Abstract

Particles of natural hydrothermal nanosilica have been characterized, and the conditions of their self-organization have been chosen for the stabilization of oil-in-water emulsions with the use of a cationic surfactant. Microcapsules, which consist of shells composed of layer-by-layer deposited chitosan and calcium alginate and contain dodecane, soybean and sesame oils, a 30% α-tocopherol acetate solution in sunflower oil, and shea butter, have been prepared on the basis of Pickering emulsions. Conclusions on the mechanical stability of the Pickering emulsions and capsules based thereon have been inferred from changes occurring in the colloidal system as a result of centrifugation at 27 000g. The capsules with the vegetable oils have exhibited a higher stability than those containing dodecane. The three-layer polymer shell has been shown to prevent the nanocapsules from coalescence and breakage upon centrifugation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Microcapsules based on Pickering emulsions, which are emulsions stabilized via the self-assembly of colloidal particles on the surface of dispersed phase droplets, are promising objects for the development of new drug delivery systems [1, 2]. Moderate wettability of nanoparticles by both liquid phases is a condition for their formation. Such wettability is usually achieved by modifying the particle surface via surfactant adsorption [3]. The self-assembly of colloidal particles at an interface between two immiscible liquids minimizes the total interfacial energy and results in the formation of a system possessing a high thermodynamic stability. However, the adsorption layer of nanoparticles often loses stability as a result of the replacement or elimination of a dispersion medium. Layer-by-layer deposition of polyelectrolytes immobilizes particles on the surface of dispersed phase droplets [4–6]. In addition, this approach increases the mechanical stability of the capsules [7].

At present, the layer-by-layer deposition of polyelectrolytes is extensively employed in the studies devoted to the development of new drug delivery systems [8, 9]. This method yields capsules with tunable sizes and surface characteristics, as well as controllable shell thickness and permeability. Combination of the layer-by-layer assembly with other approaches to capsule formation provides broad opportunities; however, works employing this approach for the preparation of colloidosomes based on Pickering emulsions are scarcer. In [4], capsules were formed by depositing a multilayer shell composed of polydiallyldimethylammonium chloride (PDADMAC) and polystyrene sulfonate (PSS) onto xylene droplets in an aqueous emulsion stabilized with positively charged Ludox Cl silica nanoparticles. In this case, to provide the self-assembly of the nanoparticles at the interface between the liquid phases, the nanoparticle surface was preliminarily modified with PSS. During the deposition of the multilayer polyelectrolyte shell, the capsules partially coalesced and fractured; therefore, negatively charged Ludox HS colloidal particles were adsorbed on the polycation layer instead of PSS to improve their stability. The nanoparticles closed the pores in the shell, thereby providing the capsules with dense walls. In addition, stable Pickering emulsions stabilized with Ludox Cl nanoparticles were prepared using other organic solvents with different polarities, such as perfluoroheptane, heptane, n-butyl acetate, and chloroform. However, colloidosomes with multilayer shells were prepared only by encapsulating xylene [4]. At the same time, to adapt the developed approach for the creation of drug delivery systems, it is reasonable to use natural oils as cores of the formed capsules.

In [5], toluene droplets in water were initially stabilized with sodium dodecyl benzene sulfonate, and PDADMAC-modified latex particles were adsorbed on their surface. Then, PSS and PDADMAC were successively deposited to fasten the adsorbed layer. It was shown that olive oil or liquid paraffin with included Sudan 1 dye could be encapsulated instead of toluene. The degree and rate of encapsulated dye release were controlled by varying medium pH, as well as depositing additional polyelectrolyte layers. The authors of [5] have declared that the chosen polymers can be used for biomedical applications; however, the use of biopolymers for the formation of polyelectrolyte shells is of greatest interest from this point of view.

Previously, the authors of this paper participated in the preparation of colloidosomes based on titania nanoparticles with shells consisting of conventional synthetic polyelectrolytes (polyallylamine and PSS) and the shells containing an incorporated biopolymer (chitosan) [6]. In another our work [7], nanocapsules were formed on dodecane droplets from SiO2 nanoparticles and biodegradable polymers, alginate and chitosan. In this case, colloidal nanoparticles of a unique natural material, hydrothermal nanosilica (HNS), were used to stabilize the Pickering emulsion [10].

