Abstract—

The article addresses matters concerned with digitalization and intellectualization of district heating systems (DHS) and is of a reviewing and problem-stating nature. Intellectualization of DHSs is viewed as a process of transition for a fundamentally new platform, within which it becomes possible to efficiently coordinate the interests, requirements, and capacities of all stakeholders participating in the heat-supply processes, and the consumer is given the role of an active full-fledged participant. The main lines, aims, and features of this process are briefly characterized. Both domestic and foreign experience gained from setting up centralized (district) heat-supply systems, including the most advanced development trends of these systems in EU member states. Special attention is paid to matters concerned with intellectualization of Russian DHSs. It is shown that the transition for a new paradigm will generate the need to cardinally revise the existing practices of DHS design, operation, and supervisory (dispatch) control. The key lines and tasks connected with transition to the new concept of managing the operation of DHSs as cyberphysical objects are formulated. The transition to this concept implies a wide use of mathematical and computer modeling methods for automating the DHS state monitoring processes, its analysis, prediction, and optimization. A significant part of the article is devoted to an analytical review of the current state of scientific-methodical developments in this field in four basic lines: mathematical modeling of DHS operation modes (hydraulic, temperature and thermal-hydraulic, stationary and dynamic, deterministic and probabilistic), identification of the DHS’s actual state (equipment characteristics, operating parameters, etc.) based on measurement data, optimization of DHS operation modes (for estimating the effectiveness of new heat-supply technologies, efficient DHS operation, and optimal control of DHS operation modes), and software for computer modeling of DHSs. Informative statements of DHS mathematical and computer modeling tasks are described along with the background developments for solving them available at ESI SB (Russian Academy of Sciences) are described.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

In Russia, as in the majority of economically developed countries, processes aimed at widescale digitalization of the economy and its sectors, including the power industry, are currently launched [1]. In a broad sense, the term “digitalization” generalizes such notions as computerization, informatization, automation, etc. The final aim of such processes is to make a transition to fully automated production with intelligent, real-time control in interaction with adjacent systems and external environment with the prospects of uniting in the global industrial network of goods and services. In a narrow sense, digitalization means providing possibilities for presenting, storing, transmitting, and processing information in digital form. From this point of view, digitalization is a necessary condition for intellectualization, which involves shifting the key management functions (analysis, prediction, making and implementation of decisions), which were previously performed by a human, to software. The wider the scope of such functions—for fulfillment of which the education, experience, and skills of specialists were previously needed, which are now entrusted to computers—the more “intelligent” is the technical system. In turn, the development of intelligent district heating systems (DHS) is the necessary condition for integration of various types of power systems.

The key intellectualization trends were formulated in the early 2000s within the Smart Grid concept, which was adopted as the power industry’s main development line in the economically developed western countries [2–4]. At present, this line is also being actively developed in the Russian electric power industry [5, 6]. Russia occupies a vast territory, a large part of which is in areas of harsh climatic conditions. This generated the need to develop DHSs that are unique in their scales and significance for the energy sector, industry, and social facilities; as regards the energy and resource saving problems, they are the most important components of the energy policy here [7, 8]. The transition for intelligent DHSs should, therefore, be considered as a strategic line of their innovative transformation, which is reflected in the strategy of scientific and technological development of the Russian Federation (RF) [9], in the priority development lines of the RF science, technologies, and engineering, critical RF technologies [10], RF technological platforms [11], and the federal project “Digital technologies” within the National Program “Digital Economy of the Russian Federation” [12].

A scientific and methodological base for intellectualization of piping energy systems (including DHSs) that could be laid at the heart of practical application is presently lacking both in our country and abroad. After having analyzed the worldwide experience with and trends in intellectualization of DHSs, and reviewed the modern achievements in the field of their mathematical modeling, we have formulated the application and scientific-methodical tasks encountered in transforming the conventional DHSs into cyberphysical systems that involve not only the main equipment but also information and computation resources directly influencing their performance. In view of these circumstances, we consider first of all in this article the key issues relating to analysis and optimal synthesis of the DHS cybernetic properties.

APPLICATION PROBLEMS OF DHS INTELLECTUALIZATION

DHS Intellectualization Notion and Aims

An unambiguous notion of a Smart Grid is still lacking, and the available ideas reflect the views and interests of the key participants of system intellectualization processes. State structures view the Smart Grid as a philosophy of national economy development programs, including the energy sector; the producers of equipment and technologies view it as a promising market for selling their products, and power companies view it as a basis for sustainable development resting on innovations. The specific features of different countries and regions also have a significant influence on the notion of intelligent power systems and pursued aims.

An analysis of the broad literature, program documents of various countries, and practical experience gained with intellectualization of power systems allows us to present the following fairly general interpretation—as we see it—of intellectualization, the notion of intelligent DHSs (IDHSs) and features that distinguish them from conventional DHSs [13–16], and put the key aims and means of implementing it in a systematic order.

The aims pursued by intellectualization of DHSs are in principle the same as the conventional requirements of achieving better efficiency, reliability, quality, and environmental friendliness of their operation. The main prospects are connected with new and, in many respects, unique possibilities of fulfilling these requirements owing to the combined use of modern information, telecommunication, and computer technologies (including the mathematical modeling and optimization methods), energy efficient main and maneuverable control equipment, and market mechanisms for coordination of interests, demand, and offers.

Intelligent DHSs are a fundamentally new platform within which it becomes possible to effectively concord the interests, requirements, and capacities of all parties participating (or interested) in the processes of end commodity production, transportation, and consumption processes. In so doing, the consumer is given the role of an active and full-pledged participant influencing on the consumption amounts, quality, and prices.

The list of main IDHS features includes the following:

1. The availability of a unified information (digital) space as the key system-forming factor ensuring observability of the production, distribution, and consumption processes for all participants of these processes.

2. A high level of controllability as the main method for harmonizing the requirements of consumers and capacities of producers (suppliers).

3. Dynamic pricing, which stimulates consumers for changing the customary consumption schedules and for energy saving.

4. A high proportion of digital, information, and telecommunication technologies and mathematical modeling and optimization methods in the real observation, control, and decision-making loops.

Brief Characterization of Foreign DHSs

The structure and capacity of DHSs differ from country to country. The countries in North America (the United States and Canada), EU member states, some CIS countries (Belarus, Ukraine, etc.) and in Northeastern Asia (China and Mongolia) are under climatic conditions commensurable with those in Russia. In the United States and Canada, there are significant prospects for the development of district heating [17] that have not been implemented as of yet. Thus, the share of DHSs in covering the heat load in the energy balance of Canada is approximately 0.4%, with 90% of this energy consumed by industrial enterprises [18]. Recent years have seen intense development of DHSs in the northern regions of China [19], in which heat-supply projects from nuclear sources are also developed.

District heating systems are developed most intensely in EU member states, in which there are approximately 3000 DHSs in cities and settlements with the population equal to or more than 5000 people; the annual generation of heat makes more than 630 million GJ, and the total length of heat networks is approximately 200 000 km [20]. Scandinavian countries are considered to be recognized leaders there, especially Denmark [21], in which state regulation of the technical and tariff policy in the heat-supply field has been conducted since the 1970s and, at present, DHSs cover approximately 60% of the heat demands, and all kinds of equipment for such systems are manufactured. In Copenhagen (with a population of 500 000 people), its DHS covers almost 100% of the thermal energy demand. More than 30 000 consumption nodes are connected to the heat networks (with the total length equal to 1400 km in the two-pipe version). The heat losses are equal to 3 and 15% in the trunk and distribution networks, respectively. The heat rates per square meter of residential area have decreased over the last 30 years by a factor of two [22]. Denmark’s national plan “Energy-21” developed for the period up to 2030 includes measures for further improvement of heat-supply efficiency [21].

DHS Development and Intellectualization Trends in the European Union

We present below a retrospective and brief characterization of the modern DHS development trends in Western Europe, in which new principles and technologies for setting up district heating are searched for most intensely in comparison with other countries. Four DHS generations are already distinguished here [23–25].

First-generation DHSs used steam as a heat carrier. These systems emerged for the first time in the United States in the 1880s and then also in Europe (up to 1930), and are presently regarded to be outdated in view of significant heat losses, safety problems, corrosion of return condensate pipes, etc. In many European cities, work on replacement of the heat carrier is either underway or has been completed.

In second-generation DHSs, hot water with a temperature above 100°C in the delivery pipeline and below 70°C in the return pipeline was used as heat carrier. These systems emerged in the 1930s and dominated up to the 1970s. Their typical components were pipes laid in concrete channels, bulky tubular heat exchangers, and control valves. Such systems were widely used in the former Soviet Union and are still used nowadays.

Third-generation DHSs began to be actively developed in the 1970s in connection with two oil crises. The characteristic features of third-generation DHSs are as follows:

1. Focusing on energy efficiency, cogeneration, and engagement of alternative energy sources (biomass, waste, solar heat, geothermal heat, etc.).

