Abstract

This study aimed to develop an electrochemical sensor based on a derivative of graphene oxide (GO) and a molecularly imprinted polymer (MIP) on a pencil graphite electrode (PGE) for the detection of ascorbic acid (AA). MIP was fabricated onto the surface of the electrode by electropolymerization technique using cyclic voltammetry with a scan rate of 10 mV/s consisting of template molecule (ascorbic acid), functional monomer (polypyrrole), cross-linker (LiClO4) and citrate buffer at pH 4. Then, the template removal process was conducted to create the imprinted cavities for detecting the analyte. Differential pulse voltammetry (DPV) and cyclic voltammetry (CV) methods were used to perform quantitative analyses of the modified electrodes. CV analysis was performed at the optimum scan rate of 10 mV/s, and the electrolyte concentration at 1.0 mM K3[Fe(CN)6] in 0.1 M KCl. MIP-PGE (2) produced the best performance by having the highest redox peak current response when scanning with the CV compared to other modified electrodes. The optimum parameters for DPV measurement are 100 mV pulse amplitude, 200 ms pulse period, and 10 mV/s scan rate. The straightforward instrumentation and easy preparation of the proposed sensor make it a valuable system for constructing simple devices for determining ascorbic acid.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Sensors are modules utilized in every industry to determine and adjust parameters to deliver more viable services to people. Researchers have recently been involved in strong competition to create and construct innovative sensors due to the high demand of the worldwide market and human interest in having a device that easily and quickly analyzes the interest species in various types of samples. An electrochemical sensor is one example of a sensor that gives exact information on analytes and concentration determination, even in low amounts [1]. Various published works revealed a strategy for producing more biocompatible and high-resolution electrodes based on electrochemical changes [2, 3]. Electrochemical sensors have several benefits over traditional sensors (based on change of color e.g Fehling test), transforming electrochemical data into a signal that can be evaluated. The most important part of an electrochemical sensor is a chemical (molecular) recognition system and a physicochemical transducer, which is a device that turns the chemical reaction into a signal that modern electrical instruments can detect. These parts work together to form a working (or sensing) electrode. Amperometry, voltammetry, potentiometry, and conductometry can be used to convert a chemical signal into an electrical signal [1].

Initially, two-electrode was utilized in electrochemical sensors; a working electrode and a reference/counter electrode were commonly employed in various electrochemical techniques, including potentiometry, where zero current is typically utilized. These two-electrode cells are still in use today in potentiometry for measuring potentials without current flow. Currently, three electrodes have been employed in electrochemical sensors: working, reference, and counter electrodes are widely used in non-zero current methods such as voltammetry and amperometry. The inclusion of a separate counter electrode allows the measurement of current, which is crucial for techniques involving current flow. Therefore, it is important to note that while two-electrode cells are utilized in potentiometry (a zero-current method), three-electrode cells are commonly employed in non-zero-current methods such as amperometry and voltammetry. This distinction ensures accurate and reliable measurements in electrochemical sensing applications [4]. Electrodes are essential in developing electrochemical sensors. Thus, it is beneficial to modify/fabricate the working electrode’s surface area [5]. Covering the electrode surface with a polymer not only performs the desired reaction but also gives a better electron transmission speed between the analyte and the electrode [6]. The conversion element converts the chemical signal produced after the recognition element selectively binds to the analyte into an output electrical signal [7]. This electroanalytical method is becoming more popular due to its unique characteristics; lower cost, smooth operation, strong repeatability and stability, independence from the laboratory, and wide linear range for fast response [8].

