Abstract

The possibility of applying silicon PIN detectors for recording the X-ray quanta in radiography within the energy range of 25–150 keV is considered with implementation of the dual-energy method. An approach for estimating the method’s resolution in determining the composition of materials is proposed. In the case of determining the atomic numbers of six chemical elements for dual-energy pairs, the resolution is quantitatively estimated. Limitations and factors affecting the method resolution are established.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

In modern X-ray scanners, the method for recording X-ray radiation in two regions of the energy spectrum is used [1–5]. It is implemented by means of a detector, the design of which includes two scintillators with a different sensitivity in the low- and high-energy regions of the spectrum, e.g., Gd2O2S: Tb and CsI, or systems of fine-crystalline scintillators ZnSe(Al) and LGSO(Ce) [6], or by means of double scanning with different voltage across the X-ray tube. In scanners applied to luggage inspection, this option makes it possible to separate organic and inorganic materials by their effective atomic number in the image of the monitored object, and also to divide the materials into groups. An object with an atomic number exceeding 18 is considered to be inorganic and highlighted in blue on the monitor screen. Objects with an atomic number of less than 10 are considered to be organic, and their image is colored yellow, while mixed objects and objects with an atomic number from 10 to 18 are displayed in green. Objects, the atomic number of which cannot be established (e.g., in the case of a system with insufficient penetrability for X-raying the object), are darker. X-ray recording in dual-energy ranges using image processing also allows dangerous items to be separated in the monitored object. In medicine this method of recording better known as dual-energy X‑ray absorptiometry is widely used in X-ray densitometers for bone-density analysis.

Among the disadvantages of the dual-energy method are errors with identifying materials (especially compounds with a close absorption coefficient), thin objects, when absorption in the material is not large, and other constraints [7]. Thus, inspection technologies need further development.

X-RAY RESEARCH FACILITY AND THE CHARACTERISTICS OF SILICON DETECTORS

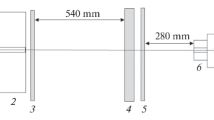

Studies were conducted at a facility, the scheme of which is shown in Fig. 1. It included the RAPAN X-ray source, an X-ray tube with a tungsten anode, the voltage across the tube anode was U = 150 keV, and the current was I = 0.16–1 mA. To record the X-ray quanta, a silicon pin detector was used [8] in the geometry where radiation is directed along the layer. The detector characteristics were as follows: the energy resolution was 1.67 keV on the source line 241Am 59.5 keV in the mode without forced cooling at room temperature 22°С, which in terms of the relative resolution is 2.8% [8]. The size of the detector entrance window is 0.5 × 3 mm. The construction of the row of silicon detectors, intended for use in the scanners, is shown in Fig. 2. The p–i–n junction should be biased at about 80 V. With the way of bias-voltage application indicated in Fig. 2, the insulator thickness can be less than 0.1 mm, while the row spacing can be decreased to 0.6 mm.

The spatial resolution with this geometry, when the radiation is directed along the layer, is quite sufficient for the effective work of scanners and can be compared with the resolution of traditional linear detectors with scintillators, in which at a small spacing of 0.2 mm light marks are observed in the scintillators of neighboring elements of the detector. In the proposed row of detectors, the individual orientation of each element can be specified, which will improve the spatial resolution of the detector and will allow detectors of any configuration to be fabricated. The energy resolution of this row is appreciably higher than that of a typical row with scintillators even in the absence of forced cooling and is sufficient for the separation of energy ranges corresponding to the Kα and Kβ lines in the radiation spectrum of a target or X-ray tube. For optimal selection of the ratios of energy values, it is possible to make a bimetallic anode of the X-ray tube and align the detector for recording the most suitable characteristic lines of the K series of the anode material. The proposed detector is easily producible, rather effective, has good resolvability and therefore is promising for application in inspection and medical equipment.

