Abstract

To increase the average and peak power of modern laser systems, a need appears for new materials or the possibility of modifying existing ones to create composites based on them. Such composite materials with the use of optical materials with a high thermal conductivity can serve to remove heat from the active medium. The substrates of X-ray optical elements operating under powerful synchrotron radiation beams should solve the same task. One of the promising materials for these purposes is single-crystal sapphire, since it has a fairly high thermal conductivity (~23–25 W/(m K) at 323 K) and a low temperature coefficient of linear expansion (~10–6 K–1 at Т = 323 K). In this work, the effect of energy and angles of incidence on the sample surface of argon ions on the surface roughness of the a cut of \(\left( {11\bar {2}0} \right)\) single-crystal sapphire is studied. In the course of the study, the effect of smoothing the surface roughness by 30% relative to the initial value in the spatial frequency range from 0.049 to 63 µm–1 is demonstrated. The possibility of the ion processing of samples is also shown; in particular, at angles of incidence of ions on the sample surface within ±40°, the value of its effective roughness does not change much, which allows local correction of object shape errors without significant changes in the surface quality.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Single-crystal sapphire is considered to be one of the promising materials for heat removal from optical elements operating under high thermal loads due to its thermophysical properties [1–6]. In this role, it may be of interest as substrates for multilayer X-ray mirrors installed under powerful beams of synchrotron radiation; this is especially important for primary optical elements. Another promising field for the application of single-crystal sapphire is the removal of heat from the active elements of modern laser systems. One of the possible ways to achieve these goals is the creation of composite materials [7]; most often this is accomplished by attaching materials to an optical contact. With such a contact, the materials come so close that intermolecular-bond forces already take place, and it is almost impossible to separate or shift them relative to each other, and most importantly, incident radiation is barely reflected from the interface (reflection coefficients are at the level from ~10—4 to 10—7).

In both cases, it is fundamental to ensure the minimum roughness of the surface (σeff < 0.5 nm) and high accuracy of its shape [8]. However, obtaining high-quality surfaces from single-crystal sapphire with a roughness of less than 0.5 nm is a difficult task. One of the promising methods that allow one to correct the surface shape and smoothen the surface roughness is ion-beam etching, which is actively used for a wide range of optical materials [9–11].

This work is devoted to studying the effect of ion-beam etching on the surface roughness of the a cut of \(\left( {11\bar {2}0} \right)\) single-crystal sapphire rotated by 3° from n. The sputtering of single crystals differs significantly from the sputtering of amorphous materials by the nonmonotonic angular dependence of the sputtering coefficient due to the presence of an ordered structure, which leads to such effects as channeling and focusing of the momentum of recoil atoms towards the densest packing [12–14].

EXPERIMENTAL

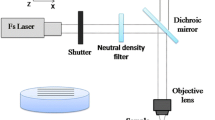

Disks with a diameter of 25 mm and thickness of 3 mm made of the a cut of \(\left( {11\bar {2}0} \right)\) single-crystal sapphire rotated by 3° from the normal vector to the surface were used as samples. The crystal orientation was determined by X-ray diffraction. The effective roughness σeff was ~0.7 nm in the spatial-frequency range ν from 0.049 to 63 µm–1. The experiments were carried out on an ion-etching setup [15] equipped with a KLAN-103M accelerated-ion source (with a thermal cathode) with a quasi-parallel ion beam, an incandescent neutralizer for working with dielectric materials, and a turntable, which was used to set the angle of incidence of ions on the sample surface. Argon was used in all experiments as the working gas. The etching depth was controlled by covering part of the sample surface with a mask. As a result of ion etching, a step was formed at the mask boundary, the height of which was measured using a TalySurf CCI2000 white-light interference microscope. For an adequate comparison of the effect of ion etching on the surface roughness, roughness measurements were carried out when the material was etched to a depth of about 1 μm or more. The surface roughness was evaluated by a technique based on plotting the power spectral density function (PSD function) of the roughness function from atomic force spectroscopy (AFM) measurements using an Ntegra Prima (NT-MDT) microscope. The measuring stand and the methodology are described in detail in [16].

Figure 1 shows AFM images of the initial surface of single-crystal sapphire with a size of 2 × 2 and 40 × 40 μm, as well as the corresponding spectra and the values of the effective roughness σeff, which is determined by the area under the curve of the PSD function.

RESULTS AND DISCUSSION

In the course of the study, the experimental dependences of the etching rate on the energy of accelerated argon ions, as well as on the angle of their incidence on the sample surface, were obtained. Figure 2 shows the dependences of the etching rate and the effective roughness on the ion energy, as well as the calculated dependence of the sputtering coefficient obtained using the TRIM08 software package.

