Abstract

In the present work, a modified carbon paste electrode was fabricated by grinding the mixture of graphite powder and paraffin oil (as a binder) with a sufficient amount of TiO2 nanoparticles. The electrochemical behavior of vitamin B2 (riboflavin) was investigated on the surface of the electrode using cyclic voltammetry and differential pulse voltammetry (DPV). The results showed that the electrochemical response of riboflavin was improved considerably at the modified electrode comparing to the unmodified electrode. Effects of TiO2 percentage, pH value, pulse time, and pulse amplitude were optimized using DPV technique. Under the optimized conditions, a linear dynamic range of 2.4 × 10–6 to 2.4 × 10–4 M with the detection limit of 1.6 × 10–6 M for vitamin B2 was obtained. The effects of some common interferences were examined, and the method was successfully employed to the detection of riboflavin in pharmaceutical formulations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Nanomaterials, specifically nanoparticles because of their small size (1–100 nm), show unique chemical, physical and electronic properties that are various from those of the bulk substances. With due attention to these different behaviors, nanoparticles have been widely used in many kinds of analytical techniques [1] and can be applied to fabricate new and improved sensing instruments, particularly electrochemical sensors and biosensors [2]. Additionally, electrochemical techniques with chemically modified electrodes have been extensively developed as sensitive and selective analytical methods for the determination of trace amounts of biologically important materials [3]. Over the past few years, carbon paste electrodes (CPEs) have been used widespread in electroanalytical chemistry because of their broad potential windows, low cost, rich surface chemistry, low background current, ease of surface renewal, individual polarizability, and ease of modification application. The disadvantage of CPE is the tendency of the organic binder to dissolve in solutions containing an appreciable fraction of organic solvent [4–6]. Moreover, application of CPEs modified with nanostructured substances provides a remarkable increase in electrochemical properties of many important compounds [7, 8]. The comparison of a nanoparticles modified electrode with a macroelectrode shows that the first has such great advantages as high effective surface area, mass transport, catalysis and control over local microenvironment [9, 10].

On the other hand, several attempts have been made to prepare TiO2 nanoparticles and to apply them in photovoltaic studies, in water and air purification using photo

catalysis and in phototelectrocatalysis techniques by many researchers in recent years, since they have high surface area, optical transparency, good biocompatibility, and relatively good conductivity [11–14]. Therefore, there is a remarkable interest in using TiO2 nanoparticles as an electrode modifier in sensors. Also, sonogel carbon electrode modified with nanostructured TiO2 for catechol detection [15], nano-TiO2 film/nafion-modified glassy carbon electrode for the investigation of dopamine [16], pyrolytic graphite electrode co-modified with nano-TiO2 and hemoglobin to study the photovoltaic effect of TiO2 nanoparticles [17], TiO2 nanoparticles-modified carbon paste electrode for buzepide methiodide determination [18] and carbon−Pt nanoparticles modified with TiO2 nanoparticles for the detection of dopamine [19] have been reported.

Vitamin B2, also known as riboflavin (7,8-dimethyl-10-ribityl-isoalloxazine), is a B-group water soluble vitamin stable in acidic aqueous solutions Scheme 1.

Scheme 1 . Chemical structure of riboflavin.

Its structure is presented Human beings as well as all animals require a constant supply of vitamin B2 [20]. Its insufficiency is associated with eye lesions and skin disorders [21]. Vitamin B2 cannot be synthesized in human body, therefore has to be obtained from food (such as vegetables, fruits, cheese, and liver) and pharmaceutical products [22]. Recently, several methods have been employed to determine concentrations of vitamin B2, including chemiluminescence [23], HPLC [24], fluorescence [25], and capillary electrophoresis [26].