2. Extensive use of consumed heat metering devices and monitoring systems.

3. Decreased temperatures of water as heat carrier (below 100°C in the delivery line and below 45°C in the return line).

4. Use of prefabricated, preinsulated pipes and laying them without conduits, compact heat distribution stations equipped with compact plate heat exchangers made of stainless steel, pumps with adjustable frequency drives, etc.

Third-generation DHSs are sometimes called “the Scandinavian DHS technology,” because it is particularly these countries in which many manufactures of the relevant equipment are located. Engineers who develop all new systems and upgrade and extend old systems in China, Korea, Europe, the United States, and Canada are oriented at using the technologies of these third-generation systems.

The technologies of the future fourth-generation DHSs (4GDH), which are supposed to be embodied for the period up to 2050, are oriented at high energy efficiency and environmental friendliness, for achieving of which the following problems have to be solved:

1. Further decreasing of the heat carrier temperature (below 70°C in the delivery line and 50–25°C in the return line) for decreasing the heat losses, increasing the equipment service life, and integrating nonconventional low-temperature heat sources.

2. Setting up of energy-efficient heat consumption, which implies better thermal insulation of buildings, more intense heat release from heating devices, use of local substations, heat pumps, etc.

3. Intellectualization of the optimal interaction of the heat generation, distribution, and consumption processes.

4. Integration with the adjacent power systems (electric power, gas, cold, and water-supply systems).

5. Providing the appropriate planning, pricing, and motivation structures, and also strategic investments connected with their transformation into the future stable power systems.

An analysis of the plans for development of heat-supply technologies in Europe shows that they are aimed, on the one hand, at achieving more diverse and better DHS components and, on the other hand, at using new principles for controlling their operation, called intelligent and integral. In our opinion, there is a general tendency toward transforming the existing DHSs into cyberphysical systems. Indeed, for such a transformation, almost all technical prerequisites have been created, which are connected with the availability of systems for performing remote centralized monitoring of consumption as a source of feedback with a DHS; maneuverable main, control, and regulating equipment; and degrees of freedom to control the heat generation, production, and consumption modes as a consequence of using independent connection circuits of heat networks and consumption nodes of various levels. In this connection, the scientific and methodical problems relating to the development of concepts and methods for optimally controlling the operation modes of the new-generation DHSs come at the forefront.

Tasks to Be Solved in Intellectualization of Russian DHSs

District heating systems that are unique in their scale and complexity have emerged in Russia, many indicators of which do not have analogs in other countries [26]. At the same time, the tasks of their intellectualization have to be solved at the background of quite a number of inherited problems, such as general ageing of equipment, poor controllability, reliability, and technical support; increased failure rate; off-design operation modes; high heat losses and energy expenditures; managerial disunity of technologically interconnected systems; and conservative regulatory and legal framework.

The transition for the IDHS paradigm involves the need to settle a large set of scientific, regulatory, legal, technical, technological, economic, information, and other matters. It is also necessary to revise the existing practice of designing, operation, and supervisory (dispatch) control of DHSs. An analysis of this practice makes it possible to single out the following main problems that arise in making a transition to the new paradigm.

District heating systems are commonly designed for one so-called design maximal load operation mode, which follows from the requirement of providing guaranteed heat supply to consumers under any conditions. At the same time, the system dwells in this mode for only a small fraction of the total time of its operation. Given a highly nonuniform consumption schedule (especially if the consumers show an active behavior) and poor DHS controllability, such an approach entails excessive investments in the development and operational costs. The existing practice of designing does not make provisions to ensure the DHS controllability as a whole, and the controllability requirements and standards are completely lacking. In the best case, typical schemes for locally automating individual structures (sources, pump stations, heat distribution stations, etc.) are used. Accordingly, the existing practice of designing is poorly adapted to ensuring efficient performance of DHSs in a multitude of their possible operation modes.

The conventional DHS operational regulations prescribe the performance of repair work in accordance with the equipment standard service life (a planned preventive operation system). However, given the growing trends toward general ageing of this equipment, on the one hand, it becomes unrealistic to comply with these standards, while, on the other hand, it makes little sense to follow these standards. Depending on the particular conditions under which the equipment operates, the equipment’s actual service life may differ from its standard value by several times either toward increasing or decreasing.

The lack of full-scale information and measurement systems (IMS) has until the present been the main factor restraining the development and introduction of advanced dispatch control concepts implying the availability of feedback (the DHS observability and identifiability). In view of this, the simplest control concept “as per regulations” has thus far occupied the dominating position, in accordance with which the control decisions are made based on indirect signs (based on outdoor air temperature forecast, return water temperature at the sources, etc.), and the control consequences (the extent to which the consumers’ demands are met, operation mode acceptability and optimality, etc.) remain partially or fully nonobservable (i.e., the feedback principle as a basis of setting up reliable and stable control is not realized).

In turn, an analysis of these problems allows us to formulate the following basic tasks arising in the course of DHS intellectualization:

1. In designing: ensuring the operational effectiveness of the DHSs being designed (modified), development of controllability and observability norms and standards, and synthesis of control and information and measurement systems;

2. In operation: making a full-scale transition for a repair planning policy based on the actual state; widescale use of identification and technical diagnostic methods, damageability analysis, and prediction techniques; optimization of the repair and restoration work plans with taking into account the equipment’s actual state, damageability statistics, and losses for consumers;

3. In control of operation modes: transition to a new concept of compromise adaptive control in state space with feedback [13–16]; optimal planning and control in the basic (operational), postaccident, and “repair” modes; continuous tracing of the DHS’s actual state, and overcoming the departmental disunity between the DHS parts and adjacent systems that have process interconnections.

The concept formulated above implies the availability of the following operation mode control levels: technical-economic (management of operation modes and tariffs), time-scheduled (scheduling of modes and operative control) and territorial-management (process hierarchy levels, interdepartmental and intersystem levels).

The compromise control notion here means the need of dynamically coordinating the demand and offers between the suppliers and consumers and also with adjacent systems with efficient use of the available technical capacities and flexible pricing (tariff) policy. The state space is understood to mean the space of operating parameters (pressures, flowrates, and temperatures), the interrelation of which satisfies the load flow physical laws, which implies involvement of the relevant mathematical and electronic models. The adaptive control with feedback is understood to mean the possibility of adapting the involved models (due to their identification) to changes in the characteristics of DHS equipment and external impacts based on observation and measurement of operating parameters and environment manifestations.

A unified information (digital) space as a basis for coordinating the pricing policy and decisions on process control of DHS cannot be set up unless the departmental disjoint is overcome. In turn, such space implies the following: setting up of unified corporate, interdepartmental, and territorial (e.g., urban) information and measurement systems (IMS); integration of process-monitoring and fiscal-metering systems into unified IMSs; provision of information support for consumers and other participants to the heat-supply processes; application of new, high-speed telecommunication technologies and methods for acquisition and processing of large amounts of information.

Summarizing what was said above, it should be stated that the key line of resolving the usual contradiction between the DHS economic efficiency and reliability requirements on the way toward DHS intellectualization is connected with improvement of their controllability and application of mathematical and computer-modeling methods in the control process. Matters concerned with the development of such methods are addressed in numerous studies and broad literature, which points to the fact that they are topical and multidisciplinary in nature, and that there are many new unresolved problems. In what follows, we present a review of the modern state of the scientific and methodical developments and software in the field of key tasks relating to analysis, identification, and optimization of the operation modes arising in intellectualization of DHS operation control processes.

SCIENTIFIC AND METHODICAL PROBLEMS OF DHS INTELLECTUALIZATION

Modeling of DHS Operation Modes

Operation mode models are a basis of almost all classes of tasks relating to analysis and decision making on control. The tasks pursued by modeling the DHS operation modes (analysis tasks) consist of determining the flowrates, pressures, and temperatures for all of the analysis circuit components given the specified circuit topology, and hydraulic and thermal-physical characteristics of its components and boundary conditions (they include the operating parameters depending on the environmental manifestations). These tasks arise at almost all decision-making stages but have different aims: in designing new DHSs for analyzing the reliability and acceptability of their operation in off-design modes of their operation; in upgrading DHSs [27, 28] for analyzing the transmission capacity and revealing bottlenecks during operation on future loads; in planning the operation modes for the coming heating season [29, 30] for elaborating and substantiating measures taken to adjust the heat networks; and in performing dispatch control [31–34] for analyzing and substantiating control solutions.

In the theory of hydraulic circuits [35], models with lumped, variable (controlled), and distributed parameters are distinguished depending on the type of equations describing the operation mode (algebraic, implicit, differential, etc.).

