Abstract

A set of multilayer X-ray mirrors for an upgraded version of the double-mirror monochromator installed on the VEPP-5 synchrotron of the Budker Institute of Nuclear Physics is fabricated, its constituent parts are optimized, and its X-ray optical characteristics are studied. Due to the use of seven subbands, for each of which an optimal pair of materials is chosen, the mirror set ensures high reflection coefficients—ranging from 10 to 75%— for a wide range of photon energies from 80 to 3000 eV and wavelengths from 0.413 to 15.48 nm. The principles of optimization of material pairs are reported. For the first time, multilayer mirrors based on the W/Be pair of materials are fabricated and studied.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

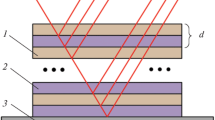

For a significant number of experiments involving synchrotron radiation, a spectral resolution at the level of λ/Δλ ~ 100 is sufficient and high peak and integrated values of the reflection coefficient come to the fore. Minimizing the effect of longwave and shortwave radiation on the experimental results at the selected wavelength is also of critical importance. Multilayer X-ray mirrors (MXMs) of the Bragg type most closely fulfill these requirements. Large operating angles substantially exceeding the critical angles of total external reflection suppress the contributions of both shortwave and longwave radiation to a monochromatic signal. Multilayer mirrors also can effectively suppress higher diffraction orders. Even diffraction orders can be suppressed almost to the level of nonresonant reflection by selecting the thickness of strongly and weakly absorbing materials for period d in the 1 : 1 ratio. The reflection of third and higher-order resonant m-harmonics is effectively suppressed because of the interlayer roughness σ, since the reflection coefficient is Rm ∼ exp(–4π2(mσ/d)2). Double reflection in the double-mirror monochromator only enhances the filtering properties of MXMs and also increases the resulting spectral resolution by about 1.4 times.

A relatively low set of requirements to the design of the spectrometer/monochromator are an additional advantage of using MXMs in practice. Large operating angles and a wide rocking curve substantially simplify requirements to the precision of mechanical components.

In 1998, a spectrometer based on a double-mirror monochromator was developed at the Budker Institute of Nuclear Physics, Siberian Branch, Russian Academy of Sciences [1]. The spectrometer allows one to study soft X-ray spectra in the range of photon energies from 150 to 1800 eV (0.7–8.2 nm) with a spectral selectivity of λ/Δλ ~ 60 in the middle of the operating band. In the study, an Fe/C-based MXM produced by the method of pulsed laser deposition [2] and a W/Si-based MXM produced by magnetron sputtering [3] were used. Such mirrors are used in the monochromator of the Kosmos station, which has been in operation since 2007 in the VEPP-4 accelerator of the Institute of Nuclear Physics, Siberian Branch, Russian Academy of Sciences [4]. To cover the range from 80 to 2000 eV, one of three available pairs of multilayer mirrors is installed in the monochromator. Measurements show that the proper selection of X-ray filters allows one to achieve rather high purity of monochromatic radiation, characterized by less than 1% of impurity photons that are outside the current operating band of the monochromator. However, a small number of mirrors leads to a low optical efficiency of the device and, consequently, to low photon fluxes in the real experiment. The set of mirrors described in the present study will be used to upgrade this monochromator in order to obtain a higher photon flux. The mechanical part of the monochromator was upgraded to allow installation of the new mirrors. The current problems require the following issues to be addressed: expanding the operating band to both shortwave and longwave ranges; and increasing the spectral selectivity and the reflection coefficients of the mirrors. Considering the significant progress made in the technology of the sputtering of multilayer mirrors in recent years, these problems can be successfully solved by increasing the number of subbands and optimizing the selection of mirrors for each subband.

In the present study, the MXM composition is optimized in accordance with the subbands, the methods for fabricating MXM samples and studying their reflective and structural properties are described, and the results of studying the reflective characteristics of the fabricated MXMs are given.

