Abstract

The process of film formation including the initial treatment of thin layers of cellulose solutions in N-methylmorpholine N-oxide with isobutanol followed by washing with water is investigated in detail, and the structural and morphological features of the obtained films are examined. The phase state of the N-methylmorpholine N-oxide–isobutyl alcohol system is studied by differential scanning calorimetry and optical interferometry, and a diagram describing the crystalline equilibrium and allowing determination of the temperature–concentration “window” of compatibility of components is constructed. The dependence of viscosity of N-methylmorpholine N-oxide solutions in isobutanol on temperature confirms the phase composition of the system. The process of film formation is modeled by analyzing the diffusion zone of the cellulose solution–isobutyl alcohol system. The IR study of the interaction of N-methylmorpholine N-oxide containing 13.3% water with isobutanol shows that the affinity of isobutanol for water is much higher than that for N-methylmorpholine N-oxide. For this reason, when the spinning solution is brought in contact with isobutanol, the redistribution of water between the interacting components occurs and the structure of the heterogeneous gel-like complex cellulose–N-methylmorpholine N-oxide–isobutanol “is frozen,” as proved by the X-ray diffraction study of the films. Complete removal of the solvent and isolation of cellulose from this film proceed only upon subsequent washing with water. The X-ray diffraction and optical interferometry study of the effect of temperature on the interaction of a hot cellulose solution with cold isobutanol suggests that at room temperature the film obtained from solution contains inclusions of the vitrified N-methylmorpholine N-oxide. Under isothermal conditions (at a temperature of 90°С), the rate of interdiffusion grows appreciably and the solution preserves the homogeneous structure. Thus, the precipitation of cellulose from the bicomponent solvent N-methylmorpholine N-oxide–water upon contact first with isobutanol and then with water proceeds via two stages: initially the system undergoes phase separation and a concentrated solution is formed in the isobutanol-N-methylmorpholine N-oxide blend, from which cellulose precipitates upon interaction with water. When the process of primary interaction of the solution with alcohol is conducted under the conditions of compatibility of isobutanol with N-methylmorpholine N-oxide, a more homogeneous morphology of the films can be obtained.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Cellulose, being a constantly renewable source of raw materials, is the most demanded natural material for the manufacture of fibers, films, and membranes [1–3]. The regular structure of cellulose (primary and secondary hydroxyl groups form a highly organized system of intramolecular and intermolecular hydrogen bonds) provides a high melting temperature, which is higher than the degradation temperature of the polymer; therefore, dissolution is the only way to obtain spinning systems for the formation of fibers and films [4]. However, a high density of the system of hydrogen bonds limits the solubility of cellulose in most conventional solvents [5]. As a consequence, the viscose manufacture of cellulose fibers [6], in which cellulose is involved in etherification with CS2 and cellulose xanthogenate is formed at the stage of reduction by sulfuric acid accompanied by the evolution of H2S, has predominated in the chemical industry up to now. The introduction of restrictive standards on the emission of CS2, Н2S, Zn++, and other harmful compounds in most countries led to the shutdown of viscose productions and their partial transfer to the Asian region, where the environmental requirements are not so strict.

This circumstance and the demand for cellulose fibers initiated the search for new methods of their production. These developments relied on two main parameters: high reactivity with respect to cellulose and ecological friendliness [7]. For example, a class of nonaqueous solvents, oxides of tertiary amines, was discovered, among which N-methylmorpholine N-oxide (MMO) hydrate was found to be the most promising solvent for cellulose [8]. This process is unique because the amount of components in the system cellulose–ММО–water is invariable at the stage of both cellulose dissolution and precipitation and only the phase composition changes. The use of ММО makes it possible to obtain concentrated cellulose solutions and to form fibers and films on their basis [9].

As was shown in [10, 11], cellulose films synthesized from ММО solutions, like cellophane films, can be used as membranes, for example, for hemodialysis. Owing to their structural features, the films are almost impermeable to a number of liquids, for example, alcohols [12]. In order to increase the rate of liquid stream passage through the film (permeability of the film), while preserving its selectivity, a partial disordering of the cellulose structure in the film is required. One of the promising ways to solve this problem is to use various alcohols as a medium in coagulation and wash baths during formation of films (fibers) from cellulose solutions in ММО [13, 14].