The methods of nodal pressures [35–37], loop flowrates [35, 36], global gradient [38], and their modifications are the conventional methods for analyzing the hydraulic operation conditions based on the use of load flow models with lumped parameters. These methods are sufficiently well elaborated; they have received wide use and occupy the basic position in calculations of thermal-hydraulic operation modes, because, for a DHS, its thermal-hydraulic model can be decomposed into the models of hydraulic and temperature operation modes [29, 39]. Various methods for decreasing the dimension of the involved models at the level of simplifying the analysis circuits are proposed, which are oriented at special properties of the tasks relating to design, modification [40, 41] or operative control [31, 42] and at the properties of the engaged models of steady-state [31, 40–43] or dynamic [33, 36, 41, 44] modes depending on the modeling purposes.

The next problem, which arises in modeling the DHS operation modes, stems from the constantly growing range of control equipment for various purposes and with various principles of its operation. Two basic approaches can be distinguished among the existing load flow analysis methods in networks equipped with controllers. The first approach is connected with applying a sufficiently universal procedure of double (or nested) iteration cycles [35], which is intended for analysis of hydraulic circuits with variable (controlled) parameters. The authors of [27, 45] consider a procedure that also implies the use of double iteration cycles, but the load flow problem at fixed operation parameters maintained by controllers is solved in the inner cycle and the composition of active controllers is updated in the external cycle. Based on the second approach, the authors of [46] developed a so-called “convolution-evolution” procedure, which consists of updating the network’s mathematical model in the external iteration cycle depending on the state of flowrate controllers. In [37], its authors proposed a new “relay” procedure, which makes it possible to significantly speed up the computations owing to the possibility of doing away with external iteration cycles. In recent years, various approaches to load flow analysis with individual types of controllers have been proposed both in Russia [45–48] and abroad [49, 50]; however, they do not cover the entire range of control equipment types. Indirect-action temperature controllers or mixing pump stations [51, 52] that are used for decreasing the temperature schedule can be mentioned as an example of such specific controllers.

In calculations of unsteady hydraulic operation modes (based on load flow models with distributed parameters), the following methods are traditionally used: the wave and boundary method [53–55], the method of characteristics [56–58], the method of “running” calculation schemes [59, 60], and the control volume method [33].

In recent years, increasingly more attention has been paid to modeling the dynamics of temperature operation modes in view of their having high inertia and being characteristic of DHSs. There is a significant diversity of the proposed models and methods with the aim of finding a rational combination of the accuracy of results and computation speed. General heat-transfer equations in differential form are, as a rule, used as the basic models [61–65]. Among the methods proposed in the foreign literature for analysis of heat-transfer dynamics, the following are proposed: the finite element method [66], the “element” method” [67, 68], the nodal method [67–71], the method of characteristics [64], the method of functions [72], the quasi-dynamic modeling method [68, 72, 73], etc. Specialists of ESI SB (Russian Academy of Sciences) have developed a quasi-dynamic method for tracing the temperature front (produced on heat sources) at all nodes of the DHS analysis circuit [74]. By using this method, it is possible to take into account heat losses during transportation, accumulating capacity of buildings, variety of consumer connection schemes [75], and other factors [63, 76, 77].

Recent years have seen a growing interest in the tasks concerned with probabilistic analysis of operation modes for obtaining adequate solutions under the real stochastic conditions of environmental impacts. Such problems are considered in application to water-supply systems (in designing them) in [78, 79], in which the probabilistic load flow models are given in implicit form, which entails certain difficulties in carrying out mass-scale calculations of systems with a high dimension. In foreign studies, probabilistic statements appear in the problems of estimating the loss caused by undersupply of water [80], in considering the uncertainty in the operation of storage reservoirs and pump stations [81–83], and in a reliability analysis [84–87]. In many cases, the problems of a probabilistic analysis of pipeline system operation modes are formulated without specifying the numerical solution methods (e.g., [88]), or it is proposed to use the classic statistical test method (the Monte Carlo method) [81–83]. In [89–92], their authors proposed an approach to obtaining analytical probabilistic models of steady-state hydraulic operation modes, which can be used for water and heat-supply systems under the conditions of a stochastic consumption pattern.

The methods presented here feature versatility, satisfactory accuracy, and low computation effort in comparison with the Monte Carlo method. By using these methods, it is possible to calculate all probabilistic characteristics of the operation modes established in a network with an arbitrary configuration (multiloop, tree-like, and mixed) and any composition of boundary conditions specified in probabilistic form (nodal pressures, nodal flowrates, and branch flow frictions).

Summarizing the review of this cluster of studies, it should be stated that it is rather limited from the viewpoint of the possibilities of applying the results of these studies for new classes of problems connected with DHS intellectualization: the mathematical models of DHS operation modes as the basis for formulation and effective solving of identification and optimal control problems (which are addressed in the subsequent sections of this review); operation mode modeling methods as a basis for development of DHS “digital twins” for analyzing the DHS properties (controllability, identifiability, effectiveness, etc.); and also for elaborating new concepts, rules, and optimal control algorithms. For both classes of the problems, real DHS operation conditions (operation mode dynamics, stochastics of external disturbances, and uncertainty of information about the equipment internal state) have to be taken into account. For these factors to be jointly taken into account, further development of the DHS mathematical modeling methods is necessary.

Identification of DHS Parameters and Operation Modes

The basic aim of DHS identification is to determine the equipment’s actual state from the measurement results. The identification aims include identification of equipment characteristics (parametric identification), identification of operation modes (state assessment), and identification of faults (technical diagnostics). In doing so, the question inevitably arises of whether these aims can be achieved based on the information accessible for measurement. Thus, the DHS identification is a complex problem generating the need to develop a self-contained methodical technique for solving two tasks: an analysis and synthesis of information and measurements systems from the viewpoint of the scope and parameters of measurement instruments, their acquisition rate, etc., and development of effective identification methods ensuring the possibility of processing large amounts of measurement information.

The problem of the optimal placement of measurement instruments is addressed in numerous literature sources dealing with electric power and pipeline systems [93–110]; this problem has been developed in electric power engineering on the whole for the possibility of estimating the state of these systems (observability) [100–104]. In recent years, much attention has been paid to the placement of phasor measurement tools (PMU, Smart meters) with the use of integer programming methods [101, 105]. In water-supply systems, studies on the problem of optimal placement of sensors for identifying load flow models are semiheuristic in nature [92–98]. Such studies are carried out mainly to ensure the possibility of identifying water quality models [93, 94, 99], tracing these parameters, and determining pollution sources [95–98]; in implementing the proposed methods, application of genetic algorithms is implied in the majority of cases [93–99]. In [106, 107, 111], the possibility of ensuring the identifiability of pipeline systems (including DHSs [109, 110]) was studied for the first time, and methods for analyzing it were proposed, including the algorithms for optimizing the scope of measurement instruments guaranteeing the possibility to obtain a global solution.

A large number of papers are devoted to development and application of methods for parametric identification of pipeline systems [77, 112–127]. Outside of Russia, these tasks are called “model calibration” for water- [99, 119–123] and heat-supply systems [124–127]. For calibrating the models of water-supply systems [119–121] and DHSs [124], a combination of load flow analysis methods and genetic algorithms is generally proposed.

In [122, 123], their authors analyze the possibility of reducing the requirements for the number and placement of measurement instruments owing to a shift from identification of individual coefficients of each system component to identification of a common coefficient for a group of components.

In [126], the possibility of state estimation for steady-state hydraulic and temperature operation modes based on the results from measurements of operation parameters at the consumers is studied as applied to radial DHSs. The method proposed in [126] is semiheuristic in nature and can hardly be applied to meshed networks. In [127], its authors consider the problem of calibrating the models of a DHS steady-state temperature operation mode, which is also proposed to be solved using genetic algorithms in combination with the temperature operation modes analysis methods. Publications also appear that deal with problem statements and DHS technical diagnostic methods using working-medium flow models (detection of leaks, malfunctions, etc.) [128–132].

Essential limitations inherent in the majority of the proposed approaches are that the problems of processing the measurement results for identification purposes are given in a stationary formulation, that the proposed methods are either semiheuristic in nature and (or) are highly labor consuming, and that the identification problems are solved without taking into account their solvability.

Studies aimed at solving the above-mentioned problems are described in [77, 108–110, 116–118]. In [77, 114, 118], its authors consider analytical methods for parametric identification and assessment of the state of pipeline systems having an arbitrary structure and configuration, which feature a rational combination of formal rigor and computation effectiveness. In [110, 118], its authors proposed an original procedure for actively identifying a DHS based on sequential application of optimal experiment planning methods. This procedure includes the measurement placement methods [109] and measurement result processing methods [112].

