Abstract

A way of synthesizing a magnetic fluid based on silicone oil with ferromagnetic nanowires is described, and its magneto-rheological effect is demonstrated. The physical characteristics of the resulting ferrophase are studied by means of optical and scanning electron microscopy, energy-dispersive X-ray spectroscopy, and X-ray phase analysis. The size of the nanowires is measured via dynamic light scattering with ferromagnetic wires stabilized in an aqueous solution by coating with polyvinylpyrrolidone.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Many works have been devoted to studying and developing new magnetically controlled materials (e.g., ferro- or magnetic fluids (MFs) that are sensitive to the action of magnetic fields) [1]. MFs are stable colloidal suspensions of nanometer-sized ferromagnetic particles or particles of their oxides in a carrier base (e.g., water or oil) [2]. MFs do not exist in nature because all natural fluids exhibit a weak magnetic interaction. However, there are numerous examples of artificially synthesized fluids and dispersed media that interact with a magnetic field. Ferrofluids were invented by Steve Papell in 1963 with the intention of creating a suitable liquid rocket fuel that could be drawn by an external magnetic field to the inlet of a pump under conditions of zero gravity. Intensive research later gave a variety of applications of these fluids due to their properties, which are determined by the combination of the components of these fluids. MFs can be magnetized in external magnetic fields, allowing them to change their shape and spatial distribution. This makes them promising for creating flexible robots and motion control systems [3]. MFs exhibit high thermal conductivity that allows their use in cooling and heat-exchange systems [4]. MFs can be used for electromagnetic separation, allowing us to separate mixtures into components with different magnetic characteristics [5].

The relevance of using MFs is confirmed by developments in biomedicine. Ferrofluids are used for targeted drug delivery and in such diagnostic systems as magnetic resonance tomography [2].

New prospects have also opened up in controlling the temperature conditions of such systems. Strategies for treating malignant tumors remain imperfect, which requires us to find safer and more effective solutions. The main problem is that there is no selective interaction with malignant cells. This results in side effects and greatly reduces the effectiveness of treatment. Using magnetic nanoparticles in cancer treatment could solve these problems. Magnetic hyperthermia is a proposed alternative approach to treating cancer [6]. It is based on the generation of heat energy when an alternating magnetic field interacts with magnetic nanoparticles [7] and is already used to treat many types of cancer [8]. Limiting the magnetic field gradient to the pathogenic zone allows a selective increase in body temperature in the targeted zone of the body.

Compared to nanowires (NWs), the spherical geometry of magnetic nanoparticles restricts their potential applications. In addition to geometrical and magnetic anisotropy, an important feature of MFs with NWs is the possibility of combining different metals along the length of a particle (e.g., core–shell layered NWs) [9].

It is thus of great interest to study the geometry and physical characteristics of ferromagnetic permalloy NWs used in ferrofluids in terms of their advanced application in biomedical and other applications.

There are several ways of obtaining the ferrophase of MFs, according to which procedures for preparing MFs are classified. These are mainly crushing, condensation, spark discharge, heat treatment, decomposition upon exposure to ultraviolet irradiation, vacuum evaporation, and galvanic treatment [10]. We used a universal way of obtaining NWs with the possibility of varying their geometry via template synthesis on polyethylene terephthalate track etched membranes (TMs). The deposition of alloys of ferromagnetic metals of the iron group in TM pores was described in [11].

The carrier fluid plays a key role in the creation and performance of MFs. Its function is to provide an environment in which magnetic particles are suspended, their uniform distribution and protection from aggregation and oxidation is ensured, and a magnetic field is transmitted. The choice of the fluid depends strongly on the area of MF application. A wide range of carrier fluids are currently used, including water, ethanol, glycols, perfluoropolyethylenes, synthetic esters, kerosene, various synthetic hydrocarbons and organic solvents, and mineral and silicone oils [12].

We chose polymerized siloxane (silicone oil (SO)) as our base carrier fluid. Its use has several advantages. SO is highly stable and inert, allowing it to preserve the magnetic properties of a material for long periods of time. This is especially important when using SO in different technical and scientific applications. SO exhibits good lubricity, which makes it easy to mix nanoparticles of a magnetic material and distribute them uniformly in a fluid. This is important to ensure uniformity and stability of a material’s properties. SO also exhibits high thermal stability, allowing the use of MFs in a wide range of temperatures (–40 to +200°C). The electrical characteristics of SO are virtually constant at high and low temperatures over a wide range of frequencies. SO is characterized by low boundary tension and strong hydrophobic characteristics. The freezing point of SO is <–60°C, and the boiling point is >+300°C. The kinematic viscosity of SO is 1000 cSt. Using SO as a carrier fluid for MFs is an effective and universal approach that allows its application in such fields as electronics, medicine, and robotics [13].

