Abstract

Being no more use than fertilizer, eggshells are generally considered as garbage. A large number of eggshell wastes are produced from food processing, baking, and hatching industries every year. As a bio-waste, the eggshell with porous structure can still be fully utilized. In this study, eggshell was used as calcium source and template to induce hydroxyapatite (HA) mineralization in hydrothermal reaction. The effects of different calcium sources and phosphorus sources on the morphology and structure of HA were examined. The synthesized particles have been characterized by X-ray diffraction, Fourier transform infrared spectroscopy, and scanning electron microscopy apparatuses. The results showed that the porous of eggshell was beneficial for the infiltration of soluble phosphorus and slowly synthesis of HA under hydrothermal conditions. Porous eggshells and creatine phosphate disodium tended to induce the mineralization of spherical HA. Thus HA derived from biological sources can be a possible material in converting bio-waste into value added products by a simple and effective way.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Eggshell is a common biological mineral. Chemical composition of eggshell crust is calcium carbonate (94%), magnesium carbonate (1%), calcium phosphate (1%), and organic matter (4%) [1]. The hardness of eggshells is guaranteed by the calcium carbonate. At the same time, the eggshell is also a porous material. Though these minerals are occasionally used as a fertilizer due to their high content of calcium and nitrogen, most of them are discarded as waste. Because of high quality calcium source, eggshell as bio-waste is used to preparation of HA with low cost and at the same time recycling of eggshell also could be taken care of [2]. Hydroxyapatite with chemical composition of Ca10(PO4)6(OH)2 is a very promising natural reinforcing material for polymers due to its high stiffness and strength. It is, in fact, the prime inorganic constituent (65–70%) of bone and hard tissue matrix that is indirectly bound to collagen through some noncollagenous proteins such as osteocalcin, osteopontin, or osteonectin in nanocrystal form [3]. Synthetic HA have attracted much attention as a reinforcing material in biomedical applications because of its excellent functional properties including biocompatibility, osteoconductivity, nontoxicity, and bioactivity [4, 5].

A number of synthetic routes were developed for preparing HA powders, such as mechanochemical, sol–gel, chemical precipitation, hydrothermal, and micro-emulsion methods. Among the various synthetic routes, the hydrothermal method was proven to be an effective and convenient way to prepare HA samples with controllable morphologies and architectures [6]. Because eggshell was a good calcium source and this source could be utilized for synthesis of HA. HA and β-tricalcium phosphate (β-TCP) ceramics was fabricated using recycled eggshell calcined at 1000°C followed by reaction with phosphoric acid [7]. Benefiting from Mg as well as carbonates, the as-prepared HA particles derived from eggshell possess high level of bioactivity [8]. The obtained HA are ideal for biomedical applications and will therefore have great scope to be utilized as a biomaterial in various bone tissue engineering applications and drug delivery [9]. More recently, nano-sized HA particles were synthesized via hydrothermal treatment of eggshell and several biomolecules obtained from waste materials (pomelo, grape, and sweet potato peel extracts) [6]. These materials offer promising opportunities for the bio-waste. Besides, the use of “biological apatite” containing some trace elements as bone substitutes, instead of “chemical apatite,” would be much beneficial for bone defect healing [10].

In the present investigation, an attempt is made to synthesize HA powder from eggshells. In the process of hydrothermal synthesis, the original eggshell powders (CaCO3) and calcined eggshell powders (CaO) which were used as the calcium source, respectively. The eggshell has biological activity, which provides a possibility for the synthesis of bioactive HA by using eggshell as a calcium source. Meanwhile, porous eggshells contribute to the synthesis of HA with large surface area. It is beneficial to increase the application of synthetic HA in anhydrous treatment and drug release. Eggshells are both reactants and templates during the synthesis process which increase the space for waste utilization. Inorganic phosphorus source (NaH2PO4) and organic phosphorus source (creatine phosphate disodium, CPDS) are used as phosphorus, respectively. Under the hydrothermal process, the hydrolys can be adjusted to control the hydrolysis rate of CPDS which determines the morphology, size, and structure of the calcium phosphate products [11]. Through hydrothermal reaction, different phosphorus supplement will help to synthesize HA with special function and structure. This study shows a great potential for the conversion of eggshell waste into highly valuable compounds using a simple and effective way.

