Abstract

In the present study, Clopidogrel (CLP), an anti-platelet drug, was analyzed utilizing electropolymerized o-aminophenol (EpoAP) and multi-walled carbon nanotubes (MWCNTs) modified graphite electrode (GE). The prepared electrode was characterized by Cyclic Voltammetry (CV) and Scanning Electron Microscopy (SEM) techniques. The dependence of peak intensities on pH, scan rate, and MWCNTs amount were further investigated. Electrochemical determination of CLP was evaluated by Differential Pulse Voltammetry (DPV) and CV analysis under optimized working conditions. The calibration curves of CLP obtained in the range of 2.0–75.0 µM by DPV and 50.0–200.0 µM by CV. The limits of detection (LOD) calculated to be 0.50 and 6.6 µM via DPV and CV, respectively. In addition, surface area and coverage of the modified electrode, electron-transfer coefficient, and the diffusion coefficient of CLP were calculated. Finally, the fabricated electrode was proved successfully for quantification of CLP in pharmaceuticals directly, which means it’s not necessary to separate the excipients of the tablets for the analysis, with a mean recovery of 97.49%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Clopidogrel hydrogen sulphate, chemically it is methyl (+)-(S)-α-(o-chlorophenyl)-6,7-dihydrothieno (3,2-c) pyridin-5(4H)-acetate hydrogen sulphate. As illustrated in Fig. 1, the molecular formula is C16H16ClNO2S.H2SO4. Clopidogrel (CLP), a potent antiplatelet agent (thienopyridine class), inhibits adenosine diphosphate-mediated platelet aggregation [1]. Clopidogrel is an inactive pro-drug which needs enzymatic transformation into its active metabolite by various types of cytochromes P450 (CYP) enzymes [2]. It is indicated for the reduction of atherosclerotic events in patients with atherosclerosis documented by recent stroke, myocardial infarction, or cardiovascular disease [2–5]. Hence, various analytical methods such as chromatography with different detectors [6–8], spectroscopy [9], electrochemical sensors [10–12], potentiometry [13, 14] and capillary electrophoresis have been reported for to the determination of CLP [15]. Chromatography methods suffered from methodological limitations such as time-consuming, high cost and difficulty of fabricating. On the other hand, electrochemical methods possess beneficial features such as; rapidity, sensitivity, ease of fabricating and affordability [16–18]. Various nano-sized materials have been utilized for development of electrochemical sensors.

Carbon nanotubes (CNTs) have unique properties such as fast electron transfer rate, excellent electrocatalytic effect, tensile strength, high conductivity, biocompatibility, and chemical stability [19, 20]. Depending on their atomic structure, CNTs behave electrically either as a metal or a semiconductor and offer a high electron transfer rate between the electrode surface and analytes, which can improve performances of biosensors and nanosensors [21]. Despite these interesting features, they lack sufficient, which might impair CNTs-based devices. Therefore, we cannot immobilize CNT onto the electrodes surfaces in a stable and uniform because of this limitation manner [18, 22]. In order to overcome this difficulty, in situ electropolymerization is a simple yet powerful procedure for developing of stable CNT modified electrodes in electrochemical sensors [23, 24].

Conducting polymer-CNT modified electrodes are of great interest due to their three-dimensional structures of the polymers that provide the opportunity for incorporating of CNTs into them and high surface areas [25]. In addition, conducting polymer-CNT based devices represent other advantages including stability, reproducibility, homogeneity, many active sites regions and excellent adherence to the electrode surface [26]. In the literature survey, various conducting polymers including poly (phenylene vinylene) [27], polypyrrole [28], polyaniline [29] and polythiophene [30] have been applied. The polymer-CNT modified electrodes were successfully applied for the constructing of electrochemical sensors. Among conducting polymer systems, polyaniline has been of much interest owing to its great electrochemical properties [31]. o-Aminophenol with the formula of C6H7NO is one of substituted anilines with two oxidizable substituents, exciting stability, easy doping, and its inherent conductivity [18, 20, 32]. These conjugated polymer structures are known to be strongly coupled to carbon nanotubes through π–π stacking interactions [33]. It has been demonstrated that the blending of carbon nanotubes (CNTs) with a polymer network improves the electric conductivity as well as the mechanical property of the pure polymer network [32].

However, to the best of our knowledge, there has been no report focusing on the application of EpoAP-MWCNTs to electrochemical detection of CLP. Herein, we applied an interesting and simple procedure for immobilizing MWCNTs on the surface of (graphite electrode) GE via in situ electropolymerization in the absence and presence of o-aminophenol (oAP). The voltammetric detection of CLP based on Electropolymerized o-Aminophenol (EpoAP)-MWCNTs nanocomposite by means of Cyclic Voltammetry (CV), differential Pulse Voltammetry (DPV) and Chronoamperometry techniques has been done. The surface properties of the modified electrode has been characterized by Scanning Electron Microscopy (SEM) and CV techniques. Moreover, kinetic, thermodynamic and electrochemical parameters including electron transfer and diffusion constant have been investigated using electrochemical techniques. Under optimum conditions, the modified electrode has been employed to detect CLP in pharmaceutical products and the assay results compared with the analysis of the same samples (same batch number) by HPLC method reported in the current United States Pharmacopoeia.