Voltammetric determination of vitamin B2 provides an alternative method, considering the low cost of the analysis, high sensitivity, rapid response time, and simple instrumentation required [27]. Glassy carbon electrodes modified with double-stranded DNA [28], flowers-like Fe3O4/rGO [29], ordered mesoporous carbon [30], high-density arrays of polythiophene nanotubes [31], poly (3-methylthiophene) [32], graphene [33], nanocrystalline metallosilicate [34], and electropolymerized film of 3-amino-5-mercapto-1,2,4-triazole [35] have been applied to determine vitamin B2. Recently, Gribat et al. [36] have measured vitamin B2 using hematite (α-Fe2O3) film modified rotating disk glassy carbon electrode. Also, bismuth-film modified copper substrate electrode [37] and homoadenine single-stranded DNA/molybdenum disulfide-graphene nanocomposite modified gold electrode [38] have been employed as new electrochemical methodologies for vitamin B2 determination. Moreover, electrically heated graphite cylindrical electrodes made from ground pencil leads have been used to perform square wave adsorptive stripping voltammetry (SWAdSV) measurements of riboflavin [39]. On the other hand, the carbon paste electrode and chemically modified carbon paste electrodes (CMCPEs) are widely used in various fields of electrochemistry [40]. The use of carbon-paste matrix, besides renewability by simple polishing, offers several other advantages including easy preparation, uniform distribution of the catalyst into the paste, better reproducibility and stability, very low Ohmic resistance, and adequate robustness in aqueous solutions [41]. Carbon paste electrodes have been used for potentiometric and voltammetric determination of various cations, anions, organic, and pharmaceutical species [42]. Only in few articles, application of a carbon paste electrode for vitamin B2 determination has been reported [43, 44]. This report describes the electrochemical behavior of vitamin B2 on the TiO2 nanoparticles bulk-modified carbon paste electrode surface, as well as application of this modified electrode for the simple and selective determination of vitamin B2.

EXPERIMENTAL

Reagents and chemicals. Vitamin B2 was purchased from Merck. TiO2 powder (Degussa P25) with a particle size of 30 nm and a surface area of 50 m2/g was obtained from Degussa. Graphite powder and high-purity paraffin oil from Fluka were used for fabrication of the carbon paste electrode. All solutions were freshly prepared with double distilled water. All other reagents were of analytical grade. The stock standard solution of vitamin B2 (0.01 M) was prepared from the dry substances in deionized water. The stock solutions were protected from light with an aluminum foil, kept in a refrigerator, and used within 2 days. Phosphate buffer (pH 1–9) was used as a supporting electrolyte and to adjust pH.

Apparatus. Voltammetric measurements were performed at a Metrohm Computrace Voltammetric Analyzer Model 797 VA with a conventional three-electrode cell. The working electrode was a bare or TiO2-modified CPE, the auxiliary electrode was a platinum rode, and an Ag/AgCl/KCl (3 M) was used as the reference electrode. During the measurements, the solution in the cell was neither stirred nor aerated; pH measurements were made on a Denver Instrument Model 827 pH meter equipped with a Metrohm glass electrode.

Procedures. Cyclic voltammetry (CV) with a scan rate of 50 mV/s (if not stated otherwise) and differential pulse voltammetry with a scan rate of 50 mV/s, a pulse amplitude of 0.05 V and a pulse time of 0.04 s were applied for characterizing the electrochemical behavior of the analyte at the unmodified and modified electrode surface. The investigated solutions were transferred into the voltammetric cell and the voltammograms (usually 3 cycles) were recorded in a potential range between –0.8 and –0.1 V for two techniques. Also, DPV with a scan rate of 50 mV/s and optimized parameters in the potential range (pulse amplitude – 0.09 V and pulse time – 0.01 s) from –0.32 to –0.0 V was used for the quantification of vitamin B2. Moreover, the difference between oxidation peak currents and residual (background) current lines was used as the method of measuring the magnitude of the analytical signals.

