Abstract

Beamlines on synchrotron radiation sources may impose different and sometimes even incompatible requirements to the X-ray beam. In some cases, implementation of probe methods for examination of samples in the mapping mode necessitates beams with the smallest possible cross–section. In contrast to this, radiation processing of material and manufacture of a commercial product using X-ray lithography approach require an X-ray beam with a relatively large area and providing a uniform exposure field. On the beamline X-Techno under development for the synchrotron radiation source SKIF, it will be possible to form synchrotron radiation beams up to 100 mm in size in the horizontal plane, differing in the spectral composition. Such beams will be used in any of the beamline’s three research chambers for study of radiation effects in materials, as well as for creation of structures in the micro- and nano-size range. The design of the beamline will enable study of the physicochemical properties of materials exposed to X-rays in the spectral range from 2 to 70 keV.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

To date, the use of synchrotron radiation sources is divided between research and technological experimental beamlines [1–4]. On the beamlines of the first group, the task of obtaining new knowledge about the composition, structure, and functional characteristics of objects is solved. On the beamlines of the second type, the goal is to modify an object X-rayed according to a given algorithm subject to the knowledge already obtained on the research beamlines. For the beamline described in this article, it was proposed for the first time to combine the possibilities of conducting a comprehensive study using analytical X-ray techniques with the targeted formation of micro- and nano-sized surface and bulk structures. The wide aperture of the incident X-ray beam makes it possible to apply the implemented methods in the operando mode, that is, during formation of structure or during operation of device under study. Simultaneous use of several signal channels and, respectively, detectors significantly increases the amount of information obtained about the object being analyzed/modified. This paper presents a preliminary concept of the beamline. Since the beamline X-Techno is one of the second-stage beamlines of the CCU SKIF, work on the development of the project continues.

CONCEPT OF DESIGN OF BEAMLINE X–TECHNO

Purpose of Beamline X-Techno

The beamline is intended for conduction of experiments in the field of materials science, radiation chemistry, and photochemistry with the aim of study and modification of the properties of a surface or thick object under the action of intense synchrotron radiation in the photon energy range from 2 to 70 keV. The purpose is creation of new materials and devices, study and optimization of radiation processing technology, and using the obtained knowledge in creation of various topological forms with high spatial resolution, as well as high or even ultra-high aspect ratio (the ratio of the depth to the characteristic size in the lateral plane). The tasks solved with the use of the beamline equipment include study of the conditions of radiation modification of materials; study of the physicochemical properties of materials under the action of high-power X-rays at varying temperature; study of the photovoltaic effect on the surface and in the volume of various materials in the course of various processes; absolute calibration of X-ray detectors [5]; study of desorption and absorption of gases by various materials under the action of X-rays; generation of short-lived radical centers in materials for further research on their physicochemical properties by the methods of electron paramagnetic resonance, nuclear magnetic resonance, luminescence spectroscopy, etc.; study of the radiation resistance of materials and microelectronic devices intended for operation in space, at nuclear power plants, and at electrophysical installations generating a high-level background radiation; optimization of conditions for formation of functional micro-components and their small-scale production for real devices.

The main parameters of the synchrotron radiation to use on the beamline are presented in Table 1. Functionally, the beamline is divided into the optical part and the complex of experimental modules.

Optical Part of Beamline X-Techno

The optical part of the beamline X-Techno includes a grazing incidence mirror and a set of absorption filters made of different materials with variable thickness: glassy carbon (thickness of 25 to 400 µm), sapphire (thickness of 100 to 500 µm), aluminum (thickness of 5 to 50 µm), titanium (thickness of 2 up to 50 µm), nickel (thickness of 1 to 50 µm), platinum (thickness of 1 to 50 µm), and other materials.

With the flat mirror moved to one of the three positions, an X-ray beam up to 100 mm wide can be delivered to one of the three experimental modules. Because of the angular divergence of the radiation, the width of the mirror should be 40 mm at least. It is supposed to use a flat mirror made of electrochemically polished silicon and divided into two working areas: the wider, reflecting one, for cutting off the hard spectral components during micro- and nanostructuring, and the relatively narrow dispersive area, which ensures wavelength scanning of the photon flux, as described in [6]. Such combination of functions will allow for a comprehensive study on the beamline, and the sample can stay in the vacuum chamber. The reflective coating is a sputtered layer of metal (platinum) several tens of nanometers thick. The dispersive element is an aperiodic multilayer system with energy resolution ΔE/E ∼ 10–2. The technology of manufacturing of aperiodic systems of mirrors is well developed [7, 8]. Since this dispersive element cannot be used with a straight SR beam, a section with a diffraction grating is envisaged in the SR transport line [9].