Studies devoted to the extraction and use of nanodispersed silica of hydrothermal origin have been intensely developed in Russia for recent 20 years [10, 11]. Depth water from the wells of geothermal power plants (GPPs) of Kamchatka is the source for the production of this material. The use of silica nanoparticles extracted from natural geothermal waters provides opportunities for broad application of new natural resources for the development of nanotechnologies for creating innovative products. The long-term studies performed by the authors resulted in revealing bioactive properties HNS, which increase the productivity of agricultural plants and animals [12–16]. This fact is of importance for the aforementioned perspectives. Moreover, an important aspect is the ecological safety of this natural nanomaterial [12, 14–16].

We have previously shown the possibility to obtain stable colloidosome from HNS and biopolyelectrolytes [7]; however, only a model hydrocarbon, dodecane, has been used as a core. It is necessary to study the self-organization of natural silica nanoparticles on the droplets of emulsions of vegetable oils to make the proposed system to be applicable in biomedicine. In contrast to hydrocarbons, these oils exhibit pronounced surface-active properties due to the presence of higher fatty acid triglycerides in concentrations as high as 96% [17]. This circumstance may have a substantial effect of the stabilization of Pickering emulsions.

In this paper, the surface characteristics of HNS were studied and optimal conditions were determined for colloidosome formation. The possibility of the layer-by-layer deposition of biopolyelectrolyte shells onto droplets of diverse oil phases stabilized with the nanoparticles of natural silica was studied, and the resistance of the capsules to mechanical loads was examined by the example of centrifugation.

EXPERIMENTAL

Emulsions were stabilized with SiO2 nanoparticles (concentration of 37.5 wt %), which were isolated from geothermal water of the wells of Mutnovskoe GPP in 2018 at the Scientific Research Geotechnological Center, Far East Branch, Russian Academy of Sciences, via ultracentrifugation by the procedure described in [11]. Dodecane, soybean oil (both, Sigma-Aldrich), sesame oil (Ros’grup), shea butter (O&3), and a solution of α-tocopherol acetate (vitamin Е) in refined sunflower oil (30 wt %, Marbiofarm) were used as the oil phases of the emulsions. In addition, low-molecular-weight chitosan, sodium alginate, and cetyltrimethylammonium bromide (CTAB) (all produced by Sigma-Aldrich) were used in this work.

Multilayer capsules were prepared via the self-organization of the nanoparticles at the oil–water interface followed by the stepwise adsorption of polyelectrolyte layers (chitosan and alginate) [7]. When preparing the emulsions, an oil (10 vol %) was used as a dispersed phase, whereas an aqueous 0.25 wt % dispersion of SiO2 nanoparticles in a 0.1 mМ CTAB solution served as a dispersion medium. Shea butter was preliminarily melted at 50°C in an oven. A mixture was dispersed with a Hielscher UP400S ultrasonic homogenizer at an amplitude of 20% for 2 min. The pH values of the aqueous phases were regulated by adding a 1 М HCl solution.

Polyelectrolyte shells were deposited by the layer-by-layer method [18]. A chitosan solution (2 mg/mL, as calculated per dispersed phase, pH 2) was added to a nanoparticle-stabilized emulsion. The mixture was stirred for 15 min on a rotational shaker (MS 3 basic, 1000 rpm). The oil-containing capsules were separated by sedimentation and washed three times with an HCl solution having pH 2. Then, a sodium alginate layer was deposited from a 10 mg/mL solution by the same procedure. After the deposition, the sodium alginate layer was jellied by adding a CaCl2 solution (10 wt %) to the system at a 1 : 1 ratio to the total volume of the 10% emulsion and intensely stirring on the shaker for 15 min. The described procedures were repeated to form multilayer shells.

The size of HNS particles and the ζ-potentials of the nanoparticles and capsules were determined using a Zetasizer Nano ZS particle analyzer (Malvern Instruments). Micrographs of the capsules were taken with an Eclipse Ti-S inverted optical microscope (Nikon) at a magnification of ×40. The morphology of the capsule shells was studied by scanning electron microscopy (SEM) with a JSM-7401F instrument (Jeol).

