Abstract

In this work, a series of hydroxylmethyl triamide (HMTA) was synthesized from vegetable oil, diethylenetriamine were and hexamethylenetetramine, which was evaluated as a crude oil flow improver. The results showed that HMTA has a good viscosity reduction effect on the crude oil from Yanchang Oilfield, with the highest viscosity reduction rate of 89%. The highest pour point reduction depression was achieved as 7.4°C. Differential scanning calorimetry and paraffin crystal morphology characterization were conducted on the crude oil to elucidate the mechanism of viscosity reduction and pour point depression.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Crude oils, containing a wide range of hydrocarbon components, are extremely different on the physical properties, among which the flow property plays an important role in the production, storage, transport and refining [1, 2]. Especially under deep water or cold weather, crude oil production encounters severe operational problems, for example, paraffin blockage is a serious economical consequence due to possible obstruction of flow pipes or production lines [3]. Several options are available in practice, which include blending with lighter oil, stream heating, mechanical scraping and use of chemical additives [4]. At present, the possible mechanism of adding pour point depressant to improve the fluidity of crude oil is: (1) Reduce the irregularity of the wax shape; (2) Reduce the degree of aggregation of wax crystals. In addition, the non-crystalline hydrocarbon chain in the molecule of the pour point depressant linked to the polar group is soluble in the crude oil and has a spatial barrier to the wax crystals, which can overcome the Van der Waals force between the wax crystals, so as to improve the dispersion of wax in crude oil. Resins and asphaltenes are the components with the highest molecular weight and the highest polarity in crude oil. Resins and asphaltenes are not isolated in crude oil, and the two unit structure is similar. To a certain extent, asphaltenes is further aggregates of resins. They contain large amounts of strong polar groups such as carboxyl, amine and carbonyl groups, and molecules can form hydrogen bonds to increase cohesion, resulting in increased viscosity of crude oil [5].

Based on the above understanding, the paper uses fatty acyl polyamines of vegetable oil as reaction intermediates, by introducing the polar hydroxyl groups, the synthesis of hydroxylmethyl triamide as crude oil flow improver. The introduction of polar hydroxyl groups can enhance the interaction between the modifier molecules and the resins and asphaltene, and improve the tendency of resins and asphaltene aggregation, so as to reduce the viscosity of crude oil [6].

EXPERIMENTAL

Materials. Castor oil, rapeseed oil and soybean oil were purchased from Shaanxi Janxing Agriculture Technology Co., Ltd. All chemicals were purchased from Sinopharm Chemical Agent Co., Ltd. The crude oil used for evaluations was obtained from Yanchang Oilfield with no suspended sand particles. The physical parameters are shown in Table 1.

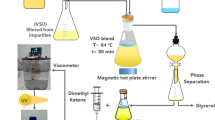

Preparation of hydroxylmethyl triamide (HMTA). Vegetable oil and diethylenetriamine were added in a beaker with the 1 : 3 molar ratio, stirred uniformly and refluxed for 4 h under 180°C to prepare the intermediate product. And then hexamethylenetetramine was added with a certain proportion of diethylenetriamine. After refluxing for another 4 h at a constant temperature of 180°C, hydroxylmethyl triamide (HMTA) was obtained. The synthetic route was shown in Scheme, and hydroxylmethyl triamides were named in Table 2.

Scheme 1. Preparation of hydroxylmethyl triamide.

Characterization of HMTA. The synthesized HMTA was characterized by FTIR. The spectra were recorded with a Bruker Tensor 37 spectrometer in the 400–4000 cm–1 region.

Effect of HMTA on crude oil’s viscosity and pour point. The viscosity of the crude oil is determined according to Petroleum and Natural Gas Industries Standard of The People’s Republic of China (SY/T0520-2008) [7]. The crude oil was sealed and heated to 45°C in a constant temperature bath, which was removed after 1 h, the crude oil was weighed 30 g and placed in the measuring cylinder, heated to 45°C, constant temperature 10 min. HMTAs was added into the waxy crude oil with the concentration of 500 mg HMTA per 1 kg crude oil, stirred uniformly and the cylinder into the thermostat, constant temperature 1.5 h, and a control experiment was carried out at the same time. Then the viscosity of crude oil was measured with a rotational viscometer at different temperatures [8, 9]. The pour point was tested according to Petroleum and Natural Gas Industries Standard of The People’s Republic of China (SY/T0541-2009) [10].

Paraffin inhibition and paraffin crystallization in simulated crude oil. Saturated hydrocarbons were separated by the column chromatography-based method according to Industrial Standard of China Petroleum SY/T 5119. The paraffin crystal in the saturated hydrocarbons of the heavy oil with and without 500 mg/kg HMTA-3 was investigated using an Olympus BH-2 polarizing microscope [11].