EXPRIMENTAL

Chemicals

CLP hydrogen sulfate standard powder (100.20% according to the USP-NF 2016) has received as a gift from the Iranian Quality Control Laboratory of the Ministry of Health and Medical Education Department (Tehran, Iran). MWCNTs (>97% purity, diameter <10 nm, 5–15 µm length with a special surface area of 180–190 m2 g−1) were obtained from Neutrino Co. (Tehran, Iran). The pharmaceutical samples of CLP have purchased from a local pharmacy. OSVIX tablets are labeled to contain Clopidogrel (as hydrogen sulfate) equivalent to 75 mg of CLP manufactured by OSVAH pharmaceutical Co (Tehran, Iran). All other chemicals in this study were of analytical grade (Merck, Darmstadt, Germany) and used without further purification.

Apparatus

All electrochemical experiments were performed by an electrochemical system comprising of AUTOLAB potentiostat/galvanostat coupled with a NOVA commercial software as well as a conventional three-electrode cell including Ag/AgCl, platinum wire, and a graphite electrode as reference, counter and working electrode (0.0314 cm2 surface area); purchased from Azar Electrode Co., Urmia, Iran. The surface morphology of the modified electrode was characterized using scanning electron microscopy (SEM, S-4160, Hitachi, Japan). All pH values were determined with a digital pH meter model 827-pH lab (Metrohm, Switzerland).

Preparation of Britton–Robinson Buffer and Stock Solutions

Britton–Robinson Buffer (BRB) solutions were prepared by mixing 0.4 M of three acid (i.e., acetic, sulfuric, and boric acids). Buffer pH has adjusted to the demanded value by 0.2 M NaOH solution and applied as a supporting electrolyte. Stock solutions of CLP (10 mM) were prepared by dissolving the powder in an appropriate volume of methanol and kept at 4°C. Standard solutions were daily prepared by diluting stock solutions using BRB solution.

Fabrication of EpoAP-MWCNTs Based Electrode

Due to low solubility of MWCNTs in water, it is necessary to purify them and generate active groups into the structure of MWCNTs [34]. In order to prepare carboxylic groups in MWCNTs, we have treated them with strong acid to increase the solubility. Herein, MWCNTs have purified by the following procedure: Firstly, 0.2 g MWCNTs added to 10 mL HNO3 and 30 mL H2SO4 for 0.5 h at room temperature. Secondly, the resulted suspension refluxed for 4 h at 65–70°C to avoid the partial destruction. Then, 15 mL H2O2 added to the solution drop by drop until brownish NO2 gas released. Purified MWCNTs were sonicated, after 24 h deionized water added to them. The pH of carboxylated MWCNTs has adjusted to 7.0 with NaOH and stored for 48 h in a dark place. The MWCNTs centrifuged and rinsed with deionized water several times (Scheme 1). Then, GE polished by alumina powder, washed by deionized water carefully, and dried at room temperature. Black homogeneous MWCNTs dispersion (0.8 mg mL–1) in deionized water has achieved by ultrasonication of the dispersion in an ultrasonic for 30 min. Then, 3 µL of the freshly prepared suspension was dropped on the polished surface of the GE and allowed to dry for 10 min in an oven at 50°C. On the other hand, 0.01 M oAP monomeric solution has been dispersed in 0.5 M HClO4 to prepare a solution. Thereafter, oAP was electropolymerized on the GE by repetitive voltammogram cycling (50 scans) in a potential window of –0.3 to 1.2 V at a scan rate of 0.1 V s–1. MWCNTs–EpoAP/GE has prepared by the same procedure, while 8% w/w MWCNTs added (Scheme 1). The modified electrodes characterized by CV and SEM techniques.

The resulted sensor was successfully applied for at least 15 measurements without losing its function. After that the response started to decrease. Therefore, we polished the modified electrode by alumina powder, washed with deionized water carefully, and dried at room temperature. Then the bare GE was modified again by MWCNTs–EpoAP as same as described above.

Scheme 1 . (1) Purification and carboxylation of MWCNTs, (2) proposed mechanism of the electropolymerization of oAP and (3) fabrication of EpoAP–MWCNTs/GE.

Preparation of Solid Dosage Forms Solutions

Ten tablets (each containing 75 mg CLP) pulverized to a fine powder and mixed well. An aliquot powder with equivalent weight of one tablet was transferred into a 100 mL volumetric flask containing 50 mL methanol. The solution was sonicated for 5 min to ensure complete dissolution of CLP. Then 5 mL of the prepared solution was diluted to 100 mL using BRB (pH 3.7).