The spectra, obtained as a result of X-raying aluminum samples, are shown in Fig. 3. To avoid overloading the detector, a low-energy filter of steel 3 mm thick was placed near the collimator of the X-ray tube.

The integrated intensity of X-ray quanta decreases exponentially with coordinate x along the X-ray propagation direction:

where I0 and I are the intensities of X-ray quanta incident on the sample and transmitted from the sample, respectively, μ is the linear absorption coefficient, and x is the coordinate along the X-ray propagation direction. The relative error of μ measurement, estimated from the aluminum spectra (Fig. 3), is about 1%. This error is caused by the instability of the voltage across the X-ray tube anode, by the bias voltage, and by the dependence of μ on E. This error value is sufficient for implementation of the dual-energy method and estimation of its resolvability.

DUAL-ENERGY METHOD AND A TECHNIQUE FOR DETERMINATION OF ITS RESOLUTION

As in [9], the resolution ability of the method was also estimated during the Z determination of samples of known composition. For studies, eight samples, consisting of elements of Al, Si, Ti, Fe, Cu, and Ge, were selected. The experiments were conducted at the X-ray facility shown in Fig. 1. The reference samples were X-rayed by quanta with an energy corresponding to the energy of the characteristic lines Kα1 and Kα2 of the K series of the elements Sn, Er, and Pb [10] (Table 1), of which three targets were made.

The energy values of the characteristic lines Kα1 and Kα2 of the targets are close, the detector resolution does not allow them to be distinguished [11]; therefore, the equipment was adjusted for their joint recording, while in the calculations, the average energy values were taken (Table 1). To count the pulses, the analog-to-digital converter ATsP-8K-V1 was used. Determining in accordance with (1) that μ(El, h) = ln(I/I0)l,h/x0 for the sample of a thickness x0 with the atomic number Z, we derive the functional dependence from the measured ratio (I/I0)l,h:

the indices h and l refer to the higher and lower energy, respectively. The dual-energy method is based on the individual dependence, defined by Eq. (2), for different substances; this dependence, in essence, is the calibration curve for the X-ray facility: material Z can be determined by measured R. Taking into account that the error ΔZ of Z determination and the error ΔR of R determination are related with the formula

for analysis of the error ΔZ and the resolution δ, the following method was offered.

Determination of the Calibration Curve for the X-ray Facility (Function Rcalc(Z))

This can be carried out for X-ray facilities by means of calculations or experimentally by means of the analysis of standard samples of substances with known Z free from impurities. Since the detector resolution is high, the dependence can be taken as the initial calibration curve Rcalc(Z). This is calculated using the tabulated values of μz(E)—NIST reference data [10]. For Z = 1–35 by the NIST reference data of μz(E), the absorption coefficients of μz(E) were determined with three energy values E = 25.16, 48.67, 73.89 keV and the dependences Rcalc(Z) were drawn for two pairs of energy values: 25.16/73.89 and 48.67/73.89 keV (Fig. 4).

Dependences of R (curve 1) and the derivative dR/dZ (curve 2) on Z for the pair of energy values: (a) 25.16/73.89; (b) 48.67/73.89 keV. Rhombi indicate the experimental dependence R(Z), vertical lines show standard deviations; crosses refer to the Rcalc(Z) calculation by the NIST reference data; dashed line presents the Rcslc(Z) approximation by the quintic polynomial; dots show the dependences of the derivative dR/dZ(Z) × 10, obtained using the NIST data.

Calculation of the Derivative dRcalc/dZ

Using quintic polynomials, we selected the approximation function for Rcalc(Z) and calculated its derivative. The dependences of the derivative dR/dZ on Z for Z = 1–35 by the NIST reference data are given in Fig. 4.