Preparation of TiO2 nanoparticles modified electrode. The unmodified CPE was constructed by hand mixing graphite powder with paraffin oil at a ratio of 82 : 19 (w/w) in an agate mortar. The TiO2 modified carbon paste electrode (TiO2/CPE) was fabricated with 0.90 mg of graphite powder, 0.23 g of paraffin, and a certain value of TiO2 powder. The amount of TiO2 was changed to prepare the modified electrode with different percentages. TiO2 powder and graphite were dissolved in diethyl ether. Then, the solvent was evaporated by stirring. The resulting mixture and paraffin were blended by hand-mixing until a uniform paste was obtained. The obtained paste was inserted at the bottom of a tube (internal radius – 3 mm) and smoothed on a weighing paper. Electrical connection was implemented by a copper wire lead fitted into the tube. A fresh electrode surface was obtained by squeezing out a small portion of the paste and polishing it with the filter paper until a smooth surface was obtained.

RESULTS AND DISCUSSION

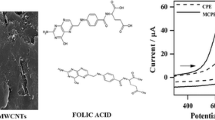

Voltammetric behavior of vitamin B2 on TiO2 nanoparticles modified carbon paste electrode. The electrochemical behavior of vitamin B2 was studied using CV and DPV. Figure 1a shows the cyclic voltammograms of 9.08 × 10–4 M vitamin B2 at the bare CPE (curve 1) and CPE modified with TiO2 nanoparticles (curve 2) in phosphate buffer of pH 7 at the scan rate of 50 mV/s. As can be seen in Fig. 1a, well-defined oxidation and reduction peaks were observed at about –419 and –425 mV, respectively, at both bare CPE and TiO2/CPE which correspond to the oxidation and reduction of electroactive hydroquinone and quinone groups, respectively. Higher peak currents were obtained with the TiO2/CPE in comparison to the bare CPE. This finding demonstrates that the TiO2/CPE is more sensitive than the bare CPE. This is mainly attributed to the presence of TiO2 particles on the surface of the modified CPE electrode. Differential pulse voltammetry was also used to characterize the electrode modification process. It indicated an increase in the oxidation current of vitamin B2 at the surface of the TiO2/CPE with respect to the bare CPE at a pulse time of 0.04 s and a pulse amplitude of 0.05 V (Fig. 1b). The results show that the TiO2 nanoparticles effectively increase the electron transfer rate between the electrode surface and vitamin B2.

Cyclic voltammograms (a) and differential pulse voltammograms (b) of 9.08 × 10–4 M vitamin B2 in phosphate buffer solution at pH 7 on the bare carbon paste electrode (1) and TiO2 modified carbon paste electrode (TiO2 percentage—10%) (2). Pulse time and pulse amplitude in differential pulse voltammograms were equal to 0.04 s and 0.05 V, respectively.

Effect of scan rate. In order to investigate the behavior of the electrochemical reaction of vitamin B2 on the TiO2/CPE, the influence of the scan rate on the anodic peak potential and anodic peak current at the TiO2/CPE with TiO2 percentage of 10% was studied using 9.08 × 10–4 M vitamin B2 in buffer solution at pH 1. The scan rate was changed in the range of 5–4000 mV/s. The peak potential shifted to more anodic values with increasing scan rate (Fig. 2a). This behavior indicates that the oxidation process is quasi-reversible. The plot of Ip vs. v1/2 was found to be linear (y = 12.383x – 47.428) with a correlation coefficient (R2) equal to 0.989. This result confirmed that the oxidation and reduction process on the electrode surface is controlled by diffusion rather than by adsorption. Also, an increase in the scan rate causes a significant increase in ∆Ep. These results indicate quasi reversibility of electrochemical reaction [45].

