Abstract

Borosiloxane materials obtained by mixing and thermostatting of hydroxyl-terminated polydimethylsiloxane and boric acid are studied. Samples synthesized at room temperature and at a temperature above 220°С are nontransparent rubberlike masses. Washing of boric acid yields single-phase transparent borosiloxanes demonstrating the rubberlike behavior. Studies are carried out using elemental analysis, dynamic light scattering, synchronous thermal analysis, and polarization optical microscopy. The viscoelastic properties of the samples are characterized by rheological methods and the ability of polymer ball-like samples to spread and rebound. It is shown that in initial states they contain boric acid microcrystalline inclusions that scatter visible light. An increase in the synthesis temperature and the presence of unreacted boric acid improve the elasticity of the materials and decrease their thermal stability. The content of boron in borosiloxane obtained at an increased temperature is an order of magnitude higher than that in borosiloxane synthesized at room temperature, whereas the radius of the effective hydrodynamic sphere is smaller by a factor of 5 than that in the high-temperature borosiloxane. The rheological properties of the tested samples are different. These materials show promise as components of multilayer self-healing and shock-absorbing composites and materials with controlled tackiness.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Sustained interest in materials and systems exhibiting various smart properties, among which are controlled tackiness and self-healing and shock-energy dissipation capabilities, is associated with prospects of their practical use in modern technologies [1–3]. Since the first synthesis in 1943 [4], materials based on the borosiloxane (BS) compounds have attracted ever growing attention from developers and researchers owing to a whole set of such properties.

In terms of molecular structure, borosiloxanes belong to the class of organosilicon compounds containing group R–Si–O–B=, where R is a hydrocarbon radical. These are the products of reaction between organosiloxanes (primarily polydimethylsiloxane) and boron-oxygen compounds, most often boric acid. Depending on the molecular structure and molecular weight of the initial organosiloxane, synthesis conditions, and the amount and properties of the introduced functional additives (fillers, plasticizers, and thickeners), BS-based materials may exhibit different mechanical properties. They may occur in both solid and liquid aggregate state and may have viscous, highly elastic, or glassy consistency [5].

Materials based on borosiloxane are employed in various fields. For example, they are extensively used in sports protective equipment as shock energy absorbers which effectively protect a person in such extreme sports as motorcycle and bicycle races and alpine skiing and are produced under the trademark D3O [6]. A number of developments concern BS used for impregnating other materials. For example, Kevlar fabric is impregnated with BS in order to improve the impact strength of body armor and other bullet-resistant and shrapnel-resistant equipment. These samples feature better properties than nonimpregnated Kevlar and are called “liquid armor” [3].

Another valuable feature of borosiloxanes is their ability to rapidly (just as common fluid) restore integrity by connecting separated parts without any signs at the point of rupture; rupture may occur both via the brittle and viscous mechanism. Owing to this ability, borosiloxanes are particularly promising for various self-healing systems. The authors of [7] created flexible electrically conductive nanocomposites with self-healing behavior on the basis of BS and carbon nanotubes. In [8], borosiloxane coatings for the corrosion protection of metals were obtained and studied, and in [9–12], borosiloxane was used as a self-healing layer in the composition of multilayer composites. In addition, borosiloxane may be employed in electronics and optical equipment [13–15] as an antimicrobial agent for the mechanical disinfection of the skin of hands [16, 17].

Even through the unique properties of borosiloxanes were studied and described in detail in the scientific and technical literature, structural features responsible for a complex of viscoelastic characteristics have been the subject of discussion up to now [5, 18–36]. There is speculation about the complex multiphase structure of BS [2]. This view is supported by the fact that the behavior of BS is similar to that of dilatant dispersions, shear thickening fluid (STF) materials. Most researchers of STF materials believe that their thickening is associated with formation of so-called hydroclusters [37–45], which are bound via hydrogen bonds. Other researchers relate its dilatant properties to hydrogen bonds [19, 20], while in accordance with [21, 26, 28] donor-acceptor interactions between boron and oxygen of neighboring molecules is the key reason for their non-Newtonian properties. The authors of a recent paper [19] assume that both hydrogen bonds and donor-acceptor interactions contribute to the non-Newtonian behavior.