In connection with the introduction of modern telecommunication and information and measurement technologies, there appear real prerequisites for setting up the processes of tracing the equipment operation modes and parameters based on measurement results. However, an analysis of data from the literature shows that, at present, methods that would make it possible to perform such tracing in the online mode are still lacking. In [16], its authors outlined the prospects of using the relevant methods and the possibility to, in principle, develop and implement them based on the existing theory and identification methods developed at ESI SB (Russian Academy of Sciences) [108–110].

Optimization of the District Heating System Operation Modes

The DHS operation modes' optimization problems are very diverse; they differ in purposes, involved models, and solution methods and arise at almost all decision-making levels for searching optimal controls.

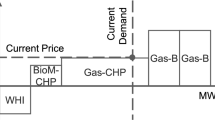

At the DHS development and modification stage, such problems are necessary to substantiate the acceptability and refine the operational costs on a set of possible (off-design) operation modes and estimate the effectiveness of new heat-supply technologies, including the potential effects from implementation of the following measures:

1. Integration of various heat sources [boiler houses, combined heat and power plants (CHPP), electricity, solar, wind energy, etc.] [133, 134].

2. Integration of “prosumer” heat sources into a DHS and transition for a mutually profitable tariff policy [135].

3. Use of various types of storage devices for shaving the heat load peaks in DHSs [136–140].

4. Use of heat accumulating capacity of buildings and heat networks for coordinating the peaks of heat generation and consumption [134, 141, 142].

5. Use of heat pumps to meet the environmental requirements [143].

6. Shifting for controlling the heat carrier flowrate and multiloop (“impersonal”) scheme of heat network operation [144].

7. Shifting for the use of decreased heat carrier temperatures in DHSs [145].

8. Changing the customary consumption schedules (control of heat demand) [142, 146, 147].

At this stage, various criteria, models, and methods are involved, including the following:

1. Criteria: of discounted costs [133–135, 145], operational costs (for fuel, electricity, penalties for emissions) [133–135], exergetic specific heat cost [145], maximum heat generation at CHPPs (minimizing the loading of peaking boiler houses), maximal load minimum [146], etc.

2. Operation mode models: simplified energy flow balance models [135], aggregated models of joint operation of CHPPs, storages, and heat networks (as the total load) [142], stationary hydraulic operation modes [133], stationary hydraulic and simplified dynamic temperature operation mode models [146].

3. Optimization methods: formal (e.g., integer-linear programming [133, 134]) and semiheuristic (annealing simulation [148], evolutionary algorithms etc. [149, 150]), which are, as a rule, selected proceeding from the convenience of application, including with the use of commercial software packages: of general purpose (MATLAB/Simulink [135]), heat network simulation (Grades Heating [144]), heat transfer in buildings (IDA-ICE [142]), etc.

In the operation stage, the DHS operation mode optimization problems arise in developing the main operation modes and heat network adjustment measures, and they are also considered as one of the main energy-saving lines [151–154]. For energy saving purposes, various formulations and methods for optimal planning of operation modes are proposed depending on the DHS’s specific features (the availability of storage devices, diversity of heat sources, DHS scale) and the specified forecasting time (from annual to daily) [41, 155–158]; furthermore, the following techniques are involved:

1. Energy, economic, and combined criteria of fuel and electricity expenditures for maintaining the operation modes.

2. Steady-state thermal and hydraulic operation mode models.

3. Linearization methods (of an initially nonlinear problem, e.g., for bringing it to a standard integer linear programming problem), evolution algorithms, etc.

At the dispatch control level, the DHS operation mode optimization problems need to be solved for short-term planning of the main equipment loading and making decisions for online control of operation modes. The optimization problems relating to operative planning and control of operation modes can be solved for small-size district heating systems (see, e.g., [155, 159, 160]). In the majority of cases, operative control methods on the basis of formal cybernetic models (“black box”) are proposed, which correlate the demand for heat with the control parameters (the frequency of pump electric drives [31, 161–163], and water heating temperatures in the sources [159, 164, 165], etc.), including with the use of transfer functions [164], sensitivity models [31, 161, 162], artificial intelligence models [165], etc. The criteria of thermal comfort in buildings [159, 160, 164] and also energy [31, 161, 162], economic [159, 161], and combined criteria are applied as optimality criteria.

The presented review of the literature (which is far from being exhaustive) allows us to state that there is a growing need of solving the problems of optimizing the DHS operation modes, and that these problems are complex and multidisciplinary in nature, that there are a lot of unresolved tasks, and that there is lack of efficient general-purpose methods suitable for wide practical use. This is attributed to quite a number of objective factors: the models of DHS operation modes have a large dimension and are nonlinear in nature; there are a number of technological requirements and constraints imposed on the operation parameters; there are various control methods and their combinations (continuous and discrete); there are limitations on their application places and on their values; the majority of arising tasks are multicriterial in nature; and there is a need to take into account the dynamics, stochastics of external conditions, etc.

ESI SB (Russian Academy of Sciences) specialists have proposed a new hierarchical approach to optimization of DHS hydraulic operation modes for planning them for the next heating season and for automating the development of adjustment measures [39]. This approach implies decomposition of the DHS analysis scheme into trunk and distribution heat networks and application of self-contained effective methods [166–171] of optimization for each hierarchical level. This approach has the following main capacities:

1. It is applicable for DHS of almost any dimension.

2. There is a guarantee to obtain a global solution without resorting to iterative coordination of the solutions at different levels.

3. Different optimality criteria (economic, technological, environmental, etc.) and also operation mode control types (continuous, discrete, and Boolean) are distributed among different hierarchy levels.

4. It is possible to take into account any technological constraints on the operation parameters.

5. It is possible to take into account all existing control methods (the composition of connected equipment, throttling, frequency control, etc.).

6. A high computation speed due to the possibility of arranging the computation process in parallel flows.

Information and Computing Technologies for Computer Modeling of DHS

The modern market of software products for computer modeling of DHSs is quite extensive, which points to its being in demand for engineering applications. Both Russian and foreign developments can be pointed out here: the ANGARA-TS information and computing system (ESI SB, Russian Academy of Sciences, Irkutsk, Russia) [172–177], ZuluThermo (Politerm, St. Petersburg, Russia) [178], City Com-TeploGraf information and graphical system (CityCom, Moscow, Russia) [179], Teploekspert (Teploteks, Ivanovo, Russia) [180], Termis (Schneider Electric) [181], NEPLAN (Neplan AG) [182], NetSim (Vitec) [183], STANET [184], PSIControl [185], WANDA (Deltares) [186], PSS Singal [187], AEM Gestioni Srl (Bentley) [188], etc.

All of the presented software systems (SS) offer the possibility to perform thermal-hydraulic analyses of stationary DHS operation modes and have a set of analytical functions for interpretation of calculation results. The Termis and NEPLAN systems allow the user to carry out simplified modeling of dynamic operation modes with a specified time step; it is possible by using the WANDA system to numerically analyze unsteady hydraulic modes of DHS operation (an analysis of consequences from connection/disconnection of pumps, closing of gate valves, etc.); the NEPLAN, PSS Singal, Teplograf, Teploekspert, and ANGARA-TC systems allow the user to perform a damageability analysis on the basis of failure statistics. By using the Termis system, it is possible to forecast heat generation taking into account the predicted loads of consumers; the NEPLAN, PSIControl, and PSS Singal systems also contain modules for predicting the consumer loads. The Termis, NEPLAN, NetSim, and WANDA systems enable the user to optimize operation modes for minimizing the operational costs, and it is possible to optimize the pipeline diameters using the Termis and STANET systems.

Nonetheless, the majority of the presented commercial SS are, as a rule, closed in functions and data (i.e., they are not suited for incorporation of new tasks requiring additional information). In view of this circumstance, many scientific schools develop their own programs for modeling heat networks [189–192]. There are hardly any scientific publications describing the SS architecture and the mathematical modeling methods incorporated in it. From reviewing publications, article [193] should be pointed out, which contains a fairly full review of the modern computer programs for modeling of heat networks that have been developed outside of Russia. In recent years, a tendency has been observed in which DHSs are modeled in interaction with their adjacent systems (power supply, gas supply, conventional and renewable energy sources, local and intra-house power systems). The software (as well as the concepts of its development and filling) for modeling and controlling intelligent heat networks is still in its formation stage.

ESI SB (Russian Academy of Sciences) specialists have developed an original platform called the ANGARA information and computing system (ICS) [172–174], which offers the following possibilities:

1. Hierarchic presentation of DHS schemes with automatically matching the boundary parameters between the levels.

2. Carrying out multilevel and single-level calculations.

3. Consideration of physically grounded behavior rules of consumers and control devices.

4. The possibility for the user to extend the scope of parameters for analysis of operation modes.

5. The possibility to carry out hydraulic and thermal-hydraulic calculations and graphic analysis of their results.

6. Using the ICS for various types of systems and application fields (operation, designing, etc.).

This platform can potentially serve as a basis for implementing the concept of a unified enterprise information space [194, 195] based on the principle of integrating the information resources “from the bottom to top,” according to which the key importance is given to information and analytical support for managerial decision-making issues rather than to automation of the document-management issues.