For reduction of heat loads, the mirror is placed in a bath filled with a eutectic gallium–indium alloy, which is liquid at room temperature.

Module System

Modular assembly. The incident SR beam will be used in each of the three experimental modules on the beamline (Fig. 1). The modules are separated from the beam transport line and thus from each other by vacuum-tight windows (made, for example, of beryllium foil 50–200 µm thick). This enables an individual gaseous environment in each module and prevents entry of volatile products of decomposition of materials (including X-ray resists) under the action of high-energy quanta into the neighboring modules.

Reflection of the X-ray beam occurs in the vertical plane. In particular, at a distance of 33 m from the mirror to the experimental setup and inclination of the mirror by 0.5°, the X-ray beam will shift upwards from the orbit plane by approximately 575 mm, at which height the entry to the module is located (Fig. 1, position 5). At a mirror tilt angle of 1°, the beam deviates from the orbit plane by 1150 mm and gets into another module (Fig. 1, position 6).

If the mirror segment coated by the multilayer structure is tilted by 0.5° and inserted into the beam propagating horizontally in the orbital plane, the reflected beam gets into module 5 and the first-order-diffraction beam enters module 6. In this case, the beamline can work with two beams simultaneously.

For minimization of the time for cleaning of the modules from adsorbed products of degradation of materials under study, the beamline is equipped with a redundant module, which has similar ports for connection of the main kinds of detecting equipment.

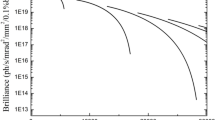

Module for straight beam. A straight SR beam incident on an object features high intensity in a wide range of photon energies 2–70 keV (Fig. 2), sufficient for heating of the irradiated area up to several hundred degrees during the acquisition time. A radiation with low degree of monochromatization is suitable both for study of sample layers about 1 μm thick (in the low-energy region of the spectrum) and for provision of dose homogeneity in millimeter-thickness layers (at high photon energies and low power levels).

Calculated spectral power of SR (in energy band ΔE/E = 10–3) at distance of 55 m from emission point per 1 cm of horizontal area, integrated over angle in vertical plane subject to filters and beryllium windows installed in the beamline. X-ray source: bending magnet with the field strength H = 20 kG. 1—Beryllium window 200 µm thick; 2—beryllium window 200 μm thick and platinum-coated mirror oriented at angle of 0.5° to horizontal plane; 3—beryllium window 200 μm thick and platinum mirror at angle of 1°; 4—beryllium window 200 µm, aluminum filter 50 µm thick, and platinum mirror at angle of 0.5°; 5—beryllium window 200 µm thick, titanium filter 10 µm thick, and platinum mirror at angle of 1°; 6—beryllium window 200 µm thick and Sm/Eu selective filter with thickness of 700/200 µm.

The module for the straight beam (Fig. 1, position 4) is equipped with the following measuring equipment: mass spectrometer, X-ray total absorption detector, position-sensitive detector for measuring the angular dependence of scattered radiation, object heat capacity meter, object electrical conductivity meter, SQUID magnetometer, detector for reflected X-rays, photoelectron current detector, ionization current detector based on a secondary electron multiplier, microstrip detector, bolometer for measuring the temperature of object, photomultiplier for detecting the luminescent radiation of object, laser-detector line for measuring the reflectivity of object, infrared spectrophotometer for measurements of the Raman spectra and reflection spectra, and optical microscope. Some of the above instruments can be connected with any of the three experimental modules of the beamline.

The straight-line module is designed for study of photodesorption, photoablation, radiation resistance, radiation annealing, targeted introduction of radiation defects, etc. The beamline is a unique one for development of new radiation-resistant materials and devices for nuclear energy, chemical industry, and space experiments. The mutually-complementary measurement equipment on the beamline will enable research within the framework of final qualification works of students and graduate students. In this module, the best conditions will be created for formation of microstructured objects with ultra-high aspect ratio at photon energies of above 10 keV.