REQUIREMENTS TO SUBSTRATES AND MXMs

In addition to the above mentioned requirements to increase the reflection coefficients and the spectral selectivity, specific requirements associated with the design of the monochromator, such as MXM dimensions of 5 × 30 × 40 mm, operating angles in the range 5°–85° (counted from the mirror plane), and photon energies in the range 80–3000 eV, were taken into account when designing the set of mirrors for a double-mirror monochromator. The range of photon energies corresponds to wavelengths of 0.413 to 15.48 nm. The ranges of wavelengths and operating angles determine the maximum range of MXM periods. A minimum period of d = 2.2 nm corresponds to the shortest-wavelength subband and a maximum period of d = 8.38 nm to the longest-wavelength subband. Taking into account the dispersion of the optical constants of materials and the guaranteed coverage of the operating wavelength band, the range of mirror periods was chosen in such a way that the subbands overlap within the angular scanning range of the monochromator. The specific characteristics of the mirrors are given below.

To ensure the maximum reflection efficiency, monochromator mirrors constituting a pair must be identical. The spectral selectivity and allowed deviations Δd of the MXM period from the nominal value dnom are connected by the following relation:

Taking into account the multiplication of the reflection curves at the output of the monochromator, the resulting spectral width of the probe beam is approximately 1.4 times less than that of a single reflection. Therefore, the relative deviation from the nominal value should be Δd/dnom < 0.007 to ensure the maximum efficiency. Since two mirrors were cut out of one plate with a diameter of 100 mm, a uniformity of the period over all plates was obtained with an accuracy of better than 0.4%.

Let us assess how the mirror parameters affect the requirements to the substrate surface. The main characteristics of the substrate surface, which have an effect on the reflection coefficients and the reflected wavefront shape, are microroughness and deviations of the surface shape from that specified—in this particular case, from the plane. Local errors of the surface shape lead to a deviation of the local incidence angle from the Bragg angle. Thus, the requirement for the planarity of substrates can be formulated in the following way. Local errors Δθerr should satisfy the following condition:

where ΔθBr is the width of the Bragg peak at half maximum of the reflection coefficient. For estimation, it can be accepted that the smallest angular width is at a minimum incidence angle of 5° for MXM operating in the last subband. Taking into account a spectral selectivity of λ/Δλ ≈ 100, the full width at half maximum of the peak equals ΔθBr = 8.7 × 10–4 rad. To minimize the cost of substrates, commonly available thin silicon plates attached by optical-contact technology to a thick stainless-steel substrate were used in the present study. This technology guarantees angular errors at a level of Δθerr < (1–2) × 10–4 rad [5].

It is known that microroughness affects the reflection-coefficient value to the largest extent. As is noted in a significant number of studies, a microroughness value at a level of 0.1–0.2 nm is acceptable for the majority of applications. Silicon substrates for the microelectronics industry were used in the present study, which were subjected to chemical-mechanical polishing at the final stage of fabrication. The microroughness value was measured using an atomic force microscope on a special stand [6]. The microroughness of the plates in a frame with dimensions of 2 × 2 μm was about 0.1 nm.

SELECTION OF SUBBANDS AND MATERIALS FOR MXM

A modern approach to the selection of pairs of MXM materials simultaneously providing maximum peak values of the reflection coefficients and high spectral selectivity in a given spectral range consists in the use of both strongly absorbing and weakly absorbing materials whose absorption jumps are as close as possible to the shortwave part of the operating band (see, for example, [7, 8]). In the range of wavelengths of λ > 12.4 nm that interests us, MXMs based on Mo/Si are widely used [9]. The reflection coefficients attained to now are 71% at λ = 12.7 nm and 70.15% at λ = 13.5 nm [10]. In the range of wavelengths of λ = 11.1–12.4 nm, the highest experimentally obtained reflection coefficients reach 70% for a structure of the Mo/Be type [11]. In the range of wavelengths λ = 9.3–11.1 nm, MXMs based on Mo/Y [12, 13], Ru/Y [8, 14], and Pd/Y [14, 15] are used. In the area of wavelengths beyond the K-edge of the absorption spectrum of boron (λ = 6.6–9.3 nm), MXMs of the Mo/B4C, La/B4C, and La/B types are used [16–18].

