Abstract

The microstructure of several Fe–xGa alloys with phase-separated structure have been studied by neutron diffraction with high Δ d/d resolution. Analysis of diffraction data shows that the microstructure of these alloys is organized as nano-sized clusters with a better-ordered atomic structure coherently embedded in a disordered or less-ordered matrix. The characteristic size of the clusters depends on the Ga content and ranges from 100–2000 Å.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The discovery of a manyfold increase in the magnetostriction of Fe-xGa alloys at x ≈ 19 at. % (in this paper we use only atomic percent) compared to pure α-iron has stimulated many theoretical and experimental investigations. At present, their enhanced magnetostriction is associated with the formation of a heterogeneous state in ferromagnetic material. Several models exist for explanation of magnetostriction behavior in ordered Fe–xGa alloys, including the presence of tetragonally modified D03 (m-D03) nanoinclusions or small Ga-rich clusters of D03 phase in A2 matrix (for example, [1, 2]). In order to describe properly the inhomogeneous state in ordering alloys, it is desirable to identify the morphology of ordered regions, i.e., their size, shape and spatial organization, as well as the degree of order in them.

The possibility of forming small clusters with an ordered atomic structure embedded within a disordered matrix for Cu–Au and Fe–Al alloys has been known since the early 1970s [3, 4]. Giant magnetostriction in Fe–xGa alloys has intensified the theoretical and experimental efforts to study their inhomogeneous cluster-like state. As a result, the mixed phase states A2 + D03 and B2 + D03 have been found in these alloys using techniques of transmission electron microscopy, scanning electron microscopy and energy dispersive spectroscopy [5–7].

In contrast with thin films or sample surface analysis, neutron diffraction studies are more effective for the analysis of bulk properties of metallic alloys. For instance, the cluster state of FeαAl and (Fe,Cr)αAl, α ≈ 3, has been definitely established in our high-resolution neutron diffraction studies [8, 9]. In quenched samples, the matrix is a disordered A2 phase with clusters of the partially ordered B2 phase, whereas in the annealed samples the clusters of the ordered D03 phase are dispersedly distributed in the B2 matrix. The characteristic size of the clusters depends on the state of the alloy (as cast or slowly cooled samples) and varies from 100–1000 Å.

In this study, we present new results concerning the cluster-like structure in several Fe–xGa compositions obtained with a high-resolution neutron diffraction technique. The analysis reveals that for some range of Ga content, the Fe–Ga alloy microstructure is organized as nano-sized clusters with an ordered atomic structure coherently embedded in a disordered or less-ordered matrix. The use of neutrons confirmed the bulk nature of the measured effects and excluded the effects of surface and local inhomogeneities.

SAMPLES AND NEUTRON DIFFRACTION EXPERIMENT

Several Fe–xGa compounds with x in the range 15.5–28.9 at. % were produced by melting the corresponding mixture of pure Fe and Ga by induction under high-purity argon gas in an Indutherm MC–20V furnace. Their chemical compositions were confirmed with an accuracy of 0.2% by energy dispersive spectroscopy. For neutron experiments, 4 × 8 × 50 mm parallelepipeds were cut from the ingots.

Neutron diffraction patterns were measured at a high-resolution Fourier diffractometer (HRFD) [10], operating at the IBR-2 pulsed reactor at the Joint Institute for Nuclear Research (Dubna). This is a time-of-flight (TOF) instrument with a fast Fourier chopper. The HRFD can be easily switched between high-resolution (Δd/d ≈ 0.0015) and high-intensity (Δd/d ≈ 0.015) diffraction modes. The high-resolution patterns are measured to estimate the phase state of the samples and organization of their microstructure, while the high-intensity mode is used for obtaining data about phase transformations upon heating and cooling, with temporal resolution of about 1 min. More detailed information about the method has been published in a comparative analysis of the results obtained from cast bulk and powder samples of Fe–27Ga alloy [11]. An example of a Fe–23.8Ga pattern measured with high-resolution in the initial (as-cast) state is shown in Fig. 1. Analysis of the widths of diffraction peaks allows the characterization of the microstructural properties of the alloys. In particular, the lattice microstrain ε ≈ Δd/d and the finite coherently scattering domain size Lcoh can be estimated from the dependence of the width of the diffraction peaks on the scattering vector or d-spacings (Williamson–Hall analysis). For a TOF-diffractometer, the Williamson–Hall relation can be written in the form \({{(\Delta d)}^{2}} = {{C}_{1}} + ({{C}_{2}} + {{C}_{3}}){{d}^{2}} + {{C}_{4}}{{d}^{4}}\), where C1 and C2 are constants relating to the HRFD resolution function (Gaussian distribution functions are assumed) and the ε and Lcoh values are taken into account by С3 ≈ (2ε)2 and C4 ≈ (1/Lcoh)2. If the size effect is absent or negligible, the dependence “(Δd)2 on \(d\)2” is linear and parabolic otherwise. Accordingly, it is possible to determine both ε and Lcoh by employing this dependence over a sufficiently large d-spacing range (more details are given in [11]).