One way to enhance the electrochemical method’s selectivity is by using electrodes modified with molecules imprinted polymers (MIP) [9]. MIP is a synthetic recognition receptor with high selectivity for the target molecule and enhanced chemical and physical consistency compared to natural receptors [10]. MIPs are stable polymers with molecular recognition abilities due to the presence of a template during their synthesis [11]. The basic idea of molecular imprinting relies on a process where monomers are polymerized in the presence of an analyte (the imprint molecule), which behaves as a molecular template in the sensor [12]. MIPs exhibit selective binding of the template molecule used during their synthesis. MIPs have several benefits, including being robust, having high stability, requiring low-cost preparation, and having a high specific identification ability towards the targeted analyte [11]. However, due to their lower surface area and conductivity, the sensors that used MIP-modified electrodes had a limited sensitivity range. Hence, it has been recognized that graphite derivatives are suitable materials that can be added to create molecularly imprinted composites because of the excellent thermal and electrical conductivity and large surface area of graphite derivatives [13].

Graphite is a crystalline carbon made of graphene layers that occurs naturally and is a stable form of carbon under normal conditions. Graphite is gaining the researchers’ attention due to its unique features, such as high conductivity, fast electron transfer rate, and high surface area, making it a highly conductive compound in electrochemical detections [14]. Graphene oxide (GO) is attracting more attention since hummers’ technique-adjusted procedures make it easier to produce. Thus, GO is the most efficient graphene derivative in electrochemical sensors that include different nanoparticles. It has been concluded that the performance of the electrochemical sensor can be enhanced by the interaction of graphene derivatives and metal nanoparticles [15]. Therefore, it may be helpful in modifying the surface of molecularly imprinted detectors [16]. Many analytes, including levofloxacin [17], didanosine [18], bisphenol A [19], and andrographolide [20], have been determined more accurately using graphene derivatives or GO that coated on electrochemical sensors. Furthermore, recent research has shown that GO enhances electrical conductivity and creates adequate electroanalytical activities for detecting analytes in real samples [21].

One of the best-performing electrode materials for electrochemical sensors is the pencil graphite electrode (PGE). PGE is preferable for detecting various analytes due to its low cost, more stable, reactive properties, and larger surface area [12, 20]. Electrochemical biosensor analysis methods with nanoparticles and graphene oxide provide unique and substantial benefits such as easy production, quick response, cheap cost, and high sensitivity [21]. A larger surface area of PGE can make the electrode able to detect the low concentration of analytes. Therefore, PGE can be applied as a trace analysis electrode when integrated with a more accurate and sensitive voltammetric technique, such as cyclic voltammetry (CV) and differential pulse voltammetry (DPV) [12].

Ascorbic acid (AA), with IUPAC name of (2R)-2-[(1S)-1,2-dihydroxyethyl]-3,4-dihydroxy-2H-furan-5-one, also known as Vitamin C was synthesized from hexose sugars, and it is one of the most prevalent water-soluble antioxidants in plants and animals [22, 23]. It is a white solid in appearance, but impure samples can be seen as yellowish. It readily dissolves in water and produces moderately acidic solutions. Small amounts of AA can be dissolved in alcohol but not in other organic materials such as diethyl ether, chloroform, benzene, petroleum ether, or lipids. AA is a significant redox buffer in plants and controls various physiological processes such as growth, development, signal transduction, and stress tolerance. It also functions as an enzyme co-factor; hence it plays several roles in plant physiological processes [24]. In the pharmaceutical field, AA can also be used as a free-radical scavenger, which can help in cancer and Parkinson’s disease treatments [12]. Considering AA’s many essential uses in various fields, it must be detectable by a simple and dependable approach within a minute.

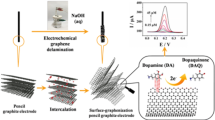

This study reported electrochemical methods, CV and DPV approaches, for determining AA using a PGE prepared by imprinting electropolymerization. GO/ZnO will be deposited onto the bare PGE. Zinc oxide acts as a metal nanoparticle and combines with GO, which increases the sensor’s performance. The proposed sensor will be made by electropolymerizing pyrrole (PPy) on the surface of a PGE modified with GO/ZnO in the presence of AA as a template molecule. AA was selected as the template molecule due to its prevalence and electroactivity. Then, the template removal will be conducted from the MIP film, and an electrochemical sensor will detect the AA. This proposed electrochemical sensor gives a new design for detecting AA in aqueous samples.