In the range of wavelengths of λ = 4.4–6.6 nm, Cr/C-, Co/C-, and Ni/C-based MXMs show the best X-ray optical characteristics [19–21] and Cr/Sc-based MXMs in the range of wavelengths of λ = 3.1–4.4 nm [22]. The region of wavelengths λ = 2.3–3.1 nm is the most problematic. Traditionally poorly absorbing materials, such as boron, carbon, and silicon, absorb rather strongly in this range, so MXMs based on them have low reflection coefficients (less than 10%). High reflection coefficients can only be achieved in the areas of dispersion anomalies of the optical constants of Ti (λ = 2.74 nm) for Cr/Ti-based MXMs [23] and V (λ = 2.4 nm) for Cr/V-based MXMs [24]. Since the range is very narrow, only fixed lines are actually observed and these mirrors cannot be used in a broadband spectrometer/monochromator.

In the region of wavelengths of 0.683–2.3 nm, up to the MV-edge of the absorption spectrum of W (λM = 0.683 nm), mirrors based on W/Si and W/B4C are widely used [25, 26]. In the short-wavelength part of the spectral band of the spectrometer/monochromator at wavelengths of 0.413–0.683 nm, mirrors with the shortest periods are used. It should be noted that W-, Mo-, and Si-containing mirrors cannot be used in this range because of absorption jumps. In this regard, short-period Cr/C-based MXMs seem to be the most promising [27].

On the basis of the performed analysis, new approaches were used in the present study to increase the reflection coefficients of mirrors, achieve better standardization, and reduce the number of subbands. First, Mo/Be-based MXMs that have, as shown in [28, 29], record-breaking reflection coefficients not only at 11 nm, but also at 13 nm were used in the first subband (Table 1) instead of traditional Mo/Si-based MXMs. This also made it possible to extend the first subband (from 12.4 to 11.1 nm) into the area of short wavelengths, which had a positive effect on the reflection coefficients in the second subband, since that did not require moving far away from the region of wavelengths corresponding to the anomalous dispersion of the optical constants of yttrium. Secondly, MXMs based on W/Be were used for the first time in the problematic region at λ = 2.3–3.1 nm. Due to the distance from the K-edge of the absorption spectrum of Be (λK = 11.1 nm) and a low density, the absorbance of this material is significantly lower than that of C, B4C, and Si, which makes it the most promising material among weakly absorbing materials. In addition, W/Be-based MXMs operating in the range of wavelengths of 0.683–2.3 nm were fabricated and studied for the first time.

SYNTHESIS OF MULTILAYER X-RAY MIRRORS AND METHODS OF STUDYING THEIR OPTICAL AND STRUCTURAL PARAMETERS

Multilayer mirrors were fabricated simultaneously in several magnetron sputtering devices. The method of direct-current magnetron sputtering was used to apply coatings. The parameters of the technological process and the peculiarities of the sputtering of Be are described in more detail in [30]. The angular dependences of the reflection coefficients at λ = 0.154 nm were measured using a PANalitycal Expert’Pro diffractometer with a Ge(220) four-crystal asymmetric monochromator. The monochromator provides an angular divergence of the probe beam at a level of 0.0036°. Such a high resolution allows one to reliably measure the reflection coefficients for high Bragg orders.

The reflection coefficients in the soft X-ray range were measured using two laboratory reflectometers based on RSM-500 spectrometers/monochromators. Demountable X-ray tubes were used as X-ray sources. Diffraction gratings with curvature radii of 6000 and 2000 mm were used in the wavelength ranges 0.7–5 nm and 4.4–17 nm, respectively. The spectral resolutions were 0.012 and 0.04 nm in the first and second ranges, respectively. Measurements were carried out at the characteristic lines of the X-ray tube anodes. A detailed description of the reflectometer can be found in [31].

It should be noted that the spectral width Δλline of a number of lines, such as the FeLα, CuLα, MgKα, and AlKα lines, in the short-wavelength range is substantially lower than the resolution Δλdev provided by a grating-based spectrometer/monochromator. Thus, the actual spectral selectivity equals λ/Δλline ≈ 1000 despite the relatively low spectral resolution of the device (for example, λ/Δλdev ≈ 83.3 at λ = 1 nm). This allows one to carry out precision measurements of both the reflection coefficients and spectral selectivity of multilayer mirrors.