(a) Experimental dependence of the etching rate of single-crystal sapphire on the energy of argon ions, (b) experimental dependence of the value of the effective surface roughness of single-crystal sapphire on the energy of argon ions, and (c) calculated dependence of the sapphire sputtering coefficient on the energy of argon ions.

It can be seen from the dependences obtained that the calculated and experimental curves have a similar shape and, at an energy value of 800 eV, do not yet reach saturation. Also, from Fig. 2b, it can be seen that for all values of the ion energy, smoothing of the initial roughness is observed, and the lowest value of the effective roughness in the spatial-frequency range from 0.049 to 63 µm–1 is achieved at Eion = 700 eV. Figure 3 shows the AFM images corresponding to this energy and the PSD function of the roughness.

It can be seen from Fig. 3b that the traces of mechanical polishing were smoothed out after ion etching, which manifested itself on the spectrum in the form of a decrease in the PSD value at a spatial frequency of more than 0.1 µm–1.

On the basis of the data obtained, a series of experiments was carried out to study the etching rate and the effect of the angles of incidence of ions on the sample surface on the value of the surface roughness at an ion energy of 700 eV. Figure 4 shows the dependences obtained and, for comparison, the calculated coefficient of sputtering of amorphous Al2O3.

(a) Experimental dependence of the etching rate of single-crystal sapphire on the angle of incidence of argon ions, (b) experimental dependence of the value of the effective surface roughness of single-crystal sapphire on the angle of incidence of argon ions, and (c) calculated dependence of the sapphire sputtering coefficient on the angle of incidence of argon ions.

There are two inflection points in Fig. 4c, and the curve itself has a form corresponding to the dependence ~ 1/cos Θ, where angle Θ is the angle of incidence of ions on the sample surface in degrees. This dependence is typical for almost all amorphous materials [17, 18]. At the same time, the curve in Fig. 4a has a different form with a maximum value of the etching rate (proportional to the coefficient of sputtering) at angles of incidence of 40°, which confirms the presence of crystal structure in the studied samples. An important issue is the comparison of data on the etching rate of sapphire with that for other materials. According to [17, 18], the etching rate of single-crystal Si is Vetch ~ 50 nm/min, and the etching rate of SiO2 is Vetch ~ 35 nm/min at ion-beam parameters of Eion = 700 eV, J = 0.7 mA/cm2, and Θ = 0°, while the rate of etching of sapphire at these parameters is Vetch ~ 7.5 nm/min. Such values of the etching rate allow one to create a shape on the surface of sapphires with a relatively large deflection.

If we talk about the behavior of the roughness, then the best result was obtained with the normal incidence of ions on the surface. At angles of incidence from 20° to 40°, the value of the effective roughness barely changed except for small deviations in the region of high spatial frequencies (from 3.7 to 63.5 µm–1), which is shown in Fig. 5a. At the same time, at angles of 60°, a wavy structure (“ripples”) begins to appear on the surface [19]. Figure 5b shows the AFM frames of such a structure.

(a) PSD functions of surfaces irradiated with accelerated argon ions with an energy of 700 eV corresponding to angles of beam incidence on the sample surface of 20°–40°, and (b) wavy structure on the surface of the sample obtained as a result of etching with argon ions at beam incidence at an angle of 60° to the sample surface.

The study showed that etching with accelerated argon ions can be used to treat the surface of single-crystal sapphire while maintaining and even slightly smoothing the surface roughness.

CONCLUSIONS

The effect of the energy and angles of incidence of argon ions on the surface roughness of single-crystal sapphire was studied. In the course of the study, the effect of smoothing the surface roughness by 30% relative to the initial value of roughness in the spatial frequency range from 0.049 to 63 µm—1 was demonstrated. The possibility of the ion treatment of such surfaces was also shown; in particular, at angles of ion incidence of ±40° on the sample surface, the value of the effective roughness does not change much, which makes it possible to carry out the local correction of shape errors and form a surface with the required parameters. The etching rate of sapphire with such parameters is rather high, Vetch ~ 23 nm/min, which, of course, is lower than that of traditional optical materials, but it is sufficient for the application of ion-beam processing methods.