EXPERIMENTAL

Chemicals

Graphite flakes (≥99.85%), potassium permanganate (KMnO4), sodium nitrate (NaNO3), zinc oxide (ZnO), dimethylformamide (DMF), and pyrrole (PPy) were purchased from Sigma Aldrich. Hydrogen peroxide (H2O2), sulphuric acid (H2SO4), potassium ferricyanide(III) [K3(Fe(CN)6], potassium chloride (KCl), lithium chlorate (LiClO4), ethanol (C2H5OH), methanol (CH3OH), citric acid (C6H8O7), sodium citrate (Na3C6H5O7), hydrochloric acid (HCl), sodium hydroxide (NaOH), acetonitrile (CH3CN) and ascorbic acid (C6H8O6) were sourced from R&M Chemicals (Malaysia).

Instrumentation

The electrochemical measurements were carried out using BASi Epsilon-EC-Ver.2.00.71_XP software. A three-electrode system (working, counter, and reference) was used to perform electrochemical measurements. A PGE was used as a working electrode, Ag/AgCl electrode was used as a reference electrode with silver wire coated with AgCl immersed in 3 M KCl electrolyte solution, and a platinum electrode was used as a counter electrode. 2B Unicorn pencil graphite with a diameter of 1.8 mm was purchased from a stationery store. Scanning electron microscopy (SEM) was performed using FEI Quanta 650 FEG along with energy-dispersive X-ray (EDX) instruments from Oxford Instruments (EDX Oxford Inca 400, USA).

Synthesis of Graphene Oxide (GO)

Paste the modified hummers method [25] was used to synthesize GO. First, 100 mL of sulphuric acid was added to the beaker set up over an ice bath. Next, 3 g of graphite powder was added to the beaker, stirring for 15 min. 3 g of sodium nitrate (NaNO3) was added to that mixture. The mixture was stirred continuously for the next 3 h. After that, 15 g of KMnO4 was added, and the ice bath was removed. The mixture was stirred continuously again for 24 h. Later, 200 mL of distilled water was added dropwise into the suspension and heated at 90°C for 15 min with continuous stirring. Then, the solution was allowed to cool. Next, 150 mL of water and 30 mL of hydrogen peroxide were added. After 20 min, the solution was filtered using filter paper, and the product was collected. The product was placed in the oven for 24 h at 50°C. The greyish-black powder of GO was obtained.

Synthesis of GO/ZnO Composites

GO/ZnO composites were prepared using the solvothermal method [26, 27]. A 3 : 1 ratio mixture of GO powder and ZnO powder was dissolved in 50 mL DMF and stirred for 30 min at 25°C. The mixture was put in the sonicator for a day to ensure both chemicals mixed well. After that, the mixture was allowed to cool at normal temperature before being centrifuged for 15 min at 3000 rpm. After removing the supernatant, the sample was washed with ethanol and water. Then, the powder was dried in an oven at 45°C for a day. Finally, composites of GO/ZnO were obtained.

Pre-Treatment of Bare Electrode

First, bare PGE electrodes were rinsed several times with distilled water to avoid disturbance during the experiment. Next, the PGE electrode was polished using 2500-grade polishing paper (RikenMT, Japan). PGE was then immersed in a mixture of ethanol and water with a ratio of 1 : 1 for 6 h. After that, the PGE was dried and exposed to CV. The bare PGE was scanned from –0.2 to 0.6 V in different concentrations of K3[Fe(CN)6] in 0.1 M KCl with a scan rate of 10 mV/s to obtain a stable voltammogram. The 0.1, 0.5, 1, 5, and 10 mM of K3[Fe(CN)6] in 0.1 M KCl were used in these measurements. All electrolyte solutions were degassed with oxygen-free nitrogen (OFN) to eliminate any soluble oxygen and gaseous contaminants prior running CV and DVP.