Effect of TiO2 percentage. The voltammetric signals of vitamin B2 were affected by the composition of the paste. According to Fig. 3, in order to investigate the effect of TiO2 percentage on Ip oxidation of vitamin B2, experiments were carried out in phosphate buffer solution (pH 7) in presence of 9.08 × 10–4 M vitamin B2 using four percentages of TiO2: 5, 10, 15, and 20%. It was observed that the sensitivity of the sensor first rapidly increased with the TiO2 content increase in the paste up to about 10%, and then started to sharply decrease with higher amounts of TiO2. This is because the sites for adsorption increase with the increase in TiO2 percentage in the modified electrode, while the excess of TiO2 increases the resistance of the electrode. Hence, the TiO2 (10%, w/w)-modified carbon paste electrode was used throughout this work.

Effect of solution pH. The mechanisms of many organic reactions are known to involve a pH dependent process. In this case, acidity of electrolyte affected the electrooxidation behavior of vitamin B2 because proton participated in the electrode reaction. Thus, the effect of pH on vitamin B2 oxidation was studied using CV and DPV at the TiO2 nanoparticles-modified CPE. In the preliminary experimental studies, nine individual pH values in the range of 1–9 were tested to identify the influence of the pH. As can be seen in Fig. 4a, the peak potential of vitamin B2 at the surface of the TiO2/CPE is shifted to the less positive values by increasing the solution pH. Also, DPV technique was applied in order to find the optimum pH. Similar to the obtained results in CV, the peak current decreased considerably beyond pH 1 (Fig. 4b). Also, the peak potential of vitamin B2 was shifted to more negative potentials with increasing of the pH of buffers (Fig. 4c). Based on these results, pH 1 was chosen for further tests. When considering pH from 1 to 9 the peak potential shift to the more negative values occurs with the corresponding equation Ep = –49.63pH – 127.83. The slope of 49.63 mV per pH unit is close to the ideal value of 59 mV which might indicate that the number of protons and electrons involved in the electrochemical reaction is in the ratio of 1 : 1. Resultant proton/electron ratio is in accordance with the oxidation reaction of vitamin B2 where two electrons and two protons are involved.

(a) Cyclic voltammograms of 9.08 × 10–4 M vitamin B2 at the surface of the TiO2/CPE with TiO2 percentage of 10% at pH: 1 (1), 3 (2), 5 (3), 7 (4) and 9 (5) at the scan rate of 50 mV/s. Effect of pH on peak current (b) and peak potential (c) of 9.08 × 10–4 M vitamin B2 in buffer solution at pH 7 on the TiO2/CPE with TiO2 percentage of 10% using differential pulse voltammetry (pulse time—0.04 s, pulse amplitude—0.05 V) at the scan rate of 50 mV/s.

Optimization of differential pulse voltammetry parameters. Differential pulse voltammetry is a powerful method for the quantitation of the analytes due to the low background currents and low detection limits, therefore, it has been used in the present study for the detection of vitamin B2. Pulse time and pulse amplitude as important parameters for DPV were optimized to obtain the best experimental setup for the determination of vitamin B2. The optimization was performed in the previously selected buffer at pH 1 with the vitamin B2 concentration of 9.08 × 10–4 M. During this optimization procedure one investigated parameter was varied while the others were kept fixed. When the pulse time was changed from 0.01 to 0.08 s, the peak current sharply decreased up to 0.05 s. With further increase in the pulse time obtained current was slightly increasing (Fig. 5a). Therefore, the most suitable peak current was observed at 0.01 s. Also, varying the pulse amplitude in the range of 0.01–0.09 V led to the sharp increase in the peak currents (Fig. 5b). Consequently, a value of 0.09 V of pulse amplitude was selected as optimum. All other tests, such as calibration curve, interference investigations, and real sample analysis were performed under these optimized factors: pH 1, TiO2 percentage – 10%, pulse time – 0.01 s and pulse amplitude – 0.09 V.

Influence of pulse time (a) and pulse amplitude (b) on the peak potential of 9.08 × 10–4 M vitamin B2 in buffer solution at pH 1 on the TiO2/CPE with TiO2 percentage of 10% using differential pulse voltammetry at pulse amplitude of 0.05 V (a) and pulse time of 0.01 s (b) at the scan rate of 50 mV/s.