Differential scanning calorimetry (DSC) analysis. The DSC analysis of crud oil and with and without 500 mg/kg HMTA-3 were performed using a rotary evaporator RE-52A DSC apparatus. The temperature profile follows two steps: (1) Previous step: Sample is heated at 11°C/min from room temperature to 50°C to completely dissolve possible solid phase and to remove any thermal history; (2) Cooling step: Sample is cooled down from 50 to –20°C at 8°C/min.

RESULTS AND DISCUSSION

Characterization of HMTA. The synthesized HMTA-1 was characterized by IR, and the spectrum was shown in Fig. 1. It was easy to see from the results that the stretching vibration absorption peaks of hydroxyl and amide carbonyl appeared at 3340 (N–H) and 1625 cm–1 (C=O), diffraction vibration absorption peak of carbon-hydrogen bond in the methyl, methylene of the long alkane chain appeared at 3005, 2928 and 2844 cm–1 (sp3 C–H). HMTA-1 has the characteristic absorption peak of hydroxyl and amide carbonyl, and the hydroxyl absorption peak is stronger and wider.

Effect of HMTA on the viscosity of crude oil. The three HMTAs were evaluated in crude oil sample from Yanchang Oilfield pipeline as viscosity reducer. The HMTAs were added to the crude oil with the concentration of 500 mg/kg, the viscosity of the crude oil after the addition of the additive was measured under different temperatures, and the blank rest was conducted at the same time. The results were shown in Fig. 2. It can be seen from the results that the viscosity increases along with decrease of temperature, and the three HMTAs can reduce the viscosity obviously under low temperature, among which HMTA-1 shows the highest efficiency, 75% (20°C).

Then the three HMTAs were evaluated in the crude oil from Chang 2 reservoir. From the results shown in Fig. 3, three HMTAs display quite different ability in viscosity reduction. Although all the three HMTAs can reduce the viscosity of the crude oil, HMTA-1 and HMTA-2 can only reduce the viscosity slightly, while HMTA-3 is more efficient on reducing the viscosity of crude oil from the Chang 2. HMTA-3 can reduced viscosity from 5780 to 582 mPa s, with the viscosity reduction rate of 89% (20°C).

The three HMTAs were evaluated in the crude oil from Chang 6 reservoir. From the results shown in Fig. 4, three HMTAs display quite different ability in viscosity reduction. Although all the three HMTAs can reduce the viscosity of the crude oil, HMTA-1 and HMTA-3 can only reduce the viscosity slightly, while HMTA-2 is more efficient on reducing the viscosity of crude oil from the Chang 6 reservoir. HMTA-2 can reduced viscosity from 4520 to 1780 mPa s, with the viscosity reduction rate of 61% (20°C).

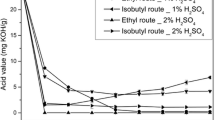

Influence of HMTA on the pour point of crude oil. The HMTAs were added into crude oil with a concentration of 500 mg/kg. The crude oil was uniformly stirred and the pour points of the three crude oil samples were measured, and the results were summarized in Table 3.

As can be seen from Table 3, the effect of HMTA on the three kinds of crude oil is quite different. HMTA-1 is noneffective for the pour point depression, but leads the pour point to increase. HMTA-2 is noneffective for the crude oil from Chang 2 reservoir, but can depress the pour point of the crude oil from Chang 6 reservoir and Yanchang pipeline by 5.2 and 3.8°C. HMTA-3 is more efficient on reducing the pour point of crude oil from Chang 2 reservoir, and the maximal pour point depression was obtained by 7.4°C. The hydroxyl groups of HMTA can act on resins and asphaltenes in the crude oil by hydrogen bonding, and the alkyl side chains interact with the non-polar parts (waxes) in the crude oil. As the types of vegetable oils are different, the alkyl side chains of the synthesized HMTA changes, which will effect the interaction of HMTA and crude oil during the precipitation and growth of wax crystals, so as to influence the pour point.

Paraffin crystal morphology analysis. When the temperature goes below the pour point value, paraffin crystals will deposit from crude oil, grow in the solution and tend to plug lines and filters. Paraffin inhibitor, alternatively known as wax crystal modifier, can reduce the growth of the paraffin crystal or lead to form smaller crystals of a higher volume to specific surface area. Besides, from the view of morphology, the paraffin inhibitors can modify the size and shape of paraffin crystals and inhibit the formation of large wax crystal lattices [12, 13]. So the morphology of paraffin crystal in HMTA-3 treated saturated hydrocarbon of crude oil from Chang 2 reservoir was investigated in the following work, and a control experiment was carried out under the same condition. The micrographs were shown in Fig. 5. From the two micrographs, it can be found that Fig. 5a shows a paraffin photograph of the saturated hydrocarbon component of the crude oil from Yanchang 2 reservoir, and the wax crystals are cotton-shaped crystals, which is easy to form a three-dimensional network and can confine the flow of the liquid so as to raise the viscosity and lead to solidification at last. Figure 5a shows the quantity and length of wax crystals decrease, so they are not so easy to form a three-dimensional network, and the viscosity and pour point was modified.