Calculation of the Standard Deviation by the Measurement Results

A series of R measurements is performed for each selected sample (Fig. 4). With repeated measurements, the standard deviation of the measured quantity is calculated by [12]

where \(\bar {R}\) is the average value, i is the number of the measurement, and n is the amount of measurements in the series. Repeated measurements in scanners can be implemented either by means of processing either the results of neighboring elements of the row (or results of successive measurements using a single element) or by means of repeated scanning. Successive measurements with the employment of a single element and repeated scanning require time expenditure and decrease the scanner operation speed. The first way is more preferable, since the sizes of the analyzed objects, as a rule, are larger than the sizes of the entrance window of the detector. It can be assumed that composition analysis is important for samples of objects with an area of ~1 cm2, then n in (4) can reach about 50. In further calculations, \({{S}_{{\bar {R}}}}\) values for the reference samples were used, which were calculated by Eq. (5) with n = 50. For the sake of illustration, the standard deviation was also calculated in the case of n measurements [12], \(S_{R}^{2}\) = \(\frac{1}{{(n - 1)}}\sum\nolimits_{i = 1}^n {{{{({{R}_{i}} - \bar {R})}}^{2}}} ,\) which is shown in Fig. 4 by vertical lines.

Determination of the Residual Bias

The technique for determining the residual bias Θ is individual for each facility. This error is influenced by impurities in samples, by a variation with time in the characteristics of the detector and X-ray tube, and by other factors. Since the dependence Rcalc(Z) is calculated from the tabulated values of μz(E), an appreciable contribution to the residual bias is made by the error of μz(E) approximation in performing calculations. To estimate the error, the following procedure was applied. For the reference samples with known Z, Ri(Z) was measured, an average \(\bar {R}\) was found in the series of measurements of each sample, the deviation of the average from the Rcalc value, derived from the calibration curve \(\bar {R}\) – Rcalc, was calculated, then the residual bias was found: Θ = (\(\bar {R}\) – Rcalc)/2.

Calculation of the Error ΔR

The error ΔR was calculated by the formula [12]

In the Θ > SR approximation, it can be considered that the coefficient K ≈ \(\sqrt 3 \) [12].

Resolution

The resolution is determined as δ = 2ΔZ, where ΔZ is found from Eqs. (3) and (4). In Table 2, the error ΔZ of multiple measurements of Z for the reference samples is given, which was calculated by Eqs. (2)–(5). The resolution, determined by the least ΔZ for the pair of energy values 25.16/73.89 keV, was δ = 0.3, while for the pair 48.67/73.89 keV, δ = 0.9. Since the error of measuring the absorption coefficient is small (the μ measurement errors of 1% for aluminum and 2% for copper are less than the average relative error of the Z measurement of 3.4% for the pair of 25.16/73.89 keV and 5.0% for the pair of 48.67/73.89 keV), while the detector energy resolution is considerably less than the energy difference of the selected pairs (1.67 keV is less than 48.73, 25.22 keV), the resolution obtained is in essence the resolution ability of the method for the selected pairs of energy values.

ANALYSIS OF FACTORS THAT HAVE AN IMPACT ON THE ERROR OF THE DUAL-ENERGY METHOD

From Fig. 4 it follows that for each pair there is an area in the middle of the range, in which the dependence of R(Z) is maximum, and there are areas along the edges, in which the dependence is weak and Z determination is difficult. As follows from Fig. 4 and Table 2, it is possible to unambiguously determine, e.g., Z = 13 for the pair of energy values 25.16/73.89 keV. In this case, the error is minimum, ΔZ ≈ 0.15, and the method resolution is reached: δ = 0.3. For other samples with Z = 14, 22, 26, 29, the error turned out to be larger: ΔZ ≈ 0.9. For the samples with Z = 14, 26, the relative error is larger than for the others. This is related to the fact that the sample with Z = 14 is thin, and the contribution of the random component to error calculation is great, and to the fact that in the case of Z = 26, the dR/dZ smallness also has an impact. For the other pair, 48.67/73.89 keV, the resolution proved to be worse: δ = 0.8.