MATERIALS AND METHODS

All chemicals used in the experiments were of analytical grade and used without further purification. Aqueous solutions were prepared by ultrapure water.

Reactors Preparation

Hen’s eggshells were collected as bio-wastes and immersed in boiling water to remove the inner membrane and surface contaminants for 30 min. Then eggshells were dried in vacuum oven for 5 h at 60°C. After preliminary pretreatments, eggshells were crushed and powdered using an agate mortar. Then the powders were sieved by a 300 mesh sieve. Eggshell powder was selected as calcium source and used with three ways in the section of experiments: CaO, CaCO3, and solution with CaCl2. The details were summarized as follow. (1) Eggshells were calcined in a muffle furnace at 900°C for 2 h to decompose organic matter and convert CaCO3 into CaO. Then CaO powders were installed by a sealed reagent bottle. (2) CaCO3 were selected from original eggshells powders after being sieved. (3) The solution with CaCl2 was prepared by 12 M HCl hydrolyzing 2.7 g eggshells for 3 h at room temperature; The supernatant was collect by centrifugation (5000g) for 10 min which pH values were also adjusted to 7 by NaOH solution and fixed volume to 250 mL. The concentration of Ca2+ ion in the final solution was about 0.1 M.

HA Preparation

In this section, NaH2PO4 and CPDS were used as phosphorus sources to prepare HA, respectively. The stoichiometric ratio of Ca/P was about corresponding to 1.67. The details of the process were as follows:

(1) 80 mL 0.06 M of NaH2PO4 solutions were selected, and 0.5 g CaO powders were added to the solution. After 30 min magnetic stirring, the pH value of the suspension were adjusted to 11 by NaOH solution.

(2) 0.5 g CaCO3 was added to 80 mL 0.06 M of NaH2PO4 solution and severed as calcium source. After 30 min magnetic stirring, the suspension was applied to synthesis HA particles.

(3) 40 mL solutions with CaCl2 and 40 mL 0.06 M CPDS solutions were selected, respectively. After mixing, the solutions were used to form HA particles by hydrothermal reaction.

(4) For comparison, the control HA particles were also prepared by anhydrous CaCl2 and CPDS under identical experimental conditions.

After stirring, the above mixtures were transferred into a 100 mL Teflon-lined stainless steel autoclave which was kept at 120°C for 24 h. After cooling to room temperature, the white precipitates were collected by centrifugation (10 000g) for 10 min and supernatants were discarded. The obtained particles were washed three times with ethanol and distilled water, dried in a vacuum oven at 60°C for 24 h. And, HA particles were collected, and named HA-1, HA-2, HA-3, HA-4, respectively.

Powder Characterization

The morphologies of raw eggshell powders and synthesized samples were characterized by scanning electron microscopy (SEM, SU-1510), Fourier transform infrared (FT-IR, Nexus 870) and X-ray powder diffraction (XRD, MAP18XAHF), respectively. FT-IR spectrum of synthesized sample was recorded in the 4000–400 cm–1 region with 4 cm–1 resolution by KBr pellet technique to evaluate functional group of the samples. While their crystalline phases and components were determined by XRD with the 2θ range between 10°–80° at a step sampling interval of 0.02°. Identification of phases were achieved by comparing the diffraction pattern of obtained particles with relevant JCPDS standards (card no. 04-0932 for HA and 37-1497 for CaO). The morphology of particles was examined by SU-1510 SEM after being sputter-coated with a thin layer of gold nanoparticles. UV–Vis spectrum of eggshell solution dissolved by HCl was recorded by a spectrophotometer (TU-1901).

RESULTS AND DISCUSSION

The morphology of eggshell was determined by SEM technique and presented in Fig. 1. It is easy to find eggshell powders irregularly morphologies in Fig. 1a. There are many pores distributed over the entire eggshell architecture. The size of the pores is different. These pores also can function as exchanger of matter between the outside and inside of eggshells while having enough strength to prevent crack from collision. The pores will be helpful to mineralization of HA when original eggshell powders are acted as calcium source. Because of the 3D porous structure, eggshell can store the active material and absorb the soluble substances contain phosphorus and serve as an excellent template of nanomaterial synthesis [12]. According to the relevant literature [13], the eggshell accounts for 11% of the total egg weight and is composed by calcium carbonate, calcium phosphate, organic matter and magnesium carbonate. To determine the crystalline phase of as-collected eggshells, XRD patterns data were collected in 2θ range of 20°–80° with a scan rate of 4 deg/min shown in Fig. 1b.