Deposition Process

After the process of pre-treatment of the bare PGE electrode, the GO and GO/ZnO composites prepared in the previous sections were fabricated on the surface of the bare PGE.

Fabrication of GO/PGE

2.0 mg of GO was mixed with 2 mL of dimethylformamide in a beaker. This suspension was sonicated for one hour. Later, the suspension was carefully poured over the tip of the electrode using a pipette, and the treated PGE was kept in this suspension for one hour. From this process, a homogenous coated layer of GO on PGE was formed. The GO/PGE electrode was then allowed to dry overnight in a confined space.

Fabrication of GO/ZnO/PGE

2.0 mg of GO/ZnO was mixed with 2 mL of dimethylformamide in a beaker and was sonicated for one hour. Later, the prepared suspension was then dropped on the PGE surface in the required volume using a pipette. The modified PGE was then submerged in this mixture for one hour and allowed to dry overnight in a confined space to form a coating of GO/ZnO composites on the surface of the PGE electrode.

Preparation of Molecularly Imprinted Modified Electrodes

0.1 M of LiClO4, 50 mM of PPy, 0.1 M of citrate buffer pH 4, and 50 M of AA were prepared and mixed with 1 mL of acetonitrile in a beaker. The solution was purged with OFN gas before conducting the voltammetry technique. Then, the GO/PGE and GO/ZnO/PGE electrodes were immersed in the solution for 30 min. Next, the electropolymerization process was carried out by using the CV. GO/PGE and GO/ZnO/PGE electrodes were scanned from –0.2 to 1.8 V at a scan rate of 10 mV/s with 5 cycles for each electrode. After that, the template molecule was removed by immersing it in the methanol-acetic acid solution (V : V = 9 : 1) for 30 min. For further removal of the template molecule, the electrode was over-oxidized with five cycles of CV scan in 5 ml of 0.1 M NaOH. The CV was scanned from 0.2 to 0.8 V with a scan rate of 10 mV/s. Finally, the MIP-modified electrodes were fully prepared namely GO/PPy/PGE known as MIP-PGE (1) and GO/ZnO/PPy/PGE known as MIP-PGE (2) respectively. Whereas the non-imprinted modified electrode was also prepared in the same method except for using AA in the electrolyte solution namely as NIP-PGE (1) and NIP-PGE (2).

Electroanalytical Measurements

The electrochemical measurements were performed using CV in the 1.0 mM of K3[Fe(CN)6] in 0.1 M KCl with a scan rate of 10 mV/s. DPV measurements were also performed in the presence of 0.1 M of citrate buffer pH 4 and AA with the potential range between –0.4 to 0.6 V, 10 mV/s of scan rate, 100 mV of pulse amplitude, and 200 ms of modulation time.

Analysis of Scan Rate and Concentration on Modified Electrode

The cyclic voltammetry was carried out in the 1.0 mM of K3[Fe(CN)6] in 0.1 M KCl with various scan rates between the potential range –0.2 to 0.8 V of MIP-PGE (2) modified electrode. The scan rates measured are 5, 10, 25, 50, 75, and 100 mV/s. In addition, DPV was carried out in the citrate buffer solution of pH 4 with different concentrations of AA. The different concentrations observed are 1, 10, 20, 30, 40, 50, 70, 80 and 100 mg/L.