It is well known that BS is formed during the long-term heating of polydimethylsiloxane with boric acid at a temperature above 200°С [4, 18, 20, 22, 26]. The molecular weight of this material is usually much lower than the molecular weight of the initial PDMS; it is on the order of hundreds to thousands daltons [20, 22]. There is also no question that BS is formed through interaction with boric acid at lower temperatures if PDMS contains terminal hydroxyl groups [4, 34–36]. As was shown in [19], Si–O–B(OH)2 groups appear at the ends of siloxane molecules instead of hydroxyl groups. BS obtained by heating contains Si‒O–B, B–O–B, and В–OH groups, as evidenced by IR spectroscopy [18, 20, 22, 24]. GPC and IR studies demonstrated [20] that borosiloxanes have a supramolecular structure, in which hydrogen bonds formed at the ends of BS by Si–O–B(OH)2 groups serve as junctions. Thus, the non-Newtonian behavior of BS is associated with noncovalent interactions between neighboring molecules [18–36]. A complex of viscoelastic properties is well defined even at a small content of boron in BS molecules (from fractions of to a few percent). With an increase in the content of boron, the glass transition temperature of borosiloxanes increases [26, 27].

The authors of [22, 26] showed that the non-Newtonian properties of BS are lost during interaction with solvents, but they reappear upon drying of the samples. In addition, it was reported [22, 46] that the hydrolysis of BS samples obtained at elevated temperatures occurs via several stages; the first stage involves the hydrolysis of B–O–B groups accompanied by the formation of free boric acid.

In practice, in order to simplify the technological process of producing BS-based materials, excess boric acid is not removed from the reaction mixture after synthesis. In this case, the molecular structure of BS contains both boron and hydroxyl groups, which may affect the non-Newtonian and other properties of BS-based materials.

The aim of this study is to examine the effect of synthesis temperature and residual boric acid on the structure and properties of borosiloxanes.

EXPERIMENTAL

Borosiloxane compounds were obtained by mixing components PDMS and orthoboric acid followed by keeping under different conditions. The initial compounds were hydroxyl-terminated PDMS of the SKTN A brand (viscosity, 2 Pa s; М ~ 20 × 103) and finely dispersed boric acid of brand B according to GOST (Russian State Standard) 18704-78 (the content of the main substance, 99.9%; the weight fraction of boric anhydride, 57.1%; and the average size of particles, 75 µm). The weight ratio of PDMS and boric acid was 10 : 1.

“Low-temperature” borosiloxane (BS-LT) samples were obtained by mixing the components followed by keeping for 24 h under normal conditions. To avoid sedimentation of the particles of the added boric acid, the mixture was periodically stirred during the reaction. After 24 h, there was no sedimentation of boric acid particles in BS-LT. “High-temperature” borosiloxane (BS-HT) samples were obtained by heating the components at a temperature above 220°С in a reaction vessel as described in [47]. For this purpose, the measured amount of boric acid was placed on the bottom of a 100 mL chemical beaker and PDMS was poured from above. The chemical beaker was placed on a lab hot plate and heated for 24 h. The synthesis temperature was controlled using an electronic thermometer immersed in the mixture. During the synthesis, a vigorous evolution of vapor substances was observed. The mixture spontaneously mixed and homogenized.

BS samples were purified from the unreacted (“free”) boric acid by dissolving BS in excess ethanol followed by the addition of excess water, boiling, and threefold washing with a 40% water–alcohol solution.

The content of boron in the samples washed from free boric acid was determined using a PGS-2 spectrograph (Germany) equipped with a multichannel emission spectrum analyzer (OOO VMK-Optoelektronika, Russia). The additive method in three repeated experiments was used. The continuous ac arc of a ShM-250 fireball generator was used as an excitation source. The sample weighing 60 mg was placed in a crater of the graphite electrode (special purity grade). Measurements were carried out in the ac arc first at a current of 3 А (50 Hz) for 15 s and then at a current of 20 А for 85 s until complete burning of the sample was achieved. The lines of boron at 249.6772 and 249.7723 nm were used for analysis. The line of silicon (element of the mineral basis of samples) was used as a reference. The spectra were measured and interpreted using the Atom 3.3 program. Calculations were carried out according to the linear approximation method.