Module for reflected beam with quantum energies of 2–15 keV. When the mirror is inclined by 0.5° (Fig. 1, position 5) relative to the orbit plane, the X–ray spectrum is optimized for research and submicron-resolution transfer by the deep X-ray lithography method [10–13] of an image of the original topology into thick layers (up to 10 mm) of materials. Optimization of the spectral flux is necessary for achievement of the maximum of the function that is expressed in the first approximation as the product of the absorption coefficient of the X-ray resist layer and the transmission of the X-ray mask, and this will provide the highest performance at the minimum radiation dose from the scattered X-rays and secondary electrons. On the beamline, it is possible to implement an extensive program in the field of development and manufacturing of X-ray lenses [4], diffraction gratings for phase-contrast study of low-contrast objects, anti-scattering grids [14], meshes with calibrated size cells, perforated electrolyte membranes, structured X-ray screens, X‑ray collimators, and chromatic optical elements for infrared and terahertz spectral ranges.

The experimental module is equipped with a system of automated linear translators for moving/scanning an object in a vertical plane. For reduction of the SR flux without distortion of the initial spectrum of the X-ray beam, it is planned to install an obturator into the experimental vacuum chamber.

Transmission diffraction gratings can ensure a quasi-planar quasi-coherent radiation front during transfer of image in the interference mode.

Other tasks that can be solved are similar to those mentioned above for the straight beam module.

The aforementioned modules are an improved version of the LIGA beamline, operating as part of the Siberian Center for Synchrotron and Terahertz Radiation [15].

Module for reflected beam with photon energies of 2–6 keV. At mirror inclination of 1° relative to the orbit plane (Fig. 1, position 6), conditions in the reflected beams are optimal for research and submicron-resolution transfer by the deep X-ray lithography method [9–11] of an image of the original topology into thin layers (up to 100 μm) of materials. The SR spectrum for this module is optimized for manufacturing of intermediate X-ray masks, as well as development and manufacture of small series of electronic and electro-mechanical devices of micron and submicron topological sizes such as test structures of large integrated circuits, artificial dendrites of lithium batteries, chromatic nano-optical elements, regular filters, matrices for self-organizing nanosystems, arrays of magnetic nanodots, etc. by methods of interference holography or direct reproduction. X-ray lithography can be used for production of spike microsystems [16, 17], large arrays of which in emission or absorption of radio waves have the properties of phased antenna arrays, which are of interest for radio detection.

A quasi-planar quasi-coherent radiation front in the transmission of image in the interference mode can be provided with the use of transmission diffraction gratings.

High-aspect-ratio refractive X-ray lenses made of a polymer material with relatively low X-ray absorption cross-section [18, 19], radiation-resistant refractive X‑ray lenses made of metal [20], beam position sensors, and aperture diaphragms created by deep X-ray lithography can be used on other beamlines of the SR source SKIF.

Other tasks that can be solved on the beamline are similar to those mentioned above for the straight beam module.

CONCLUSIONS

The presented project of the X-Techno synchrotron experimental station is unique because it will enable implementation of full-cycle technologies in the field of microstructuring. Materials research carried out on the beamline will become the foundation for development and small-scale production of microstructured products with submicron spatial resolution. The planned beamline will be of interest to graduates of universities, as well as to organizations involved in research and development in the field of creation of elements of microstructural technology, micro-optics, and micro– and nanoelectromechanical systems.

REFERENCES

ANKA Instrumentation Book (Karlsruhe, 2005). http://www.fzk.de/anka/November2005.

X. Meng, H. Yu, Y. Wang, J. Ren, C. Xue, S. Yang, Z. Guo, J. Zhao, Y. Wu, and R. Tai, J. Synchrotron Rad. 28, 902 (2021). https://www.doi.org/10.1107/S1600577521003398

R. Shukla, H. K. Kannojia, C. Mukherjee, P. R. Sankar, B. S. Thakur, A. K. Sinha, and D. Pandey, ISSS J. Micro Smart Syst. 9, 173 (2020). https://www.doi.org/10.1007/s41683-020-00064-z

J. R. Kong, Q. J. Leonard, Y. Vladimirsky, and A. J. Bourdillon, Proc. SPIE 3997, 721 (2000). https://www.doi.org/10.1117/12.390044

A. N. Subbotin, V. V. Gaganov, A. V. Kalutsky, V. F. Pindyurin, V. P. Nazmov, A. D. Nikolenko, and A. K. Krasnov, Metrologia 37, 497 (2000). https://www.doi.org/10.1088/0026-1394/37/5/34

