicon–Carbon Films. Phys. Solid State 62, 1780–1786 (2020). https://doi.org/10.1134/S1063783420100261

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063783420100261