Alcohols are amphiphilic in nature owing to the presence of a polar hydroxyl group and an apolar hydrocarbon fragment. The acidic properties of alcohols are associated not only with the difference in the electronegativities of oxygen and hydrogen atoms in the hydroxyl group but also with the nature of radical. For example, methanol exhibits stronger acidic properties than water, because the acidity constant pKα of methanol is 15.5 [15] while that of water is 15.7. With increasing size of the aliphatic radical, the acidity of alcohols is reduced, achieving 17.1 for propanol and 18.0 for butanol. The branched character of the alkyl group leads to even smaller acidity values of alcohols. According to this reasoning and taking into account the basic character of MMO as a solvent, it can be assumed that alcohols are milder precipitants of cellulose than water. The branched character of aliphatic groups is responsible for certain steric hindrances affecting diffusion processes in solvent–precipitant systems. This makes it possible to control the kinetics of precipitation of fibers and the rate of structural rearrangements in cellulose.

The replacement of an aqueous precipitating bath with an ethanol one [16] allowed one to reduce the structural order and led to a decrease in the degree of orientation of cellulose macromolecules and in the elastic modulus of the resulting fibers. The transition from ethanol to higher alcohols causes a more pronounced disordering of the structure and leads to reduction in the rigidity of the final articles. For example, a number of higher alcohols were used as precipitating agents in coagulation baths to decelerate crystallization processes occurring during cellulose precipitation [16–18].

Another way of controlling cellulose structuring processes during formation of fibers and films is variation in the rate of mass exchange processes through a change in the temperature of a precipitating agent. As was shown in [14], an increase in the temperature of isopropanol in the precipitating bath from 20 to 35°С entails the growth of microporosity (the effective pore radius is less than 1000 А) and causes an increase in the amount of macrodefects (vacuoles) in the spun fibers.

When aqueous precipitating baths are replaced with alcohol (or other baths) during spinning of fibers and films from cellulose solutions in ММО, an important role is played by the phase states of the system ММО–water–precipitant. This problem was discussed in the most detail in [18]. Using optical methods, the phase state of the ternary system ММО–water–isobutanol was investigated, the phase diagram was constructed, and the ways of solvent and precipitant regeneration were proposed.

To carry out this approach further, it is extremely important to widen the scope of the study, that is, to analyze variation in the phase state of the system ММО–isobutanol–water with the ratio of components and temperature in order to ascertain optimum conditions of polymer isolation from the spinning solution as a gel film of a certain structure. Therefore, the goal of this work is to study the possibility of controlling the processes of creation of the structure and morphology of cellulose films formed from solutions of MMO or isobutanol solely or sequentially from isobutanol and water taking into account evolution in the phase composition of the multicomponent system during the process.

EXPERIMENTAL

We used cellulose sulfate (Baikal Pulp and Paper Mill, Russia) (DP = 600, moisture content of ~8%, weight content of α-cellulose in the dry residue of ~94%). N-Methylmorpholine N-oxide monohydrate (Demochem, China) containing 13.3% water (Тm ~ 77°C) was used as a solvent for cellulose. To suppress thermo-oxidative degradation processes, 0.5% propyl gallate (Sigma-Aldrich, United States) was added to the system. Isobutyl alcohol (Komponent-Reaktiv, Russia) was used as a precipitating agent.

Cellulose solutions (12%) in ММО monohydrate were prepared according to the solid-phase dissolution technique described in [19]:

Owing to stronger donor properties, MMO molecules rupture first intermolecular and then intramolecular Н bonds and form solid solutions. Subsequent heating to the melting point of the solvent and additional homogenization at a temperature of 100°C by passing through a capillary (the channel geometry d = 0.5 mm and l/d = 10) of a Rheoscope 1000 viscometer (CEAST, Italy) gave rise to liquid spinning solutions. The quality of cellulose solutions in ММО and their morphology at different temperatures were investigated by polarization optical microscopy using a Boetius microscope (VEB Kombinat Nadema, former German Democratic Republic).

The viscosity of the ММО–isobutyl alcohol system at various temperatures was measured on a Kinexus-pro+ rotary rheometer (Malvern Panalytic, United Kingdom) equipped with a cone–plane operating unit with a diameter of 50 mm. Tests were conducted under the steady-state flow in the regime of fixed shear rate (1 s–1). The testing temperature was varied within 10–100°C.

