Abstract

The possible mechanisms of bainitic transformation in steels are discussed. According to the known models of the growth of Widmanstatten ferrite, an acicular shape of bainitic lathes is due to anisotropy in the surface energy. However, the lath replication mechanisms in upper and lower bainite presumably differ from each other. Upper bainite results from the diffusion-controlled transformation, at which the pearlitic autocatalysis due to the formation of cementite at the interface with ferrite takes place. Lower bainite is formed at a smaller temperature via the diffusionless mechanism, when the branching of precipitates or the autocatalysis of lathes can be provided by a decrease in the system energy due to the disposition of structural defects at the interfaces of precipitates, so the existence of a characteristic lath size is energetically stipulated (Weissmüller effect). The combined effect of different autocatalysis mechanisms leads to a variety of possible bainite modifications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 INTRODUCTION

Bainite (alongside with ferrite, pearlite, and martensite) is one of the possible products of the γ–α transformation occurring in steel under cooling [1]. Alloyed bainitic steels of high and medium strength have found a wide application in large-dimensioned welded structures and automotive and power production industries. However, in spite of extensive experimental and theoretical studies, the mechanisms of the formation of a bainitic microstructure still remain not quite clear [2].

Upper bainite is formed by Widmanstatten ferrite (α) lathes spaced apart by cementite (θ) interlayers. In contrast to pearlite, lattice coherence is partially retained at the γ/α interface, and α and θ precipitates may grow in a noncooperative fashion (in upper bainite, ferrite precipitates first [1, 3]), though the volumetric α/θ ratio at the developed colony growth stages is nearly constant [4]. Lower bainite is formed at a smaller temperature and consists of ferrite lathes spaced apart by austenite interlayers; cementite precipitates at latter transformation stages both at the boundaries of ferrite lathes and in their volume.

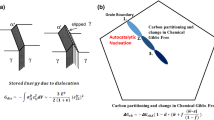

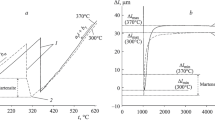

At the present time, it has been established that the bainitic transition is shear lattice reconstruction by nature [2], but the dispute on whether its rate is controlled by either the diffusion of carbon or the relaxation of stresses is still continued [1, 5, 6]. According to Bhadeshia [1], both types of bainite are formed below the temperature T0' (see Fig. 1, regions UB1, LB), i.e., in the phase diagram region, where the γ → α transition is possible in the absence of carbon diffusion. Moreover, several regimes have been revealed for the γ–α transformation in pure iron depending on the temperature [7] and may be associated with two bainitic and/or two martensitic transformations (isothermic and athermic) [8].

Diagram of phase transformations in carbon steel: A1, A3, and Acm are the boundaries of the two-phase γ + α and γ + θ regions; WS and MS are the start lines of Widmanstatten ferrite [5] and martensite; T0' is the line of equality between the free energies of the γ and α phases (with consideration for the contribution of stresses) at a constant carbon concentration [1]; TP is the starting pearlite autocatalysis temperature [10]; and WF, UB1, UB2, and LB are the Widmanstatten ferrite and upper and lower bainite regions.

However, there exists some experimental facts [3], according to which the structure morphologically equivalent to upper bainite appears within the temperature range T0 < T < Ws (Ws is the Widmanstatten ferrite start line, above which the γ–α transition can not occur via the shear lattice reconstruction [5] (see Fig. 1, region UB2). In this case, the formation of upper bainite is controlled by the diffusion of carbon, and the phase diagram regions of upper bainite and pearlite overlap each other [3, 9]. Lattice coherence is completely lost at the γ/α interface in pearlite, but partially retained for bainitic ferrite. The start of the transformation by one or another scenario is likely to depend on the start conditions for the nucleation of the first ferrite precipitate.

Another unclarified question is the mechanism of the replication of ferrite lathes in a bainitic colony. The proposed model of phase transformations [10–13] in steel with first-principle parametrization elements has provided the possibility to construct the major lines of the iron–carbon phase diagram in compliance with experiment and to perform a simulation of the ferrite, pearlite, and martensitic transformations. However, it has not allowed us to observe the growth of a bainitic colony. If the replication of lathes follows the pearlitic autocatalysis mechanism, as hypothesized in the works [14, 15], the criterion of distinction between pearlite and bainite is lost within the framework of this model. In addition, it is well established that at least lower bainite can be formed in the absence of cementite. On the other hand, elastic stresses stimulate the autocatalysis of ferrite lathes by the martensitic type (twinning), but the ferrite lathes in a bainitic colony in experiments have the same crystallographic orientation. To the Bhadeshia’s opinion [1], “it seems that strain-induced autocatalysis does not play an important role in bainite formation.”