In this work, we give particular attention to stabilizing an aqueous solution of ferromagnetic nanowires with the water-soluble polymer polyvinylpyrrolidone (PVP). Nanowires must be stabilized to correctly estimate their size, prevent aggregation, preserve their properties, and control interactions in different environments. This is important for applications in different fields, including materials science and medicine. Stabilizing nanowires allowed us to estimate their size using dynamic light scattering.

RESULTS AND DISCUSSION

Polyethylene terephthalate TMs with a pore diameter of 100 nm manufactured at the Flerov Laboratory of Nuclear Reactions (Joint Institute of Nuclear Research, Dubna) were used as matrices for template synthesis. The parameters were: membrane thickness, 12 μm; surface density of the system of crossed pores, 1.3 × 109 cm–2; and surface density of the system of parallel pores, 5 × 108 cm–2.

The synthesis of the TM-based FeNi NWs included obtaining a conductive copper layer, the electrochemical deposition of FeNi into the TM pores, and removal of the contact layer and polymer matrix [14]. The electrodeposition of FeNi was performed in potentiostatic mode at U = 1.5 V. We chose a sulfuric acid electrolyte of the composition H3BO3 (25 g/L), NiSO4·7H2O (16 g/L), NiCl·6H2O (40 g/L), FeSO4·7H2O (8 g/L), C12H25SO4Na (<1 g/L), C6H8O6 (1 g/L). The period of deposition to obtain single non-overlapping NWs of different lengths varied from 90 to 180 s for TMs with a system of crossed and parallel pores, respectively. The copper layer was removed selectively using a 3% H2O2 solution (1 L); C6H8O7 (300 g/L); NaCl (50 g/L). A solution of sodium hydroxide NaOH (6 M) was used to remove the matrix. Suspensions of NWs in distilled water were obtained as a result, and the geometry of NWs inherited the features of the matrix pores.

REXANT PMS-1000 silicon oil was chosen as a basic carrier fluid for MFs. An SH Scientific SH-HZD homogenizer was used to introduce NWs into the carrier fluid. NWs were added to the carrier fluid and mixed until homogeneity was achieved.

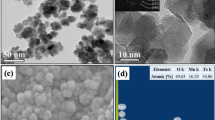

Optical and Scanning Electron Microscopy

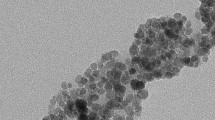

After etching the matrix, the geometry of a sample with an FeNi NW array was studied via scanning electron microscopy using a JCM-6000plus microscope. Results from studying the SEM images (Fig. 1a) and optical images of the FeNi NW suspensions in distilled water (Fig. 1b) showed that when the nanowires grew in a potentiostatic mode for 90 s, they reached a length of approximately 1.3 μm (Fig. 1a). When the grew for 180 s, they reached a length of 9.3 μm (Fig. 1b). The agglomeration of FeNi NWs is observed in Fig. 1b.

Energy-Dispersive X-Ray Spectroscopy

EDS (energy-dispersive X-ray spectroscopy) showed the relative content of Fe and Ni in NWs in the obtained samples was Fe : Ni = 46 : 54 (Fig. 2a), which corresponds to permalloy. The calculated density of the NWs was 8.43 g/cm3. Our studies were performed along with scanning electron microscopy using a JCM-6000plus microscope. Peaks of Ni and Fe are observed in the spectra, confirming the elemental composition of NWs.

X-Ray Phase Analysis of Samples

X-ray phase analysis was performed after obtaining the suspension: 1 mL of distilled water with NWs was applied to a conductive tape, after which the sample was placed into an X-ray diffractometer with CuKα radiation of 1.54 nm; tube voltage, 40 kV; current, 40 mA. X-ray phase analysis of the samples indicated the crystalline structure of NWs predominated. Figure 2b exhibits 3 peaks in the range of 2ϴ = 43.9 (111); 50.3 (200); 74.5 (220). The observed crystalline structure corresponds to FeNi with a face-centered cubic (fcc) lattice. According to data from X-ray analysis, the predominant orientation of the grown NWs was (111). Two series of samples of anisotropic NWs were thus obtained with lengths of 1.3 and 9.3 μm—much greater than the diameter (100 nm)—which were then introduced into the SO.

