Abstract

Polyhydroxybutyrates (PHBs) are macromolecules synthesized by bacteria. PHBs are the most promising type of bioplastic; they are nontoxic, biodegradable and biocompatible and have properties similar to those of conventional plastics. In the present study, an attempt was made to screen of different bacterial isolates accumulating PHB from soil samples collected from Istanbul, Turkey. A total of 86 different bacterial isolates were isolated from soil samples and a total of 32 isolates were suggested to be PHB producer when stained with Sudan Black B, a preliminary screening agent for lipophilic compounds. 13 bacterial isolates were selected as PHB producing isolates by using the Nile blue A dying technique. 16S rRNA gene sequences analysis showed that PHB producing 13 isolates belonged to Pseudomonas, Arthrobacter and Bacillus genera. The PHB from the isolates was extracted using the dispersion method of the hypochlorite and chloroform method. The highest PHB production and percentage productivity were obtained from Pseudomonas plecoglossicida M9 (0.94 PHB g/L; 78.8% PHB) and Pseudomonas baetica Y6 (0.81 PHB g/L; 74.3% PHB) respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Petroleum based plastics are not biodegradable and are causing serious environmental problems. The resistance of these chemicals to biodegradation is quite high and thus they remain persistent in soil for a long time (Reddy et al., 2003). Therefore, there is increasing demand to new methods for synthesis of biodegradable polymers.

These biodegradable polymers or plastics are considered the best solution for solving the environmental pollution problems by replacing conventional plastics industries (Gabr, 2018). Among the various types of biodegradable plastics, polyhydroxyalkanoic acids (PHAs) are drawing much attention. PHAs are the most well-known, being recognized as completely biosynthetic, biodegradable composted or burned without producing toxic by-products (Phanse et al., 2011). Because of their biological nature, PHAs completely hydrolyzes into water and carbon dioxide by different soil microorganisms (Gabr, 2018). Plastics produced from PHAs are regarded as eco-friendly useful polyester overcoming the problem of pollution caused by non-degradable plastics (Reddy et al., 2003; Prasanna et al., 2011).

Polyhydroxyalkanoic acids (PHAs) are very promising materials because they can be used as fully biodegradable and bioresource-based alternatives to petrochemical polymers since the mechanical and technological properties of PHAs are similar to those of some polymers produced from petrochemical resources. However, several limitations currently exist when polyhydroxybutyrate (PHB) is produced on an industrial scale. The high costs of production, low yield, susceptibility to degradation, and technology complexities including extraction difficulties are among the challenges faced in PHB production (McAdam et al., 2020). Because of these limitations, industrial production of PHB is still not well established. This means it is unable to compete with conventional plastics in the commercial market. To reduce the costs of production and achieve economic viability in competition with the current low costs of manufacturing petroleum plastics, a series of new emerging bacterial fermentation processes are being evaluated. They have the potential to accentuate the kinetics of microbial growth and PHB accumulation to the levels necessary for profitable process engineering and production serving the plastics value chain stakeholders (Pernicova et al., 2020).

The PHBs content and its composition are influenced mainly by the strain of the microorganism, the type of substrate employed and its concentration, and other growth conditions such as pH, time and temperature. Therefore, much research is needed to discover and identify novel species with vastly superior production capacity and optimization of conditions for maximal synthesis of PHB (Thapa et al., 2018).

Many microorganisms can accumulate PHB as intracellular energy and carbon storage inclusions when the amount of carbon substrate is greater than that of nitrogen, sulfur, phosphorus, or oxygen (Naheed et al., 2011). Among the microbes like bacteria, fungi, yeast, algae, etc., bacteria-based biopolymer fabrication has gained more attention due to its ease of control, maximum biomass, simple downstream processing, greater gene modification possibilities, etc. (Narayanan et al., 2020).

Presently, more than 300 bacterial species are known that are able to produce these polymers but only a few species can produce PHB at a high concentration, e.g., Alcaligenes latus, Pseudomonas oleovorans, and Cupriavidus necator (Motamedi et al., 2015).