DSC analysis. The HMTA-3 was added to the crude oil from Chang 2 reservoir with a concentration of 500 mg/kg, uniformly stirred at 50°C and cooled to room temperature, then subjected to DSC analysis. The results were shown in Fig. 6.

According to the literature [14], the final temperature of wax precipitation range is selected at –20°C, 210 J/g was chosen as the average heat release during wax crystallization, and the wax content in crude oil was calculated by using formula, in other words, the ratio of the heat released by wax crystallization and the average heat of crystallization of crude oil samples from the wax precipitation point (T0) to –20°C is calculated:

In the formula, dQ is the amount of heat released from the wax in the crude oil sample at the temperature t ~ (t + dt), and its unit is J/g. \(\bar {Q}\) is the average crystallization heat of crude oil, unit is J/g. Heat of the temperature range [t0, ts] of the wax point to the pour point on the DSC curve is integrated to obtain the amount of wax before the pour point, the results were shown in Table 4.

It can be seen from Table 4, the wax precipitation point, wax content and peak temperature of wax precipitation were increased after adding HMTA-3. According to the nucleation theory, with the decrease of crude oil temperature, HMTA-3 precipitates and forms nuclei, becoming the center of wax crystal development, so that the wax in the crude oil can precipitate earlier than the blank oil sample, and the wax peak temperature reaches preferentially. At the same time, because the hydroxyl group (−OH) of the polar group in the HMTA-3 can interact with the resins and asphaltene in the crude oil, the long alkyl chain can interact with the wax crystals to increase the van der Waals force between the wax crystals in the crude oil, resulting in an increase in the amount of wax crystals in the crude oil [15].

CONCLUSIONS

Hydroxylmethyl triamide (HMTA) was synthesized from vegetable oil, diethylenetriamine and hexamethylenetetramine. HMTAs were evaluated as flow improver from the crude oil from Yanchang Oilfield. The three HMTAs display quite different ability in viscosity reduction in different crude oils. HMTA-3 got the most effective viscosity reduction on the crude oil from the Chang 2 with the viscosity reduction rate of 89% (20°C). The effect of HMTAs is general on the pour point of the three crude oils. HMTA-3 is more efficient on reducing the pour point of crude oil from Chang 2 reservoir, and the maximal pour point depression was obtained by 7.4°C. Paraffin crystal morphology analysis and DSC analysis discover the mechanism of the interaction between HMTA and crude oil.

REFERENCES

N. F. Carnahan, J. Pet. Technol. 41, 1024 (1989).

R. Martinez-Palou, M. Mosqueira, B. Zapata-Rendon, et al., J. Pet. Sci. Eng. 75, 274 (2011).

Y. P. Song, T. H. Ren, X. S. Fu, and X. H. Xu, Fuel Process. Technol. 86, 641 (2005).

X. M. Wei, X. L. Liu, W. D. Wang, and F. T. Xu, Specialty Petrochem. 5, 45 (2002).

W. J. Yu and Y. F. Yin, Sci. Eng. 39, 209 (2010).

Q. Z. Jiang and Z. Z. Song, J. Southwest Pet. Univ. 28, 59 (2006).

SY/T0520-2008: Viscosity Determination of Crude Petroleum-Equilibrium Method by Rotational Viscometer.

B. E. Wilburn and W. J. Heilman, US Patent No. 495 6111 (1990).

M. K. Mishra and R. G. Saxton, US Patent No. 5 834 408 (1998).

SY/T0541-2009: Test Method for Gel Point of Crude Oils.

G. Chen, Y. Tang, and J. Zhang, Chem. Cent. J. 5, 82 (2011).

A. G. Holder and J. Winkler, Nature 207, 719 (1965).

R. C. Price, Inst. Pet. 57, 106 (1971).

G. Chen, Y. F. Li, W. Zhao, et al., Fuel Process. Technol. 133, 64 (2015).

S. J. Chen, K. Zhao, G. Chen, et al., J. Clim. 2016, 1 (2016).

ACKNOWLEDGMENT

This work was financially supported by the grants from National Science Foundation of China (51504193), Scientific Research Program Funded by Shaanxi Provincial Education Department (17JF025) and Postgraduate Innovation Project of Xi’an Shiyou University (YCS16211028).

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Jie Zhang, Guo, Z., Du, W. et al. Preparation and Performance of Vegetable Oils Fatty Acids Hydroxylmethyl Triamides as Crude Oil Flow Improvers. Pet. Chem. 58, 1070–1075 (2018). https://doi.org/10.1134/S0965544118120046

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965544118120046