Repeatability and stability of TiO2 nanoparticles modified carbon paste electrode. To evaluate and confirm the repeatability of the TiO2/CPE electrode, five repeated DPV measurements were performed under the optimized conditions. The relative standard deviation was 5.6% for five measurements. This result showed that the repeatability of the electrode was suitable. The stability of the electrode was estimated using monitoring of current peak of 9.08 × 10–4 M vitamin B2 after being stored at room temperature for one month. It was observed that the current response preserved almost 95% of its initial value.

Calibration curve. The differential pulse voltammograms were recorded for calibration graph construction on the TiO2/CPE under the optimum conditions described above using a standard addition method as presented in Fig. 6a. Under the optimized experiment conditions, the anodic peak current was proportional to the concentration of vitamin B2 in a range from 2.4 × 10–6 to 2.4 × 10–4 M and a linear calibration plot (y = 936.98x + 3.51 with R2 = 1.000) was obtained. The detection limit (3σ) was estimated to be 1.6 × 10–6 M. This sensor offers low detection limit, suitable linear range for the quantification of vitamin B2. The simplicity of the electrode preparation is the main advantage of this method for the determination of vitamin B2. The comparison of several studies for vitamin B2 detection at some modified electrodes is summarized in Table 1 [28–39, 43, 44]. It can be seen, the present study provides suitable linear range and detection limit for the determination of vitamin B2. Although, some of the mentioned methods have lower limits of detection and wider linear concentration ranges, but, unlike these methods, in this work graphite and TiO2, as available and low cost substances, for the electrode preparation have been used. Also, some research groups have applied preconcentration techniques for vitamin B2 detection that have not been used in this study.

Interference studies. An important parameter for a sensor is its ability to discriminate between the interfering species commonly present in a similar physiological environment and the target analyte. In order to evaluate the selectivity of the method toward vitamin B2, electrochemical effects of some possible interferences, for example vitamins B1, B6 and B12, folic acid, diclofenac sodium, ascorbic acid, diphenhydramine, and ibuprofen, were examined in the concentration of 1.6 × 10−4 M under the optimized experimental conditions. It was considered that tested compounds strongly interfered with the determination of vitamin B2 if gave signal changes more than ±10%. It should be mentioned that the selected interferences are electroactive, but their oxidation potentials are different from that of vitamin B2 and in the concentration of 1.6 × 10–4 M, in absence of vitamin B2, practically do not provide electrochemical activity in the tested potential range (Table 2). The presence of these interferences at the same concentration levels as vitamin B2 (1.6 × 10–4 M) does not cause changes in the peak current obtained for vitamin B2. Based on these results, this method has a good selectivity for the electrochemical determination of vitamin B2.

Real sample analysis. In order to demonstrate the capability of the TiO2/CPE toward the determination of vitamin B2 in a real sample, this modified electrode was used in voltammetric determination of vitamin B2 in the B-complex capsules produced by Euro OTC Pharma Company. The content of vitamin B2 was determined from the calibration curve by the optimized DPV method. One vitamin B2 capsule (0.2053 g) containing 9.0 mg of vitamin B2 was dissolved in 150 mL of buffer solution (pH 1.0) and an aliquot (12.5 mL) was added to 12.5 mL of buffer (pH 1) and recorded by DPV under the optimized experimental conditions. The concentration of vitamin B2 was evaluated from the calibration curve based on a standard addition method. By this method, the mean value of vitamin B2 content of 9.02 mg was measured using the calibration curve with the mean recovery of 100.2% (n = 3). The obtained results show that the proposed method is suitable for the quantification of vitamin B2 in pharmaceutical formulations.

CONCLUSIONS

The electrochemical behavior of vitamin B2 at the surface of the TiO2/CPE was studied and this modified electrode was used for the determination of the vitamin B2 by differential pulse voltammetry. The obtained results confirm that incorporating of TiO2 in the structure of carbon paste electrode increases its affinity toward the determination of vitamin B2 with good linearity, low detection limit and high selectivity. Additionally, the proposed methodology was successfully applied to the determination of vitamin B2 in commercial capsules.