The compatibility of ММО–isobutyl alcohol systems and cellulose solution in ММО–isobutyl alcohol was studied by optical interferometry in the temperature range of 20–90°С. This method enables registration of the distribution of components in the process of interdiffusion [20]. An analysis of concentration profiles in the diffusion zone makes it possible to construct phase diagrams and to calculate parameters of the diffusion process. The technique of experiments and the processing of interferograms were described in [20, 21]. Experiments were carried out in the step-by-step heating and cooling regime.

To study the features of ММО interaction with isobutyl alcohol, the IR spectra of solid blends were registered in the region of full compatibility of components and analyzed. ATR IR spectra were measured on a HYPERION-2000 IR microscope conjugated with a Bruker IFS-66 v/s FTIR spectrometer (Ge crystal, 50 scans, resolution of 2 cm–1, range of 4000–600 cm–1).

The thermal behavior of ММО–isobutyl alcohol systems was studied on a Mettler Toledo DSC 823e thermal analyzer (Switzerland). Measurements were carried out in aluminum cruсibles with a volume of 40 µL without perforation in the temperature range of 50–100°С at a heating rate of 10°С/min. The rate of inert gas (argon) was 70 mL/min.

Films were formed by the rolling method on a ChemInstruments HLCL-1000 laminator (United States) at a temperature of 100°С. The adhering of cellulose solution in ММО to rolls was prevented owing to the use of antiadhesive poly(ethylene terephthalate) and polyimide films. The gap between rollers was set using calibration plates in order to obtain a solution layer ~50 µm thick taking into account the presence of antiadhesive films. Afterwards, the upper cover film was removed and the solution layer formed on the lower substrate was immersed in an alcohol precipitating bath at two temperatures: room temperature and 90°С. The bath volume was one liter. After the film was immersed in the bath, the lower substrate was also removed. The films were in the alcohol bath for one day and then were placed for another day in the aqueous bath of the same volume. Prolonged washing with water was repeated two times. The films were dried under room conditions in a frame preventing shrinkage until equilibrium water content was attained.

The structure of the films was studied by X-ray diffraction on a Rigaku Rotaflex D/MAX-RC setup equipped with a rotating copper anode (the X-ray source operating mode: 30 kV, 100 mA, the wavelength of characteristic radiation λ = 0.1542 nm, CuKβ radiation absorbed by the nickel filter), a horizontal goniometer, and a scintillation detector. X-ray diffraction patterns were taken in reflection and transmission geometries according to the Bragg–Brentano scheme in the continuous θ–2θ scan mode in the angular range of 2.5°–50.0° at a scan step of 0.04° at room temperature.

The surface and cross-section morphology of freeze-dried cellulose films was studied by low voltage scanning electron microscopy (SEM) on a FEI Scios microscope (United States) at accelerating voltage less than 1 kV in the secondary electron mode.

The amount of residual solvent in the films was estimated using a Thermo Scientific Flash 2000 multielement CHNS/O analyzer (United States).

RESULTS AND DISCUSSION

When the films were formed from 12% cellulose solution in isobutanol at room temperature, the color of the layer changed from amber, transparent to white; that is, the sample fully lost transparency possibly as a result of specific phase decomposition and underwent cornification. To gain insight into reasons behind this behavior of the as-formed cellulose film, samples kept in isobutyl alcohol for a day were chosen and their structure was studied after drying in air to a constant weight (Fig. 1).

As is seen in Fig. 1, the diffraction pattern shows only a single broad peak in the range of angles 2θ ~ 20°. The pattern of the curve almost fully coincides with the diffraction patterns of cellulose solutions in ММО [22]. It is possible that, in a milder alcohol precipitant, mass-exchange processes and solvent removal from solution layer proceed more slowly than those in aqueous baths. As a result, the residual solvent should certainly affect the structure of the as-formed cellulose film, which in this case is similar to the structure of solution.

Elemental analysis of the chemical composition of the films demonstrated that the film precipitated in isobutyl alcohol contained a considerable amount of ММО. It was found that in the film the content of nitrogen involved in the composition of the ММО solvent is less than 1% of the sample weight. This fact gives us grounds to assume that, during precipitation of solution layer in isobutanol, more than 10% ММО can remain in the film and, as is seen from the diffraction pattern in Fig. 1, ММО occurs in the amorphized (vitrified) rather than crystalline state. Possibly, this is associated with the features of specific interaction of ММО with isobutanol.

