Abstract—

A one-dimensional differential model describing condensation of a vapor–gas mixture in tubes and its implementation on a computer in the Visual Basic integrated development environment is presented. The model is intended for studying the operation conditions and parameters of the relevant types of condensing devices and, in the future, for carrying out technical computations and providing information support to design developments and tests. The compute kernel is based on mathematical models that take into account the main significant effects during condensation, such as gravitation (with different tube orientations), friction at the phase interface boundary (taking into account the cross flow of mass and specific roughness of the boundary), availability of noncondensing, admixtures, different external cooling methods, and the possibility of dangerous operation conditions to occur (freezing and flooding). The well-studied limiting models, such as a gravity or shear condensate film, are united by the interpolation method between asymptotes. The mathematical formulation of the problem consists of conservation equations (of momentum, energy, and mass of mixture components) for averaged flows of coolants supplemented with algebraic relations for local coefficients of heat transfer, mass transfer, and friction at the interface boundaries. The remoteness of working fluid thermodynamic parameters from the critical point, which is almost always observed in condensing installations, is the natural limitation of the analysis model’s application field. A special analysis for determining heat transfer and friction in gravity–shear condensate films based on an adequate differential turbulence model is carried out.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

The vapor–gas mixture condensation computer model was developed as a tool for providing design analysis and information support to special types of condensing devices, e.g., air cooled condensers for the steam turbines of thermal, geothermal, and nuclear power plants (TPPs, GeoTPPs, and NPPs), evaporative condensers (steam generators) used in two-loop GeoTPPs, and condensing installations used in passive heat removal systems (PHRSs) for confining accidents at NPPs (see, e.g., [1–4]). Long pipelines used in the steam supply systems of industrial enterprises are also an object to which the model can be applied.

The computing program has been developed as an interactive medium in the Visual Basic programming system. The compute kernel is based on mathematical models that take into account all significant effects observed during condensation, such as gravity, friction at the phase interface permeable surface, availability of noncondensable admixtures, and flow stratification in inclined tubes. The computer program includes the possibility to specify different boundary conditions at the wall (i.e., the condenser cooling conditions), to reveal dangerous operation conditions (freezing and flooding), and to calculate changes in the vapor–gas flow and condensate film parameters along the channel’s longitudinal axis. The local characteristics of heat and mass transfer and friction are determined using the method of “constructing” an objectively complex full description composed of relatively simple asymptotic (partial) models (condensation of quickly moving vapor on shear films, condensation of stagnant vapor on gravity films, and integral models of heat and mass transfer on permeable surfaces). The partial models are incorporated into the full model through the use of interpolation relations, which ensure correct limiting transitions to asymptotic limits and satisfactory approximation in the intermediate parameter’s variation region (see, e.g., [5]).

The model’s mathematical formulation is positioned as a one-dimensional differential model [6, 7] composed of the conservation equations for momentum, energy, and mass of mixture components for averaged longitudinal coolant flows supplemented with algebraic equations for calculating the local coefficients of heat transfer, mass transfer, and friction at the phase interface’s boundaries.

The processes in a turbulent condensate film under the conditions of commensurable gravity and friction effects at the phase interface’s boundary are considered as a special problem. Possible operation conditions with recirculation in the flowing down liquid films are of interest for designing various heat and mass transfer devices. Flooding effects accompanied by the occurrence of pulsating modes in the passive heat removal systems at NPPs [2, 4] may be of critical significance.

It is assumed that the flow and heat and mass transfer in the considered steady problem obey the well-known restrictions of a viscous, continuous, and incompressible medium. It is also assumed that the values of working fluid parameters are essentially far from the thermodynamically critical point.

CALCULATION OF LOCAL HEAT TRANSFER

The basic film condensation modes are described by the following relations [1, 8]:

1. a laminar gravity film flow or LG in abbreviated form

where α is the heat transfer coefficient; \({{l}_{{gr}}}\) is the linear scale, a so-called viscous–gravity length; λ is the condensed phase heat conductivity coefficient; g is the acceleration of gravity; gx is the gravity acceleration projection on the х axis; \({\varepsilon }\) is the wave correction; G is the condensate flowrate per unit film width; \({{{\rho }}_{l}}\) and \({{{\rho }}_{{v}}}\) are the liquid and vapor densities, and ν is the kinematic viscosity coefficient;

2. turbulent gravity film (ТG, D.A. Labuntsov’s formula [8])

where Pr is the condensate Prandtl number;

3. laminar shear film (LS)

where SSF is the shear factor and τs is the friction stress at the phase interface boundary; and

4. turbulent shear film (TS)

Relations (1)–(4) presented above are considered below as the limiting modes whose film moves under the effect of two forces: gravity and surface friction. The interpolation expressions satisfying the limiting transitions can be written in a unified form

where \({\text{N}}{{{\text{u}}}_{{glob}}}\) is the generalized Nusselt number value valid for any film condensation mode; \({\text{Nu}}_{{lim1}}^{n}\) and \({\text{Nu}}_{{lim2}}^{n}\) are the Nusselt numbers for limiting modes (1)–(4); the values of exponent n depend on the film condensation mode.