REFERENCES

Penn, S.G., He, L., and Natan, M.J., Curr. Opin. Chem. Biol., 2003, vol. 7, no. 5, p. 609.

Tiwari, I., Singh, K.P., and Singh, M., Russ. J. Gen. Chem., 2009, vol. 79, no. 12, p. 2685.

Zen, J.M., Kumar, A.S., and Tsai, D.M., Electroanalysis, 2003, vol. 15, no. 13, p. 1073.

Švancara, I., Walcarius, A., Kalcher, K., and Vytřas, K., Cent. Eur. J. Chem., 2009, vol. 7, no. 4, p. 598.

Zima, J., Švancara, I., Barek, J., and Vytřas, K., Crit. Rev. Anal. Chem., 2009, vol. 39, no. 3, p. 204.

Švancara, I., Vytřas, K., Kalcher, K., Walcarius, A., and Wang, J., Electroanalysis, 2009, vol. 21, no. 1, p. 7.

Norouzi, B. and Rajabi, M., J. Anal. Chem., 2017, vol. 72, no. 8, p. 897.

Naeemy, A., Mohammadi, A., and Assi, N., J. Anal. Chem., 2017, vol. 72, no. 7, p. 783.

Katz, E., Willner, I., and Wang, J., Electroanalysis, 2004, vol. 16, nos. 1–2, p. 19.

Welch, C.M. and Compton, R.G., Anal. Bioanal. Chem., 2006, vol. 384, no. 3, p. 601.

Pearson, A., Jani, H., Kalantar-zadeh, K., Bharga-va, S.K., and Bansal, V., Langmuir, 2011, vol. 27, no. 11, p. 6661.

Ogino, C., Kanehira, K., Sasai, R., Sonezaki, S., and Shimizu, N., J. Biosci. Bioeng., 2007, vol. 104, no. 4, p. 339.

Ardakani, M.M., Talebi, A., Naeimi, H., Barzoky, M.N., and Taghavinia, N., J. Solid State Electrochem., 2009, vol. 13, no. 9, p. 1433.

Xie, X., Yang, K., and Sun, D., Colloids Surf., B, 2008, vol. 67, no. 2, p. 261.

Lunsford, S.K., Choi, H., Stinson, J., Yeary, A., and Dionysiou, D.D., Talanta, 2007, vol. 73, no. 1, p. 172.

Yuan, S. and Hu, S., Electrochim. Acta, 2004, vol. 49, no. 25, p. 4287.

Zhou, H., Gan, X., Liu, T., Yang, Q., and Li, G., Bioelectrochemistry, 2006, vol. 69, no. 1, p. 34.

Kalanur, S.S., Seetharamappa, J., and Prashanth, S.N., Colloids Surf., B, 2010, vol. 78, no. 2, p. 217.

Mahshid, S., Luo, S., Yang, L., Mahshid, S.S., Askari, M., Dolati, A., and Cai, Q., J. Nanosci. Nanotechnol., 2011, vol. 11, no. 8, p. 6668.

Squires, V.R., The Role of Food, Agriculture, Forestry and Fisheries in Human Nutrition, vol. 4 of Encyclopedia of Life Support Systems, EOLSS, 2011, p. 121.

Qi, H., Cao, Z., and Hou, L., Spectrochim. Acta, Part A, 2011, vol. 78, no. 1, p. 211.

Hua, L., Yang, X.,Wang, C., Yuan, H., and Xiao, D., J. Chromatogr. B: Anal. Technol. Biomed. Life Sci., 2007, vol. 856, nos. 1–2, p. 245.

Wang, M., Zhao, L., Liu, M., and Lin, J.M., Spectrochim. Acta, Part A, 2007, vol. 66, nos. 4–5, p. 1222.