CONCLUSIONS

(1) Intellectualization of Russian DHSs is a topical line of their innovative transformation for which there is hardly any alternative. We have for the first time taken an attempt to analyze and systematize the key problems that arise in transforming the conventional DHSs into cyberphysical systems. The feature that qualitatively distinguishes such systems is that these systems contain not only their main equipment but also information and computation resources directly determining their performance indicators.

(2) Experience gained around the world in the evolution of district heating technologies shows that there are presently all prerequisites necessary for intellectualization of DHS technological control processes. The existing practices of designing, operation, and dispatch control of Russian DHSs were analyzed, and the tasks that have to be solved toward this aim have been formulated based on the analysis results. A new concept of DHS optimal control in the state space has been proposed, which implies the availability of a full-scale feedback, the possibility of adapting to the varying external and internal conditions, and a compromise control of these operation modes featuring a multilevel structure in time and space.

(3) The main lines of further investigations in the field of fundamental problems relating to analysis and synthesis of the DHS cybernetic features have been outlined. It is shown that the theoretical and application results obtained at ESI SB (Russian Academy of Sciences) on the basis of such original scientific discipline as the theory of hydraulic circuits can potentially be laid at the heart of such investigations.

REFERENCES

K. Schwab, The Fourth Industrial Revolution (World Economic Forum, Cologny, Switzerland, 2016; Eksmo, Moscow, 2020).

B. B. Kobets, I. O. Volkova, and V. R. Okorokov, “Smart Grid as a concept of innovational development of electric power industry abroad,” Energoekspert, No. 2, 24–30 (2010).

"GRID 2030" — A National Vision for Electricity’s Second 100 Years (Office of Electric Transmission and Distribution of U. S. Department of Energy, 2003).

European SmartGrids Technology Platform: Vision and Strategy for Europe’s Electricity Networks of the Future (European Communities, Belgium, 2006).

B. B. Kobets and I. O. Volkova, Innovational Development of Electric Energy Industry Based on Smart Grid Concept (Energiya, Moscow, 2010) [in Russian].

The Concept of an Intelligent Electric Power System in Russia with an Active-Adaptive Grid, Ed. by V. E. Fortov and A. A. Makarov (NTTs FSK EES, Moscow, 2012) [in Russian].

On Energy Saving and on Improving Energy Efficiency and on Amendments to Certain Legislative Acts of the Russian Federation, RF Federal Law of November 23, 2009 No. 261-FZ.

Energy Strategy of the Russian Federation for the Period Until 2035, Approved by RF Government Decree of June 9, 2020 No. 1523-r.

On the Strategy of Scientific and Technological Development of the Russian Federation, RF President’s Decree of 01.12.2016 No. 642.

On the Approval of the Priority Directions for the Development of Science, Technology and Technics and the List of Critical Technologies of the Russian Federation, RF President’s Decree of 07.07.2011 No. 899.

List of Technological Platforms of the Russian Federation (2011).

National Program “Digital Economy of the Russian Federation” (2019).

N. N. Novitskii, “Intelligent pipeline systems: Arguments, content, prospects,” Kommun. Khoz. Gor., Ser. Tekh. Nauki Arkhit., No. 101, 456–464 (2011).

N. N. Novitskii, “Intelligent pipeline systems as a new object of application of the theory of hydraulic circuits,” in Russia’s Energy Industry in 21th Century: Innovational Development and Control: Proc. All-Russian Conf., Irkutsk, Russia, Sept. 1–3, 2015 (Inst. Sist. Energ. im. L. A. Melent’eva Sib. Otd. Ross. Akad. Nauk, Irkutsk, 2015), pp. 378–389.

N. N. Novitskii, “Methodical problems of intellectualization of pipeline systems and directions of development of the theory of hydraulic circuits for their solution,” in A. A. Atavin, N. N. Novitskii, M. G. Sukharev, A. M. Chionov, T. E. Ovchinnikova, V. A. Emel’yanov, L. B. Korel’shtein, E. A. Mikhailovskii, O. V. Vanteeva, S. A. Korshunov, R. V. Popov, V. V. Tokarev, Z. I. Shalaginova, V. V. Tarasevich, A. N. Ser’eznov, et al., Energy Pipeline Systems: Mathematical and Computer Technologies of Intellectualization (Nauka, Novosibirsk, 2017), pp. 167–183 [in Russian].

N. N. Novitsky, Z. I. Shalaginova, A. A. Alekseev, V. V. Tokarev, O. A. Grebneva, A. V. Lutsenko, O. V. Vanteeva, E. A. Mikhailovsky, R. Pop, P. Vorobev, and M. Chertkov, “Smarter smart district heating,” Proc. IEEE 109, 1596–1611 (2020). https://doi.org/10.1109/JPROC.2020.2990490

H. C. Gils, J. Cofala, F. Wagner, and W. Schöpp, “GIS-based assessment of the district heating potential in the USA,” Energy 58, 318–329 (2013). https://doi.org/10.1016/j.energy.2013.06.028

Energy Policies of IEA Countries: Canada 2009 Review (Organisation for Economic Co-operation and Development / International Energy Agency, Paris, 2010).

V. G. Semenov, “Foreign experience in operating heat supply systems,” Energosberezhenie, No. 7, 62–65 (2005).

A. Colmenar-Santos, D. Borge-Díez, and E. Rosales-Asensio, District Heating and Cooling Networks in the European Union (Springer, Cham, 2017).

A. Krolin, “Efficient heat supply: Danish experience,” EnergoRynok, No. 4 (2005).

Yu. V. Yarovoi, “Experience in managing district heating systems in the cities of Denmark,” Ekol. Sist., No. 9 (2010).

H. Lund, S. Werner, R. Wiltshire, S. Svendsen, J. E. Thorsen, F. Hvelplund, and B. V. Mathiesen, “4th Generation District Heating (4GDH) integrating smart thermal grids into future sustainable energy systems,” Energy 68, 1–11 (2014). https://doi.org/10.1016/j.energy.2014.02.089

H. Lund, N. Duic, P. A. Ostergaard, and B. V. Mathiesen, “Future district heating systems and technologies: on the role of smart energy systems and 4th generation district heating,” Energy 165A, 614–619 (2018). https://doi.org/10.1016/j.energy.2018.09.115

A. Piacentino, N. Duic, N. Markovska, B. V. Mathiesen, Z. Guzović, V. Eveloy, and H. Lund, “Sustainable and cost-efficient energy supply and utilisation through innovative concepts and technologies at regional, urban and single-user scales,” Energy 182, 254–268 (2019). https://doi.org/10.1016/j.energy.2019.06.015

I. A. Bashmakov, “Analysis of the main trends in the development of heat supply systems in Russia,” Energ. Polit., No. 2, 10–25 (2009).

E. V. Sennova and V. G. Sidler, Mathematical Modeling and Optimization of Developing Heat Supply Systems (Nauka, Novosibirsk, 1987) [in Russian].

V. A. Stennikov, E. A. Barakhtenko, and D. V. Sokolov, “Determination of optimal parameters of heating systems based on advanced information technologies,” Energy Syst. Res. 1 (1), 84–93 (2018). https://doi.org/10.25729/esr.2018.01.0010

V. V. Tokarev and Z. I. Shalaginova, “Technique of multilevel adjustment calculation of the heat-hydraulic mode of the major heat supply systems with the intermediate control stages,” Therm. Eng. 63, 68–77 (2016). https://doi.org/10.1134/S0040601516010110

N. N. Novitskii, Z. I. Shalaginova, V. V. Tokarev, and O. A. Grebneva, “Technology for the development of operating modes of large heat supply systems based on methods of multilevel thermohydraulic modeling,” Izv. Ross. Akad. Nauk, Energ., No. 1, 12–24 (2018).

E. Guelpa, C. Toro, A. Sciacovelli, R. Melli, E. Sciubba, and V. Verda, “Optimal operation of large district heating networks through fast fluid-dynamic simulation,” Energy 102, 586–595 (2016). https://doi.org/10.1016/j.energy.2016.02.058

M. Vesterlund, A. Toffolo, and J. Dahl, “Optimization of multi-source complex district heating network, a case study,” Energy 126, 53–63 (2017). https://doi.org/10.1016/j.energy.2017.03.018

E. Guelpa, A. Sciacovelli, and V. Verda, “Thermo-fluid dynamic model of large district heating networks for the analysis of primary energy savings,” Energy 184, 34–44 (2019). https://doi.org/10.1016/j.energy.2017.07.177

N. N. Novitskii, “Development of the hydraulic circuit theory for solving problems of controlling the operation of heat supply systems,” Therm. Eng. 56, 1024–1029 (2009). https://doi.org/10.1134/s0040601509120052

A. P. Merenkov and V. Ya. Khasilev, Theory of Hydraulic Circuits (Nauka, Moscow, 1985) [in Russian].

B. S. Gilani, M. Bachmann, and M. Kriegel, “Evaluation of the temperature regimes of multi-level thermal networks in urban areas through exergy analysis,” Energy Procedia 122, 385–390 (2017).