The size of particles was determined by dynamic light scattering on an ALV-5 photometer (ALV, Germany) equipped with a He–Nе laser with a capacity of 25 mW (l = 632.8 nm) at a scattering angle of 90°. The autocorrelation functions of the fluctuations of scattered light intensity were measured using a Photocor-М 280-channel logic correlometer. Prior to measurements, the samples were dedusted by passing two to three times through Millipore membrane filters with an average pore size of 1.2 µm. The measurement results were processed by the Tikhonov regularization method. The radius of equivalent hydrodynamic spheres was calculated according to the Stokes equation. Analytical-grade toluene of was used as a solvent.

Rheological tests were carried out on an Anton Paar MCR 302 rheometer (Switzerland) equipped with a plate–plate cell with a diameter of 25 mm. Samples were thermostatted at 23°С using a Peltier element. The relative deformation amplitude at which the frequency dependences of the dynamic modulus were measured was 0.1%.

The viscosity was estimated by measuring the spreading time of a BS ball (2 g) over the surface of a glass substrate. The relative increase in diameter b was calculated by the formula

where D0 and Di are the diameters at the initial time and time t, respectively.

The elastic properties of the sample were characterized by measuring the value of relative elastic rebound а (%) according to the following technique. The BS ball with a weight of 2 g was thrown from height H on a flat glass surface. The rebound height of the ball h was fixed visually. The ratio of the rebound height to the initial height from which the ball was thrown was calculated as

Synchronous thermal analysis (STA) was carried out on an STA 449 F1 Jupiter thermal analyzer (Netzsch). The microstructure of the samples was studied on a POLAR 3 polarization optical microscope (Altami, Russia) in crossed polarizers.

RESULTS AND DISCUSSION

The mixing of PDMS with boric acid resulted in the formation of low-temperature and high-temperature borosiloxane samples which were additionally purified from free boric acid (Fig. 1).

The reaction of BS-LT occurring at room temperature becomes noticeable immediately after mixing of the components. It is seen that the viscosity of a cloudy white suspension gradually changes from an initial value of 2 Pa s to more than 1000 Pa s, as shown using a rotational viscometer [14]. After 24 h, a milky white viscoelastic mass was obtained from which a ball could be rolled or any other shape could be given to it. This mass stretches into threads and cracks under rapid loading, and under the action of the force of gravity, BS-LT spreads over the substrate surface (Fig. 2).

Note that the reference sample of methyl-terminated PDMS (PMS-100) which contains the same amount of boric acid is a milky white flowable suspension tending to sediment boric acid particles and exhibiting no elastic properties. Thus, for BS samples synthesized at room temperature, hydroxyl groups should be contained in the structure of the initial PDMS.

In the synthesis of BS-HT, the viscosity of the reaction mixture rapidly increases with increasing temperature, and once the synthesis temperature is reached, the reaction proceeds vigorously to evolve white vapors. High-temperature borosiloxane may also be synthesized by heating BS-LT, because it is the intermediate of BS-HT. The criteria for the reaction completeness were as follows: obtainment of a homogeneous transparent flowable mass without visible inclusions, the rebound ability of the ball rolled from BS-HT, and no sticking of the samples to the hands.

The BS-HT sample is a transparent mass which rapidly becomes turbid in air (Fig. 2a). The turbid samples become harder, elastic, and brittle but retain the ability to spread over the substrate as all the tested samples (Fig. 2b).

The BS samples washed from boric acid and dried are transparent masses with viscoelastic properties which tear, spread, and stretch into threads. However, for BS-HT without boric acid, the elastic properties are preserved, while for BS-LT without boric acid they are almost lost.

Upon washing, the content of boron in BS-LT and BS-HT samples per terminal groups –B(OH)2 was ~0.30 ± 0.15 and 5.0 ± 2.5 wt %, respectively. The theoretical calculation of the amount of terminal groups –B(OH)2 attached to the initial PDMS with a weight of 20 000 g/mol yields a value of ~0.6 wt %, which is in good agreement in order of magnitude with the results of elemental analysis. The underestimated content of boron in BS-LT samples washed from boric acid may be associated with both the error of analyses and assumptions of calculations and the partial hydrolysis of BS-LT during washing from free boric acid.