Among the members of PHA family, the PHB is a preferable one due to high thermoplastic like traditional polymers and possesses most suitable physical, mechanical, immunological properties, which promotes this PHB is suitable alternate for traditional polymers (Narayanan et al., 2020). These PHBs are accumulated intracellular membrane enclosed up to 90% of the cell dry weight under conditions of nutrient stress and act as energy reserve material (Bhuwal et al., 2013).

The present study involved the screening of different bacterial isolates accumulating PHB from oil-polluted soil samples collected from Istanbul, Turkey.

MATERIALS AND METHODS

Isolation of Bacterial Strains

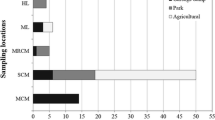

Soil samples were collected from the 3–4 cm upper layer and used for isolation of bacteria. This process was performed with oil-contaminated soil from four districts (Yeniköy, Maltepe, Kartal, and Buyukcekmece) in Istanbul.

Two methods were used for the isolation of bacteria. In the first, a 1.0 g soil sample was weighed and 99 mL of distilled H2O was added to it. The suspension was then homogenized and diluted 10–1, 10–2, 10–3, 10–4, 10–5, and 10–6 in 9 mL of distilled water; 1 mL from each dilution was spread on nutrient agar (beef extract 3 g, peptone 5 g, and agar 15 g per liter, adjusted to pH 7.0) plates. The plates were incubated for 24 h at 30°C. In the second method, 1.0 g soil was added to flasks containing 100 mL of nutrient broth medium. The flasks were incubated at 30°C with rotary shaking (150 rpm, 24 h). After incubation, 1 mL of the supernatant was taken and serial dilution was performed in distilled water as stated above. Next, 1 mL of the dilution samples was spread on nutrient agar plates and incubated for 24 h at 30°C. After incubation, a large number of colonies formed on each petri dish. The morphology of the bacterial colonies was examined and 86 colonies (in total) with distinct features were selected. Bacterial isolates were obtained from Yenikoy district (29), Kartal district (23), Maltepe district (20), and Buyukcekmece district (14). These isolates were encoded by letter and number for Yenikoy district (Y 1–29), Kartal district (K 1–23), Maltepe district (M 1–20), and Buyukcekmece district (B 1–14). All selected colonies were subcultured until they were confirmed to be pure. Glycerol stocks of the 86 isolates were prepared and stored at –20°C (Inan et al., 2011a).

Screening of PHB-Producing Isolates

For the rapid detection and isolation of PHB-producing bacteria, all the isolates were qualitatively screened using Sudan Black B dye. The isolates were grown on nutrient agar medium containing 1% glucose and incubated at 30°C for 48 h. After incubation, ethanolic solution of Sudan Black B (0.05%) was spread over the colonies and the plates were left undisturbed for 30 minutes. Finally, the plates were washed with ethanol (96%) to remove the excess stain from the colonies (Desouky et al., 2014). The dark blue colonies were regarded as proof of PHB production.

Nile blue A staining was carried out as a second screening method to determine the PHB-accumulating ability of the microbial strains isolated. Mineral salt medium (MSM) agar was prepared for Nile blue screening. Each liter of MSM contained 15 g agar, 6.7 g Na2HPO4·7H2O, 10 g NaCl, 1.5 g KH2PO4, 0.1 g NH4Cl, 0.2 g MgSO4·7H2O, 0.01 g CaCl2, 0.06 g ferrous ammonium citrate, and 1 mL trace elements (Ramsay et al., 1990; Berlanga et al., 2006). MSM agar was supplemented with 2% (w/v) glucose and 0.5 µg/mL Nile blue A (Sigma) (dissolved in dimethylsulfoxide) as the final concentration (Van and Thi, 2012). Positive staining isolates with Sudan Black B dye were streaked on MSM agar. The petri dishes were incubated at 30°C for 3 days. After Nile blue A staining, the agar plates were exposed to UV light to detect PHB-accumulating colonies (Fig. 1). The isolates that were fluorescent orange were selected as PHB accumulators (Buhuwall et al., 2013).