RESULTS AND DISCUSSION

Characterization of Modified Electrodes

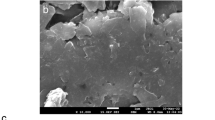

The SEM-EDX analysis investigated the surface morphology of bare PGE, MIP-PGE (2), and NIP‑PGE (2) electrodes. The images of these electrode surfaces can be seen as shown in Fig. 1. The images illustrate that the bare electrode surface is almost flat, has regular streaks, and is smoother than the surface of the imprinted electrodes [28]. The imprinted polymer electrode (MIP) surfaces have random and rough shapes, while NIP has uniform and smooth surfaces due to the absence of recognition sites for the analyte. In contrast, the roughness and randomness surface of the imprinted polymer electrodes were caused by the analyte-recognizing sites created. Based on the image of MIP-PGE (2), ZnO particles are shown clearly as the out layers on the surface. Therefore, the MIP-PGE (2) can be differentiated from the other electrodes due to their presence of Zn.

The EDX analysis was used to study the number of main chemicals present on the surface of electrodes. This analysis is a quantitative analysis. The EDX analysis of electrodes is shown in Fig. 2 and the main chemical composition present on the surface of electrodes has been tabulated and embedded in Fig. 2. The MIP-PGE (2) can be differentiated from the other electrodes due to their presence of Zn (2.39%). Low amounts of other elements are present on the electrode surface due to the oxidation effect and electrode impurity.

Analysis of PGE at Different Concentrations and Different Scan Rates

The PGE response at different concentrations of K3[Fe(CN)6] in 0.1 M KCl solution was observed, as shown in Fig. 3. The voltammogram indicates that the redox peak currents increase with increasing the concentration of K3[Fe(CN)6] due to the electron transfer from the solution to the surface of the PGE electrode being faster in higher electrolyte concentrations compared to the lower concentration. At 0.1 mM of K3[Fe(CN)6] in 0.1 M KCl, the redox peak currents produced are scarce and lead to lower electron transfer kinetics. As a result of its low performance, it was discarded from the experiment. The oxidation and reduction peaks were found at specified points with a specific pattern at concentrations of 1.0 and 5.0 mM of K3[Fe(CN)6]. At 10 mM of K3[Fe(CN)6], the redox peak currents produced the highest peak current and nearly reached the detection limit. Thus, 1.0 mM of K3[Fe(CN)6] in 0.1 M KCl was selected as an electrolyte due to its good selectivity and sensitivity. Hence, we can presume that the concentration in a higher ratio has a high impact on the peak of oxidation and reduction compared to a lower concentration of the solution.

The PGE response at different scan rates was performed in the 1.0 mM K3[Fe(CN)6] in 0.1 M KCl solution. The voltammogram showed that the current of the bare PGE is directly proportional to scan rate, as shown in Fig. 4. The higher the scan rate of the PGE electrode, the higher the redox peak current. The electrochemical characteristic will regain reversibility for higher scan rates when oxidation outcompetes the chemical process. At higher scan rates, the electrochemical process of oxidation will become dominant over any chemical reactions that might occur. This results in the restoration of the reversibility of the electrochemical process, which means that the electrode response becomes more predictable and reproducible. The chemical reactions that might have occurred at lower scan rates are no longer a factor, and the electrode response is determined mainly by the electrochemical process. In addition, faster scan rates reduce the size of the diffusion layer, resulting in higher currents [29]. Based on the result, the optimal voltammogram reversibility was found at a scan rate of 10 mV/s, and it was selected due to its good selectivity and sensitivity.

Electrochemical Behavior of Modified Electrodes

Different types of modified electrodes were scanned in 1.0 mM K3[Fe(CN)6] in 0.1 M KCl at 10 mV/s after the removal of the template by using cyclic voltammetry. The electrochemical behavior of modified electrodes can be seen in Fig. 5. The redox peak current of NIP-PGE (2) is slightly higher than GO/PGE. Fabricating ZnO nanoparticles with graphene oxide can improve the conductivity and performance of the sensor in the redox process [30]. The peak current of a bare electrode is almost similar to the peak current of GO/ZnO/PGE due to the non-fabricated compounds on the bare electrode. In addition, the electrodes fabricated with the molecularly imprinted molecule gave a higher redox peak current compared to other electrodes. MIP-PGE (2) obtained the highest peak current, followed by MIP-PGE (1). The modified electrode fabricated with the nanoparticle, MIP, and graphene oxide shows the best performance. Thus, MIP-PGE (2) was chosen to detect the AA due to its highest response in redox peak current.