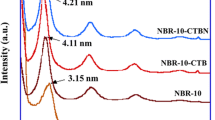

Dynamic light scattering studies (Fig. 3) showed that a difference between PDMS and washed BS-LT and BS-HT is the molecular weight of molecules. The hydrodynamic size for PDMS is 82 nm; for BS-LT and BS-HT, it is 64 and 14 nm, respectively. Reduction in the hydrodynamic size during the formation of BS-LT is apparently associated with a change in polarity of the initial PDMS molecule due to an increase in the number of terminal hydroxyl groups. The hydrodynamic size of BS-HT is slightly smaller than that of BS-LT, which is most likely related to the cleavage of Si–O–Si bonds in PDMS during heating in the presence of boric acid and, as supposed, is accompanied by the insertion of terminal groups Si–O–B(OH)2 at the points of rupture.

The study of the samples on the polarization optical microscope in crossed polarizers revealed that the initial PDMS and BS without free boric acid do not demonstrate birefringence. In the structure of BS-LT, particles of the initial boric acid are observed (Fig. 4a), whereas in the initial BS-HT, which has no time to react with atmosphere, the birefringence regions are almost absent (Fig. 4b).

According to the characteristic alternation of dark and light bands (Fig. 4), the direction of stretching of these samples is well seen, which indicates their anisotropy induced by deformation. This is a good illustration of the manifestation of rubberlike properties of BS samples under mechanical action. In the course of time, the oriented BS samples relax and becomes isotropic.

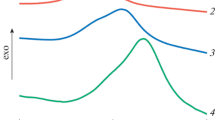

The STA analysis of the initial components of the reaction demonstrated that PDMS is fully thermally stable to a temperature of 250°С (Fig. 5a, curves 1), while boric acid has several DSC peaks and its weight loss is in the range of 100–190°С (curves 2).

The heat absorption peaks observed on the DSC curve and the weight loss may be attributed to the processes of boric acid melting and the successive decomposition of orthoboric acid to metaboric and tetraboric acids. In the temperature range from 160 to 180°С, the processes of melting of components of the formed mixture take place. The occurrence of combined melting and decomposition processes during the heating of boric acid is confirmed by the data from [48, 49].

A peak on the DSC curve of the BS-LT sample (Fig. 5b) with a maximum at a temperature of ~150°С is evidently attributed to the above-described processes related to boric acid and the reaction between boric acid and PDMS. This peak is absent in the case of the BS-LT sample without boric acid. It is seen that, in the studied temperature range, the BS-LT sample without boric acid exhibits a high thermal stability which is similar to that of the initial PDMS (Fig. 5b, curves 2).

On the DSC curve of BS-HT not contacting the wet atmosphere (Fig. 5c, curves 1), there are no peaks characteristic of processes involving boric acid, although the thermal stability of the sample is much lower than that of the BS-LT sample. This can apparently be explained by the occurrence of reactions related to the ongoing process of BS synthesis and, accordingly, to a decrease in the molecular weight of BS accelerated by residual boric acid.

Figure 5c (curves 2) presents the BS-HT sample held in an atmosphere under normal conditions to a constant weight. There is a peak on the DSC curve, and the corresponding weight loss is seen on the TGA curve. A number of STA control experiments showed that this process is accompanied by the release of water which is captured by BS-HT from the air atmosphere. This process is reversible: keeping of the sample in air after heating restores its turbidity and gain in weight (~2 wt %). Upon removal of the unbound boric acid from BS-HT, the BS-HT sample without boric acid becomes steadily transparent in air and no previously detected characteristic signals related to the release of water are observed on the STA curve (Fig. 5c, curves 3). BS-HT without boric acid also features better thermal stability than the initial BS-HT.

Figure 6 shows the optical image and photomicrographs taken using polarization optical microscopy for the portion of the sample before and after interaction with the surrounding atmosphere. On the photomicrographs taken in crossed polarizers, birefringence is clearly seen in the region of turbidity of the sample (Figs. 6b, 6c).