Selection of the pair of energy values considerably influences the resolution ability. On the one hand, the larger the difference in the energy values, the better the resolution (Table 2). On the other hand, a large difference limits the choice of materials, for which the absorption coefficient and material thickness should correspond to the working range for two energy values simultaneously. The working range is determined from the conditions: (I – I0), I0 ⪢ In, where In is the signal component due to the detector noise.

The errors of Z measurements, given in Table 2, are caused by the following factors: an error in the approximation upon μz determination at working energy values for the Rtabl calculation; impurities in the materials of the samples under study; and the measurement error of the analog-to-digital converter. These errors can be considerably reduced if the initial calibration curve R(Z) is derived experimentally, with the employment of reference samples without impurities, and if this calibration is performed directly before scanning. In this case, the limiting resolution ability of the method can be achieved.

CONCLUSIONS

Results of the application of silicon pin detectors for recording quanta, emitted by an X-ray tube with voltage across an anode of 150 kV, are demonstrated. A technique is proposed for estimating the error of atomic-number determination using the dual-energy method in radiography. In accordance with the experimental data, estimation of the resolution ability for two pairs of energy values is performed. Conditions are found at which the atomic number can be determined with a resolution of 0.3. The technique can be applied for X-ray facilities, used both in safety technologies and in medicine, which provides the possibility of performing correct estimation of their technical characteristics. The results can be helpful in solving problems of dividing materials of elementary substances and compounds.

REFERENCES

V. A. Udod, Ya. Wang, S. P. Osipov, S. V. Chakhlov, E. Yu. Usachev, M. B. Lebedev, and A. K. Temnik, Defektoskopiya, No. 9, 11 (2016).

S. V. Naidenov and V. D. Ryzhikov Tech. Phys. Lett. 28 (9), 357 (2002).

S. M. Osadchii, in Abstracts VII Natl. Conf. “X-Ray, Synchrotron Radiation, Neutrons and Electrons for Nanosystems and Materials Research. Nano-Bio-Info-Cognitive Technologies” (RSNE-NBIK, Moscow, 2009), p. 506 [in Russian].

R. Ch. Bokun and S. M. Osadchii, J. Surf. Invest.: X‑ray, Synchrotron Neutron Tech. 4 (4), 591 (2010).

S. P. Osipov, V. A. Udod, and Ya. Wang, Russ. J. Nondestr. Test. 53 (8), 568 (2017).

V. A. Litichevskyi, A. D. Opolonin, S. N. Galkin, A. I. Lalaiants, and E. F. Voronkin, Instrum. Exp. Tech. 56, 436 (2013).

S. P. Osipov, S. V. Chakhlov, O. S. Osipov, S. Li, X. Sun, J. Zheng, X. Hu, and G. Zhang, Int. J. Appl. Eng. Res. 12 (23) 13127 (2017).

S. M. Osadchii, A. A. Petukhov, and V. B. Dunin, Meas. Tech. 62, 465 (2019).

V. D. Ryzhikov, S. V. Naydenov, G. M. Onyshchenko, P. Lecoq, and C. F. Smith, Nucl. Instrum. Methods Phys. Res., Sect. A 603, 349 (2009).

National Institute of Standards and Technology. www.nist.gov

S. M. Osadchii, A. A. Petukhov, and V. B. Dunin, J. Surf. Invest.: X-ray, Synchrotron Neutron Tech. 13, 690 (2019).

GOST (State Standard) R 8.736-2011. State System for Ensuring Uniformity of Measurements. Multiple Direct Measurements. Methods for Processing Measurement Results. Basic Provisions (Standartinform, Moscow, 2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by M. Samokhina

Rights and permissions

About this article

Cite this article

Osadchii, S.M., Petukhov, A.A. & Dunin, V.B. Resolution of the Dual-Energy Method for Detecting Materials in Radiography. J. Surf. Investig. 14, 1274–1278 (2020). https://doi.org/10.1134/S1027451020060403

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451020060403