To verify this assumption, interaction of the pair ММО–isobutyl alcohol was studied by different methods. However, it should be taken into account that owing to polarity and electron-donating ability, ММО has a high affinity for water and can form three thermodynamically equilibrium crystal hydrate forms: 2.5 hydrate containing 28% water, Тm = 38°С; monohydrate containing 13.3% water, Тm = 78°С; and many nonequilibrium sesquihydrate forms. For anhydrous ММО, Тm = 180°С.

In turn, isobutanol containing branched hydrophobic aliphatic groups is limitedly compatible with water. At room temperature, the blend undergoes delamination into aqueous and organic phases containing ~10% of the second component. In addition, isobutanol forms an azeotrope with water which contains 33 wt % water and has a boiling temperature of 89°С. There is no doubt that such a different behavior of components in the system ММО–isobutyl alcohol during interaction with water needs detailed study.

The DSC study of the system ММО–isobutyl alcohol (Fig. 2) showed that the introduction of isobutanol in a solvent entails reduction in its melting temperature. At a weight fraction wisobutanol of 0.5, the thermal effect of ММО melting disappears completely. This is evidence that the components are fully compatible; that is, the solution is formed.

Important information about the phase behavior of the system MMO–isobutyl alcohol is provided by the rheological behavior of blends of different compositions at different temperatures. The temperature dependence of the viscosity of the blends is presented in Fig. 3.

Three regions can be distinguished on the temperature dependence of viscosity obtained under cooling of molten blends from 100°С to room temperature. The first region is in the temperature range from 100 to 80°С, in which viscosity is almost independent of temperature. The break of the curve observed at 80°С indicates the transition of the system to the second region, nucleation, which is characterized by the appearance of nuclei of the crystalline phase of ММО. However, the effect of supercooling typical of large molecules, the more so under deformation of the system, inhibits the process of crystallization; therefore, the region with a gradual increase in viscosity is observed up to 40°С. Then follows the third region, the region of rapid crystallization, which is accompanied by a sharp drop of viscosity and full loss of flowability. An increase in the content of alcohol in the blend ММО–isobutyl alcohol entails reduction in viscosity and temperature at which the blend crystallizes.

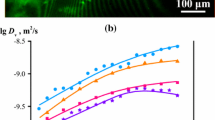

The character of diffusion processes occurring during the contact of ММО with isobutyl alcohol at different temperatures was investigated by optical interferometry. Figure 4 shows the typical interferograms of the interdiffusion zone for the system ММО–isobutyl alcohol at different temperatures.

As is clear from the interferograms, at temperatures of 26 and 42°С, only partial compatibility of the components is observed, and only at a temperature of 78°С does the interface disappear, thereby suggesting their unlimited mutual solubility. According to the interferograms, the boundary concentrations of the components in the interdiffusion zone were determined and the dependence of the temperature of transition to the single-phase state on composition was constructed (Fig. 5). In addition to the interferometry data (curve 1), the figure presents the corresponding dependences of transition points determined by DSC (curve 2). In fact, these dependences reflect phase equilibria in the system; that is, these are phase diagrams. This system is characterized by crystalline equilibrium. At a temperature above the liquidus line, the components are fully compatible.

The obtained phase curves make it possible to estimate the temperature–concentration interval in which the system is a single-phase solution. A similar character is also exhibited by the dependence of break points on the temperature dependences of viscosity shown in Fig. 3. However, the rheological behavior is too sensitive to the overcooling processes. Moreover, the viscosity does not reflect the thermodynamics of the process of phase transition; therefore, these data are omitted in Fig. 5.

Because ММО is a strongly polar hydroscopic solvent always containing water, it is of interest to analyze features of its behavior with isobutyl alcohol using IR spectroscopy. For example, we registered the IR spectra of ММО obtained from solutions in isobutyl alcohol and water as a result of evaporation of alcohol or water.

A comparison of the IR spectra of ММО obtained from isobutyl alcohol and water (Fig. 6) reveals an increased intensity of bands in the region of stretching vibrations of –ОН bonds (3400–3500 cm–1) and stretching (2800–3000 cm–1) and bending (1360–1470 cm–1) vibrations of ССН bonds and angles. Note that the spectrum of ММО obtained from alcohol exhibits absorption bands due to alcohol. It is worth noting that the intensity of the band at 1660 cm–1 (bending vibrations of Н–О–Н bonds) in the spectrum of ММО obtained from isobutyl alcohol is very high and that the band at 675 cm–1 due to the libration vibrations of water is present in this spectrum. Both of these bands can be attributed solely to vibrations of water molecules, and in the spectrum of ММО obtained from isobutyl alcohol, they are more intense than those in the spectrum of ММО obtained from water. As follows from analysis of the spectra, in the system ММО–water–isobutanol, alcohol is bound by hydrogen bonds with water. This bonding is so strong that a part of water is released from ММО crystals and occurs as a separate liquid phase (the intense band at 1660 cm–1) and possibly as a water–alcohol associate. The existence of such associates is indicated by a broad band at 2250 cm–1. Hence, it can be assumed that water is involved in the interaction of ММО crystal hydrates with isobutyl alcohol.