X-ray diffraction pattern of eggshell shows a major peak at 2θ = 29.58° and indicates that calcite is a major phase of the eggshell which corresponds to the JCPDS files for calcite (PDF no. 05-0586). FT-IR spectrum (Fig. 1c) of raw eggshell shows peaks at 716, 874, and 1425 cm–1 which are the characteristic peaks of calcite-type calcium carbonate. At the same time, the evident peaks were the two corresponding to the resonance of amide group (amide C=O and C–N stretch, at 1800–1500 cm–1 of the spectrum) which suggests a major protein component [14, 15].

Calcium chloride solution was prepared by dissolving eggshell powders with HCl solution. After centrifugation, the resulting solution was evaluated by UV–Vis spectroscopy. Because of many biomolecules in the eggshell, there is an obvious absorption peak (275 nm) in UV–Vis spectrum of solution (Fig. 2a). The peak at about 275 nm belongs to the π–π* transition of tyrosine, tryptophan, or phenylalanine residues of proteins. This result is consistent with the above result of FT-IR spectrum of raw eggshell which further confirms that the solution contains protein. Also, the protein can mediate the formation of HA [16]. After calcination, the material appears a porous appearance, white color and fragile consistence. The corresponding X-ray diffraction pattern Fig. 2b (calcined eggshell) shows reflections corresponding to JCPDS file (PDF no. 37-1497) for CaO and no other species is found. CaO phase with 2θ values of 32.38°, 37.48°, 53.98°, 64.28° and 67.48° are found. It is implied that the CaCO3 is completely transformed into CaO phase [17].

The morphologies of particles which were prepared by using a hydrothermal method with different calcium and phosphorus source at 120°C for 30 min was characterized by SEM. According to above results, calcined eggshell most is CaO. Calcium hydroxide (Ca(OH)2) is immediately formed when CaO is mixed with NaH2PO4 aqueous solution. With the hydrothermal method, HA is formed. The reaction can be described by the Eqs. (1) and (2).

From Fig. 3a, it is not difficult to find that the synthesized particles are sheets. Most of sheets are about 2–5 μm in length and 1–2 μm in width while CaO is severed as calcium source. When original eggshell powders being selected as calcium source, the synthesized particles are composed of porous spherical particles with the radius about 10 μm (Fig. 3b).

As we know, the \({\text{PO}}_{4}^{{3 - }}\) ions can be produced by the hydrolysis of CPDS under hydrothermal conditions, so CPDS can be used as a biocompatible phosphate source for the synthesis of calcium phosphate salts materials. Compared with traditional phosphate salts, the use of CPDS as the organic phosphorus source can effectively prevent the rapid aggregation of HA [18].

Because containing a large amount of calcium carbonate, Ca2+ ions and soluble protein are left in the solution after HCl dissolving eggshell powder. When above solution is used as calcium source and CPDS as the organic phosphorus source under hydrothermal condition, the synthesized particles are partially spherical with a radius of about 2–3 μm which are constructed by the self-assembly of regular hexagonal HAs (Fig. 3c). These results indicate that CPDS plays an important template role in the formation of HA hierarchically porous hollow microspheres [19]. Because of highly negatively charged groups, CPDS has a high affinity to calcium ions. At the same time, CPDS molecules with hydrophilic and lipophilic groups tend to form spheres by self-assembly. With the addition of calcium oxide the solution pH value increasing, CPDS gradually decomposed and slowly released \({\text{PO}}_{4}^{{3 - }}\) ions under hydrothermal conditions. As a result, Ca–CPDS complexes are formed which appearing as nanospheres. Subsequently, with Ca2+ and dangling phosphate groups on their surfaces, these nanospheres provide nucleation sites for HA formation, presumably by electrostatic attraction with \({\text{PO}}_{4}^{{3 - }}\) and/or Ca2+. HA crystals thus nucleate on the nanospheres and grow into shells, with the nanospheres becoming cores. With the continuous hydrolysis, CPDS is finally hydrolyzed thoroughly. Ca–CPDS cores gradually are decomposed, thereby forming hollow HA shells. Simultaneously, the proteins retained in the reaction system can also become nucleation sites. Under synergistic effect of protein and CPDS, the formation of HA can be effectively regulated. This results are very consistent with the related literatures [20, 21].