Influence of Different Scan Rates to MIP-PG (2)

In order to investigate the diffusion-controlled process at the electrode surface, a linear Randles–Sevcik plot was used to analyze the relationship between the square root of the scan rates and the peaks in the redox current. It will depend on the scan rate for molecules that adsorb on the electrode surface. As shown in Fig. 6, the MIP-PGE (2) was scanned at various scan rates ranging from 5 to 100 mV/s in 1.0 mM K3[Fe(CN)6] in 0.1 M KCl. The reduction peak current increased as the square root of the scan rate increased, as well as the oxidation peak current increased as the square root of the scan rate increased [29]. A Randles–Sevcik plot as depicted in Fig. 7 shows the linear equation of the redox process. The linear equation for oxidation is Ipa = –3E–05x + 5E–05 with linear regression 0.9939 and the linear equation for the reduction process is Ipc = 2E–05x + 3E–05 with linear regression 0.9752. The results reveal that the system has occurred in a diffusion-controlled process. It was also observed that faster scan rates reduce the size of the diffusion layer. As a result, higher currents were obtained.

Determination of Ascorbic Acid by MIP-PGE (2) and DPV Response towards Ascorbic Acid

The DPV method is an electrochemically sensitive technique and it was employed in this study to identify the AA. Different concentrations of AA were observed by using MIP-PGE (2) as a working electrode with the optimum condition scan rate of 10 mV/s, pulse amplitude of 100 mV and pulse period of 200 ms as shown in Fig. 8. The intensity of AA’s oxidation peak current depends on its concentration. It clearly showed that the highest peak current is achieved at 50 mg/L.

The DPV response of MIP-PGE (2), MIP-PGE (1), bare electrode, and NIP-PGE (2) towards 50 mg/L AA and citrate buffer pH 4 is shown in Fig. 9. The NIP electrode did not produce any significant anodic peak current because no imprinted cavity was formed on its surface due to the absence of a template molecule (AA) during the electropolymerization. The PGE produced a minor anodic current response at 0.000244 A due to oxidation groups in the structure of AA. The anodic current response towards the MIP electrode is lower compared to the MIP-PGE (1). The MIP electrode did not show the highest response compared to other electrodes, although the presence of metallic nanoparticles, molecularly imprinted polymer and imprinted cavities.

CONCLUSIONS

In determining the electrochemical behavior of the modified electrode, the modified electrode has been deposited with the metallic nanoparticle (ZnO), graphene derivative (GO), and molecular imprinted polymer (PPy) by using the MIP technique. It shows the highest response of redox current compared to other modified electrodes. This reveals that the nanoparticle, MIP, and graphene derivative plays an important role on the electrode surface to increase the electrode performance. By having the imprinted cavities of the template molecule, the AA can be detected successfully by MIP-PGE (2). The concentration of the analyte and the scan rates also influenced the electrode performance. The straightforward instrumentation and easy preparation of the proposed sensor make the system helpful in constructing simple devices for the sensing and recognization of AA.

REFERENCES

Faridbod, F., Gupta, V.K., and Zamani, H.A., Electrochemical sensors and biosensors, Int. J. Electrochem., 2011, vol. 2011, p. 352546.

Bollella, P., Fusco, G., Tortolini, C., Sanzo, G., Favero, G., Gorton, L., and Antiochia, R., Beyond graphene: electrochemical sensors and biosensors for biomarkers detection, Biosens. Bioelectron., 2017, vol. 89, p. 152.