The revealed association of ММО hydrates with isobutyl alcohol should certainly contribute to the understanding of specific interaction appearing upon contact of cellulose solution with isobutyl alcohol under formation conditions. The use of interferometry makes it possible to model these processes directly in the cell of the optical interferometer. It should be emphasized that, in order to gain insight into the role of phase state of the blend MMO–isobutyl alcohol, experiments were conducted at two temperatures: room temperature, at which the blend can be two-phase depending on composition, and 90°С, that is, in the region of full solubility of butanol in MMO.

Figure 7 shows interferograms reflecting the interdiffusion of components of this system at 25°С. It is seen that, at the beginning of contact, the interdiffusion process occurs fairly intensely, as evidenced by the tempo of widening the dark region in the interdiffusion zone and the appearance of droplets of the liquid phase in cellulose solution in the region close to the interdiffusion zone (Fig. 7a). The intense diffusion of isobutanol having a high affinity for water triggers the redistribution of water in the system and, accordingly, the saturation of diffusing stream of alcohol with water. When the limiting concentration of compatibility is exceeded, the phase isobutyl alcohol–water delaminates and water droplets appear in the contact region (Fig. 7b). In addition, in this zone, from the solution side, a transparent layer is formed, in which interference fringes are seen.

Diffusion is intense from both sides, as indicated by the bends of interference fringes; however, issues as to what diffuses from the side of solution and what is the nature of the transparent liquid phase formed in solution at the boundary with alcohol are not so simple as they seem at first glance. As was mentioned above, the strong interaction of isobutanol with water results in the detachment of crystallization water from ММО molecules and its diffusion in isobutyl alcohol. In this case, the electron-donating activity of ММО grows, because free unshared electron pairs appear on the oxygen atom of the N–O bond and ММО molecules begin to interact with the hydroxyl groups of isobutanol. In other words, in ММО molecules, crystallization water is replaced with isobutanol molecules; therefore, in general, the state of the system changes substantially. Instead of a molecule of ММО hydrate, which is a solvent for cellulose, solvate isobutyl alcohol–ММО, which is a thermodynamically poor solvent (rather, precipitant) of cellulose, is formed. In addition, this solvate, owing to the presence of branched hydrophobic aliphatic ligand in an isobutanol molecule, possesses unfavorable steric parameters. This, first, may hamper its crystallization and, second, will affect diffusion processes, decelerating the kinetics of precipitation and the rate of structural rearrangements in cellulose. It is likely that a change in the phase composition of solution can initiate microphase amorphous lamination of the hydrophilic system polymer–solvent in the environment of the hydrophobized liquid phase. That is why no reflections of the crystalline MMO are detected in the film layer dried in air (Fig. 1).

With an increase in the time of contact between solution and precipitant, the considered diffusion processes become more distinct: the dark region in the interdiffusion zone increases and shifts to the side of solution and the amount of droplets of the aqueous phase on the interface grows appreciably. After 45 min, the interdiffusion processes fully stop, and it appears as if freezing of the amorphous solution without isolation of the crystalline cellulose takes place.

As regards a wide dark region of the interdiffusion zone, it is improbable that its appearance is associated with the formation of a dense heterogeneous gel-like film that fully blocks the stream of isobutanol to solution. Meanwhile, in the amorphous solution, as is seen from the interference picture presented in Fig. 7, the formed solvates ММО–isobutyl alcohol cause the processes of further phase transformations, as a result of which water is released in the bulk of solution, thereby initiating the precipitation of cellulose in the microvolumes of solution. The totality of the considered factors contribute to the microheterogeneous amorphous lamination of cellulose solution, causing its “whitening.”

When the film is formed in isobutanol at a temperature of 90оС, washed with isobutyl alcohol, and dried, the resulting film is nontransparent and lusterless. The X-ray diffraction pattern of such a film (Fig. 8), much like the case of cold alcohol, shows only an amorphous halo in the range of 2θ ~ 20°. This finding gives us grounds to state that the structure of cellulose is fully amorphized.