As a comparison, anhydrous CaCl2 which was used as calcium source and CPDS could also successfully synthesize hollow spherical HA under hydrothermal condition (Fig. 3d). From the SEM image, there are too much broken hollow microspheres with about 1.5 μm in diameter and 500 nm in wall thickness.

The eggshell with porous structure was crushed into powders and used to synthesize HA as calcium sources. This synthetic method has some advantages. First, the eggshell as a waste is fully utilized to avoid environmental pollution. Then, original eggshell powders sever as organic calcium source. The HA obtained by this synthetic method can avoid the introduction of too many chemicals and conforms to the concept of green chemistry. Last, porous structure is helpful NaH2PO4 solution to penetrate in to the interior of particles and dissolution-precipitation reaction take place [22].

FT-IR spectra of the obtained products which derived from differential calcium and phosphate sources were shown in Figs. 4a, 4b. From the spectra, it is easy to find that the typical bands at 1033 and 1093 cm–1 can be assigned to \({\text{PO}}_{4}^{{3 - }}\) anti-symmetric stretching vibrations and the bands at 561 and 606 cm–1 stand for \({\text{PO}}_{4}^{{3 - }}\) anti-symmetric bending vibrations. Additionally, the 963 cm–1 band is due to the symmetric stretching vibrations of \({\text{PO}}_{4}^{{3 - }}\) [18, 23], indicating the presence of HA. The broad band extending from 2500 to 3600 cm–1 is attributed to the ν3 and ν1 stretching modes of the H2O molecules. The band at 1642 cm–1 is owned to the ν2 bending mode of the H2O molecules. Furthermore the characteristic bands of the \({\text{CO}}_{3}^{{2 - }}\) are identified by characteristic peaks at 1457, 874, and 714 cm–1 in Fig. 4a. Because of eggshell powders used as calcium sources, it is possible leaving a small amount of eggshell powders in HA-1 particles. While CaO acted as calcium sources, it is sensitive to CO2 that may be present in the atmosphere and acted as a precursor during the course of the mixing reaction. CO2 dissolved in alkaline solutions and resulted in \({\text{CO}}_{3}^{{2 - }}\) substitution in the OH– or \({\text{PO}}_{4}^{{3 - }}\) sites in the HA crystal lattice, thereby forming an carbonated HA [24–26].

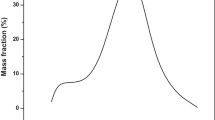

To clearly characterize the crystal structure of the samples with respecting to different calcium sources and phosphorus sources,the XRD patterns of were shown in Figs. 5a, 5b. All the samples show the diffraction patterns corresponding to the hexagonal phase of HA and according to the standard card of HA (JCPDS file, PDF no. 09-0432).On the whole, the characteristic peaks of HA are correlated to the (hkl) indices (002), (211), (300), and (202).The peaks at 26.61° and 30.31° are consistent with (002) and (211) of hexagonal HA. However, the intensity of diffraction peaks is varied with different synthetic methods. When CaO and CaCO3 used as raw materials, the characteristic diffraction peaks of HA partials are sharp and obvious. Also, the characteristic peak of calcite, diffraction peaks 2θ = 29.35° (JCPDS file, PDF no. 72-1652) is found (Fig. 5a). The results are consistent with FT-IR spectrum (Fig. 3a). However, some of the predominant HA diffraction peaks in the XRD pattern of HA-3 and HA-4 (Fig. 5b) are obscure, indicating low crystallinity.

From the FT-IR, XRD results, it is concluded that HA is successful synthesized. The morphology and phase of prepared HA particles are significantly influenced by different calcium source and phosphorus source with the hydrothermal reaction mode.

CONCLUSIONS

In this study, chicken eggshells were used as calcium source to synthesize HA powders via a simple hydrothermal method. Meanwhile, in order to investigate the effects of different phosphorus sources on the structure and morphology of HA, NaH2PO4, and CPDS were selected as phosphorus sources, respectively. The results show that eggshell powders are excellent templates for the synthesis of spherical hydroxyapatite. CPDS which acted as phosphorus source can release phosphate to synthesize HA with special morphology under hydrothermal conditions. But from the cost of synthesis, eggshell will become the best choice for the synthesis of HA in the future. The obtained products can be a potential material for biomedical applications.