RESULTS AND DISCUSSION

Cyclic Voltammetry Characterization of the Modified Electrodes

The oAP monomer in the presence of the 8% w/w MWCNTs was electropolymerized on the GE surface by repetitive voltammogram cycling (50 scans) in a potential window of –0.3 to 1.2 V at a scan rate of 0.1 V s–1. As seen in Fig. 2a, at the first scan two peaks are defined: one peak (A1) at 0.60 V is attributed to the oxidation of oAP to monocation radical (oAP+) and another peak (A2) around 0.85 V probably due to the oxidation of the oAP+ to dication [35]. On the reverse scan none of these peaks shows complementary peaks, indicating irreversibly oxidation of the monomers [18]. At the second cycle, a pair of redox peaks appeared at 0.3 and 0.31 V (A3–C3) attributed to the formation of an intermediate during the oxidation process of the oAP and another pair at 0.1 and 0.23 V (A4–C4) is related to the redox process of the phenoxazine units. When the number of CV cycles is increased, the current of the redox peaks at around A3–C3 gradually declined because of oAP monomer absence, implying generation of the polymer [18, 32, 35]. Also, EpoAP was fabricated at the bare graphite electrode in the same way. As illustrated in Fig. 2b, a board anodic peak around 0.8 V, at the first scan, was observed which is related to the irreversibly oxidation of the –OH and NH2 groups of oAP, resulting in the formation of mono-cation radicals on the surface of GE [18, 32]. However, the anodic peak around 0.8 V dropped slowly after continuous cycling indicating that the oxidation process cannot significantly occurred after multiple cycles [36].

Characterization of the Modified Electrodes by SEM Technique

The surface morphology of the EpoAP/GE and EpoAP–MWCNTs/GE nanocomposites were characterized using SEM technique. The SEM micrographs of EpoAP/GE and EpoAP–MWCNTs/GE are represented in Figs. 3a and 3b. Figure 3a micrograph indicates that the EpoAP/GE surface has a globular (spherical) structure that was in compact and uniform state on the surface of electrode. A large number of polymer chains were generated these globular particles. Figure 3c shows the EpoAP/GE in the higher magnification (500 nm). A very high magnification of SEM micrograph of EpoAP shows the coexistence of particle agglomerates, resulting in formation of a coarse surface. It could be seen from Fig. 3b that MWCNTs is well blended into the 3D globular structure of EpoAP. No distinct MWCNTs can be observed on the micrograph, implying that the MWCNTs are probably wrapped by EpoAP [37]. A strong interconnected network was generated between MWCNTs and EpoAP matrix, which enhanced electron transfer properties of the nanocomposite. This observation is well similar to the other reported studies [37–39]. In the previous reports, the prepared EpoAP structure has been characterized via spectroscopy, FT-IR, and the other techniques [40–42].

Electrochemical Behaviors of the Modified Electrodes

Figure S1 (Supporting Materials) shows the cyclic voltammogram recorded with the bare GE in a 0.5 M HClO4 solution (curve 1). The voltammogram shows no peaks in the potential window of experiment. Figure S1 (curve 2 and 3) display the cyclic voltammograms recorded with the EpoAP/GE and EpoAP–MWCNTs/GE in a 0.5 M HClO4 solution, respectively. Curve 2 and 3 represented a pair of redox peaks at around 0.1 and –0.1 V are attributed to the redox process of the phenoxazine units. In order to evaluate of the effect of MWCNTs on the property of EpoAP film, electrochemical performance of the EpoAP–MWCNTs/GE was examined by carrying out cyclic voltammogram experiment at the same condition (0.5 M HClO4 solution). As seen in Fig. S1 (curve 3), the recorded cyclic voltammogram of the EpoAP–MWCNTs /GE shows a pair of redox peaks at around 0.1 and –0.1 V. The results revealed that the presence of the EpoAP–MWCNTs/GE could increase the peaks in comparison to EpoAP/GE.

Effect of MWCNTs Amount

The thickness of the polymeric film affect the electrochemical response, hence, this thickness is controlled by changing the MWNCTs amount during the electrochemical polymerization. This was performed by measuring CV results, obtained by adding various amount of the MWCNTs (1–15% w/w) to the constant amount of oAP. As shown in Fig. S1 inset, the current of CVs dramatically increased with the increase of the MWCNTs amount from 1 to 8% w/w, while starts to slightly decrease when MWCNTs amount continues to increase from 8 to 15% w/w. This behavior is due to a saturation limit near 8%w/w. Subsequently, using higher amount of MWCNTs may adversely affect the sensitivity of the CLP detection. Thus, the optimal value of MWCNTs was selected to be 8%w/w for whole electrochemical experiments.