2 MODELING RESULTS

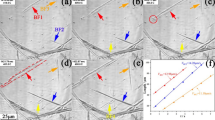

An acicular shape of Widmanstatten ferrite precipitates is usually explained by surface energy anisotropy [16, 17], which was not taken into account in [11, 12] for simplicity. It is likely that this anisotropy is lost when lattice coherence is destroyed at the γ/α interface, thus changing the “upper bainite/pearlite” scenario. The simulation of the growth of a colony of ferrite and cementite precipitates within the framework of the autocatalytic decomposition model [10] is illustrated in Fig. 2 without (upper row) and with (lower row) surface energy anisotropy, which was taken into account via the replacement \(\sigma {{(\nabla c)}^{2}}\) → \({{\sigma }_{x}}{{({{\nabla }_{x}}c)}^{2}}\) + \({{\sigma }_{y}}{{({{\nabla }_{y}}c)}^{2}}\) in the Ginzburg–Landau free energy functional. It can be seen that the kinetics of transformation is different in these cases. The first case is characterized by the cooperative growth of α and θ precipitates. In the second case, a ferrite acicula broadening with time appears first, and cementite is formed at the following stage. This mechanism relates first of all to upper bainite in region UB2 (see Fig. 1). Bainite in region UB1 may be formed by the same scenario: carbon is forced out of ferrite at a rather high temperature to form a “locking” shell, thereupon the transformation becomes diffusion-controlled. However, this mechanism can not explain the growth of lower bainite colonies in the absence of cementite. It seems that an additional mechanism, which is not associated with both cementite or stresses, may exist for the replication of ferrite lathes.

Autocatalytic decomposition of austenite (grey) into ferrite (black) and cementite (white) within the model [10] with isotropic (σx/σy = 1, upper row, pearlite colony) and anisotropic (σx/σy = 5, lower row, upper bainite analogue) surface energy at T = 625 K and a carbon concentration c0 = 0.06.

Experiments argue for the existence of a characteristic size of bainite lathes (for both their length and width). This cannot be explained by the elastic equilibrium with the matrix, as the relaxation of stresses in the course of long-term exposure does not lead to the change in the size of lathes. In addition, according to Bhadeshia [1], lathes are not isolated, but linked to each other by bridges, which are not always visible in a two-dimensional specimen cross section. In the latter case, the matter concerns the strong branching of the only ferrite precipitate rather than the autocatalytic replication of lathes.

Hence, it is possible to conclude that a bainitic colony is similar to a system with zero surface energy, i.e., the limitation of the growth and coalescence of ferrite precipitates is caused by the energetic advantage of γ/α interfaces. A similar effect was considered by Weissmüller for the recrystallization of grains in the presence of impurity grain boundary segregation (GBS) [18] and experimentally confirmed in the work [19]. It has been demonstrated that an equilibrium grain size, at which the energy of grain boundaries is zero, is attained in some systems due to GBS. In the case of the bainitic transformation, the role of GBS may be played by dislocations, which are generated as a result of plastic deformation during the growth of a lath and have the lowest energy, being placed at the γ/α interface to compensate the mismatch between the lattices. In this case, the existence of extensive interfaces in the absence of any pronounced trend to the coalescence of ferrite precipitates becomes energetically advantageous.

For the qualitative illustration of this effect, let us formulate a simple model without carbon in which point defects with a negative energy of bonding with the γ/α interface are formed on it instead of dislocations. Let us write the Ginzburg–Landau free energy functional as

Here, ϕ is the nonconservative order parameter (ϕ = 0 in austenite, and ϕ = ±1 in ferrite), ξ is the density of defects, fb(ϕ) is the energy density along the Bain path, \(\sigma _{\phi }^{{x(y)}}\) are the anisotropic surface energy parameters, σϕξ is the energy of interaction between defects and the interface of precipitates, Aξ is the native energy of defects, and \({{\sigma }_{\xi }}{{(\nabla \xi )}^{2}}\) is the auxiliary contribution hampering the clustering of defects. Similarly to [12], let us determine the Bain path by a sixth-order polynomial as

where gα(γ) is the energy density in ferrite (austenite), and gb characterizes the height of the barrier between these states. Let us note that though the native energy of defects Aξ may be high, it does not depend on the configuration and has no effect on the phase composition, so we further set A = 0. Taking into account the qualitative character of this discussion, the model parameters are selected rather arbitrarily.

To analyze the evolution of this system, let us use the Monte-Carlo method on a square 400 × 400 grid with reflectionally symmetric boundary conditions. At every grid node (corresponding to a physically small material volume), the instantaneous point values \({{\bar {\phi }}_{i}}\), \({{\bar {\xi }}_{i}}\) are either 0 or 1. The order parameters ϕ, ξ incorporated into Ginzburg–Landau functional (1) are calculated by averaging \({{\bar {\phi }}_{i}}\), \({{\bar {\xi }}_{i}}\) over three coordination spheres. One of the grid nodes is randomly selected at each iteration. The value \({{\bar {\phi }}_{i}}\) may switch at this node, and the value \({{\bar {\xi }}_{i}}\) can be exchanged with one of the neighboring node. The change of values occurs with the Metropolis algorithm probability calculated using Ginzburg–Landau functional (1). Moreover, if a selected node is free from a defect (\({{\bar {\xi }}_{i}}\) = 0), an attempt to generate a defect (\({{\bar {\xi }}_{i}}\) = 1) at this node is made with the probability

Equation (3) means that defects are generally generated at the γ/α interface. The generation of defects is stopped, if their ultimate concentration Cξ is attained in the neighborhood of a selected node.