REFERENCES

H. Furuse, Y. Koike, and R. Yasuhara, Opt. Lett. 43, 3065 (2018). https://doi.org/10.1364/OL.43.003065

C. D. Boley and A. M. Rubenchik, Appl. Opt. 52, 3329 (2013). https://doi.org/10.1364/AO.52.003329

A. De Zanet, V. Casalegno, and M. Salvo, Ceram. Int. 47, 7307 (2021). https://doi.org/10.1016/j.ceramint.2020.11.146

A. Morán-Ruiz, K. Vidal, A. Larranaga, R. Montero, and M. I. Arriortua, Int. J. Hydrogen Energy 41, 17053 (2016). https://doi.org/10.1016/j.ijhydene.2016.07.122

A. Z. Freitas, L. R. Freschi, R. E. Samad, D. M. Zezell, S. C. Gouw-Soares, and N. D. Vieira, Jr., Laser Phys. Lett. 7, 236 (2010). https://doi.org/10.1002/lapl.200910133

L. E. S. Soares, A. A. Martin, and A. L. B. Pinheiro, J. Clin. Laser Med. Surg. 21, 357 (2003). https://doi.org/10.1089/104454703322650167

I. Kuznetsov, A. Pestov, I. Mukhin, M. Volkov, M. Zorina, N. Chkhalo, and O. Palashov, Opt. Lett. 45, 387 (2020). https://doi.org/10.1364/OL.384898

M. S. Mikhailenko, M. V. Zorina, I. I. Kuznetsov, O. V. Palashov, A. E. Pestov, and N. I. Chkhalo, Tech. Phys. 65, 1828 (2020). https://doi.org/10.1134/S1063784220110286

M. S. Mikhailenko, A. E. Pestov, N. I. Chkhalo, M. V. Zorina, A. K. Chernyshev, N. N. Salashchenko, and I. I. Kuznetsov, Appl. Opt. 61, 2825 (2022). https://doi.org/10.1364/AO.455096

M. S. Mikhailenko, N. I. Chkhalo, S. A. Churin, M. A. E. Pestov, V. N. Polkovnikov, N. N. Salashchenko, and M. V. Zorina, Appl. Opt. 55, 1249 (2016). https://doi.org/10.1364/AO.55.001249

N. I. Chkhalo, S. A. Churin, A. E. Pestov, N. N. Salashchenko, Yu. A. Vainer, and M. V. Zorina, Opt. Express 22, 20094 (2014). https://doi.org/10.1364/OE.22.020094

D. Onderdelinden, Appl. Phys. Lett. 8, 189 (1966). https://doi.org/10.1063/1.1754548

Ch. Lehmann and P. Sigmund, J. Phys. Status Solidi B 16, 507 (1966).

N. I. Chkhalo, I. A. Kaskov, I. V. Malyshev, M. S. Mikhaylenko, A. E. Pestov, V. N. Polkovnikov, N. N. Salashchenko, M. N. Toropov, I. G. Zabrodin, Precis. Eng. 48, 338 (2017). https://doi.org/10.1016/j.precisioneng.2017.01.004

N. I. Chkhalo, N. N. Salashchenko, and M. V. Zorina, Rev. Sci. Instrum. 86, 016102 (2015). https://doi.org/10.1063/1.4905336

J. F. Ziegler, M. D. Ziegler, and J. P. Biersack, Nucl. Instrum. Methods Phys. Res., Sect. B 268, 1818 (2010). https://doi.org/10.1016/j.nimb.2010.02.091

Q. Wei, K.-D. Li, J. Lian, and L. Wang, J. Phys. D: App-l. Phys. 41, 172002 (2008). https://doi.org/10.1088/0022-3727/41/17/172002

P. Sigmund, Phys. Rev. 187, 383 (1969). https://doi.org/10.1103/PhysRev.184.383

R. M. Bradley and J. M. E. Harper, J. Vac. Sci. Technol., A 6, 2390 (1988). https://doi.org/10.1116/1.575561

Funding

This study was supported financially by the Ministry of Science and Higher Education of the Russian Federation (agreement no. 075-15-2021-1362) with the use of equipment of the Center for Collective Use “Physics and Technologies of Microstructures and Nanostructures” at the Institute of Physics of Microstructures, Russian Academy of Sciences. The samples were studied at the Laboratory for Diagnostics of Radiation Defects in Solid-State Nanostructures of the Institute of Physics of Microstructures, Russian Academy of Sciences, with support of the Ministry of Science and Higher Education of the Russian Federation (state assignment no. 0030-2021-0030).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by S. Rostovtseva

Rights and permissions

About this article

Cite this article

Mikhailenko, M.S., Pestov, A.E., Zorina, M.V. et al. Study of the Influence of Ion-Beam Etching on the Surface Roughness of Single-Crystal Sapphire. J. Surf. Investig. 17, 1338–1342 (2023). https://doi.org/10.1134/S102745102306037X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S102745102306037X