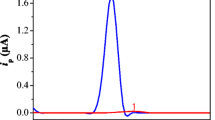

Electrochemical Behavior of CLP at the Surface of the EpoAP–MWCNTs/GE

Cyclic voltammograms in the Fig. 4 represented the electrochemical oxidation of CLP at the bare, MWCNTs, EpoAP, EpoAP–MWCNTs modified GEs in BRB solution (pH 3.7) containing 100 μM CLP. CLP exhibits an anodic peak around 1.15 V, and in the reverse scan, no cathodic peak was observed. The anodic peak current of CLP at modified electrodes is higher than that of unmodified, which can be in this order; EpoAP–MWCNTs > EpoAP > MWCNTs > bare. These results have evidenced for enhanced electrochemical performances of these nanocomposites towards CLP oxidation, suggesting an interesting electrical construction on the electrode surface and accelerating the electron transfer through it. It is assumed that hydroxyl and amine bonds were formed between polymeric film at the surface of the electrode and a carboxylic group of CLP molecule, resulting in improvement of charge transfer kinetics of CLP at the surface of EpoAP–MWCNTs/GE.

Effect of pH

The pH of solution plays an important role in the electrochemical behavior of CLP during voltammetric experiments at EpoAP–MWCNTs/GE. To investigate of pH effect, electrochemical response of 180 µM CLP in BRB solution over a pH range (from 1.0 to 6.0) was studied. According to the Fig. S2, anodic peak current of CLP increases with increasing pH till 3.7. Afterward, the peak current decreases with increasing pH, possibly because of decreasing solubility of CLP at neutral and basic media [43]. In order to get the highest oxidation current peak, the electrochemical determination of CLP was performed at pH 3.7 (BRB solution).

Effect of Scan Rate

In Fig. 5a, the influence of the potential scan rate with CLP electrochemical reaction at EpoAP–MWCNTs/GE was examined by cyclic voltammetry. Gradual increasing of the oxidation peak current were observed with increasing scan rate, and the oxidation peak current versus square root of scan rate display an excellent linear proportionality over the range of 20 to 1000 mV s−1 (Fig. 5d). This behavior imply that the electrochemical oxidation of CLP at the EpoAP–MWCNTs/GE is a diffusion-controlled process. In addition, dependence of peak on the logarithm of scan rate was also plotted for EpoAP–MWCNTs/GE in Fig. 5b. It can be realized from Fig. 5b that, with increasing scan rate, the oxidation peak potential shifts to more positive potentials. The relationship between peak potential and logarithm of scan rate corresponded to the equation as follow: Epa (V) = 0.0568 log v (V/s) + 1.0895 (R2 = 0.997). The electron transfer coefficient (αn) for the reaction can be achieved from the following equation, which is suitable for totally irreversible diffusion-controlled process [44, 45]:

(a) Recorded CVs of the EpoAP–MWCNTs/GE in BRB solution (pH 3.7) containing 100 µM CLP with different scan rates (from inner to outer correspond to v = 0.002, 0.005, 0.01, 0.02, 0.03, 0.04, 0.05, 0.075, 0.1, 0.15, 0.25, 0.4, and 0.9 V s−1). (b) The relationship between the peak potentials and the natural logarithm of scan rate. (c) The dependency of the natural logarithm of peak current on (Ep – E0'), which Ep is the peak potential and E0' is the formal potential. (d) Linear relationship between the anodic peak currents of CVs and the square root of scan rates using 10 mM [Fe(CN)6]3–/4– and 0.1 M KCl solution. Error bars indicate the standard deviation (SD) of three times measurements (n = 3).

On the basis of this equation, the evaluated slope of the Ep vs. log v is b/2 = 56.8 mV, therefore b (Tafel slope) = 113.6. The value of the electron transfer coefficient for CLP oxidation on EpoAP–MWCNTs/GE was calculated to be 0.48. These results indicated that the number of electrons involved in the electrochemical oxidation of CLP is one.

The surface area of the EpoAP–MWCNTs/GE was determined using 10 mM [Fe(CN)6]3–/4– and 0.1 M KCl solution by cyclic voltammetry technique (Fig. 5d). For a reversible process, the Randles–Sevcik equation was reported as follow [46]:

Where Ipa, n, A, D0, v, and C0 are the anodic peak current, the number of electron transfer (n = 1), the surface area of the electrode (cm2), the diffusion coefficient (7.6 × 10–6 cm2 s–1), the scan rate and the concentration of [Fe(CN)6]3–/4– (10 × 10–6 mol cm–3). Therefore, from the slope of Ipa versus square root of scan rate (v1/2), the active surface area of the EpoAP–MWCNTS/GE was found to be 0.53 cm2, indicating that the surface area of the modified electrode was increased by deposition of EpoAP-MWCNTs nanocomposite.

Calculation of Surface Coverage on the Surface of the Modified Electrode

The surface coverage of the GE was determined in 0.5 M HClO4 at a scan rate of 0.1 V s−1 by CV according to the following equation [47, 48]:

Considering this equation, the peak current (Ip) is related to the surface concentration of the electroactive species (Γ). Where n represents the number of electrons involved in the reaction, A is the surface area of the electrode, Γ (mol cm–2) is the surface concentration, and the other symbols have their common meanings. Subsequently, from the slope of plotting Ip against the scan rate (v), the surface concentration calculated to be 3.44 × 10−6 mol cm−2.