N. N. Novitskii and V. V. Tokarev, “Relay method for calculating the flow distribution in hydraulic circuits with adjustable parameters,” Izv. Ross. Akad. Nauk, Energ., No. 2, 88–98 (2001).

E. Todini and S. Pilati, “A gradient algorithm for the analysis of pipe networks,” in Computer Applications in Water Supply, Ed. by B. Coulbeck and C.-H. Orr (Wiley, London, 1988), Vol. 1, pp. 1–20.

N. N. Novitsky, A. V. Alekseev, O. A. Grebneva, A. V. Lutsenko, V. V. Tokarev, and Z. I. Shalaginova, “Multilevel modeling and optimization of large-scale pipeline systems operation,” Energy 184, 151–164 (2019). https://doi.org/10.1016/j.energy.2018.02.070

A. Lazzaretto, A. Toffolo, M. Morandin, and M. R. von Spakovsky, “Criteria for the decomposition of energy systems in local/global optimizations,” Energy 35, 1157–1163 (2010). https://doi.org/10.1016/j.energy.2009.06.009

M. Vesterlund and J. Dahl, “A method for the simulation and optimization of district heating systems with meshed networks,” Energy Convers. Manage. 89, 555–567 (2015). https://doi.org/10.1016/j.enconman.2014.10.002

A. D. Nardo, A. Cavallo, M. D. Natale, R. Greco, and G. F. Santonastaso, “Dynamic control of water distribution system based on network partitioning,” Procedia Eng. 154, 1275–1282 (2016). https://doi.org/10.1016/j.proeng.2016.07.460

V. V. Tokarev, “Developing a procedure for segmenting meshed heat networks of heat supply systems without outflows,” Therm. Eng. 65, 400–409 (2018). https://doi.org/10.1134/S0040601518060101

G. Schweiger, P.-O. Larsson, F. Magnusson, P. Lauenburg, and S. Velut, “District heating and cooling systems — Framework for Modelica-based simulation and dynamic optimization,” Energy 137, 566–578 (2017). https://doi.org/10.1016/j.energy.2017.05.115

S. P. Epifanov and V. I. Zorkal’tsev, “Application of the theory of duality in modeling hydraulic systems with flow controllers,” Izv. Vyssh. Uchebn. Zaved., Mat., No. 9, 76–81 (2010).

G. V. Monakhov and Yu. A. Voitinskaya, Control Modeling of Heating Network Modes (Energoatomizdat, Moscow, 1995) [in Russian].

S. P. Epifanov, V. I. Zorkal’tsev, and D. S. Medvezhonkov, “Hydraulic network model with flow controllers,” Upr. Bol’shimi Sist., No. 30.1, 286–299 (2010).

N. I. Baranchikova, S. P. Epifanov, V. I. Zorkal’tsev, A. V. Kurtin, and S. Yu. Obuzin, “Flow distribution in water supply and distribution systems with automatic pressure regulators,” Vodosnabzh. Sanit. Tekh., No. 4, 55–62 (2017).

A. Ayad, H. Awad, and A. Yassin, “Developed hydraulic simulation model for water pipeline networks,” Alexandria Eng. J. 52, 43–49 (2013). https://doi.org/10.1016/j.aej.2012.11.005

S. Ateş, “Hydraulic modelling of control devices in loop equations of water distribution networks,” Flow Meas. Instrum. 53B, 243–260 (2017).

V. V. Tokarev and N. N. Novitskii, “Development of methods for calculating the hydraulic modes of heating networks with mixing pumping stations,” in Proc. 14th All-Russian Sci. Seminar on Mathematical Models and Methods of Analysis and Optimal Synthesis of Developing Pipeline and Hydraulic Systems, Belokurikha, Altai Krai, Russia, Sept. 8–13, 2014 (Inst. Sist. Energ. im. L. A. Melent’yeva Sib. Otd. Ross. Akad. Nauk, Irkutsk, 2014), pp. 104–118.

V. V. Tokarev and N. N. Novitsky, “The method of adjustment of heat supply systems with the multistage temperature control at pumping stations,” MATEC Web Conf. 212, 02006 (2018). https://doi.org/10.1051/matecconf/201821202006

B. N. Gromov, “Wave processes in main heating networks when circulating pumps are turned off,” Elektr. Stn., No. 1, 42–44 (1973).

B. N. Gromov and V. G. Sidler, “Calculation of non-stationary hydraulic modes of heating networks on a digital computer,” Teploenergetika, No. 3, 16–21 (1973).

B. N. Gromov, L. P. Kanina, K. Nestke, and P. Shnaidenbakh, “Methods for calculating unsteady hydraulic modes in water heating networks,” Teploenergetika, No. 7, 36–40 (1981).

L. Bergeron, Du Coup de Bélier en Hydraulique au Coup de Foudre en Électricite Méthode Graphique Genérale (Dunod, Paris, 1949; Mashgiz, Moscow, 1962).

B. I. Rozhdestvenskii and N. N. Yanenko, Systems of Quasilinear Equations and Their Applications to Gas Dynamics (Nauka, Moscow, 1968) [in Russian].

E. G. Vasilenko, O. V. Kosovtsev, and B. I. Pavlov, Dynamics of the “Pump–Pipeline–Devices” System: Algorithms for Analysis and Synthesis of Mechanisms (Nauka, Moscow, 1977), pp. 89–113 [in Russian].

V. V. Tarasevich, Development of the Theory and Methods for Calculating Hydrodynamic Processes in Pressure Head Pipeline Systems, Doctoral Dissertation in Engineering (Novosibirsk State Univ. of Architecture and Civil Engineering, Novosibirsk, 2017).

A. A. Atavin and V. V. Tarasevich, “Modeling large pipeline systems with concentrated and distributed systems,” in Energy Pipeline Systems. Methods of Mathematical Modeling and Optimization: Compilation of Scientific Papers (Nauka, Novosibirsk, 2007), pp. 7–17 [in Russian].

K. Sartor, D. Thomas, and P. Dewallef, “A comparative study for simulating heat transport in large district heating networks,” Int. J. Heat Technol. 36, 301–308 (2018). https://doi.org/10.18280/ijht.360140

K. Sartor and P. Dewalef, “Experimental validation of heat transport modelling in district heating networks,” Energy 137, 961–968 (2017). https://doi.org/10.1016/j.energy.2017.02.161

P. Jie, Z. Tian, S. Yuan, and N. Zhu, “Modeling the dynamic characteristics of a district heating network,” Energy 39, 126–134 (2012).

V. D. Stevanovic, B. Zivkovic, S. Prica, B. Maslovaric, V. Karamarkovic, and V. Trkulja, “Prediction of thermal transients in district heating systems,” Energy Convers. Manage. 50, 2167–2173 (2009). https://doi.org/10.1016/j.enconman.2009.04.034

M. Chertkov and N. N. Novitsky, “Thermal transients in district heating systems,” Energy 184, 22–33 (2019). https://doi.org/10.1016/j.energy.2018.01.049

I. Gabrielaitiene, R. Kacianauskas, and B. Sunden, “Thermo-hydraulic finite element modelling of district heating network by the uncoupled approach,” J. Civil Eng. Manage. 9, 153–162 (2003). https://doi.org/10.3846/13923730.2003.10531321

A. Benonysson, Dynamic Modelling and Operational Optimization of District Heating Systems (Laboratory of Heating and Air Conditioning, Technical Univ. of Denmark, 1991), pp. 148–160.

H. Palsson, “Analysis of numerical methods for simulating temperature dynamics in district heating pipes,” in Proc. 6th Int. Symp. on District Heating and Cooling Simulation, Reykjavik, Iceland, Aug. 28–30, 1997 (Háskóli Íslands, 1997).