At least 500 optical micrographs of the capsules were analyzed to determine their sizes. The average size was calculated by the following equation:

where di is the average particle diameter in the range of the number ni of particles and ∑ni is the total number of analyzed particles.

The polydispersity index was calculated as

where D[v.90] is the size (nm) below which are the sizes of 90% of the particles, D[v.10] is the size (nm) below which are the sizes of 10% of the particles, and D[v.50] is the size (nm) below which are the sizes of 50% of the particles.

Mechanical stability of the capsules was estimated from the changes resulting from the centrifugation of the colloidal system at 27 000g for 10 min (Sigma 3-18K centrifuge).

RESULTS AND DISCUSSION

Silica is formed in a hydrothermal solution from orthosilicic acid present in hydrothermal deposits. When the solution gets out of a well, its temperature decreases and it becomes supersaturated relative to the solubility of amorphous silica, thereby inducing the nucleation and polycondensation of silicic acid molecules. As a result, colloidal particles of hydrated silica nSiO2⋅mH2O are formed in the solution. The particle surface acquires a negative electric charge due to the dissociation of surface silanol groups SiOH and detechment of protons H+. Electrostatic repulsion forces hinder the coagulation of the particles and stabilize colloidal silica in the hydrothermal solution. Finally, spherical silica nanoparticles with radii of 5−100 nm are formed [10, 11].

In addition to silica, such solutions contain other components. There is a technological approach to the extraction of useful components from hydrothermal solutions, with this approach being based on their pressure-driven membrane concentration. The concentrated aqueous sol of silica used in this work was prepared from the liquid phases of hydrothermal heat carriers (separates) of GPP wells. The liquid phase was separated from the vapor phase of a two-phase flow in the separators of the GPP. The ranges of initial separate pH values, silica concentrations, and solution temperatures were 4.5−9.4, 400−800 mg/kg, and 20–90°C, respectively [11].

It has been found that ultrafiltration membranes have selectivity with respect to colloidal silica of nearly 1.0 without preliminary addition of coagulants and a low selectivity with respect to silicic acid molecules and ions [11]. Therefore, the ultrafiltration yields a solution with a high content of SiO2 and low concentrations of foreign Na+, K+, Ca2+, Mg2+, Fe2+, Fe3+, Al3+, \({\text{SO}}_{4}^{{2 - }}\), and Cl– ions. The concentration of the impurity ions can be decreased via the dilution of a sol and repeated ultrafiltration concentration. Using ultrafiltration membranes, the authors of this article have increased the content of SiO2 in the silica sols to 100−600 g/dm3. The density of the sols was in a range of 999−1325 g/dm3, the dynamic viscosity was 1−150 mPa s, the radius of silica particles was 5−135 nm, and the ζ-potential of the particles was −(32.4−42.5) mV. Ultrafiltration provided a rather low content of impurities and made silica hydrosols to be stable up to the highest SiO2 contents that have been achieved in the technological experiments (up to 600 g/dm3). This corresponded to the 1500-fold concentration relative to the silica content in an initial hydrothermal solution [11].

The performed study has revealed that the modal hydrodynamic diameter of HNS particles used to form the Pickering emulsions is nearly 9 nm. Figure 1 shows the SiO2 nanoparticle size distribution, which was measured by dynamic light scattering (pH 9.4). The first peak corresponds to the distribution of the nanoparticles themselves, whereas the second peak is due to the formation of aggregates in the system. A decrease in the medium pH to 2 enhanced the particle aggregation. No remarkable decrease in the aggregative stability of the system was observed, because the aggregates were almost completely disintegrated under the action of ultrasonic cavitation during the homogenization of the system. Nevertheless, it cannot be excluded that few small aggregates remain in the system and may be subsequently adsorbed on the surface of oil droplets.