PHB Extraction and Quantitative Analysis

PHB-producing isolates were grown in 50 mL of MSM medium containing 2% (w/v) glucose and incubated at 30°C with rotary shaking at 150 rpm for 48 h. After incubation, the bacterial cells were collected by centrifugation at 8000 rpm for 15 min. The pellet was resuspended in 10 mL of 4% sodium hypochlorite and incubated at 50°C for 1 h for cell lysis. The whole mixture was centrifuged at 12,000 rpm for 30 min and the supernatant discarded. The cell pellet containing PHB was washed sequentially with distilled water, acetone, and ethanol. Finally, the polymer granules were dissolved in 10 mL of chloroform and incubated overnight at 50°C, and then left to evaporate at room temperature. Next, 10 mL H2SO4 was added to the polymer granules and placed in water bath for 10 min at 100°C. The addition of sulfuric acid converts PHAs into crotonic acid, which is brown. crotonic acid gives maximum absorbance at 235 nm, the absorbance was read at 235 nm against a sulfuric acid blank. PHB (Sigma Aldrich) was used as standard to create a standard curve. By referring to the standard curve, the quantity of PHB produced was determined (Law and Slepecky, 1961; Lee et al., 1995; Singh et al., 2011; Buhuwal et al., 2013).

For the quantitative analysis of PHB, the dry cell weight (DCW) was determined. A cell culture was grown as described above and 10 mL of the culture was centrifuged at 10,000 rpm for 15 min in a pre-weighed centrifuge tube. The pellet was washed with 10 mL of distilled water, centrifuged, and dried at 105°C until constant weight was obtained. The centrifuge tube was weighed to estimate the DCW in g/L (Du et al., 2001; Zakaria et al., 2010; Buhuwall et al., 2013). The PHB content (%) was calculated from the DCW.

Phenotypic Features of PHB-Producing Isolates

All phenotypic tests were conducted in duplicate and repeated if inconsistent results were first observed. The colony morphology of isolates was observed under a light microscope as described by (Inan et al., 2016). The cell morphology and motility were examined by light microscopy of native preparations. Gram staining was carried out using the standard Gram’s reaction (Savas et al., 2009) and was confirmed by a nonstaining procedure using the KOH lysis test (Gregersen, 1978). The formation of spores was determined by microscopic observations at different incubation periods, both in liquid cultures and in single colonies of isolates.

The presence of catalase and oxidase was investigated as described by (Inan et al., 2015). The bacterial isolates’ need for atmospheric O2 was detected after they were incubated in brain heart infusion agar. The temperature and pH range for growth were determined following incubation of the strains in Lysogeny broth (LB) at different temperatures (25–50°C) and pH (4.0–11.0) with 5°C and one-unit intervals, respectively. The NaCl requirement for growth was also tested in LB containing 1.0–8.0% (w/v) NaCl. Growth was determined by visual observation after three days of incubation (Inan et al., 2012).

Biochemical characteristics of isolates were screened by Analytical Profile Index (API) 20E® test strip (bioMérieux, France) according to the manufacturer’s instructions with some modifications. In the API 20E test strip, the plastic strip contains 20 test mini-chambers (wells) containing dehydrated media with chemically defined compositions for each test. The following 21 tests were performed in the wells: β‑galactosidase production (ONPG test); lysine decarboxylase; ornithine decarboxylase; urease production; citrate utilization; deamination of phenylalanine; malonate utilization; aesculin hydrolysis; fermentation of arabinose, xylose, adonitol, rhamnose, cellobiose, melibiose, sucrose, trehalose, raffinose, and glucose; production of indole; production of acetoin; and production of cytochrome oxidase. Bacterial isolates were grown on nutrient agar overnight at 30°C. After incubation, several colonies of identical morphology were taken from the overnight cultures grown on nutrient agar. These colonies were suspended in 3 mL of a saline solution (NaCl 0.9%, w/v) in order to achieve turbidity of McFarland Standard No. 1 and 200 μL of suspension was transferred into each well of the API strips. The strips were put into a plastic container, the bottom of which was filled with sterilized water to minimize evaporation, and then incubated at 37°C. The API strips were observed at 4, 8, 16, and 24 h. During incubation, bacterial metabolism produced color changes that were either spontaneous or revealed by the addition of reagents. The reading of these reactions (positive or negative) was done according to the variations in colors.