REFERENCES

R. Bardhan, S. Mahata, and B. Mondal, Adv. Appl. Ceram. 110, 80 (2009).

E. M. Rivera, M. Araiza, W. Brostow, V. M. Castano, J. R. Dıaz-Estrada, R. Hernández, and J. R. Rodrıguez, Mater. Lett. 41, 128 (1999).

M. Rahman, A. Netravali, B. Tiimob, V. Apalangya, and V. Rangari, J. Appl. Polym. Sci. 133, 43477 (2016).

N. Pramanik and T. Imae, Langmuir 28, 14018 (2012).

B. Song, Q. Xu, C. Wang, S. Xu, and H. Zhang, J. Appl. Polym. Sci. 133, 42871 (2016).

S. Wu, H. Tsou, H. Hsu, S. Hsu, S. Liou, and W. Ho, Ceram. Int. 39, 8183 (2013).

S. J. Lee and S. H. Oh, Mater. Lett. 57, 4570 (2003).

G. Suresh Kumar and E. K. Girija, Ceram. Int. 39, 8293 (2013).

P. Deb, E. Barua, S. Lala, and A. Deoghare, Mater. Today: Proc. 15, 277 (2019).

M. Boutinguiza, J. Pou, R. Comesaña, F. Lusquiños, A. De Carlos, and B. León, Mat. Sci. Eng. C: Mater. 32, 478 (2012).

J. Zhao, Y. Zhu, G. Cheng, Y. Ruan, T. Sun, F. Chen, J. Wu, X. Zhao, and G. Ding, Mater. Lett. 124, 208 (2014).

S. H. Chung and A. Manthiram, Adv. Mater. 26, 1360 (2014).

E. Rivera, M. Araiza, W. Brostow, V. Castano, J. Dıaz-Estrada, R. Hernández, and J. Rodrıguez, Mater. Lett. 41, 128 (1999).

U. Anjaneyulu and S. Sasikumar, B. Mater. Sci. 37, 207 (2014).

J. Martín-Durán, M. Duocastella, P. Serra, and R. Romero, J. Exp. Zool. B 310, 668 (2008).

H. Chen, C. Qing, J. Zheng, Y. Liu, and G. Wu, Mat. Sci. Eng. C: Mater. 63, 485 (2016).

T. Witoon, Ceram. Int. 37, 329 (2011).

C. Yao, J. Zhu, A. Xie, Y. Shen, H. Li, B. Zheng, and Y. Wei, Mat. Sci. Eng. C: Mater. 73, 709 (2017).

C. Qi, Y. Zhu, B. Lu, X. Zhao, J. Zhao, F. Chen, and J. Wu, Chem. Eur. J. 19, 5332 (2013).

D. Xiao, Z. Tan, Y. Fu, K. Duan, X. Zheng, X. Lu, and J. Weng, Ceram. Int. 40, 10183 (2014).

A. W. Xu, Q. Yu, W. F. Dong, M. Antonietti, and H. Cölfen, Adv. Mater. 17, 2217 (2005).

K. Ishikawa, S. Matsuya, X. Lin, Z. Lei, T. Yuasa, and Y. Miyamoto, J. Ceram. Soc. Jpn. 118, 341 (2010).

C. Qi, Q. L. Tang, Y. J. Zhu, X. Y. Zhao, and F. Chen, Mater. Lett. 85, 71 (2012).

G. S. Kumar, A. Thamizhavel, and E. K. Girija, Mater. Lett. 76, 198 (2012).

S. Koutsopoulos, J. Biomed. Mater. Res. A 62, 600 (2002).

N. Nga, N. T. Chau, and P. Viet, Colloid Surface B 172, 769 (2018).

Funding

This work is supported by the National Science Foundation of China (21101054), Program of Visiting Scholar for Young Scholar Sponsored by Department of Education Anhui Province (gxgnfx2018024, gxgwfx2019051) and Anhui Province Key Laboratory of Environment Friendly Polymer Materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chengli Yao, Jinmiao Zhu Mineralization of Hydroxyapatite Induced by Eggshell As Calcium Source with Hydrothermal Synthesis Method. Crystallogr. Rep. 65, 1242–1247 (2020). https://doi.org/10.1134/S1063774520070299

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063774520070299