(a) Optical image of BS-HT, where a part of the sample is present under the cover glass; (b, c) photomicrographs in crossed polarizers for the framed part of the sample in Figs. 6a and 6b, respectively.

It is supposed that the tendency of BS-HT toward partial hydrolysis by air moisture accompanied by the characteristic turbidity of the sample is associated with the hydrolysis of metaborosiloxane groups and the subsequent formation of free boric acid and Si–O–B(OH)2 groups in BS-HT. The presence of metaborosiloxane groups in BS-HT samples obtained by this method was described in [19, 20, 22, 25–27, 44]. Figure 6c shows well-defined microspherulitic structures, which evidently indicate the formation and precipitation of free orthoboric acid hydrolyzed by air moisture.

According to the rheological studies, for BS-LT in the initial state, the frequency dependence of the loss modulus is a nonlinear curve (Fig. 7). The dependence of the loss modulus intercepts the dependence of the storage modulus at its extremum point (the crossover point) at a frequency of 9 rad/s. This behavior is typical of polymer materials in the viscous-flow state. For the low-temperature BS in the washed state, the loss and storage moduli grow with increasing frequency and the crossover point is at 50 rad/s. The washed BS-LT exhibits properties characteristic of adhesives [50–53]. BS-LT filled with boric acid demonstrates properties inherent in traditional polymer materials in the viscous-flow state [54, 55].

For the high-temperature BS in both cases, the frequency dependences of the loss and storage moduli are of the same nature typical of Maxwellian fluids. The crossover point for BS-HT in the initial state, as for the initial BS-LT, is at 9 rad/s, while for BS-HT in the washed state it is in the region of 2 rad/s.

In the considered frequency range, the loss modulus for BS-LT increases at high frequencies while for BS-HT the loss modulus decreases. This is the reason behind the poorer elastic characteristics of BS-LT. In BS-HT, boric acid mostly likely plays the role of a reinforcing finely dispersed filler.

The measurements of spreading of the ball-like samples for the initial BS and BS without boric acid showed that the samples without boric acid spread quicker than the initial samples, which is confirmed by the above rheological data.

The rate of spreading of BS-HT is lower than that of BS-LT. This may be explained by the fact that free boric acid also serves as an active thickening filler.

The study of the elastic characteristics of the sample by the method of ball rebound from the substrate demonstrated that the samples filled with boric acid are more elastic and better rebound from the substrate. BS-HT samples without boric acid also have a good rebound, whereas BS-LT samples without acid are hardly separated from the substrate after blow.

The study of elastic properties revealed that the samples of BS-LT and BS-HT in the initial state before washing from the “unbound” boric acid are more elastic than the samples purified from it. The value of rebound for the ball made from BS-LT in the initial state is 29%; after washing, it is 0–4%. In the case of the sample of BS-HT in the initial state, the rebound is 88%; after washing, it is 70%.

The molecular weight of BS-HT samples is lower and the content of boron is higher and, accordingly, the amount of Si–O–B(OH)2 groups per molecule, which are responsible for hydrogen and donor-acceptor bonds between molecules, is higher. Different viscoelastic characteristics of BS-LT and BS-HT are apparently explained by the fact that the density of the dynamic entanglement network formed by noncovalent interactions is higher in the case of BS-HT.

REFERENCES

K. A. Boval’dinova, N. E. Sherstneva, M. M. Fel’dshtein, A. P. Moskalets, and A. R. Khokhlov, Polym. Sci., Ser. B 61, 458 (2019).

A. L. Aleshina, A. V. Shibaev, O. E. Filippova, and A. R. Khokhlov, Dokl. Phys. Chem. 491, 29 (2020).

C. Xu, Y. Wang, J. Wu, S. Song, S. Cao, S. Xuan, W. Jiang, and X. Gong, Compos. Sci. Technol. 153, 168 (2017).

R. R. McGregor and E. L. Warrick, US Patent No. 2431878 (1943).

S. N. Borisov, M. G. Voronkov, and E. Ya. Lukewitz, Organoelement Compounds. Derivatives of Inorganogens (Publishing House “Chemistry”, Leningrad, 1966).