Genomic DNA Isolation of Bacterial Isolates

DNA isolation was performed using a Genomic DNA Mini Kit (Invitrogen) according to the instructions provided by the manufacturer. These isolated DNAs were stored at –20°C for further studies.

Gene Amplification, Cloning, and Sequencing for Phylogenetic Studies

PHB-producing isolates were identified based on 16S rRNA gene sequence analysis. Extracted DNA was used as a template for 16S rRNA gene amplification.

The 16S rRNA genes were selectively amplified by using oligonucleotide primers designed to anneal to conserve positions in the 3' and 5' regions of the bacterial 16S rRNA genes. The forward primer UNI16S-L (5'ATTCTAGAGTTTGATCATGGCTTCA) and the reverse primer UNI16S-R (5'-ATGGTACCGTGTGACGGGCGGTGTTGTA) were used (Bektas et al., 2016). The PCR conditions were as described by Inan et al. (2011b); PCR products were cloned into pGEM-T vector systems according to the manufacturer’s instructions (Promega).

The DNA sequences of the 16S rRNA gene were determined with a high throughput Applied Biosystems 3730XL sequencer using a 23 ABI 3730XLs sequencing kit (Macrogen, Netherlands). Sequences consisting of about 1400 nt of 16S rRNA gene were determined. The results of 16S rRNA gene sequencing were analyzed using the EzTaxon server (http://www.eztaxon.org/) (Chun et al., 2007). The 16S rRNA gene sequences of related taxa were obtained from the EzTaxon-e server and edited using the program BioEdit (Hall, 1999) and multiple alignments were performed with the program CLUSTAL_X (Thompson et al., 1997). Phylogenetic analyses were performed by the neighbor-joining (Saitou and Nei, 1987) algorithm with MEGA version 6.0 (Tamura et al., 2013). Evolutionary distances were calculated using Kimura’s two parameter model (Kimura, 1980). Bootstrap analysis based on 1000 replicates was also conducted in order to obtain confidence levels for the branches (Felsenstein, 1985).

RESULTS AND DISCUSSION

Isolation of Bacterial Isolates and Screening of PHB-Producing Isolates

For the rapid detection and isolation of PHB-producing bacteria (86 totally) were screened on MSM agar medium with Sudan Black B, for lipophilic compounds. A total of 32 isolates were stained with Sudan Black B. The 32 isolates obtained from the preliminary screening were then re-cultivated on MSM agar medium containing Nile blue A, a specific dye for the staining of PHB granules. Thirteen bacterial isolates exhibited fluorescence and were selected as PHB-producing isolates (Fig. 1).

Conventional Analysis of PHB-Producing Isolates

Thirteen bacterial isolates producing PHB were subjected to conventional tests to characterize them and the results are shown in Table 1. These tests indicated that all of the isolates were aerobic and motile. 10 isolates were catalase positive, 6 were oxidase positive. All isolates screened for temperature tolerance were able to grow between 25 and 45°C, with variation among strains. It was noted that all isolates grew at 30°C for 24 h to 2 days. Salt was not required for growth since all the strains were able to grow in the salt-free medium. The isolates tolerated salt concentrations in medium supplemented with 1 to 6% NaCl (w/v). None of the strains were able to grow in medium supplemented with 7% NaCl (w/v). In addition, the pH values tested ranged from 4.0 to 11.0. All strains grew at pH ranging between 6.0 and 8.0.