Vidović, S., Stojanović, B., Veljković, J., Prazi, A.L., Roglić, G., and Manojlović, D., J. Chromatogr. A, 2008, vol. 1202, no. 2, p. 155.

Niazi, A., Yazdanipour, A., Ghasemi, J., and Abbasi, A., J. Chin. Chem. Soc., 2006, vol. 53, no. 2, p. 503.

Safavi, A., Maleki, N., Ershadifar, H., and Tajabadi, F., Anal. Chim. Acta, 2010, vol. 674, no. 2, p. 176.

Bandžuchová, L., Šelešovská, R., Navrátil, T., Chýlková, J., and Novotný, L., Electrochim. Acta, 2012, vol. 75, p. 316.

Kowalczyk, A., Sadowska, M., Krasnodebska-Ostrega, B., and Nowicka, A.M., Talanta, 2016, vol. 163, p. 72.

Madhuvilakku, R., Alagar, S., Mariyappan, R., and Piraman, S., Sens. Actuators, B, 2017, vol. 253, p. 879.

Bai, J., Ndamanisha, J.C., Liu, L., Yang, L., and Guo, L., J. Solid. State Electrochem., 2010, vol. 14, no. 12, p. 2251.

Hajian, A., Rafati, A.A., Afraz, A., and Najafi, M., J. Mol. Liq., 2014, vol. 199, p. 150.

Zhang, H., Zhao, J., Liu, H., Wang, H., Liu, R., and Liu, J., Int. J. Electrochem. Sci., 2010, vol. 5, p. 295.

Bagoji, A.M. and Nandibewoor, S.T., Phys. Chem. Commun., 2016, vol. 3, no. 2, p. 65.

Kaur, B. and Srivastava, R., Electroanalysis, 2014, vol. 26, no. 5, p. 1.

Revin, S.B. and John, S.A., Electrochim. Acta, 2012, vol. 75, p. 35.

Gribat, L.C., Babauta, J.T., Beyenal, H., and Wall, N.A., J. Electroanal. Chem., 2017, vol. 798, p. 42.

Sá, É.S., Silva, P.S., Jost, C.L., and Spinelli, A., Sens. Actuators, B, 2015, vol. 209, p. 423.

Wang, Y., Zhuang, Q., and Ni, Y., J. Electroanal. Chem., 2015, vol. 736, p. 47.

Wu, S.H., Sun, J.J., Lin, Z.B., Wu, A.H., Zeng, Y.M., Guo, L., Zhang, D.F., Dai, H.M. and Chen, G.N., Electroanalysis, 2007, vol. 19, no. 21, p. 2251.

Ensafi, A. and Maleh, H.K., Int. J. Electrochem. Sci., 2010, vol. 5, p. 1484.

Kalcher, K., Kauffmnann, J.M., Wang, J., Svancara, I., Vytras, K., Neuhold, C., and Yang, Z., Electroanalysis, 1995, vol. 7, no. 1, p. 5.

Nezamzadeh-Ejhieh, A. and Hashemi, H.S., Talanta, 2012, vol. 88, p. 201.

Mehmeti, E., Stanković, D.M., Chaiyo, S., Švorc, L., and Kalcher, K., Microchim. Acta, 2016, vol. 183, no. 5, p. 1619.

Nezamzadeh-Ejhieh, A. and Pouladsaz, P., J. Ind. Eng. Chem., 2013, vol. 20, no. 4, p. 2146.

Bard, A.J. and Faulkner, L.R., Electrochemical Methods: Fundamentals and Applications, New York: Wiley, 2001.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Ebrahim Zarei, Jamali, M.R. & Bagheri, J. Application of TiO2 Nanoparticles Modified Carbon Paste Electrode for the Determination of Vitamin B2. J Anal Chem 74, 1213–1222 (2019). https://doi.org/10.1134/S1061934819120049

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061934819120049