Lahcen, A.A., Rauf, S., Beduk, T., Durmus, C., Aljedaibi, A., Timur, S., Alshareef, H.N., Amine, A., Wolfbeis, O.S., and Salama, K.N., Electrochemical sensors and biosensors using laser-derived graphene: a comprehensive review, Biosens. Bioelectron., 2020, vol. 168, p. 112565.

Bard, A.J., Faulkner, L.R., and White, H.S., Electrochemical Methods: Fundamentals and Applications, Oxford: John Wiley & Sons, 2022.

Maduraiveeran, G. and Jin, W., Nanomaterials based electrochemical sensor and biosensor platforms for environmental applications, Trends Environ. Anal. Chem., 2017, vol. 13, p. 10.

Aghoutane, Y., Diouf, A., Osterlund, L., Bouchikhi, B., and El Bari, N., Development of a molecularly imprinted polymer electrochemical sensor and its application for sensitive detection and determination of malathion in olive fruits and oils, Bioelectrochemistry, 2020, vol. 132, p. 107404.

Dong, C., Shi, H., Han, Y., Yang, Y., Wang, R., and Men, J., Molecularly imprinted polymers by the surface imprinting technique, Eur. Polym. J., 2021, vol. 145, no. 2, p. 110231.

Lipskikh, O.I., Korotkova, E.I., Khristunova, Y.P., Barek, J., and Kratochvil, B., Sensors for voltammetric determination of food azo dyes—a critical review, Electrochim. Acta, 2018, vol. 260, p. 974.

Cui, B., Liu, P., Liu, X., Liu, S., and Zhang, Z., Molecularly imprinted polymers for electrochemical detection and analysis: progress and perspectives, J. Mater. Res. Technol., 2020, vol. 9, no. 6, p. 12568.

Güney, S., Arslan, T., Yanık, S., and Güney, O., An electrochemical sensing platform based on graphene oxide and molecularly imprinted polymer modified electrode for selective detection of amoxicillin, Electroanalysis, 2021, vol. 33, no. 1, p. 46.

Lahcen, A.A. and Amine, A., Recent advances in electrochemical sensors based on molecularly imprinted polymers and nanomaterials, Electroanalysis, 2019, vol. 31, no. 2, p. 188.

Özcan, L., Şahin, M., and Şahin, Y., Electrochemical preparation of a molecularly imprinted polypyrrole-modified pencil graphite electrode for determination of ascorbic acid, Sensors, 2008, vol. 8, p. 5792.

Zhang, M., Zhao, H.T., Xie, T.J., Yang, X., Dong, A.J., Zhang, H., Wang, J., and Wang, Z.Y., Molecularly imprinted polymer on graphene surface for selective and sensitive electrochemical sensing imidacloprid, Sens. Actuators B, 2017, vol. 252, p. 991.

Hosseinzadeh, A., Bidmeshkipour, S., Abdi, Y., Arzi, E., and Mohajerzadeh, S., Graphene based strain sensors: a comparative study on graphene and its derivatives, Appl. Surf. Sci., 2018, vol. 448, p. 71.

Ramalingam, R.J., Arunachalam, P., Amer, M.S., AlOthman, Z.A., Alanazi, A.G., Al-Anazy, M.M., Al-Lohedan, H.A., and Dahan, W.M., Facile sonochemical synthesis of silver nanoparticle and graphene oxide deposition on bismuth doped manganese oxide nanotube composites for electro-catalytic sensor and oxygen reduction reaction (ORR) applications, Intermetallics, 2021, vol. 131, p. 107101.

Dong, C., Shi, H., Han, Y., Yang, Y., Wang, R., and Men, J., Molecularly imprinted polymers by the surface imprinting technique, Eur. Polym. J., 2021, vol. 145, p. 110231.

Wang, F., Zhu, L., and Zhang, J., Electrochemical sensor for levofloxacin based on molecularly imprinted polypyrrole-graphene-gold nanoparticles modified electrode, Sens. Actuators B, 2014, vol. 192, p. 642.

