Abstract

The decomposition of a solid solution of interstitial magnesium Mgi in silicon is studied. Float-Zone dislocation-free single-crystal n-Si with a resistivity of ~8 × 103 Ω cm and oxygen and carbon contents of ~5 × 1014 cm–3 and ~1 × 1015 cm–3 is used in the experiments. The samples are doped using the diffusion sandwich method at T =1100°C followed by quenching. Decomposition of the supersaturated Mgi solid solution is studied by observing the kinetics of increasing the resistivity of doped samples resulting from their annealing in the range T= 400–620°C. It is found that the decomposition is characterized by an activation energy of Ea ≈ 1.6 eV, which is close to the previously determined diffusion activation energy of Mgi in silicon. It is also shown that Si:Mg exhibits stable properties at temperatures not exceeding 400°C, which is important for its possible practical application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 INTRODUCTION

To date, the magnesium impurity in silicon remains little studied, although the first studies of Si:Mg were performed more than half a century ago. It is known that the magnesium atom (Mgi) is a double donor in the interstitial position in the silicon lattice [1, 2]. In [2, 3], using optical absorption spectroscopy, a decrease in the Mgi concentration in samples kept at room temperature (e.g., sixfold after 49 months) was detected. In [4], it was shown that the selection of ultrapure-grade initial materials and the optimum sample cooling rate after diffusion doping makes it possible to obtain Si:Mg with room-temperature stable characteristics.

For the practical application of magnesium in silicon technology, it is important to have information about the effect of heat treatment on the properties of Si:Mg. So far, systematic studies in this field have not been performed. The objective of this work is to study changes in the electrical characteristics of Si:Mg samples resulting from annealing at various temperatures. Along with their practical importance, such studies can yield useful information on the mechanism of Mg migration in silicon.

2 EXPERIMENTAL

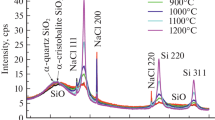

As the initial material, we used Float-Zone dislocation-free n-Si grown under vacuum conditions (ρinit ≈ 8 × 103 Ω cm with oxygen and carbon contents of ~5 × 1014 and ~1 × 1015 cm–3). Silicon wafers 30 mm in diameter and 2 mm thick were doped with 99.995% purity magnesium using the diffusion sandwich method [1–4]. Diffusion was performed from metal magnesium layers sputtered onto both wafer sides. Doping was performed in sealed quartz ampuls in an argon atmosphere at 1100°С for 2.5 hours followed by ampul cooling by a compressed air jet. Such a procedure provided almost uniform sample doping over volume. According to Hall effect and four-probemeasurement data, the Mgi concentration in the prepared samples was N0 ≈ 6 × 1014 cm–3. Doped wafers were cut into samples 10 × 10 × 2 mm in size and then were subjected to a number of successive annealings in vacuum in the range of 400–620°C. The result of annealing was determined by measuringthe sample resistivity by the four-probe method before and after each annealing.

3 RESULTS AND DISCUSSION

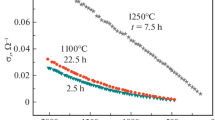

The dependences of the Mgi concentration on the time of annealing in the temperature range T = 400–620°С are shown in Fig. 1. The data are presented as the ratio N(t)/N0. We can see that annealing occurs in it should be “one stage”, and annealing at 400°C barely leads to a change in the sample conductance.

The solid lines in Fig. 1 correspond to the exponential dependences

where τ is the characteristic time of decomposition of the Mgi solid solution in silicon crystals, which decreases with increasing annealing temperature.

Figure 2 shows the dependence of τ on the inverse annealing temperature. The data presented on the figure scale are well approximated by a straight line, which points to the activation mechanism of the process under study. The corresponding activation energy is Ea ≈ 1.6 eV.

The effect of annealing on the electrical characteristics of Si:Mg is similar to that observed upon decomposition of solid solutions of other rapidly diffusing impurities in silicon [5] and germanium [6, 7].

It can be believed that a decrease in the concentration of Mgi donor centers upon annealing is caused by the fact that the solid solution of interstitial magnesium in the silicon lattice is supersaturated in the temperature region studied here. Supersaturation is provided by sample quenching after doping. The obtained activation energy of decomposition of the solid solution (Ea ≈ 1.6 eV) is close to the Mgi diffusion activation energy of 1.83 eV in dislocation-free silicon [4]. From this we can conclude that solid-solution decomposition occurs via impurity diffusion to precipitation centers of magnesium atoms (diffusion-limited annealing) [8], which do not contribute to the sample conductance. A decrease in the Mgi concentration can be associated, e.g., with the formation of magnesium-silicide particles or small-sized magnesium clusters. However, analysis of a cleavage of studied samples using a high-resolution scanning electron microscope does not allow the detection of inhomogeneous inclusions in them.

It was determined relatively long ago (see the Si–Mg phase diagram [9] for the region of low magnesium contents) that the total magnesium concentration in doped crystals can significantly, by two orders of magnitude and larger, exceed the corresponding value for Mgi. The state of the electrically inactive magnesium impurity in silicon is still unknown.We emphasize that the presented data concern the decomposition of a solid solution of an electrically active impurity component only which can be studied by measuring the sample resistivity.

4 CONCLUSIONS

It follows from the data of the present study that the electrical characteristics of Si:Mg, made from high-quality silicon using appropriate doping and quenching procedures, appear rather stable not only at room temperature, but also in the temperature region of <400°C. It is obvious that significant concentrations of unintentional impurities and defects in the crystal can significantly enhance decomposition of the Mgi solid solution in silicon.

REFERENCES

R. F. Franks and J. B. Robertson, Solid State Commun. 5, 479 (1967).

L. T. Ho and A. K. Ramdas, Phys. Rev. B 5, 462 (1972).

L. T. Ho, Phys. Status Solidi A 28, K73 (1975).

Yu. A. Astrov, V. B. Shuman, L. M. Portsel, A. N. Lodygin, S. G. Pavlov, N. V. Abrosimov, V. N. Shastin, and H.-W. Hübers, Phys. Status Solidi A 214, 1700192 (2017).

B. I. Boltaks, M. K. Bakhadyrkhanov, S. M. Gorodetskii, and G. S. Kulikov, Compensated Silicon, Ed. by B. I. Boltaks (Nauka, Leningrad, 1972) [in Russian].

F. P. Morin and H. Reiss, J. Chem. Sol. 3, 196 (1957).

J. R. Carter and R. A. Swalin, J. Appl. Phys. 31, 1191 (1960).

F. S. Ham, J. Phys. Chem. Sol. 6, 335 (1958).

H. Sigmund, J. Electrochem. Soc. 129, 2809 (1982).

ACKNOWLEDGMENTS

This study was supported by the Presidium of the Russian Academy of Sciences, program no. 8 “Condensed Matter Physics and Next Generation Materials”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Kazantsev

Rights and permissions

About this article

Cite this article

Shuman, V.B., Lodygin, A.N., Portsel, L.M. et al. Decomposition of a Solid Solution of Interstitial Magnesium in Silicon. Semiconductors 53, 296–297 (2019). https://doi.org/10.1134/S1063782619030175

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063782619030175