To reconstruct the structural parameters of MXMs on the basis of X-ray reflection data, the so-called “extended” model was used [32]. The main difference of this model from existing models is that the transitional regions in the process of fitting the experimental curves are represented as linear combinations of the most frequently used functions. Such a model is best suited for a variety of physical processes taking place at the interfaces of multilayer thin-film structures. In particular, the interlayer roughness values are best described by an error function [33], whereas diffusion is better described by a linear function (see, for example, [34, 35]). It turned out to be very interesting to add a step function to this combination, which allows one to detect stoichiometric layers in the transitional region when describing the interfaces [32]. The best fitting is achieved when using several reflection curves measured at different wavelengths.

Let us illustrate an example when the described model was used to study the structural parameters of multilayer mirrors based on W/Be. The measured and fitted angular dependences of the reflection coefficients for wavelengths of 0.154, 0.989, 1.759, and 3.14 nm are given Fig. 1. The solid lines correspond to fitting, and the symbols and the broken line in Fig. 1d show the measured values. As one can see, the experimental curves, except the one for a wavelength of 3.14 nm, match the curves calculated with the following structural parameters of MXM: the number of periods is N = 200; the period is d = 2.278 nm; the layer thickness averaged over the structure is d(W) = 0.951 nm for tungsten and d(Be) = 1.327 nm for beryllium; the density is 18 g/cm3 for W and the tabulated value for Be; and the layer thickness is 0.4 nm for the Be-to-W transitional layers and 0.21 nm for the Be-to-W transitional layers. It should be noted that the sequence of interfaces cannot unambiguously be determined by the method of reflectometry and, accordingly, the Be-to-W boundary area can also be the best interface. Typically, this problem is solved using the additional method of the electron microscopy of cross sections. The poor match at a wavelength of 3.14 nm is explained by low intensities of the probe beam and reflection coefficient values of MXMs. The situation worsened because of the proximity of the incidence angle to the Brewster’s angle, which automatically reduced the reflection coefficient of unpolarized radiation by two times.

STUDY OF THE X-RAY OPTICAL CHARACTERISTICS OF THE SET OF MIRRORS

The appearance of one mirror is shown in Fig. 2. Fourteen mirrors with identical geometric dimensions were fabricated in the set. The selected subbands and key parameters of multilayer mirrors fabricated for a two-crystal monochromator are given in Table 1.

The spectral dependences of the peak reflection coefficient, the integrated reflection coefficient in the operating subband of wavelengths, and the spectral selectivity to s-polarized radiation (a two-crystal monochromator in the synchrotron operates in this configuration) for individual mirrors are given in Fig. 3. The curves were calculated using the structural parameters of each MXM fabricated as described above. In each case, fitting was carried out over four experimental reflection curves. As is seen from Fig. 3, the maximum reflection coefficients—up to 75%—are provided by Mo/Be-based MXMs near 11 nm. The reflection coefficients oscillate in the range 10 to 40% upon moving toward the short-wavelength region. The reflection coefficient falls below 10% only in very narrow regions near 3 and 4 nm. The spectral selectivity of a single mirror varies in the range of λ/Δλ ≈ 25–150. Accordingly, the maximum spectral selectivity in a double-mirror monochromator is achieved at a level of λ/Δλ ≈ 210. For example, the energy width of the probe beam is about 1.5 eV in the range of photon energies of 277–395 eV, which allows one to use this device for spectroscopic studies of organic materials taking into account a lack of the noticeable optical dispersion of Cr and Sc.

DISCUSSION OF RESULTS AND CONCLUSIONS

As a result of the performed research, a set of multilayer mirrors for a double-mirror X-ray monochromator designed to operate in a synchrotron is developed, fabricated, and studied. Compared to the previous version of the developed mirrors, the operating spectral range is extended increased and the reflection coefficients and the spectral selectivity of the device are increased. The maximum reflection coefficient for s-polarized radiation is 75% in the region near 11 nm. The reflection coefficients oscillate in the range 10 to 40% upon moving toward the short-wavelength region. Only in very narrow regions near 3 and 4 nm does the reflection coefficient fall below 10%. The spectral selectivity of a single mirror varies in the range λ/Δλ ≈ 25–150. Accordingly, the maximum spectral selectivity in the double-mirror monochromator is λ/Δλ ≈ 210.