R. M. Palmer and P. C. Green, US Patent No. 7381460 (2008).

T. Wu and B. Chen, ACS Appl. Mater. Interfaces 8, 24071 (2016).

P. Puneet, R. Vedarajan, and N. Matsumi, Electrochem. Commun. 93, 1 (2018).

N. N. Sitnikov, I. A. Khabibullina, V. I. Mashchenko, and R. N. Rizakhanov, Perspekt. Mater., No. 2, 5 (2018).

N. N. Sitnikov, I. A. Khabibullina, V. I. Mashchenko, and R. N. Rizakhanov, Inorg. Mater. Appl. Res. 9, 785 (2018).

N. N. Sitnikov, K. S. Mostovaya, I. A. Khabibullina, and V. I. Mashchenko, Videosci.: Network J. 2 (14), 1 (2019).

N. N. Sitnikov, I. A. Khabibullina, V. I. Mashchenko, A. V. Shelyakov, K. S. Mostovaya, and E. A. Vysotina, Perspekt. Mater., No. 4, 11 (2020).

M. V. Ermakova, V. I. Mashchenko, O. V. Chausova, A. S. Solomatin, N. I. Volosnikova, and D. N. Chausov, Liq. Cryst. Their Appl. 19 (4), 61 (2019).

V. I. Mashchenko, N. N. Sitnikov, I. A. Khabibullina, M. V. Ermakova, D. N. Chausov, and O. V. Chausova, J. Phys.: Conf. Ser. 1309, 012026 (2019).

V. I. Mashchenko, A. S. Solomatin, Yu. O. Shashkova, and V. V. Belyaev, Bull. Moscow State Reg. Univ., No. 2, 34 (2017).

V. I. Mashchenko, I. V. Medvedeva, and Yu. P. Molokanova, Vestn. Mosk. Gos. Obl. Univ., Ser. Estestv. Nauki, No. 2, 18 (2015).

V. I. Mashchenko, A. N. Alekseev, T. V. Kartavenko, and A. V. Olenin, RF Patent No. 2473216 (2013).

G. V. Motsarev, M. V. Sobolevskii, and V. R. Rozenberg, Carbofunctional Organosilanes and Organosiloxanes (Khimiya, Moscow, 1990) [in Russian].

M. Tang, W. Wang, D. Xu, and Z. Wang, Ind. Eng. Chem. Res. 55, 12582 (2016).

Z. Liu, S. J. Picken, and N. A. M. Besseling, Macromolecules 47, 4531 (2014).

X. Li, D. Zhang, K. Xiang, and G. Huang, Synth. RSC Adv. 4, 32894 (2014).

G. A. Zinchenko, V. P. Mileshkevich, and N. V. Kozlova, Vysokomol. Soedin., Ser. A 23, 1282 (1981).

V. F. Gridina, A. L. Klebanskii, L. P. Dorofeenko, and L. E. Krupnova, Vysokomol. Soedin., Ser. A 9, 1946 (1967).

V. N. Gruber, A. L. Klebanskii, N. V. Kozlova, E. V. Kuz’mina, G. A. Kruglova, Vysokomol. Soedin., Ser. A 14, 1638 (1972).

V. D. Lobkov, A. L. Klebanskii, and E. V. Kogan, Vysokomol. Soedin. 9, 1099 (1967).

L. A. Mitrofanov, E. A. Sidorovich, A. V. Karlin, and A. I. Marei, Vysokomol. Soedin., Ser. A 11, 782 (1969).

V. N. Gruber, A. L. Klebanskii, G. A. Kruglova, E. V. Kuz’mina, E. A. Sidorovich, L. Ya. Mokrousova, G. N. Pavlov, and A. I. Marei, Vysokomol. Soedin., Ser. A 14, 1476 (1972).

V. N. Gruber, A. L. Klebanskii, T. G. Degteva, A. S. Kuz’minskii, T. A. Mikhailova, and E. V. Kuz’mina, Vysokomol. Soedin. 7, 462 (1965).

K. A. Akhmed-zade, V. A. Zakrevskii, and L. A. Mitrofanov, Vysokomol. Soedin., Ser. B 17, 661 (1975).

M. A. Sokolova, G. A. Zinchenko, G. G. Kartashova, I. Ya. Poddubnyi, and V. P. Mileshkevich, Vysokomol. Soedin., Ser. A 25, 3 (1983).