Biochemical Characterization

The API 20E profiles of the isolates demonstrated biochemical diversity (Table 2). All strains were negative for reduction of nitrates and lysine decarboxylase. The utilization of carbohydrates varied; positive assimilation results for D-glucose and D-mannitol were obtained for all strains. The carbohydrate assimilation test was positive for 8 strains on L-arabinose, 6 strains on sucrose, and 4 strains each on inositol and sorbitol. Only 1 strain assimilated amygdalin. The number of positive tests displayed by the isolates ranged from four to ten.

16S rRNA Gene Sequence Analysis

In order to determine the phylogenetic relationship between the PHB-producing isolates and the known types, the 16S rRNA gene sequences were analyzed. A total of 1400 nucleotides of the 16S rRNA from 13 isolates were aligned and compared to sequences of related bacteria using EzTaxon; the results are summarized in Table 3. The phylogenetic tree was constructed using the neighbor-joining method (Figs. 2, 3). On the basis of the 16S rRNA gene sequence analysis, nine of the isolates (K3, K9, Y1, Y2, Y6, Y9, M5, M8, M9) were detected to be strains belonging to Pseudomonas species at a similarity rate of ≥99%. Further, two of the isolates (Y3, B6) were related to Arthrobacter species at a ≥99% rate, and one of them (K2) to Pseudarthrobacter species (≥98% rate of similarity); in addition, one of the isolates (Y9) belonged to Bacillus species at a rate of ≥99%.

Kim et al. (2014) reached the conclusion that strains belonging to the same genus that exhibit less than 98.65% 16S rRNA gene sequence similarity should be considered members of different species. These similarities showed that nine isolates (K3, K9, Y1, Y2, Y6, Y9, M5, M8, M9) were members of the genus Pseudomonas, Y3 and B6 belonged to the genus Arthrobacter, and K2 and Y9 were members of the genera Pseudarthrobacter and Bacillus, respectively.

Three of the isolates (M5, M9, Y7) were detected to be strains belonging to Pseudomonas plecoglossicida at a similarity rate of 99%. Further, K3 belonged to Pseudomonas moorei, Y1 to Pseudomonas laurylsulfativorans, Y6 to Pseudomonas baetica, Y2 to Pseudomonas piscium, K9 to Pseudomonas soli, and M8 to Pseudomonas putida at a similarity rate of 99%. Further, Y3 and B6 were related to Arthrobacter oryzae and K2 to Pseudarthrobacter oxydans at a similarity rate of 99%. In addition, Y9 belonged to Bacillus proteolyticus at a rate of 99%.

The 16S rRNA gene sequence analysis showed that the PHB-producing isolates belonged to the genera Pseudomonas, Arthrobacter, Pseudarthrobacter, and Bacillus.

Production of PHB

The PHB-positive isolates selected after Nile blue A staining were employed to extract PHB after 48 h of incubation. Thirteen isolates reportedly accumulated PHB granules as reserve material. The PHB from the isolates was extracted using dispersion in the hypochlorite and chloroform method as described earlier. Yields of PHB (%) were calculated from the weight of PHB per dry cell weight extracted (Table 4).

PHB was accumulated by strains M5, M6, M8, M9, K2, K3, K6, B6, Y1, Y2, Y3, Y6, Y7, and Y9. The highest PHB production and percentage productivity were obtained from Pseudomonas plecoglossicida M9 (0.94 PHB g/L; 78.8% PHB) and Pseudomonas baetica Y6 (0.81 PHB g/L; 74.3% PHB), respectively. In the present study, two strains of Pseudomonas showed high PHB accumulation as well when compared with other Pseudomonas sp. strains like Pseudomonas sp. 28/D (66.5% PHB yield) (Reddey and Thirumala, 2012) and Pseudomonas putida CA-3 (59.0% PHB yield) (Ward and O’Connor, 2005) reported so far.