The relatively high energy resolution attained in the double-mirror scheme for the range of photon energies of 277–395 eV is a very interesting result. The energy width of the probe beam is about 1.5 eV, which is comparable to the resolution of grating-based spectrometers/monochromators of the RSM-500 or McPherson-247 type in this range. It is known that it is very difficult to perform spectroscopic measurements in the area of the K-edge of the spectral band of carbon because of artifacts caused by hydrocarbon contaminants on the surfaces of diffraction gratings and mirrors of grating monochromators. Due to the normal incidence of radiation and also to a lack of noticeable dispersion of the optical constants of Cr and Sc in this region, the spectroscopic study of organic materials by using a double-mirror monochromator is significantly simplified.

For the first time, MXMs based on W/Be have been used for a wide spectral region of 0.67–3.14 nm. In the work, their internal structure and X-ray optical characteristics are studied. It is shown that samples with a period of up to 2 nm provide good reflective properties. It is found that the unit cell of this type of MXMs is asymmetrical. Best fitting is achieved with the following parameters of the transitional areas: 0.4 nm for the Be-to-W layer and 0.21 nm for the W-to-Be layer. It should be noted that reflectometry does not clearly determine the sequence of interfaces, so the Be-to-W transitional layer can be the best interface. Typically, this problem is solved by using the electron microscopy of cross sections. The presence of one good interface gives reason to hope for a substantial increase in the reflection coefficient of W/Be-based MXMs due to the formation of a sublayer at this interface. Such studies are planned in the near future.

REFERENCES

N. G. Gavrilov, A. A. Legkodymov, A. D. Nikolenko, et al., Poverkhnost, No. 1, 129 (2000).

N. I. Chkhalo, M. V. Fedorchenko, N. V. Kovalenko, et al., Nucl. Instrum. Methods Phys. Res. 359, 121 (1995).

E. P. Kruglyakov, A. D. Nikolenko, E. P. Semenov, et al., Poverkhnost, No. 1, 151 (1999).

A. D. Nikolenko, S. A. Avakyan, I. M. Afanas’ev, et al., J. Surf. Invest.: X-ray, Synchrotron Neutron Tech. 6 (3), 388 (2012).

A. D. Akhsakhalyan, E. B. Klyuenkov, A. Ya. Lopatin, et al., J. Surf. Invest.: X-ray, Synchrotron Neutron Tech. 11 (1), 1–19 (2017). https://doi.org/10.1134/S1027451017010049

N. I. Chkhalo, N. N. Salashchenko, and M. V. Zorina, Rev. Sci. Instrum. 86, 016 102 (2015). https://doi.org/10.1063/1.4905336