Electrochemical Determination of CLP

CV and DPV techniques were applied to determine the sensitivity of EpoAP–MWCNTs/GE in terms of concentration range and the quantification and detection limits for the CLP. Figure 6a represents the recorded CVs of BRB solution (pH 3.7) containing various concentrations of CLP over the range of 50–200 µM using EpoAP–MWCNTs/GE under the optimized condition. The response of the nanosensor was increased linearly with increasing CLP concentration at the range of 50–200 µM (Fig. 6a, inset). The regression equation was derived as; Ipa (mA cm–2) = 0.1299[CLP] µM + 16.087, R2 = 0.9991. LOQ and LOD values were obtained using the equations as follows:

Where σ is the standard deviation of the y-intercept and S is slope of the calibration curve. Consequently, using CV technique, the LOD and LOQ were determined to be 20.1 and 6.6 µM, respectively. DPV technique was also utilized to achieve a lower linear range of concentrations using EpoAP–MWCNTs/GE. Figure 6b displays the recorded DPVs of BRB solution (pH 3.7) CLP at various concentration. The corresponding calibration curve (Fig. 6b, inset) shows a linear concentration range of 2.0–75.0 µM. The regression equation was Ipa (mA cm–2) = 0.0701[CLP] µM + 0.0678 and correlation coefficient R2 = 0.9978 in this range. According above equations, the LOD and LOQ were calculated to be 0.5 and 2.0 µM, respectively.

(a) CVs of the EopAP–MWCNTs/GE in the solutions containing different concentrations (from bottom to top, 0, 40, 50, 70, 100, 120, 140, 160, 180, and 200 µM) of CLP. Conditions: in BRB buffer (pH 3.7); scan rate: 0.1 V s−1. Inset: the corresponding linear relationship between the CV currents and CLP concentration. (b) Dependence of the DPV response at the EpoAP–MWCNTs/GE surface on the CLP concentration in BRB (pH 3.7): Concentrations from bottom to top are 0, 2, 5, 7.5, 15, 20, 30, 40, and 75 µM. Insets show the corresponding calibration graphs. Error bars indicate the standard deviation (SD) of three times measurements (n = 3).

The results obtained from these techniques were summarized in the Table1.

Chronoamperometric Studies

Chronoamperometry was employed for the investigation of the electrode process as well. Figure 7a shows the current-time profiles obtained by setting the EpoAP–MWCNTs/GE at 0.9 V for the various concentrations of CLP in the range of 80–200 µM in BRB solution (pH 3.7). The useful net current signals were linearly dependent on the concentration of CLP which is recorded at 90 seconds (Fig. 7b). Herein, a diffusion-controlled mechanism is dominant in electro-oxidation process, which obtained in the previous section by CV technique. Diffusion coefficient of the CLP using the slopes of these lines can be obtained according to the Cottrell equation [47, 49]:

Where D, C*, n, F, and A are the diffusion coefficient, the bulk concentration, the number of electrons, Faraday’s constant and electrode area, respectively. The plot of net currents against the minus square roots is linear and according to the Cottrell equation (Fig. 7c). From the slope, the diffusion coefficient of CLP was calculated to be 2.4 × 10–6 cm2 s–1.

(a) Chronoamperograms of different concentrations of CLP: 0, 50, 70, 100, 120, 140, 160, 180, and 200 µM on the surface of EpoAP–MWCNTs/GE in BRB. The potential step was 0.9 V. (b) DPV responses as a function of concentrations of CLP from 0 to 200 µM (n = 3), and (c) the plot of transient current versus t−0.5.

Analytical Application of EpoAP–MWCNTs/GE

To assess the applicability of the proposed method, the EpoAP–MWCNTs/GE and a reliable HPLC method [50] were used to determine the content of CLP in “Clopidogrel” tablets as a real pharmaceutical sample. The developed nanosensor has been assessed for practical applicability. To this purpose, pharmaceutical samples of CLP were evaluated by using EpoAP–MWCNTs/GE and compared with HPLC method. The result yielded 97.49 and 100.5% of label claim using the proposed nanosensor and HPLC, respectively (n = 3 for each method). In the fabricated nanosensor, the recovery was calculated by comparing the CLP response in the tablet solution and that of in standard solution with CLP direct addition. The recoveries were 95.4–98.2% (n = 3), with a RSD lower than 3%. The findings indicated that the developed nanosensor is well suitable for the micro-molar detection of CLP in the presence of excipients in tablets which may have potential application in bio-clinical. Finally, the performance of the prepared device for CLP determination is compared with results reported by other methods [11, 12, 51–53] in the Table 2.

CONCLUSIONS

In this paper, we designed a nano-device utilizing EpoAP–MWCNTs nanocomposite for sensitive detection of CLP by electrochemical techniques. The results showed that combination of EpoAP and MWCNTs in the fabricated electrode can lead to extraordinarily sensitivity for determination of CLP. This behavior is most probably due to three dimensional structure of the nanocomposite, which cause excellent electrochemical performance and higher electroactive surface area for sensing purpose. Application of the fabricated sensor for the determination of CLP in pharmaceuticals exhibited satisfactory results, even in the presence of excipients. In the Table 2, the obtained results were compared with the other studies according to linearity range, LOD and LOQ values. The proposed sensor displayed LOD value of 0.5 µM which is comparable or lower than other published methods. In additionally, EpoAP–MWCNTs/GE exhibited a fast response, high sensitivity, good precision and accuracy. Considering all these advantages, the present nanosensor can also be utilized for sensitive quantification of other molecules of biomedical interest.