HNS particles are hydrophilic and have a negative surface charge in a wide pH range (Fig. 2). For this reason, the partial hydrophobization of their surface, which is necessary for the self-assembly of colloidal particles on oil droplets, was carried out using a cationic surfactant. As the CTAB concentration is increased, the effect of dispersion medium pH on the ζ-potential of nanoparticles diminishes (Fig. 2). At a CTAB concentration of 0.1 mМ, the dependence of the ζ-potential on the medium pH does not differ significantly from the dependence for SiO2 particles in the absence of the surfactant, and only a slight shift of the curve towards a lower negative surface charge is observed. The addition of CTAB (0.5 mM) to the dispersion medium causes a significant decrease in |ζ| by nearly 20 mV. At a CTAB concentration of 1 mM, the surface charge of the particles is reversed; the ζ-potential becomes positive throughout the pH range, and its value oscillates in the vicinity of +18 mV. This fact indicates the formation of a surfactant bilayer on the particle surface. Thus, it may be assumed that a CTAB concentration of nearly 10–4 М and an acidic medium are the optimal experimental conditions, for the partial hydrophobization of the HNS particle surface.

To optimize the conditions for the formation of the Pickering emulsion, the dependence of the ζ-potential of HNS particles on CTAB concentration in an acidic medium (pH 2) was obtained (Fig. 3). As the surfactant concentration increases from 0.1 to 0.5 mМ, the value of |ζ| decreases, thereby indicating the adsorption of the surfactant and, consequently, the partial hydrophobization of the nanoparticle surface. A subsequent increase in the concentration leads to the charge reversal of the particle surface (Fig. 3). After the isoelectric point is passed at a CTAB concentration of 0.5 mM, a bilayer of surfactant molecules begins to be formed on the particle surface, with the hydrophilic head groups of the molecules facing the dispersion medium. As a result, the particle surface becomes hydrophilic again. It should also be noted that, under these conditions, the surfactant will compete for the free surface of oil droplets, and nanoparticles will be desorbed into the aqueous phase.

Taking into account the results of studying HNS particles, the emulsions were prepared using a 0.1 mM CTAB solution with pH 2 as an aqueous phase. A model hydrocarbon, dodecane, was initially used as an oil phase. Polyelectrolyte layers were successively deposited onto the droplets of a Pickering emulsion as has been mentioned in the Experimental section. The data on variations in the ζ-potential (Fig. 4) served as a criterion of the successful coating of a capsule with a current polymer layer. After the deposition of each layer, the capsule charge was reversed. Low values of the ζ-potential after the deposition of an even number of layers were due to the jellification of an alginate layer, which led to a partial compensation for the charges of carboxyl groups. However, although the capsules containing calcium alginate in the upper layer were aggregated because of the low surface charge, the subsequent deposition of chitosan resulted in the disaggregation of the capsules and successful deposition of a subsequent odd layer. The employed procedure yielded stable dodecane-containing capsules with a shell thickness up to nine biopolymer layers.

SEM micrographs of the capsules based on the Pickering emulsion exhibit a developed shell surface, on which nanoparticle aggregates are seen (Figs. 5a, 5b). In vacuum, the capsules obtained in a suspension with pH 2 release the encapsulated oil without a significant failure of the shell integrity (Fig. 5c). As the pH increases to 7, the majority of the capsules are disrupted under the conditions of taking the micrographs (Fig. 5d). It is seen that the density of the capsule shell decreases at the neutral pH. This is presuambly caused by a rise in the value of the negative surface charge of HNS particles (ζ = –13 and –28 mV at pH 2 and 7, respectively) and, accordingly, an increase in the electrostatic repulsion of the nanoparticles in the shell upon the passage from the acidic to the neutral medium. The observed effect enables one to control the release of an active substance from a capsule by varying the medium pH. This approach was used for releasing an encapsulated model dye in [5]: capsules with a core formed from liquid paraffin containing Sudan 1 and a shell composed of latex particles and sodium dodecyl benzene sulfonate with alternating layers of PSS and PDADMAC released the dye in larger amounts and faster at pH 7 than they did at pH 4.

Using the procedure developed for the encapsulation of dodecane, the following vegetable oils were encapsulated into shells composed of HNS particles and polyelectrolyte layers: soybean oil, sesame oil, a 30% solution of α-tocopherol acetate in sunflower oil, and shea butter. These oils contain large amounts of higher fatty acid triglycerides (Table 1), which are amphiphilic compounds exhibiting surface activity. Such composition of the oil phase may affect the formation of the Pickering emulsion. However, the experiments have shown that all vegetable oils form stable Pickering emulsions with HNS under the chosen conditions. Therewith, the average sizes of collo-idosomes with SiO2 + CTAB shells are almost equal for dodecane and vegetable oils (Table 2).