RESULTS AND DISCUSSION

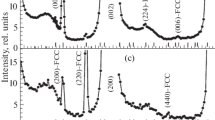

All as-cast Fe–xGa alloys with x up to 19.5 at. % have a disordered A2 structure with no indications of long-range order in the Fe and Ga arrangement. Only weak diffuse maxima are observed because of some degree of short-range order. For x = 20.7, wide (due to size effect) superstructure peaks belonging to the partially ordered D03 structure appear (Fig. 2). There are no visible changes in the diffraction patterns of the alloys with x up to 26.9, except for an increase in the intensity of the superstructure peaks due to an increase in the degree of atomic order. Starting at x = 28.1, the intensity of superstructure peak 111, which characterizes the D03 phase, decreases rapidly and, conversely, the intensity of the peak 200, belonging to the B2 phase, continues to increase (Fig. 3).

Comparison of neutron diffraction patterns of Fe–19.5Ga and Fe–20.7Ga in the large dhkl range. The superstructure diffraction lines with Miller indices 111, 200, 311 etc. are absent for the first and visible for the second compositions. The vertical bars indicate the calculated peak positions for the D03 phase.

The full widths at half maximum of the diffraction lines for the compositions in the A2 state only slightly exceed the contribution of the HRFD resolution function, and W 2 ∼ (Δd)2 linearly depends on d 2, indicating the absence of size contribution and a low level of microstresses (Fig. 4a). For x > 19.5, the widths of the fundamental peaks remain almost unchanged, while a large size effect is seen in the widths of the superstructure peaks (Fig. 4b). Up to x = 23.8, three different dependences are observed in the widths of the peaks, but for larger x there remain a linear relationship for the fundamental peaks and a parabolic one for the superstructure peaks of the D03 phase. This means that, at first, small clusters of both B2 and D03 phases appear, while for x > 24 only D03 clusters remain. At approximately the same x value, the cluster size is stabilized (Fig. 5).

The W 2 over d 2 dependence (Williamson–Hall plot) for: (а) Fe–15.5Ga (1) and Fe–19.5Ga (2) measured in the initial state (A2 phase), the bottom line shows the diffractometer resolution function; (b) Fe–23.1Ga (D03 phase). For fundamental peaks, the dependence is linear, while for superstructure peaks it is parabolic.

Another significant effect is found in the dependence of the unit-cell parameter on the atomic concentration of gallium. Two linear segments and a transition region between them are distinguished in Fig. 6. The a(x) dependence becomes nonlinear from x ≈ 18, i.e., the lattice parameter is more sensitive to the beginning of the ordering process than the intensities of the diffraction lines. The inverse a(x) dependence corresponds to decrease in the unit-cell parameter due to the transition from a disordered to a long-range ordered state (for example, [12]). The same phenomenon has been observed in the temperature dependence of the Fe–25Al–9Cr lattice parameter [9]. The similar qualitative behavior of a(x) was predicted by first principles calculations [13] and was found experimentally [1]. The values of a(x) (Fig. 6) are determined from the positions of the fundamental peaks, corresponding to the matrix in the x range where ordered clusters occupy a small part of the sample volume. The deviation from the linear dependence observed starting from x ≈ 18 means that the matrix “adjusts” to the clusters, and a high degree of coherence remains between the lattices of the matrix and the clusters.

Lattice constant as a function of Ga content in Fe–xGa alloys determined from the position of fundamental peaks. For D03 phase, the a/2 value is shown. The linear trendlines through the experimental points are the result of least-squares regression. The vertical dashed line separates (conditionally) the disordered state from the ordered cluster one.