Karimi-Maleh, H., Bananezhad, A., Ganjali, M.R., Norouzi, P., and Sadrnia, A., Surface amplification of pencil graphite electrode with polypyrrole and reduced graphene oxide for fabrication of a guanine/adenine DNA based electrochemical biosensors for determination of didanosine anticancer drug, Appl. Surf. Sci., 2018, vol. 441, p. 55.

Tan, F., Cong, L., Li, X., Zhao, Q., Zhao, H., Quan, X., and Chen, J., An electrochemical sensor based on molecularly imprinted polypyrrole/graphene quantum dots composite for detection of bisphenol A in water samples, Sens. Actuators B, 2016, vol. 233, p. 599.

Hussain, R.T., Islam, A.K.M.S., Khairuddean, M., and Suah, F.B.M., A polypyrrole/GO/ZnO nanocomposite modified pencil graphite electrode for the determination of andrographolide in aqueous samples, Alex. Eng. J., 2022, vol. 61, p. 4209.

Hasanjani, H.R.A. and Zarei, K., DNA/Au-Pt bimetallic nanoparticles/graphene oxide-chitosan composites modified pencil graphite electrode used as an electrochemical biosensor for sub-picomolar detection of anti-HIV drug zidovudine, Microchem. J., 2021, vol. 164, p. 106005.

Hossain, M.A., Munné-Bosch, S., Burritt, D.J., Diaz-Vivancos, P., Fujita, M., and Lorence, A., Ascorbic Acid in Plant Growth, Development and Stress Tolerance, Cham: Springer, 2017.

Iqbal, K., Khan, A., and Khattak, M., Pak. J. Nutr., 2004, vol. 3, p. 5.

Zhang, Y., Ascorbic Acid in Plants: Biosynthesis, Regulation and Enhancement, New York, Heidelberg, Dordrecht, London: Springer Science & Business Media, 2012.

Chen, J., Yao, B., Li, C., and Shi, G., An improved Hummers method for eco-friendly synthesis of graphene oxide, Carbon, 2013, vol. 64, p. 225.

Ghalkhani, M., Shahrokhian, S., and Navabi, M., Development of an electrochemical sensor based on (rGO-CNT) nanocomposite for raloxifene analysis, Mater. Chem. Phys., 2021, vol. 263, p. 124131.

Yaqoob, A.A., Ibrahim, M.N.M., Yaakop, A.S., Umar, K., and Ahmad, A., Modified graphene oxide anode: a bioinspired waste material for bioremediation of Pb2+ with energy generation through microbial fuel cells, Chem. Eng. J., 2021, vol. 417, p. 128052.

Nacef, M., Chelaghmia, M.L., Affoune, A.M., and Pontié, M., Electrochemical investigation of glucose on a highly sensitive nickel-copper modified pencil graphite electrode, Electroanalysis, 2019, vol. 31, p. 113.

Elgrishi, N., Rountree, K.J., McCarthy, B.D., Rountree, E.S., Eisenhart, T.T., and Dempsey, J.L., A practical beginner’s guide to cyclic voltammetry, J. Chem. Educ., 2018, vol. 95, p. 197.

Shtepliuk, I., Ivanov, I.G., Vagin, M., Khan, Z., Iakimov, T., Pliatsikas, N., Sarakinos, K., Giannazzo, F., and Yakimova, R., Manipulation of epitaxial graphene towards novel properties and applications, Mater. Today: Proc., 2020, vol. 20, p. 37.

Funding

This work was supported by ongoing institutional funding. No additional grants to carry out or direct this particular research were obtained.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yaacob, S.F., Din, S.N. & Suah, F.B. Ascorbic Acid Sensor Using Modified Pencil Graphite Electrodes: A Preliminary Study. Russ J Electrochem 60, 392–399 (2024). https://doi.org/10.1134/S1023193524050094

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1023193524050094