REFERENCES

Mehta, S.R., Yusuf, S., Peters, R.J., Bertrand, M.E., Lewis, B.S., Natarajan, M.K., Malmberg, K., Rupprecht, H.J., Zhao, F., and Chrolavicius, S., Effects of pretreatment with clopidogrel and aspirin followed by long-term therapy in patients undergoing percutaneous coronary intervention: the PCI-CURE study, Lancet, 2001, vol. 358, p. 527.

Frishman, W.H., Cheng-Lai, A., and Nawarskas, J., Current Cardiovascular Drugs, London: Current Medicine Group, 2005.

Huynh, K., Clopidogrel is a favourable alternative to ticagrelor in older patients with NSTE-ACS, Nat. Rev. Cardiol., 2020, vol. 17, p. 384.

Savi, P., Pereillo, J., Uzabiaga, M., Combalbert, J., Picard, C., Maffrand, J., Pascal, M., and Herbert, J., Identification and biological activity of the active metabolite of clopidogrel, Thromb. Haemost., 2000, vol. 84, p. 891.

Xu, L., Hou, Y., Zhang, M., Yang, X., Jenkins, G., Huang, W., Yao, C., and Wu, Q., A novel electrochemical biosensor for detection of cholesterol, Russ. J. Electrochem., 2016, vol. 52, p. 239.

Bahrami, G., Mohammadi, B., and Sisakhtnezhad, S., High-performance liquid chromatographic determination of inactive carboxylic acid metabolite of clopidogrel in human serum: application to a bioequivalence study, J. Chromatogr. B, 2008, vol. 864, p. 168.

Mitakos, A. and Panderi, I., A validated LC method for the determination of clopidogrel in pharmaceutical preparations, J. Pharm. Biomed. Anal., 2002, vol. 28, p. 431.

Mitakos, A. and Panderi, I., Anal. Chim. Acta, 2004, p. 107.

Cholke, P.B., Ahmed, R., Chemate, S., and Jadhav, K., Development and validation of spectrophotometric method for clopidogrel bisulfate in pure and in film coated tablet dosage form, Arch. Appl. Sci. Res., 2012, vol. 4, p. 59.

Satyanarayana, M., Goud, K.Y., Reddy, K.K., Kumar, V.S., and Gobi, K.V., Silver nanoparticles impregnated chitosan layered carbon nanotube as sensor interface for electrochemical detection of clopidogrel in-vitro, Mater. Sci. Eng. C, 2019, vol. 101, p. 103.

Dizavandi, Z.R., Aliakbar, A., and Sheykhan, M., Electrocatalytic determination of clopidogrel using Bi2O3-Pp-AP/GCE by differential pulse voltammetry in pharmaceutical productions, J. Electroanal. Chem., 2017, vol. 805, p. 24.

Nascimento, L.O., Scremin, J., Mattos, G.J., Gomes, A., Clausen, D.N., and Sartori, E.R., A novel strategy for quantifying clopidogrel using square-wave voltammetry and a boron-doped diamond film, Electroanalysis, 2020, vol. 32, p. 191.

Khorshid, A.F., Determination of clopidogrel bisulphate in plavix tablet and human biological fluids utilizing chemically modified carbon paste sensor, J. Bioprocess Biotech., 2014, vol. 4, no. 3.

Rele, R.V. and Rane, D.G., A validated non-aqueous potentiometric titration method for quantitative determination of clopidogrel bisulphate from pharmaceutical preparation, Asian J. Chem., 2017, vol. 10, p. 26.

Fayed, A.S., Weshahy, S.A., Shehata, M.A., Hassan, N.Y., Pauwels, J., and Hoogmartens, J., Separation and determination of clopidogrel and its impurities by capillary electrophoresis, J. Pharm. Biomed. Anal., 2009, vol. 49, p. 193.

Nematollahi, D., Feyzi Barnaji, B., and Amani, A., Electrochemical evidences for the reaction of N-acetyl-p-benzoquinone-imine with organosulfur compounds contained in garlic and onion extracts. Treatment of acetaminophen poisoning using garlic and onion extracts, J. Sulphur Chem., 2015, vol. 36, p. 1.

Idris, A.O., Mafa, J.P., Mabuba, N., and Arotiba, O.A., Nanogold modified glassy carbon electrode for the electrochemical detection of arsenic in water, Russ. J. Electrochem., 2017, vol. 53, p. 170.