CONCLUSIONS

Eighty-six bacteria were isolated from oil-contaminated soil samples collected from Istanbul, Turkey. The isolates were screened for PHB production using Sudan Black B staining and Nile blue A fluorescence staining. Thirteen bacterial isolates accumulated PHB as reserve material. Based on the 16S rRNA gene sequences analysis, PHB-producing isolates belonged to the genera Pseudomonas, Arthrobacter, Pseudarthrobacter, and Bacillus. These bacteria were screened in terms of PHB production and the maximum was found in Pseudomonas plecoglossicida M9 (78.8% PHB) and Pseudomonas baetica Y6 (74.3% PHB). These isolates can be regarded as good candidates for the industrial production of PHB.

REFERENCES

Arun, A., Murrugappan, R.M., David, R., Veeramanikandan, V., and Balaji, S., Utilization of various industrial wastes for the production of poly-hydroxy butyrate (PHB) by Alcaligenes eutrophus, Afr. J. Biotechnol., 2006, vol. 6, pp. 1524–1527.

Beffa, T., Blanc, M., Lyon, P.F., and Vogt, G., Isolation of Thermus strains from hot composts (60 to 80°C), Appl. Environ. Microbiol., 1996, vol. 62, pp. 1723–1727.

Bektas, K.I., Belduz, A.O., Guvenmez, H.K., and Sihay, D., Fontibacillus pullulanilyticus sp. nov. isolated from soil, J. Basic Microbiol., 2016, vol. 56, pp. 857–863.

Berlanga, M., Montero, M.T., Hernándezj-Borrell, J., and Guerrero R., Rapid spectrofluorometric screening of poly-hydroxyalkanoate-producing bacteria from microbial mats, Int. Microbiol., 2006, vol. 9, pp. 95–102.

Bhuwa, A., Sing, G., Aggarwa, N.K., Goya, V., and Yadav, A., Isolation and screening of polyhydroxyalkaoates producing bacteria from pulp, paper, and cardboard industry eastes, Int. J. Biomater., 2013, p. 752821.

Bhuwal, A.K., Singh, G., Aggarwal, N.K., Goyal, V., and Yadav, A., Isolation and screening of polyhydroxyalkanoates producing bacteria from pulp, paper, and cardboard industry wastes, Hindawi Publ. Corp. Int. J. Biomater., 2013, p. 752821.

Chun, J., Lee, J.H., Jung, Y., and Kim M., EzTaxon: a web-based tool for the identification of prokaryotes based on 16S ribosomal RNA gene sequences, Int. J. Syst. Evol. Microbiol., 2007, vol. 57, pp. 2259–2261.

Desouky, S.E., El-Shiekh, H.H., Elabd, M.A., and Shehab, A.M., Screening, optimization and extraction of polyhydroxyalkanoates (PHAs) from Bacillus thuringienesi, J. Adv. Biol. Biotechonol., 2014, vol. 1, pp. 40–54.

Du, G., Chen, J., Yu, J., and Lun A., Continuous production of poly-3-hydroxybutyrate by Ralstonia eutropha in a two-stage culture system, J. Biotechnol., 2001, vol. 88, pp. 59–65.

Felsenstein, J., Confidence limits on phylogenies: an approach using the bootstrap, Evolution, 1985, vol. 39, pp. 783–791.

Gabr, A.G., Isolation and identification of bacterial strains able to biopolymer polyhydroxybutyrate (Phb) production from soil of Al-Kharj probes, Saudi Arabia, J. Pharm. Res. Int., 2018, vol. 21, pp. 1–11.

Hall, T.A., BioEdit: a user-friendly biological sequence alignment editor and analysis program for Windows 95/98/NT, Nucleic Acids Symp. Ser., 1999, vol. 41, pp. 95–98.

Inan, K., Canakcı, S., and Belduz, A.O., Isolation and characterization of xylanolytic new strains of Anoxybacillus from some hot springs in Turkey, Turk. J. Biol., 2011a, vol. 35, pp. 529–542.