It is important to note that these TM characteristics allowed us to obtain SO-based MF samples with a fairly high content of 0.25 wt % NWs for both of their geometries, letting us use this means of synthesizing NWs to prepare MFs.

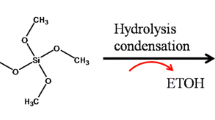

Dynamic Light Scattering and the Stabilization of Nanoparticles

An aqueous solution of FeNi nanowires was stabilized in 32.1 mg of PVP in 12.5 mL. The mass of PVP was in this case 10 times greater than that of the nanowires. The stabilization of FeNi nanowires by PVP is attractive because of PVP’s strong affinity for the surfaces of nanowires, which results in a uniform coating and protective layer that prevents aggregation and provides dispersion stability even under changing conditions. The deposition of PVP facilitates the processing and control of the characteristics of nanowires, increasing their suitability for various applications. The thickness of the PVP layer on nanowires can vary as a function of the conditions of synthesis and mode of processing. The PVP layer on nanoparticles is typically several to tens of nanometers thick.

Dependences of complex viscosity |η*| on angular frequency ω for a MF sample with FeNi NWs 1.3 μm long with no external magnetic field (blue) and with one at B = 1 T (red); for a MF sample with FeNi NWs 9.3 μm long with no external magnetic field (green) and one at B = 1 T (yellow). The weight content of FeNi NWs is 0.25%.

Stabilization allowed us to estimate the size of nanowires via dynamic light scattering (DLS). We studied a sample of a suspension of FeNi NWs 9.3 μm long, stabilized in distilled water using PVP (Fig. 4a). No agglomerates were observed in optical images obtained at 100× magnification, testifying to the effectiveness of stabilization. Optical images showed that the mean length of stabilized nanowires was 8.62 μm (Fig. 4b). According to data obtained on a BENANO 180 PRO device (Bettersize, China), the nanowires were 12.8 μm long (Fig. 5), which corresponds to parameters of growth within the measuring error (1–5%). Measurements were made at room temperature (26°C); the viscosity of the fluid was 0.8734 mPa s; the coefficient of absorption for FeNi nanowires was 0.03; the operating wavelength was 671 nm; and the scattering angle was 90 deg. Measurements were stabilized for 60 s.

Rheological Measurements

Rheological measurements were made at a fixed amplitude of 3% and variable frequency. Experiments were performed with an Anton Paar MCR-301 rotational rheometer at a temperature of 25 ± 0.05°C. This device utilizes the Searle principle. A universal plane-to-plane system was used for rheological measurements. The diameter of the upper measuring plate was 20 mm with a gap of 0.5 mm. The measurements were made in a mode of oscillation and range of angular frequencies ω = 0.04–50 s–1. A special magneto-rheological cell made of non-magnetic material was used to make measurements in a magnetic field with B = 1 T, directed normal to the shear. An external magnetic field, having an orienting effect on particles, leads to a change in the macroscopic properties of magnetic fluids [15].

Results from rheological measurements on MF samples with FeNi NWs of different lengths were used to obtain the dependence of complex viscosity |η*| on angular frequency ω. The experimental results in Fig. 3 show that at low angular frequencies, dynamic viscosity |η*| was higher for the MF sample with a filler that had a higher degree of anisotropy (FeNi NWs 9.3 μm long; green curve). When a magnetic field was applied to a MF sample with FeNi NWs 9.3 μm long, its viscosity grew by four times. Our results show there was a magneto-rheological effect in all samples when a magnetic field was applied.

CONCLUSIONS

We studied the synthesis of a ferrofluid based on silicone oil and filled with ferromagnetic FeNi nanowires. Anisotropic ferromagnetic FeNi NWs were obtained via matrix synthesis on polyethylene terephthalate track membranes. Optical and scanning electron microscopy were used to estimate the geometrical parameters of NWs, and the resulting NWs were 1.3 and 9.3 μm long (periods of deposition, 90 and 180 s, respectively). EDS was used to study the elemental composition of the filler of MFs. The ratio of atoms of Fe and Ni in NWs was Fe : Ni = 46 : 54. The ratio of iron and nickel in NWs corresponded to permalloy. The calculated density of NWs was 8.43 g/cm3. X-ray phase analysis of the samples indicated that the crystal structure of the NWs predominated. The observed crystalline structure corresponds to fcc-FeNi. Our data show that the nanowires were 12.8 μm long, which corresponds to the parameters of growth within the limits of error. It was confirmed that the deposition of PVP facilitates the processing and control of the nanowires’ characteristics.