Wen, W., Zhao, D.M., Zhang, X.H., Xiong, H.Y., Wang, S.F., Chen, W., and Zhao, Y.D., One-step fabrication of poly(o-aminophenol)/multi-walled carbon nanotubes composite film modified electrode and its application for levofloxacin determination in pharmaceuticals, Sens. Actuators B: Chem., 2012, vol. 174, p. 202.

Mohammadi, A., Moghaddam, A.B., Eilkhanizadeh, K., Alikhani, E., Mozaffari, S., and Yavari, T., Electro-oxidation and simultaneous determination of amlodipine and atorvastatin in commercial tablets using carbon nanotube modified electrode, Micro Nano Lett., 2013, vol. 8, p. 413.

Gopal, J.V., Reddy, M.J., and Kannabiran, K., Immobilization of an antibacterial compound from Streptomyces sp. onto multi-walled carbon nanotubes, Russ. J. Electrochem., 2021, vol. 57, p. 92.

Oliveira, T.M. and Morais, S., New generation of electrochemical sensors based on multi-walled carbon nanotubes, Appl. Sci., 2018, vol. 8, p. 1925.

Moghaddam, A.B., Mohammadi, A., Mohammadi, S., Rayeji, D., Dinarvand, R., Baghi, M., and Walker, R.B., The determination of acetaminophen using a carbon nanotube:graphite-based electrode, Microchim. Acta, 2010, vol. 171, p. 377.

Wu, K. and Hu, S., Deposition of a thin film of carbon nanotubes onto a glassy carbon electrode by electropolymerization, Carbon, 2004, vol. 42, p. 3237.

Li, Y., Wang, P., Wang, L., and Lin, X., Overoxidized polypyrrole film directed single-walled carbon nanotubes immobilization on glassy carbon electrode and its sensing applications, Biosens. Bioelectron., 2007, vol. 22, p. 3120.

Barsan, M.M., Ghica, M.E., and Brett, C.M., Electrochemical sensors and biosensors based on redox polymer/carbon nanotube modified electrodes: a review, Anal. Chim. Acta, 2015, vol. 881, p. 1.

Jin, G., Huang, F., Li, W., Yu, S., Zhang, S., and Kong, J., Sensitive detection of trifluoperazine using a poly-ABSA/SWNTs film-modified glassy carbon electrode, Talanta, 2008, vol. 74, p. 815.

Woo, H., Czerw, R., Webster, S., Carroll, D., Park, J., and Lee, J., Organic light emitting diodes fabricated with single wall carbon nanotubes dispersed in a hole conducting buffer: the role of carbon nanotubes in a hole conducting polymer, Synth. Met., 2001, vol. 116, p. 369.

Schnoor, T.I., Smith, G., Eder, D., Koziol, K.K., Burstein, G.T., Windle, A.H., and Schulte, K., The production of aligned MWCNT/polypyrrole composite films, Carbon, 2013, vol. 60, p. 229.

Dhand, C., Solanki, P.R., Datta, M., and Malhotra, B., Polyaniline/single-walled carbon nanotubes composite based triglyceride biosensor, Electroanalysis, 2010, vol. 22, p. 2683.

Coleman, J., Curran, S., Dalton, A., Davey, A., Carthy, B., Mc., Blau, W., and Barklie, R., Physical doping of a conjugated polymer with carbon nanotubes, Synth. Met., 1999, vol. 102, p. 1174.

Liu, F., Dong, S., Zhang, Z., Dai, X., Xin, Y., Wang, X., Liu, K., Yuan, Z., Zhang, J., and Chen, M., Polyaniline/MWCNT nanocomposite as sensor for electroanalytical determination of phenol in oil field wastewater, Int. J. Electrochem. Sci., 2019, vol. 14, p. 9122.

Ajami, N. and Panah, N.B., One-step electrosynthesis of multi-walled carbon nanotube/poly-ortho-aminophenol composite film and investigation of its electrocatalytic properties, J. Nanostruct. Chem., 2013, vol. 3, art. no. 76.

Gajendran, P. and Saraswathi, R., Enhanced electrochemical growth and redox characteristics of poly(o-phenylenediamine) on a carbon nanotube modified glassy carbon electrode and its application in the electrocatalytic reduction of oxygen, J. Phys. Chem., 2007, vol. 111, p. 11320.

Das, R., Hamid, Sb., Ali, M., Annuar, Ms., Samsudin, Em., and Bagheri, S., Covalent functionalization schemes for tailoring solubility of multi-walled carbon nanotubes in water and acetone solvents, Sci. Adv. Mater., 2015, vol. 7, p. 2726.

Barbero, C., Silber, Jj., and Sereno, L., Formation of a novel electroactive film by electropolymerization of ortho-aminophenol: study of its chemical structure and formation mechanism. Electropolymerization of analogous compounds, J. Electroanal. Chem. Interfacial Electrochem., 1989, vol. 263, p. 333.

Sayyah, Sm., El-Rabiey, Mm., El-Rehim, Sa., and Azooz, Re., Electropolymerization kinetics of o-aminophenol and characterization of the obtained polymer films, J. Appl. Polym. Sci., 2006, vol. 99, p. 3093.