Inan, K., Bektas, Y., Canakci, S., and Belduz, A.O., Use of rpoB sequences and rep-PCR for phylogenetic study of Anoxybacillus species, J. Microbiol., 2011b, vol. 49, pp. 782–790.

Inan, K., Canakcı, S., Belduz, A.O., and Sahin, F., Brevibacillus aydinogluensis sp. nov., a moderately thermophilic bacterium isolated from Karakoc hot spring in Turkey, Int. J. Syst. Evol. Microbiol., 2012, vol. 62, pp. 849–855.

Inan, K., Kacagan, M., Ozer, A., Belduz, A.O., and Canakci, S., Algoriphagus trabzonensis sp. nov., isolated from freshwater, and emended description of Algoriphagus alkaliphilus, Int. J. Syst. Evol. Microbiol., 2015, vol. 65, pp. 2234–2240.

Inan, K., Ozer, A., Guler, H.I., Belduz, A.O., and Canakci, S., Brevibacillus gelatini sp. nov., isolated from a hot spring, Int. J. Syst. Evol. Microbiol., 2016, vol. 66, pp. 712–718.

Kim, M., Oh, H.S., Park, S.C., and Chun, J., Towards a taxonomic coherence between average nucleotide identity and 16S rRNA gene sequence similarity for species demarcation of prokaryotes, Int. J. Syst. Evol. Microbiol., 2014, vol. 64, pp. 346–351.

Kimura, M., A simple method for estimating evolutionary rates of base substitutions through comparative studies of nucleotide sequences, J. Mol. Evol., 1980, vol. 16, pp. 111–120.

Kitamara, S., Doi, Y., Staining method of poly(3-alkanoic acid) producing bacteria by Nile blue, Biotechnological Techniques, 2004, vol. 8, pp. 345–350.

Law, J. and Slepecky, R.A., Assay of poly-beta-hydroxybutyric acid, J. Bacteriol., 1961, vol. 82, pp. 52–55.

Lee, I.Y., Chang, H.N., Park, Y.H., A simple method for recovery of microbial poly-3-hydroxybutyrate by alkaline solution treatment, J. Microbiol. Biotechnol., 1995, vol. 5, pp. 238–240.

McAdam, B., Fournet, MB., McDonald, P., and Mojicevic, M., Production of polyhydroxybutyrate (PHB) and factors impacting its chemical and mechanical characteristics, Polymers (Basel), 2020, vol. 12, p. 2908.

Motamedi, H., Ardakani, M.R., and Mayeli, N., Isolation and screening of native polyhydroxyalkanoate producing bacteria from oil contaminated soils of Abadan refinery, Biol. J. Microorganism, 2015, vol. 3, pp. 93–104.

Naheed, N., Jamil, N., and Hasnain, S., Screening of contaminated soils for biodegradable plastic producing bacteria and profiling of their resistance markers, Afr. J. Microbiol. Res., 2011, vol. 5, pp. 4097–4104.

Narayanan, M., Kandasamy, S., Kumarasamy, S., Gnanavel, K., Ranganathan, M., and Kandasamy, G., Screening of polyhydroxybutyrate producing indigenous bacteria from polluted lake soil, Heliyon, 2020, vol. 6, p. e05381.

Pernicova, I., Novackova, I., Sedlacek, P., Kourilova, X., Kalina, M., Koller, M., Krzyzanek, J., Hrubanova, K., Masilko, J., and Obruca, S., Introducing the newly isolated bacterium Aneurinibacillus sp. H1 as an auspicious thermophilic producer of various polyhydroxyalkanoates (PHA) copolymers–1. Isolation and characterization of the bacterium, Polymers (Basel), 2020 vol. 12, p. 1235.

Phanse, N., Chincholikar, A., Patel, B., Rathore, P., Vyas, P., and Patel, M., Screening of PHA (poly hydroxyalkanoate) producing bacteria from diverse sources, Int. J. Biosci., 2011, vol. 1, pp. 27–32.