C. Montcalm, P. A. Kearney, J. M. Slaughter, et al., Appl. Opt. 35 (25), 5134 (1996).

M. M. Barysheva, A. E. Pestov, N. N. Salashchenko, et al., Usp. Fiz. Nauk 182 (7), 727 (2012).

S. Bajt, J. Alameda, T. Barbee, et al., Opt. Eng. 41 (8), 1797 (2002).

A. E. Yakshin, R. W. E. van de Kruijs, I. Nedelcu, et al., Proc. SPIE 6517, 65 170 (2007).

C. Montcalm, S. Bajt, P. B. Mirkarimi, et al., Proc. SPIE 3331, 42 (1998).

B. Sae-Lao, S. Bajt, C. Montcalm, and J. F. Seely, Appl. Opt. 41 (13), 2394 (2002).

D. L. Windt, S. Donguy, J. Seely, et al., Proc. SPIE 5168, 1 (2004).

D. L. Windt and E. M. Gullikson, Appl. Opt. 54 (18), 5850 (2015).

D. Xu, Q. Huang, Y. Wang, et al., Opt. Express 23 (26), 33 018 (2015).

A. F. Jankowski and P. L. Perry, Thin Solid Films 206, 365 (1991).

N. I. Chkhalo, S. Künstner, V. N. Polkovnikov, et al., Appl. Phys. Lett. 102, 011 602 (2013).

D. S. Kuznetsov, A. E. Yakshin, J. M. Sturm, et al., Opt. Lett. 40 (16), 3778 (2015).

A. V. Andreev, Yu. V. Ponomarev, I. R. Prudnikov, and N. N. Salashchenko, Poverkhnost, No. 1, 50 (1999).

M. Wen, Q. Huang, S. Ma, et al., Opt. Express 24 (24), 27 166 (2016).

V. A. Chernov, N. I. Chkhalo, M. V. Fedorchenko, et al., J. X-Ray Sci. Technol. 5, 389 (1995).

N. N. Salashchenko and E. A. Shamov, Opt. Commun. 134, 7 (1997).

N. Ghafoor, P. O. Persson, J. Birch, et al., Appl. Opt. 45 (1), 137 (2006).

Q. Huang, J. Fei, Y. Liu, et al., Opt. Lett. 41 (4), 701 (2016).

D. L. Windt, F. E. Christensen, W. W. Craig, et al., J. Appl. Phys. 88 (1), 460 (2000).

M. S. Bibishkin, N. I. Chkhalo, A. A. Fraerman, et al., Nucl. Instrum. Methods Phys. Res., Sect. A 543, 333 (2005).

S. S. Andreev, M. S. Bibishkin, N. I. Chkhalo, et al., J. Synchrotron Radiat. 10, 358 (2003).

S. A. Bogachev, N. I. Chkhalo, S. V. Kuzin, et al., Appl. Opt. 55 (9), 2126 (2016).

N. Chkhalo, S. Gusev, A. Nechay, et al., Opt. Lett. 42 (24), 5070 (2017).

N. I. Chkhalo, D. E. Pariev, V. N. Polkovnikov, et al., Thin Solid Films 631, 106 (2017).

M. S. Bibishkin, D. P. Chekhonadskih, N. I. Chkhalo, et al., Proc. SPIE 5401, 8 (2004).

M. Svechnikov, D. Pariev, A. Nechay, et al., J. Appl. Crystallogr. 50, 1428 (2017).

L. Névot and P. Croce, Rev. Phys. Appl. 15, 761 (1980).

S. S. Andreev, M. M. Barysheva, N. I. Chkhalo, et al., Tech. Phys. 55 (8), 1168 (2010).

I. A. Makhotkin, E. Zoethout, R. van de Kruijs, et al., Opt. Express 21, 29 894 (2013).

ACKNOWLEDGMENTS

Works on upgrading the monochromator of the Kosmos station and on fabricating the majority of mirrors were performed using equipment of the Center for Collective Use “Siberian Center of Synchrotron and Terahertz Radiation” based on the VEPP-4 synchrotron of the Institute of Nuclear Physics, Siberian Branch, Russian Academy of Sciences, under financial support of the Ministry of Education and Science of the Russian Federation, project unique identification no. RFMEFI62117X0012. In the part of the sputtering of W/Be coatings, the works were performed using equipment of the Center for Collective Use “Physics and Technology of Micro- and Nanostructures” of the Institute of Physics of Microstructures, Russian Academy of Sciences, under financial support of the Russian Science Foundation and the German Research Foundation (RNF–DFG, grant no. 16-42-01034), the Russian Foundation for Basic Research (grant nos. 17-52-150006, 18-02-00588, 18-07-00633, and 18-02-00173), and also within State Assignment no. 0035-2014-0204 for the Institute of Physics of Microstructures, Russian Academy of Sciences, under Programs I.1. Physics of Condensed Matter and New-Generation Materials and I.2. Nanostructures: Physics, Chemistry, Biology, and Basics of Technologies of the Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Kadkin

Rights and permissions

About this article

Cite this article

Akhsakhalyan, A.A., Vainer, Y.A., Garakhin, S.A. et al. Set of Multilayer X-Ray Mirrors for a Double-Mirror Monochromator Operating in the Wavelength Range of 0.41–15.5 nm. J. Surf. Investig. 13, 1–7 (2019). https://doi.org/10.1134/S1027451019010026

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451019010026