Hao, Z., Zheng, W., Yu, W., and Long, B., Electrical conductivity of poly(vinylidene fluoride)/carbon nanotube composites with a spherical substructure, Carbon, 2009, vol. 47, p. 2118.

Verma, S.K., Kar, P., Yang, D.J., and Choudhury, A., Poly(m-aminophenol)/functionalized multi-walled carbon nanotube nanocomposite based alcohol sensors, Sens. Actuators B: Chem., 2015, vol. 219, p. 199.

Pan, L., Chortos, A., Yu, G., Wang, Y., Isaacson, S., Allen, R., Shi, Y., Dauskardt, R., and Bao, Z., An ultra-sensitive resistive pressure sensor based on hollow-sphere microstructure induced elasticity in conducting polymer film, Nat. Commun., 2014, vol. 5, p. 1.

Guenbour, A., Kacemi, A., Benbachir, A., and Aries, L., Electropolymerization of poly(ortho-aminophenol) film electrodes: a review article, Int. J. Spectrosc., 2013, vol. 2013, no. 2.

Tucceri, R., Arnal, P.M., and Scian, A.N., Spectroscopic characterization of poly (ortho-aminophenol) film electrodes: a review article, Int. J. Spectrosc., 2013, vol. 2013, art. ID 951604.

Tucceri, R., Arnal, P., and Scian, A., Electrosynthesis and spectroscopic characterization of poly (o-aminophenol) film electrodes, Int. Scholarly Res. Not., 2012, vol. 2012, art. ID 942920.

Moffat, A.C., Osselton, M.D., Widdop, B., and Watts, J., Clarke’s Analysis of Drugs and Poisons, London: Pharmaceutical press, 2011.

Wu, J.j., Wang, W.t., Wang, M., Liu, H., and Pan, H.c., Electrochemical behavior and direct quantitative determination of tanshinone IIA in micro-emulsion, Int. J. Electrochem. Sci., 2016, vol. 11, p. 5165.

Abbaspour, A. and Kamyabi, M.A., Electrocatalytic oxidation of hydrazine on a carbon paste electrode modified by hybrid hexacyanoferrates of copper and cobalt films, J. Electroanal. Chem., 2005, vol. 576, p. 73.

Feyzi-Barnaji, B., Darbasizadeh, B., Arkan, E., Salehzadeh, H., Salimi, A., Nili, F., Dinarvand, R., and Mohammadi, A., Immunoreaction-triggered diagnostic device using reduced graphene oxide/CuO NPs/chitosan ternary nanocomposite, toward enhanced electrochemical detection of albumin, J. Electroanal. Chem., 2020, vol. 877, p. 114642.

Bard, A.J. and Faulkner, L.R., Fundamentals and applications, Electrochem. Methods, 2001, vol. 2, p. 580.

Richards, G. and Swavey, S., Electrooxidation of Fe, Co, Ni and Cu metalloporphyrins on edge-plane pyrolytic graphite electrodes and their electrocatalytic ability towards the reduction of molecular oxygen in acidic media, Eur. J. Inorg. Chem., 2009, vol. 2009, p. 5367.

Fotouhi, L., Fatollahzadeh, M., and Heravi, M.M., Electrochemical behavior and voltammetric determination of sulfaguanidine at a glassy carbon electrode modified with a multi-walled carbon nanotube, Int. J. Electrochem. Sci., 2012, vol. 7, p. 3919.

U. S. Pharmacopoeia, USP39 NF34, The USP Convention, Rockville, 2016, p. 308.

Mladenović, A.R., Jovanović, V., Petrović, S.D., Mijin, D., Drmanic, S.Z., and Avramov, I.M., Determination of clopidogrel using square wave voltammetry at a gold electrode, J. Serb. Chem. Soc., 2013, vol. 78, p. 2131.

Dermiş, S. and Aydoğan, E., Electrochemical study of the antiplatelet agent clopidogrel and its determination using differential pulse voltammetry in bulk form and pharmaceutical preparations with a glassy carbon electrode, Int. J. Pharm., 2010, vol. 65, p. 175.

Ozcelikay, G., Kurbanoglu, S., Bozal-Palabiyik, B., Uslu, B., and Ozkan, Sa., MWCNT/CdSe quantum dot modified glassy carbon electrode for the determination of clopidogrel bisulfate in tablet dosage form and serum samples, J. Electroanal. Chem., 2018, vol. 827, p. 51.

Funding

The authors would like to acknowledge the Tehran University of Medical Sciences, Tehran, Iran, for financial assistance of this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Authors announce that there is no conflict of interest.

Supplementary Information

Rights and permissions

About this article

Cite this article

Bahareh Feyzi-barnaji, Barin, S.M., Mohammadi, A. et al. Voltammetric Detection of Clopidogrel in Pharmaceuticals Utilizing Electropolymerized o-Aminophenol-MWCNTs Modified Electrode. Russ J Electrochem 59, 930–940 (2023). https://doi.org/10.1134/S1023193523110071

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1023193523110071