The interferometry studies of phase transformations occurring during the contact of cellulose solution with a hot alcohol bath (Fig. 9) indicate a high rate of interdiffusion. In this case, a liquid solution of cellulose in MMO is implemented. This makes it possible to remove microheterogeneity inherent in solution at room temperature and to observe interference fringes of the homogeneous solution. Note that the interdiffusion zone also becomes dark and water droplets are formed on the solution side. The opacity of the interaction zone provides evidence that a heterophase (nontransparent) multicomponent film is formed. Thus, the precipitation of cellulose upon contact with hot isobutanol is analogous to that in the previous case; that is, an amorphous film saturated with isobutanol is formed. It is not impossible that almost no MMO crystal hydrate, which at this temperature is soluble in isobutanol, remains in solution. This is apparently the crucial moment, because during washing with water and isolation of the cellulose film, its morphology is not complicated by the crystallization of MMO.

Moreover, in the preparation of interdiffusion experiments, the liquid solution of cellulose was loaded in the cell at a temperature above 100°С so that the thin layer could be obtained. In the course of time and especially during contact with cold isobutanol, it becomes cool and the crystallization of MMO begins in it (Fig. 7). Isobutanol “takes away” water from crystal hydrate and occupies its place. In this case, crystallinity apparently disappears, but the heterophase state (possibly, amorphous delamination) remains. When interaction with isobutanol is conducted at 90°С, the interdiffusion process proceeds under isothermal conditions, and in general there is no crystallization of MMO and the exchange of water for isobutanol in the MMO solvate proceeds under homogeneous conditions.

Thus, the morphologies of the cellulose films in two experiments should be much different, although in both cases the contact of solution with isobutanol is followed by washing with water, during which MMO is fully removed and the cellulose film is formed.

Let us consider first the structure of cellulose films obtained upon the contact of solution with isobutanol of different temperature and water treatment. Figure 10 presents the diffraction patterns of cellulose films formed in isobutyl alcohol at a temperature of 25 and 90°С followed by washing with water.

As is seen from Fig. 10, the diffraction patterns of the cellulose films formed in isobutyl alcohol at different temperature followed by washing with water show two basal peaks with angular positions of 2θ ~ 12° (d ~ 0.737 nm) and 2θ ~ 20.5° (d ~ 0.433 nm), as is typical of the structure of cellulose II [23]. With increasing temperature of alcohol, the ratio of intensities of the main peaks decreases somewhat owing to increase in interlayer periodicity (plane 101) and decrease in the intensity of peak 002. At the same time, decrease in the half-width of this peak suggests a certain increase in order in this layer.

Thus, various kinds of phase equilibrium in the studied systems solution–precipitating agent which are attained depending on precipitant temperature insignificantly change the structure of the final cellulose hydrate film after long storage in water (Fig. 10).

Taking into account the observed features of MMO interaction with isobutyl alcohol (and cellulose solution with isobutyl alcohol), it is advisable to turn to examination of the morphology of cellulose films precipitated in isobutanol at different temperatures and washed with water. Just morphology predetermines not only their mechanical but also separation properties. The cross section morphology of the films formed in isobutanol at a temperature of 25°С is shown in Fig. 11 at various magnifications.

On the micrographs of the films, defects are observed as cracks and layered large cavities in the polymer bulk. Their longitudinal dimension may reach 15–20 µm; the cross section, several microns. In more or less homogeneous regions, pores with an average diameter of ~100 nm are seen. Most probably, this can be explained by the presence of MMO in the solution layer before contact with isobutanol and preservation of heterogeneity when water in the MMO crystal hydrate is replaced with isobutyl alcohol. Because of steric reasons, solvate MMO–isobutyl alcohol does not crystallize, but the heterophase state is preserved after washing with water as well. In other words, the heterogeneity of solution is transformed into the heterogeneity of the film.

If “freezing” of the amorphous delamination of solution is excluded at the first stage of formation because of an increase in the temperature of the precipitating agent, the morphology of the films is changed substantially (Fig. 12).

Unlike defective films formed at room temperature, an increase in the temperature of alcohol to 90°С causes emergence of an almost homogeneous morphology without large defects. There are no cracks and visible pores on the surface of the cleaved film.