V. O. Reikhsfel’d and D. A. Khankhodzhaeva, Vysokomol. Soedin., Ser. A 9, 638 (1967).

V. F. Gridina, A. L. Klebanskii, L. P. Dorofeenko, L. E. Krupnova, and N. V. Kozlova, Vysokomol. Soedin., Ser. A 11, 426 (1969).

T. I. Zatsepina, M. L. Brodskii, E. A. Frolova, A. A. Trapeznikov, V. N. Gruber, and G. A. Kruglova, Vysokomol. Soedin. 12, 2559 (1970).

O. G. Khelevina and A. S. Malyasova, Russ. J. Appl. Chem. 87, 480 (2014).

O. G. Khelevina, Russ. J. Appl. Chem. 85, 277 (2012).

J. Modell and S. Thuresson, US Patent No. 7,862894 (2006).

R. S. Farr, J. R. Melrose, and R. C. Ball, Phys. Rev. E: Stat. Phys., Plasmas, Fluids, Relat. Interdiscip. Top. 55, 7206 (1997).

K. Talreja, I. Chauhan, A. Ghosh, A. Majumdar, and B. S. Butola, RSC Adv. 7, 49787 (2017).

D. Li, R. Wang, X. Liu, S. Fang, and Y. Sun, Polymers 10, 1356 (2018).

F. Ye, W. Zhu, W. Jiang, Z. Wang, Q. Chen, X. Gong, S. Xuan, J. Nanopart Res. 15, 2122 (2013).

H. A. Barnes, J. Rheol. 33, 329 (1989).

J. Bergenholtz, J. F. Brady, and M. Vicic, J. Fluid Mech. 456, 239 (2002).

V. A. Chatterjee, P. Dey, S. K. Verma, D. Bhattacharjee, I. Biswas, and S. Neogi, Mater. Res. Express 6, 075702 (2019).

M. Li, B. Lyu, J. Yuan, C. Dong, and W. Dai, Int. J. Mach. Tools Manuf. 94, 88 (2015).

A. Bosco, V. Calado, and J. Maia, Mater. Res. 22, 1 (2019).

G. Wang, X. Liu, C. Mi, H. Fan, B. Xu, and X. Bai, Pigm. Resin Technol. 47, 308 (2018).

V. I. Mashchenko, N. N. Sitnikov, and I. A. Khabibullina, RF Patent No. 2714203 (2019).

R. A. Lidin, V. A. Molochko, L. L. Andreeva, and R. A. Lidin, Chemical Properties of Inorganic Substances (Publ. House “Chemistry”, Moscow, 2000).

K. V. Tkachev and Yu. S. Plyshevsky, Technology of Inorganic Compounds of Boron (Publishing House “Chemistry”, Leningrad, 1983).

Yu. D. Semchikov, High-Molecular Compounds (Akademiya, Moscow, 2010) [in Russian].

T. Borodulina, E. Bermesheva, N. Smirnova, S. Ilyin, T. Brantseva, and S. Antonov, J. Adhes. Sci. Technol. 28, 1629 (2014).

T. Brantseva, S. Antonov, A. Kostyuk, V. Ignatenko, N. Smirnova, Y. Korolev, and S. Ilyin, Eur. Polym. J. 76, 228 (2016).

A. V. Pocius, Adhesion and Adhesives Technology: An Introduction (Hanser Publ., Munchen, 2002).

A. Ya. Malkin, Foundations of Rheology (TsOP “Professiya”, St. Petersburg, 2018) [in Russian].

A. Y. Malkin, S. O. Ilyin, M. P. Arinina, and V. G. Kulichikhin, Colloid Polym. Sci. 295, 555 (2017).

Funding

This work was supported by the Russian Foundation for Basic Research (grant no. 18-29-18095(mk)).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Soboleva

Rights and permissions

About this article

Cite this article

Mashchenko, V.I., Sitnikov, N.N., Khabibullina, I.A. et al. Effect of Boric Acid on the Structure and Properties of Borosiloxanes. Polym. Sci. Ser. A 63, 91–99 (2021). https://doi.org/10.1134/S0965545X21020085

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965545X21020085