I. Gabrielaitiene, B. Bøhm, and B. Sunden, “Evaluation of approaches for modeling temperature wave propagation in district heating pipelines,” Heat Transfer Eng. 29, 45–56 (2008). https://doi.org/10.1080/01457630701677130

I. Gabrielaitiene, B. Bøhm, and B. Sunden, “Modelling temperature dynamics of a district heating system in Naestved, Denmark — A case study,” Energy Convers. Manage. 48, 78–86 (2007). https://doi.org/10.1016/j.enconman.2006.05.011

I. Gabrielaitiene, B. Bøhm, and B. Sunden, “Dynamic temperature simulation in district heating systems in Denmark regarding pronounced transient behavior,” J. Civil Eng. Manage. 17, 79–87 (2011). https://doi.org/10.3846/13923730.2011.553936

J. Duquette, A. Rowe, and P. Wild, “Thermal performance of a steady state physical pipe model for simulating district heating grids with variable flow,” Appl. Energy 178, 383–393 (2016). https://doi.org/10.1016/j.apenergy.2016.06.092

J. Zheng, Z. Zhou, J. Zhao, and J. Wang, “Function method for dynamic temperature simulation of district heating network,” Appl. Therm. Eng. 123, 682–688 (2017). https://doi.org/10.1016/j.applthermaleng.2017.05.083

Z. I. Shalaginova, Development and Application of Methods for Calculating Thermohydraulic Modes in Heat Supply Systems with Multistage Control, Candidate’s Dissertation in Engineering, (Siberian Energy Inst. of the Siberian Branch of the Russian Academy of Sciences, Irkutsk, 1995).

Z. I. Shalaginova, “Mathematical model for calculation of the heat-hydraulic modes of heating points of heat-supplying systems,” Therm. Eng. 63, 222–232 (2016). https://doi.org/10.1134/S0040601516020075

N. N. Novitskii and V. V. Tokarev, “Taking into account the ambiguity of flow directions when modeling steady-state non-isothermal flow distribution in hydraulic circuits,” in Modern Optimization Methods and Their Applications to Energy Models: Compilation of Scientific Papers (Nauka, Novosibirsk, 2003), pp. 178–188 [in Russian].

N. N. Novitsky and V. V. Tokarev, “Computation of steady thermohydraulic operation regimes of thermal networks from limited number of measurements,” Thermophys, Aeromech. 14, 277–286 (2007). https://doi.org/10.1134/S086986430702014X

S. N. Karambirov, Mathematical Modeling of Water Supply and Distribution Systems in the Conditions of Multimode and Uncertainty (Mosk. Gos. Univ. Prirodoobustroistva, Moscow, 2004) [in Russian].

S. N. Karambirov, Improvement of Methods for Calculating Water Supply and Distribution Systems in the Conditions of Multimode and Incomplete Initial Information, Doctoral Dissertation in Engineering (Moscow State Univ. of Environmental Engineering, Moscow, 2005).

Y. R. Filion, B. J. Adams, and B. W. Karney, “Stochastic design of water distribution systems with expected annual damages,” J. Water Resour. Plann. Manage. 133, 244–252 (2007). https://doi.org/10.1061/(ASCE)0733-9496(2007)133:3(244)

H. A. Kretzmann, J. E. Van Zyl, and J. Haarhoff, “Stochastic analysis of water supply systems using MOCASIM II,” in Proc. Water Institute of Southern Africa Biennial Conference & Exhibition (WISA 2004), Cape Town, South Africa, May 2–6, 2004 (Document Transformation Technologies, Irene, South Africa, 2004), pp. 1132–1142.

M. F. K. Pasha and K. Lansey, “Strategies to develop warm solutions for real-time pump scheduling for water distribution systems,” Water Resour. Manage. 28, 3975–3987 (2014). https://doi.org/10.1007/s11269-014-0721-0

P. Cutore, A. Campisano, Z. Kapelan, C. Modica, and D. Savic, “Probabilistic prediction of urban water consumption using the SCEM-UA algorithm,” Urban Water J. 5, 125–132 (2008). https://doi.org/10.1080/15730620701754434

A. V. Babayan, Z. Kapelan, D. A. Savic, and G. A. Walters, “Least-cost design of water distribution networks under demand uncertainty,” J. Water Resour. Plann. Manage. 131, 375–382 (2005). https://doi.org/10.1061/(ASCE)0733-9496(2005)131:5(375)

K. E. Lansey, N. Duan, L. W. Mays, and Y. K. Tung, “Water distribution system design under uncertainties,” J. Water Resour. Plann. Manage. 115, 630–645 (1989). https://doi.org/10.1061/(ASCE)0733-9496(1989)115:5(630)

C. Xu and I. C. Goulter, “Reliability-based optimal design of water distribution networks,” J. Water Resour. Plann. Manage. 125, 352–362 (1999). https://doi.org/10.1061/(ASCE)0733-9496(1999)125:6(352)

Z. Kapelan, A. V. Babayan, D. Savic, G. A. Walters, and S.-T. Khu, “Two new approaches for the stochastic least cost design of water distribution systems,” Water Sci. Technol. Water Supply 4, 355–363 (2004). https://doi.org/10.2166/ws.2004.0126

V. H. Alcocer-Yamanaka, V. G. Tzatchkov, and F. I. Arreguin-Cortes, “Modeling of drinking water distribution networks using stochastic demand,” Water Resour. Manage. 26, 1779–1792 (2012).

N. N. Novitskii and O. V. Vanteeva, “Tasks and methods of probabilistic modeling of hydraulic modes of pipeline systems,” Nauchno-Tekh. Vedomosti SPbGTU, No. 1, 68–75 (2008).

N. N. Novitskii and O. V. Vanteeva, “Simulation of stochastic flow distribution in hydraulic circuits,” Izv. Ross. Akad. Nauk, Energ., No. 2, 122–131 (2011).

O. V. Vanteeva, Probabilistic Models and Methods for Analyzing the Modes of Operation of Pipeline Systems, Candidate’s Dissertation in Engineering (Melentiev Energy Systems Inst. of the Siberian Branch of the Russian Academy of Sciences, Irkutsk, 2011).

N. N. Novitsky and O. V. Vanteyeva, “Modeling of stochastic hydraulic conditions of pipeline systems,” Chaotic Model. Simul., No. 1, 95–108 (2014).

B. H. Lee and R. A. Deininger, “Optimal locations of monitoring stations in water distribution system,” J. Environ. Eng. 118, 4–16 (1992). https://doi.org/10.1061/(ASCE)0733-9372(1992)118:1(4)

A. Ostfeld, J. G. Uber, E. Salomons, J. W. Berry, W. E. Hart, C. A. Phillips, J.-P. Watson, G. Dorini, P. Jonkergouw, Z. Kapelan, F. di Pierro, S.-T. Khu, D. Savic, D. Eliades, M. Polycarpou, et al., “The battle of the water sensor networks (BWSN): A design challenge for engineers and algorithms,” J. Water Resour. Plann. Manage. 134, 556–568 (2008).

A. Preis and A. Ostfeld, “Optimal sensors layout for contamination source identification in water distribution systems,” in Proc. 8th Annual Water Distribution Systems Analysis Symp., Cincinnati, Oh., Aug. 27–30, 2006 (American Society of Civil Engineers, Reston, Va., 2006). https://doi.org/10.1061/40941(247)127

M. E. Tryby, M. Propato, and S. Ranjithan, “Monitoring design for source identification in water distribution systems,” J. Water Resour. Plann. Manage. 136 (6) (2010). https://doi.org/10.1061/(ASCE)WR.1943-5452.0000080

S. Liu and P. Auckenthaler, “Optimal sensor placement for event detection and source identification in water distribution networks,” J. Water Supply: Res. Technol. ̶ AQUA 63, 51–57 (2014). https://doi.org/10.2166/aqua.2013.106

L. Cozzolinoa, R. Della Mortea, A. Palumbo, and D. Pianese, “Stochastic approaches for sensors placement against intentional contaminations in water distribution systems,” Civil Eng. Environ. Syst. 28, 75–98 (2011).

Z. S. Kapelan, D. A. Savic, and G. A. Walters, “Multiobjective sampling design for water distribution model calibration,” J. Water Resour. Plann. Manage. 129, 466–479 (2003). https://doi.org/10.1061/(ASCE)0733-9496(2003)129:6(466)

A. Z. Gamm, L. N. Gerasimov, I. I. Golub, Yu. A. Grishin, and I. N. Kolosok, State Evaluation in Electric Power Engineering (Nauka, Moscow, 1983) [in Russian].

I. I. Golub and Y. I. Kuzkina, “Solving the problem of distribution network observability with smart meters,” Acta Energ. 33, 4–9 (2017).

A. Z. Gamm and I. I. Golub, Observability of Electrical Power Systems (Nauka, Moscow, 1990) [in Russian].

F. C. Schweppe, “Power system static-state estimation, Part III: Implementation,” IEEE Trans. Power Appar. Syst. PAS-89, 130–135 (1970). https://doi.org/10.1109/TPAS.1970.292680

A. S. Debs and R. E. Larson, “A dynamic estimator for tracking the state of a power system,” IEEE Trans. Power Appar. Syst. PAS-89, 1670–1678 (1970). https://doi.org/10.1109/TPAS.1970.292822

B. Xu and A. Abur, “Observability analysis and measurement placement for systems with PMUs,” in Proc. IEEE PES Power Systems Conf. and Expo., New York, N.Y., Oct. 10–13, 2004 (IEEE, Piscataway, N.J., 2004). https://doi.org/10.1109/PSCE.2004.1397683

N. N. Novitskii and O. A. Grebneva, Methods for Analyzing and Ensuring the Identifiability of Pipeline Systems (Neft i Gaz, Moscow, 2000), pp. 90–105 [in Russian].