Prasanna, T., Babu, P.A., Lakshmi, P.D., Chakrapani, R., and Rao, C.S.V.R., Production of poly(3-hydroxybutyrates) by Bacillus species isolated form soil, J. Pharma Res. Rev., 2011, vol. 1, pp. 15–18.

Ramsay, B.A., Lomaliza, K., Chavarie, C., Dubé, B., Bataille, P., and Ramsay, J.A., Production of poly-β-hydroxybutyric-co-β-hydroxyvaleric acids, Appl. Environ. Microbiol., 1990, vol. 56, pp. 2093–2098.

Reddy, C.S.K., Ghai, R., Rashmi, S., and Kalia, V.C., Polyhydroxyalkanoates: an overview, Bioresour. Technol., 2003, vol. 87, pp. 137–146.

Reddy, S.V. and Thirumala, M., Isolation of polyhydroxyalkanoates (PHA) producing bacteria from contaminated soils, Int. J. Environ. Biol., 2012, vol. 2, pp. 104–107.

Saitou, N. and Nei, M., The neighbor-joining method: a new method for reconstructing phylogenetic trees, Mol. Biol. Evol., 1987, vol. 4, pp. 406–425.

Savas, S., Adiguzel, A., Inan, K., Ozkan, H., Gulluce, M., and Sahin, F., Molecular characterization of thermophilic bacteria isolated from Van City Ercis Town Hasanabdal hot spring, Roman. Biotechnol. Lett., 2009, vol. 14, pp. 4445–4454.

Shaaban, M.T., Attia, M., Turky, A.S., and Mowafy, E.I., Production of some biopolymers by some selective Egyptian soil bacterial isolates, J. Appl. Sci. Res., 2012, vol. 8, pp. 94–105.

Singh, G., Mittal, A., Kumari, A., Goel, V., Aggarwal, N.K., and Yadav, A., Optimization of poly-B-hydroxybutyrate production from Bacillus species, Eur. J. Biol. Sci., 2011, vol. 3, pp. 112–116.

Tamura, K., Stecher, G., Peterson, D., and Filipkski, A., MEGA6: molecular evolutionary genetics analysis version 6.0, Mol. Biol. Evol., 2013, vol. 30, pp. 2725–2729.

Thapa, C., Shakya, P., Shrestha, R., Pal, S., and Manandha, P., Isolation of polyhydroxybutyrate (PHB) producing bacteria, optimization of culture conditions for PHB production, extraction and characterization of PHB, Nepal J. Biotechnol., 2018, vol. 6, pp. 62–68.

Thompson, J.D., Gibson, T.J., Plewniak, F., Jeanmougin, F., and Higgins, D.G., The CLUSTAL_X windows interface: flexible strategies formultiple sequence alignment aided by quality analysis tools, Nucleic Acids Res., 1997, vol. 25, pp. 4876–4882.

Van, D.T. and Thi, N.B., Polyhydroxyalkaoates production by a bacterium isolated from mangrove soil samples collected from Quang Ninh province, J. Vietnam. Environ., 2012, vol. 3, pp. 76–79.

Ward, P.G. and O’Connor, K.E., Bacterial synthesis of polyhydroxyalkanoates containing aromatic and aliphatic monomers by Pseudomonas putida CA-3, Int. J. Biol. Macromol., 2005, vol. 35, pp. 127–133.

Zakaria, M.R., Ariffin, H.J., Aziz, N.A.M., Nishida, S.A., Shirai, H.Y., and Hassan, M.A., Biosynthesis and characterization of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) copolymer from wild-type Comamonas sp. EB172, Polym. Degrad. Stab., 2010, vol. 95, pp. 1382–1386.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest. This article does not contain any studies involving animals or human participants performed by any of the authors.

Rights and permissions

About this article

Cite this article

Kadriye İnan Bektas, Can, K. & Belduz, A.O. Isolation and Screening of Polyhydroxybutyrate (PHB) Producing Bacteria from Soils. Biol Bull Russ Acad Sci 50, 319–328 (2023). https://doi.org/10.1134/S106235902210065X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S106235902210065X