The typical evolution in the case of starting from a solitary ferrite nucleus is illustrated in Fig. 3. At the initial stage, the acicular shape of a lath is caused by surface energy anisotropy. The broadening of this lath is inhibited by the accumulation of defects at the interface, and this predetermined the width of a lath in the long run. Further evolution occurs via either the branching or nucleation of new lathes. Austenite or, more precisely, the γ/α phase interface remains to be a preferable state in the regions where defects are concentrated due to σϕξ < 0. A colony, which is qualitatively similar to lower bainite, is formed at the developed stages.

Growth of a lower bainite like colony on a square 400 × 400 grid under the conditions of the generation and accumulation of defects at the interface of precipitates (upper row) and corresponding distribution of defects (lower row) at gα = 0, gγ = 4, gb/kT = 58, σϕξ/kT = −0.07, \(\sigma _{\phi }^{x}\)/kT = 10–4, \(\sigma _{\phi }^{y}\) = 10–3, σξ/kT = 10–2, Cξ = 0.03, and Q0 = 2.5 × 10–5. Time is expressed via the number of iterations N.

3 CONCLUSIONS

Hence, the performed analysis allow us to presume that the formation of upper bainite is a diffusion-controlled transformation, in which the morphology of precipitates is stipulated by surface energy anisotropy similarly to Widmanstatten ferrite, and the replication of lathes follows the mechanism of pearlite autocatalysis with participation of cementite. On the contrary, the formation of lower bainite is a diffusionless transformation, in which the replication/branching of lathes occurs due to the Weissmüller effect; i.e., a negative energy of bonding between the defects, generated during the growth of precipitates, with the γ/α interface leads to energetically advantageous extensive surface area of γ/α interfaces.

REFERENCES

H. K. D. H. Bhadeshia, Bainite in Steels (IOM Commun., London, 2001).

L. C. D. Fielding, Mater. Sci. Tech. 29, 383 (2013).

O. P. Morozov, V. M. Schastlivtsev, and I. L. Yakovleva, Fiz. Met. Metalloved., No. 2, 150 (1990).

P. Vasudevan, L. W. Graham, and H. J. Axon, J. Iron Steel Inst. 190, 386 (1958).

M. Hillert, L. Hoglund, and J. Agren, Met. Mater. Trans. A 35, 3693 (2004).

V. M. Schastlivtsev, Metal Sci. Heat Treatment 47 (7–8), 276 (2005).

D. A. Mirzaev, M. M. Shteinberg, T. N. Ponomareva, and V. M. Schastlivtsev, Fiz. Met. Metalloved. 47, 125 (1979).

V. A. Lobodyuk and E. I. Estrin, Phys. Usp. 48, 713 (2005).

V. M. Schastlivtsev, D. A. Mirzaev, and I. L. Yakovleva, Perlit in Carbon Steels (UrO RAN, Yekaterinburg, 2006) [in Russian].

I. K. Razumov, Yu. N. Gornostyrev, and M. I. Katsnelson, Phys. Rev. Appl. 7, 014002 (2007).

I. K. Razumov, Yu. N. Gornostyrev, and M. I. Katsnelson, J. Phys.: Condens. Matter 25, 135401 (2013).

I. K. Razumov, D. V. Boukhvalov, M. V. Petrik, V. N. Urtsev, A. V. Shmakov, M. I. Katsnelson, and Yu. N. Gornostyrev, Phys. Rev. B 90, 094101 (2014).

I. K. Razumov, Phys. Solid State 59, 1906 (2017).

A. Hultgren, Trans. ASM 39, 915 (1947).

H. J. Lee, G. Spanos, G. J. Shiflet, and H. I. Aaronson, Acta Met. 36, 1129 (1988).

A. Yamanaka, T. Takaki, and Y. Tomita, Mater. Trans. 47, 2725 (2006).

A. Bhattacharya, K. Ankit, and B. Nestler, Acta Mater. 123, 317 (2016).

J. Weissmüller, Nanostruct. Mater. 3, 261 (1993).

M. Saber, C. C. Koch, and R. Scattergood, Mater. Res. Lett. 3, 65 (2015).

ACKNOWLEDGMENTS

This work was performed within the state task on the subjects “Magnet” (project no. AAAA-A18-118020290129-5) and “Structure” (project no. AAAA-A18-118020190116-6).

The author is grateful to Yu.N. Gornostyrev and M.I. Katsnel’son for the useful discussions of scenarios and mechanisms of phase transformations in carbon steels.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Glushachenkova

Rights and permissions

About this article

Cite this article

Razumov, I.K. Possible Mechanisms of the Formation of Bainitic Colonies. Phys. Solid State 61, 80–83 (2019). https://doi.org/10.1134/S1063783419020203

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063783419020203