N. N. Novitskii, “Identifiability of pipeline systems,” in System Studies in Power Engineering: A Retrospective of Research Areas of Melentiev Energy Systems Institute (Nauka, Novosibirsk, 2010), pp. 279–291 [in Russian].

N. N. Novitsky and O. A. Grebneva, “Quantitative assessment of the identifiability of pipeline systems,” E3S Web Conf. 39, 03004 (2018). https://doi.org/10.1051/e3sconf/20183903004

O. A. Grebneva and N. N. Novitskii, “Optimizing the composition of measurements for identifying pipeline systems,” Therm. Eng. 61, 685–690 (2014). https://doi.org/10.1134/S0040601514090067

O. A. Grebneva and N. N. Novitskii, “Optimal planning and processing of the results of tests for hydraulic and heat losses in heat systems,” Therm. Eng. 61, 754–759 (2014). https://doi.org/10.1134/S004060151410005X

A. P. Merenkov, E. V. Sennova, S. V. Sumarokov, and V. G. Sidler, Mathematical Modeling and Optimization of Heat, Water, Petroleum, and Gas Supply Systems (Nauka, Novosibirsk, 1992) [in Russian].

N. N. Novitskii, Evaluation of Hydraulic Circuit Parameters (Nauka, Novosibirsk, 1998) [in Russian].

N. N. Novitskii, Development of the Theory and Methods of Network Identification of Pipeline Systems, Doctoral Dissertation in Engineering (Melentiev Energy Systems Inst., Irkutsk, 1999).

N. N. Novitskii, “Elements of the theory and methods of network identification of pipeline systems,” Izv. Ross. Akad. Nauk, Energ., No. 6, 87–97 (2000).

N. N. Novitskii, “Identification of pipeline systems,” in System Studies in Power Engineering: A Retrospective of Research Areas of Melentiev Energy Systems Institute (Nauka, Novosibirsk, 2010), pp. 314–324.

M. G. Sukharev and R. V. Samoilov, Analysis and Control of Stationary and Non-Stationary Modes of Gas Transport (Ross. Gos. Univ. Nefti i Gaza, Moscow, 2016) [in Russian].

M. G. Sukharev and K. O. Kosova, “A parameter identification method for natural gas supply systems under unsteady gas flow,” Autom. Remote Control 78, 882–890 (2017). https://doi.org/10.1134/S0005117917050101

N. N. Novitskii, O. A. Grebneva, and V. V. Tokarev, “Investigation of active identification methods for thermohydraulic testing of heat networks,” Therm. Eng. 65, 453–461 (2018). https://doi.org/10.1134/S0040601518070066

S. Lingireddy and L. E. Ormsbee, “Hydraulic network calibration using genetic optimization,” Civil Eng. Env. Syst. 19, 13–39 (2000). https://doi.org/10.1080/10286600212161

Z. Y. Wu, T. Walski, R. Mankowski, G. Herrin, R. Gurrieri, and M. Tryby, “Calibrating water distribution model via genetic algorithms,” Presented at AWWA IMTech Conf. 2002, Kansas City, Missouri, Apr. 14–17, 2002.

Z. Y. Wu, “Optimal calibration method for water distribution water quality model,” J. Environ. Sci. Health, Part A 41, 1363–1378 (2006). https://doi.org/10.1080/10934520600657115

Z. Y. Wu and T. M. Walski, “Diagnosing error phone application of optimal model calibration,” in Proc. 8th Int. Conf. on Computing and Control for the Water Industry, Exeter, UK, Sept. 5–7, 2005 (Exeter, 2005).

S. M. Kumar, S. Narasimhan, and S. M. Bhallamudi, “Parameter estimation in water distribution networks,” Water Resour. Manage. 24, 1251–1272 (2010). https://doi.org/10.1007/s11269-009-9495-1

Y. Liu, P. Zou, and Y. Kang, “Study on impedance identification of pipes in heat-supply networks,” in Proc. 2009 Int. Conf. on Information Engineering and Computer Science (ICIECS 2009), Wuhan, China, Dec. 19–20, 2009 (IEEE, Piscataway, N.J., 2009). https://doi.org/10.1109/ICIECS.2009.5365891

M.-Q. Zhang, Q. Chen, W. Shao, X. Chen, and J.‑H. Hao, “An integral identification method of characteristic parameters and optimization of parallel connection heat transfer systems based on the power flow method,” Appl. Therm. Eng. 143, 1057–1067 (2018). https://doi.org/10.1016/j.applthermaleng.2018.08.016

T. Fang and R. Lahdelma, “State estimation of district heating network based on customer measurements,” Appl. Therm. Eng. 73, 1211–1221 (2014). https://doi.org/10.1016/j.applthermaleng.2014.09.003

J. Wang, Z. Zhou, and J. Zhao, “A method for the steady-state thermal simulation of district heating systems and model parameters calibration,” Energy Convers. Manage. 120, 294–305 (2016). https://doi.org/10.1016/j.enconman.2016.04.074

L. B. Kublanovskii, Determination of the Sites of Damage to Pressure Pipelines (Nedra, Moscow, 1971) [in Russian].

M. Valinčius, M. Vaišnoras, and A. Kaliatka, “Study and demonstration of pressure wave-based leak detection in a district heating network,” Struct. Infrastruct. Eng. 14, 151–162 (2018). https://doi.org/10.1080/15732479.2017.1330892

S. Zhou, Z. O’Neill, and C. O’Neill, “A review of leakage detection methods for district heating networks,” Appl. Therm. Eng. 137, 567–574 (2018). https://doi.org/10.1016/j.applthermaleng.2018.04.010

M. Henrie, P. Carpenter, and R. E. Nicholas, “Real-time transient model–based leak detection,” in Pipeline Leak Detection Handbook (Elsevier, 2016), pp. 57–89. https://doi.org/10.1016/B978-0-12-802240-5.00004-2

N. Zimmerman, E. Dahlquist, and K. Kyprianidis, “Towards on-line fault detection and diagnostics in district heating systems,” Energy Procedia 105, 1960–1966 (2017). https://doi.org/10.1016/j.egypro.2017.03.567

D. Buoro, P. Pinamonti, and M. Reini, “Optimization of a distributed cogeneration system with solar district heating,” Appl. Energy 124, 298–308 (2014). https://doi.org/10.1016/j.apenergy.2014.02.062

W. Gu, J. Wang, S. Lu, Z. Luo, and C. Wu, “Optimal operation for integrated energy system considering thermal inertia of district heating network and buildings,” Appl. Energy 199, 234–246 (2017). https://doi.org/10.1016/j.apenergy.2017.05.004

K. Lichtenegger, D. Wöss, C. Halmdienst, E. Höftberger, C. Schmidl, and T. Pröll, “Intelligent heat networks: First results of an energy-information-cost model,” Sustainable Energy, Grids Networks 11, 1–12 (2017).

M. Hazami, S. Kooli, N. Naili, F. Mehdaoui, and A. Guizani, “Energy, exergy and economic viability of a heat storage system used for domestic hot water supply in urban and isolated households,” Appl. Therm. Eng. 124, 442–453 (2017). https://doi.org/10.1016/j.applthermaleng.2017.06.049

Y. Zhang, X. Wang, S. Zhuo, and Y. Zhang, “Pre-feasibility of building cooling heating and power system with thermal energy storage considering energy supply–demand mismatch,” Appl. Energy 167, 125–134 (2016). https://doi.org/10.1016/j.apenergy.2016.01.040

V. Verda and F. Colella, “Primary energy savings through thermal storage in district heating networks,” Energy 36, 4278–4286 (2011). https://doi.org/10.1016/j.energy.2011.04.015

J. Xu, R. Z. Wang, and Y. Li, “A review of available technologies for seasonal thermal energy storage,” Sol. Energy 103, 610–638 (2014). https://doi.org/10.1016/j.solener.2013.06.006

T. Nuytten, B. Claessens, K. Paredis, J. Van Bael, and D. Six, “Flexibility of a combined heat and power system with thermal energy storage for district heating,” Appl. Energy 104, 583–591 (2013). https://doi.org/10.1016/j.apenergy.2012.11.029

G. Baccino, S. Cosentino, E. Guelpa, A. Sciacovelli, and V. Verda, “Reduction of primary energy consumption through distributed thermal storage in buildings connected with a district heating network,” in Proc. 2014 ASME Int. Mechanical Engineering Congr. and Expo. (IMECE2014), Montreal, Quebec, Canada, 2014 (American Society of Mechanical Engineers, New York, 2015), Vol. 6A: Energy.