CONCLUSIONS

The magnetostriction constant of Fe–xGa alloys as a function of x displays two maxima at x ≈ 19 and 28 increasing to the value up to ~400 ppm [14]. Our results illustrate some definite correlations of the magnetostriction behavior of these alloys and organization of their microstructure. The increase in magnetostriction up to x ≈ 19% coincides with a gradual increase in the degree of heterogeneity of the atomic structure due to an increase in the size of regions with a short-range order and a degree of order in them. In the concentration range of 19 < x < 25, clusters with the long-range B2 and D03 ordered structures are formed in the disordered A2 matrix, cluster dimensions gradually increase, accompanied by a slight decrease in magnetostriction.

The subsequent conversion of the D03 phase into B2 one leads to a new round of disorder in the atomic structure and formation of the second magnetostriction peak. Thus, it is possible to conclude that an increase in the degree of structural disorder leads to an increase in magnetostriction. A similar speculation has been made earlier [15] and more recently experimentally confirmed [2]. In the latter, samples in the form of melt-spun ribbons of ∼50 μm thick were studied, although completely different processes were assumed as specific reasons for disorder. In particular, the formation of inhomogeneities in the form of a tetragonally modified D03 structure was assumed [2]. In our results, there is no sign of tetragonality in the alloy lattice. To explain this discrepancy, we suggest that formation of the inhomogeneous state may proceed differently in melt-spun ribbons than in bulk samples. In particular, it can be assumed that the concentration of the modified-D03 phase is higher in the near-surface layers, to which X-rays are sensitive, and lower in the volume that neutrons feel.

REFERENCES

Zh. Nie, Z. Wang, Y. Liang, et al., J. Alloys Compd. 763, 223 (2018). https://doi.org/10.1016/j.jallcom.2018.05.327

Y. He, X. Ke, Ch. Jiang, et al., Adv. Funct. Mater. 28, 1800858 (2018). https://doi.org/10.1002/adfm.201800858

M. Greenholz and A. Kidron, Acta Crystallogr., Sect. A: Cryst. Phys., Diffr., Theor. Gen. Crystallogr. 26, 306 (1970).

H. Warlimont and G. Thomas, Met. Sci. J. 4, 47 (1970).

O. Ikeda, R. Kainuma, I. Ohnuma, K. Fukamichi, and K. Ishida, J. Alloys Compd. 347, 198 (2002).

S. Bhattacharyya, J. R. Jinschek, A. Khachaturyan, et al., Phys. Rev. B: Condens. Matter Mater. Phys. 77, 104107 (2008). https://doi.org/10.1103/PhysRevB.77.104107

S. Bhattacharyya, J. R. Jinschek, J. F. Li, et al., J. Alloys Compd. 501, 148 (2010). https://doi.org/10.1016/j.jallcom.2010.04.063

A. M. Balagurov, I. A. Bobrikov, S. V. Sumnikov, and I. S. Golovin, Acta Mater. 153, 45 (2018). https://doi.org/10.1016/j.actamat.2018.04.015

A. M. Balagurov, I. A. Bobrikov, S. V. Sumnikov, and I. S. Golovin, Phys. Rev. Mater. 3, 13608 (2019). https://doi.org/10.1103/PhysRevMaterials.3.013608

A. M. Balagurov, Neutron News 16 (3), 8 (2005). https://doi.org/10.1080/10446830500454346

A. M. Balagurov, I. S. Golovin, I. A. Bobrikov, et al., J. Appl. Crystallogr. 50, 198 (2017). https://doi.org/10.1107/S1600576716020045

B. E. Warren, X-Ray Diffraction (Addison Wesley, New York, 1969).

M.V. Matyunina, M. A. Zagrebin, V. V. Sokolovskiy, et al., Phase Transitions 92, 101 (2019). https://doi.org/10.1080/01411594.2018.1556268

A. E. Clark, K. B. Hathaway, M. Wun-Fogle, et al., J. Appl. Phys. 93, 8621 (2003). https://doi.org/10.1063/1.1540130

T. A. Lograsso, A. R. Ross, D. L. Schlagel, et al., J. Alloys Compd. 350, 95 (2003).

ACKNOWLEDGMENTS

The experiments were carried out using the IBR-2 (Joint Institute for Nuclear Research) neutron source.

Funding

This work was supported by the Russian Foundation for Basic Research (project nos. 18-02-00325 and 17-52-44 024) and partly (sample preparation and characterization) by the Russian Scientific Foundation (project no. 19-72-20 080).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balagurov, A.M., Bobrikov, I.A., Sumnikov, S.V. et al. Cluster-Like Structure of Fe-Based Alloys with Enhanced Magnetostriction. J. Surf. Investig. 14 (Suppl 1), S11–S14 (2020). https://doi.org/10.1134/S1027451020070058

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451020070058