N. I. Chkhalo, S. A. Garakhin, I. V. Malyshev, V. N. Polkovnikov, M. N. Toropov, N. N. Salashchenko, B. A. Ulasevich, Ya. V. Rakshun, V. A. Chernov, I. P. Dolbnya, and S. V. Raschenko, Tech. Phys. 67 (8), 1075 (2022). https://www.doi.org/10.21883/TP.2022.08.54576.100-22

N. N. Kolachevskii, A. S. Pirozhkov, and E. N. Ragozin, Quantum Electron. 30, 428 (2000). https://www.doi.org/10.1070/QE2000v030n05ABEH001736

E. N. Ragozin, E. A. Vishnyakov, A. O. Kolesnikov, A. S. Pirozhkov, and A. N. Shatokhin, Aperiodic Elements in Soft X-Ray Optics (Fizmatlit, Moscow, 2018) [in Russian].

T. Weitkamp, I. Zanette, G. Schulz, M. Bech, S. Rutishausere, S. Lang, T. Donath, A. Tapfer, H. Deyhle, P. Bernard, J.-P. Valade, E. Reznikova, J. Kenntner, J. Mohr, B. Müller, F. Pfeiffer, C. David, and J. Baruchel, AIP Conf. Proc. 1365, 28 (2011). https://www.doi.org/10.1063/1.3625297

A. El-Kholi, J. Mohr, and V. Nazmov, Nucl. Instrum. Methods Phys. Res., Sect. A 448, 497 (2000). https://www.doi.org/10.1016/S0168-9002 (00)00239-4

U. Wallrabe and V. Saile, in MEMS: A Practical Guide to Design, Analysis and Applications, Ed. by J. G. Korvink and O. Paul (Springer, Berlin, 2006), p. 853. https://www.doi.org/10.1007/978-3-540-33655-6_16

V. Nazmov, E. Reznikova, J. Mohr, J. Schulz, and A. Voigt, J. Mater. Process. Technol. 225, 170 (2015). https://www.doi.org/10.1016/j.jmatprotec.2015.05.030

V. P. Nazmov, L. A. Mezentseva, V. F. Pindyurin, V. V. Petrov, and E. N. Yakovleva, Nucl. Instrum. Methods Phys. Res., Sect. A 448, 493 (2000). https://www.doi.org/10.1016/S0168-9002 (00)00238-2

B. G. Goldenberg, V. P. Nazmov, and A. G. Lemzyakov, Bull. Russ. Acad. Sci.: Phys. 83, 124 (2019). https://www.doi.org/10.3103/S106287381902014X

B. G. Goldenberg, A. G. Lemzyakov, V. P. Nazmov, and V. F. Pindyurin, Phys. Procedia 84, 205 (2016). https://www.doi.org/10.1016/j.phpro.2016.11.036

E. Reznikova, J. Mohr, M. Boerner, V. Nazmov, and P.-J. Jakobs, Microsyst. Technol. 14, 1683 (2008). https://www.doi.org/10.1007/s00542-007-0507-x

V. Nazmov, B. Goldenberg, A. Vasiliev, and V. Asadchikov, J. Micromech. Microeng. 31, 055011 (2021). https://www.doi.org/10.1088/1361-6439/abf331

V. Nazmov, E. Reznikova, A. Last, J. Mohr, V. Saile, R. Simon, and M. DiMichiel, AIP Conf. Proc. 879, 770 (2007). AIP Conf. Proc. 879, 770 (2007). https://doi.org/10.1063/1.2436174

M. Simon, E. Reznikova, V. Nazmov, A. Last, and W. Jark, Proc. SPIE 7077, 70771Q (2008). https://www.doi.org/10.1117/12.795423

V. Nazmov, E. Reznikova, A. Last, J. Mohr, V. Saile, M. DiMichiel, and J. Gottert, Nucl. Instrum. Methods Phys. Res., Sect. A 582, 120 (2007). https://www.doi.org/10.1016/j.nima.2007.08.076

Funding

The work was done at the Shared Research Center SSTRC on the basis of the complex VEPP-4 and VEPP-2000 at BINP SB RAS. The work was partly performed under Agreement no. 075-15-2021-1359 with the Russian Ministry of Education and Science and RFBR Grant no. 19-29-12 045.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Nazmov, V.P., Goldenberg, B.G. The SKIF X–Techno Beamline Project. J. Surf. Investig. 17, 1273–1277 (2023). https://doi.org/10.1134/S1027451023060150

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451023060150