The deposition of polyelectrolyte layers increases the average size of the dodecane-containing capsules from 4.1 to 5.1 μm (Table 2, row 1; Figs. 6а, 6b), while the size the capsules containing vegetable oils remains almost unchanged (Table 2, rows 2−5; Figs. 6e, 6f). This fact indicates a higher stability of the capsules containing fatty acid triglycerides, which presumably promote the self-organization of HNS particles at the interface. The average size of the dodecane-containing capsules increases due to a partial coalescence of droplets during the sedimentation of the system and the washing of the microcapsules in the course of the deposition of polyelectrolyte layers. This is caused by the lower density of dodecane than that of vegetable oils, due to which dodecane droplets rise faster and are easier concentrated in the near-surface layer of the dispersion medium.

Micrographs of capsules with dodecane (upper row) and soybean oil (lower row) cores and (a, e) HNS + CTAB and (b, f) (HNS + CTAB)/chitosan/calcium alginate/chitosan shells before centrifigation and (c, g) HNS + CTAB and (d, h) (HNS + CTAB)/chitosan/calcium alginate/chitosan shells after centrifigation. The scale size is 20 μm.

The capsules containing vitamin E and shea butter (Table 2, rows 4 and 5, respectively) have the largest scatter of the sizes among the samples with vegetable oils. In the former case, this may be caused by the incorporation of 30 wt % α-tocopherol acetate, which has different surface properties, to a vegetable oil; whereas, in the latter case, this is due to the nonuniform transition of shea butter droplets to the solid state during the formation of the emulsion.

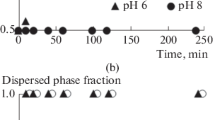

Then, the mechanical stability of the emulsion droplets and the microcapsules with polymer shells were compared by evaluating the changes in the system as a result of centrifugation at 27 000g. The droplets of a dodecane emulsion stabilized with HNS + CTAB were unstable with respect to the centrifugal forces; their average size increased by more than three-fold from 4.1 to 13.2 μm (Table 2, row 1; Fig. 6c), and the oil exfoliated in the system. When encapsulating liquid vegetable oils into similar shells, the capsule size increased by 1.7−2.5 times (Table 2, rows 2−4; Fig. 6g). In this case, the oil was exfoliated to a lower extent than in the case of dodecane encapsulation. The encapsulation of shea butter to the shell composed of HNS and CTAB yielded mechanically stable capsules (the change in the average size of the emulsion droplets is small (Table 2, row 5) and the exfoliation is absent) due to the solidification of the oil core. The formation of an additional three-layer polymer shell inhibited the coalescence of the droplets and the release of oils in all samples upon centrifugation (Table 2, Figs. 6d, 6h).

CONCLUSIONS

The study of the ζ-potential of HNS particles as a function of the dispersion medium pH at different CTAB concentrations and as a function the CTAB concentration in an acidic medium has resulted in the choice of the following conditions for the formation of the Pickering emulsion: an aqueous phase with pH 2 and concentrations of CTAB and SiO2 nanoparticles equal to 0.1 mM and 0.25 wt %, respectively. Droplets of an emulsion, which contained dodecane as an oil phase and was stabilized with natural silica nanoparticles and a surfactant, were covered with as many as nine polyelectrolyte layers of chitosan and alginate, while sodium alginate layers were subjected to jellification with calcium ions. Soybean and sesame oils, a 30% solution of α-tocopherol acetate in sunflower oil, and shea butter were encapsulated into shells composed of HNS + CTAB and polymer layers of chitosan and calcium alginate. The average size of the capsules with vegetable oils was 2.5−4.2 μm. It was found that the capsule shell density was lower at neutral pH than in the acidic medium probably due to a stronger electrostatic repulsion between the particles in the shell. Nevertheless, the capsules with three polymer layers withstood a sufficiently high load of centrifugal forces, thereby confirming the efficiency of the employed method of encapsulation.