Rheological studies showed that interaction between FeNi NWs was induced in the resulting ferrofluids based on silicone oil and FeNi NWs when an external magnetic field was applied. This changed the internal structure and viscoelastic characteristics of the entire system in a rapid and reversible manner. Results from rheological studies show there was a magneto-rheological effect in all samples, but it was most pronounced in the MF sample with highly anisotropic FeNi NWs (the FeNi NWs were 9.3 μm long). Applying a magnetic field to this sample raised its dynamic viscosity by four times at low angular frequencies.

Our technique seems promising for obtaining various ferrofluids with variable geometric parameters of NWs adjusted for specific problems.

REFERENCES

Socoliuc, V., Avdeev, M.V., Kuncser, V., et al., Nanoscale, 2022, vol. 14, no. 13, p. 4786.

Kole, M. and Khandekar, S., J. Magn. Magn. Mater., 2021, vol. 537, p. 168222.

Bangxiang, C., Yanhe, Z., Jie, Z., and Hegao, C., Proc. IEEE Conf. on Robotics and Biomimetics, Zhuha, 2015, p. 511.

Zakipim, R.G. and Smerek, Yu.L., Nauka Innovatsionnye Tekhnol., 2005, no. 43, p. 100.

Vaisberg, L.A., Kononov, O.V., and Ustinov, I.D., Osnovy geometallurgii (Fundamentals of Geometallurgy), St. Petersburg: Russ. Kollektsiya SGPb, 2020.

Racca, L. and Cauda, V., Nano- Micro Lett., 2021, vol. 13, p. 26.

Liu, X., Zhang, Y., Wang, Y., Zhu, W., et al., Theranostics, 2020, vol. 10, no. 8, p. 3793.

Włodarczyk, A., Gorgoń, S., Radoń, A., and Bajdak-Rusinek, K., Nanomaterials, 2022, vol. 12, no. 11, p. 1807.

Mukhtar, A., Wu, K., and Cao, X., Nanotecnology, 2020, vol. 31, no. 43, p. 433001.

Taketomi, S. and Chikazumi, S., Magnetic Fluids—Principle and Application, Tokyo: Nikkan Kogyo Shinbun, 1988.

Zagorskiy, D.L., Doludenko, I.M., Kanevsky, V.M., et al., Bull. Russ. Acad. Sci.: Phys., 2021, vol. 85, no. 8, p. 848.

Genc, S. and Derin, B., Curr. Opin. Chem. Eng., 2014, vol. 3, p. 118.

Li, L., Li, D., Wang, L., Liang, Z., and Zhang, Z., J. Magn. Magn. Mater., 2023, vol. 584, p. 171077.

Filippova, Y.A., Bizhetsky, A.S., Papugaeva, A.V., et al., Bull. Russ. Acad. Sci.: Phys., 2023, vol. 87, no. 10, p. 1483.

Prokopieva, T.A., Danilov, V.A., and Kantorovich, S.S., J. Exp. Theor. Phys., 2011, vol. 113, p. 435.

Funding

This work was performed as part of a State Task for Moscow Pedagogical State University, “Physics of Nanostructured Materials: Fundamental Research and Applications in Materials Science, Nanotechnologies and Photonics” with the support of the RF Ministry of Enlightenment, project no. 122122600055-2; and as part of a State Task from the RF Ministry of Enlightenment, project no. AAAA-A20-120061890084-9 “Laser Technologies for Biomedical Applications.” Yu.A. Filippova, E.P. Kozhina, and S. A. Bedin are members of the RF leading scientific school “Optical Spectral Nanoscopy of Quantum Objects and Diagnostics of Promising Materials” (project no. NSh-776.2022.1.2).

The work was partially carried out within the framework of the state assignment of the Federal Scientific Research Center “Crystallography and Photonics” of the Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by N. Podymova

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

About this article

Cite this article

Filippova, Y.A., Papugaeva, A.V., Panov, D.V. et al. Studying the Geometry and Physical Characteristics of FeNi Nanowires in Ferrofluids. Bull. Russ. Acad. Sci. Phys. 87, 1885–1889 (2023). https://doi.org/10.1134/S1062873823704142

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1062873823704142