We showed that the precipitation of cellulose solutions in isobutanol at room temperature does not make it possible to remove the solvent from the film being formed during subsequent drying and entails considerable defects of cellulose morphology even after washing with water. Most likely, this is caused by the heterophase amorphous structure of solution at this temperature related to the formation of the MMO–isobutyl alcohol solvate. Using differential scanning calorimetry and optical interferometry, the phase state of the system ММО–isobutyl alcohol was studied and a diagram describing the crystallization equilibrium and defining the temperature–concentration “window” of compatibility of components was constructed. An analysis of the diagram makes it possible to determine the temperature–concentration region where cellulose films are formed under conditions excluding the appearance of morphological defects. For example, when isobutanol with a temperature above the liquidus line of the phase diagram was used, films possessing an almost homogeneous morphology were obtained.

REFERENCES

E. M. Aizenshtein, Fibre Chem. 48, 90 (2016).

K. E. Perepelkin, Fibre Chem. 39, 163 (2007).

V. M. Irklei, Fibre Chem. 22, 181 (1990).

Y. Teramoto, Molecules 20, 5487 (2015).

S. M. Hudson and J. A. Cuculo, J. Macromol. Sci., Polym. Rev 18, 1 (1980).

K. E. Perepelkin, Fibre Chem. 40, 10 (2008).

L. K. Golova, I. S. Makarov, E. V. Matukhina, S. A. Kuptsov, G. K. Shambilova, and V. G. Kulichikhin, Polym. Sci., Ser. A 50, 665 (2008).

D. L. Johnson, US Patent No. 3447939 (1969).

L. K. Golova, Fibre Chem. 28, 5 (1996).

Y. Abe and A. Mochizuki, J. Appl. Polym. Sci. 84, 2302 (2002).

Y. Abe and A. Mochizuki, J. Appl. Polym. Sci. 89, 333 (2003).

J. W. McBain and S. S. Kistler, Trans. Faraday Soc. 26, 157 (1930).

I. S. Makarov, L. K. Golova, L. K. Kuznetsova, S. V. Antonov, A. V. Kotsyuk, V. Ya. Ignatenko, and V. G. Kulichikhin, Fibre Chem. 48 (4), 298 (2016).

V. V. Romanov, A. N. Sokira, O. B. Lunina, and M. M. Iovleva, Fibre Chem. 20 (38) (1988).

O. A. Reutov, A. L. Kurts, and K. P. Butin, Organic Chemistry (Binom, Moscow, 2012) [in Russian].

H. P. Fink, P. Weigel, and H. J. Purz, Lenzinger Ber. 78, 41 (1998).

H. P. Fink, P. Weigel, H. J. Purz, and J. Ganster, Prog. Polym. Sci. 26, 1473 (2001).

V. A. Platonov and V. V. Smolikov, in Physicochemical Foundations of Production of Hydrated Cellulose Fibers by Nontraditional Methods, Ed. by S. P. Papkova and I. P. Baksheeva (VNIIVproekt, Mytishchi, 1989), p. 166 [in Russian].

L. K. Golova, RF Patent No. 1645308 (1992).

V. Makarova and V. Kulichikhin, in Interferometry – Research and Applications in Science and Technology, Ed. by I. Padron (InTech Publ., Rijeka, 2012), p. 393.

A. Malkin and A. Chalykh, Diffusion and Viscosity of Polymers: Methods of Measurement (Khimiya, Moscow, 1979).

L. Golova, I. Makarov, L. Kuznetsova, E. Plotnikova, V. Kulichikhin, in Cellulose – Fundamental Aspects, Ed. by T. Ven and L. Godbout (InTech, Tijeka, 2013), Chap. 13, p. 303.

Biodegradable and Sustainable Fibres, Ed. by R. Blackburn (Elsevier, Boca Raton; Boston; New York, 2005).

ACKNOWLEDGMENTS

We are grateful to L.K. Kuznetsova for participation in this work and discussion of the results.

Funding

This work was supported by the Russian Science Foundation, grant no. 17-79-30108.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Soboleva

Rights and permissions

About this article

Cite this article

Makarov, I.S., Golova, L.K., Vinogradov, M.I. et al. The Role of Isobutanol as a Precipitant of Cellulose Films Formed from N-Methylmorpholine N-Oxide Solutions: Phase State and Structural and Morphological Features. Polym. Sci. Ser. A 61, 598–609 (2019). https://doi.org/10.1134/S0965545X19050110

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965545X19050110