This study has shown a higher stability of the Pickering emulsions of vegetable oils, as compared with those of a model hydrocarbon, and the prospects of the deposition of polyelectrolyte layers for increasing the mechanical stability of colloidosomes.

REFERENCES

Thompson, K.L., Williams, M., and Armes, S.P., J. Colloid Interface Sci., 2015, vol. 447, p. 217.

Dinsmore, A.D., Hsu, M.F., Nikolaides, M.G., Marquez, M., Bausch, A.R., and Weitz, D.A., Science, 2002, vol. 298, p. 1006.

Binks, B.P. and Rodrigues, J.A., Langmuir, 2007, vol. 23, p. 3626.

Li, J. and Stover, H.D.H., Langmuir, 2010, vol. 26, p. 15554.

Yang, F., Ma, S., Zong, W., Luo, N., Lv, M., Hu, Y., Zhou, L., and Han, X., RSC Adv., 2015, vol. 5, p. 51271.

Demina, P.A., Grigoriev, D.O., Kuz’micheva, G.M., and Bukreeva, T.V., Colloid J., 2017, vol. 79, p. 198.

Palamarchuk, K.V., Artemov, V.V., and Bukreeva, T.V., Nanotechnol. Russ., 2018, vol. 13, p. 199.

Kurapati, R., Groth, T.W., and Raichur, A.M., ACS Appl. Bio Mater., 2019, vol. 2, p. 5512.

Sharma, V. and Sundaramurthy, A., Beilstein J. Nanotechnol., 2020, vol. 11, p. 508.

Potapov, V.V., Fediuk, R.S., and Gorev, D.S., J. Sol-Gel Sci. Technol., 2020, vol. 94, p. 681.

Potapov, V.V., Fediuk, R.S., and Gorev, D.S., Nanomaterials, 2020, vol. 10, p. 624.

Lapin, A.A., Kalayda, M.L., Potapov, V.V., Zelenkov, V.N., and Voropaeva, N.L., Int. J. Nanotechnol., 2018, vol. 15, p. 422.

Lapin, A.A., Kalayda, M.L., Potapov, V.V., and Zelenkov, V.N., in Nanoscience and Nanoengineering. Novel Application, Dement’ev, V.B., Haghi, A.K., and Ko-dolov, V.I, Eds., Toronto–New Jersey: AAP, 2019, p. 283.

Potapov, V., Muradov, S., Sivashenko, V., and Rogatykh, S., Nanoindustriya, 2012, vol. 33, no. 3, p. 32.

Potapov, V., Sivashenko, V., and Zelenkov, V., Nanoindustriya, 2013, vol. 42, no. 4, p. 18.

Zelenkov, V.N. and Potapov, V.V., Nanoindustriya, 2020, vol. 13, no. 1, p. 22.

Shcherbakov, V.G. and Lobanov, V.G., Biokhimiya i tovarovedenie maslichnogo syr’ya (Biochemistry and Commodity Research of Oilseeds), Moscow: Koloss, 2012, 6th ed.

Sukhorukov, G.B., Donath, E., Davis, S., Lichtenfeld, H., Caruso, F., Popov, V.I., and Mohwald, H., Polym. Adv. Technol., 1998, vol. 9, p. 759.

ACKNOWLEDGMENTS

The study was carried out using the equipment of the Resource Center of Optical Microscopy and Spectroscopy of the National Research Center “Kurchatov Institute” and the Center Shared Research of the Federal Scientific Research Center “Crystallography and Photonics” of the Russian Academy of Sciences. The authors are grateful to V.V. Artemov for taking SEM micrographs from the capsules.

Funding

The study of the effect of medium pH on the stability and morphology of the capsules was supported by UMNIK (Contract no. 13386GU/2018 of July 17, 2018).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by A. Muravev

Rights and permissions

About this article

Cite this article

Palamarchuk, K.V., Bukreeva, T.V., Kalashnikova, I.V. et al. Encapsulation of Oil Phases with Different Compositions into a Shell Composed of Nanoparticles of Natural Hydrothermal Silica and Polyelectrolyte Layers. Colloid J 83, 228–235 (2021). https://doi.org/10.1134/S1061933X21020083

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061933X21020083