For a laminar-to-turbulent transition, it is recommended to take n = 4, while it is recommended to take n = 2 for the combined effect of unidirectional gravity and friction forces at the surface.

Thus, the following approximation is used for describing generalized heat transfer under pure vapor condensation conditions:

where \({\text{N}}{{{\text{u}}}_{{gr}}} = {{\left( {{\text{Nu}}_{{{\text{LG}}}}^{{\text{4}}} + {\text{Nu}}_{{{\text{TG}}}}^{{\text{4}}}} \right)}^{{{1 \mathord{\left/ {\vphantom {1 4}} \right. \kern-0em} 4}}}}\) is for laminar and turbulent gravity condensate films, and Nushear = \({{({\text{Nu}}_{{{\text{LS}}}}^{4} + {\text{Nu}}_{{{\text{TS}}}}^{4})}^{{{1 \mathord{\left/ {\vphantom {1 4}} \right. \kern-0em} 4}}}}\) is for laminar and turbulent shear condensate films.

CALCULATION OF FRICTION AT THE PHASE INTERFACE BOUNDARY

In calculating the friction stress τs at the phase interface boundary for a turbulent vapor–gas flow, the specific surface roughness associated with wave disturbances and turbulence in the condensate film should be taken into account. The relative growth of friction stress is given, according to the modified Wallis formula [9], by

where τs0 is the friction force at the smooth phase interface surface, deq is the channel equivalent diameter, and δ is the condensate film thickness.

For the limiting cases, the following two convenient dimensionless expressions for the gravity and shear film thicknesses \({{{\delta }}_{{{{l}_{{gr}}}}}}\) and \(D\) are used:

where \({{{\tau }}_{w}}\) is the tangential stress at the wall and \({{{\nu }}_{l}}\) is the liquid kinematic viscosity coefficient.

The expression linking the film thickness with the condensate flowrate and acting forces, namely, gravity and friction at the phase interface boundary, is given by the following interpolation relation:

The thickness D for gravity and shear films is calculated from the formula

For the gravity film, the terms \({{D}_{{lam}}}\) and \({{D}_{{turb}}}\) appearing in this formula are determined as follows:

and \({{{\delta }}_{{{{l}_{{gr}}}}}}{{\left( {{\text{R}}{{{\text{e}}}_{F}}} \right)}_{{gr}}} = {{D}^{{{{\text{2}} \mathord{\left/ {\vphantom {{\text{2}} {\text{3}}}} \right. \kern-0em} {\text{3}}}}}}.\)

For the shear film, the following holds:

and \({{{\delta }}_{{{{l}_{{gr}}}}}}{{{\text{(R}}{{{\text{e}}}_{F}}{\text{,}}SSF{\text{)}}}_{{shear}}}{\text{ = }}{D \mathord{\left/ {\vphantom {D {SSF}}} \right. \kern-0em} {SSF}}.\)

It should be emphasized that the friction factor SSF is now supposed to be linked with the condensate film thickness through Wallis’ formula (7) written in the following form:

where SSF0 is the friction factor at a smooth surface, which is calculated from the vapor–gas flow parameters.

Equation (9) shows what the film-thickness value should be for the friction to increase in a certain specified ratio (SSF/SSF0). Thus, equations (8) and (9) form a nonlinear system for determining the film thickness \(\left( {{{{\delta }}_{{{{l}_{{gr}}}}}}} \right)\) and shear factor (SSF) at the specified values of ReF and SSF0. The relevant calculations are carried out in the computer program at each integration step of the conservation equations along the channel axis. The algorithm includes means for monitoring the developed roughness conditions by comparing the vapor–gas flow viscous sublayer thickness with the condensate film thickness.

The main computations in this study were carried out for two stable condensation modes with simultaneous action of gravity and shear, which are of relevance for practical applications. The problem concerned with different directions in which these factors act is discussed below in the final part of the article.

For intense condensation processes, the effect of mass cross flow on friction must be taken into account. Interpolation between asymptotes is the simplest and efficient method of doing so:

where τ0 is the friction when there is no cross flow of mass; \({{{\tau }}_{j}} = j\,{{u}_{\infty }}\) is the asymptotic friction under strong suction conditions, which is defined as the flow of momentum through the phase interface boundary; j is the condensation rate; and \({{u}_{\infty }}\) is the velocity in the vapor–gas flow core.

EFFECT OF NONCONDENSABLE ADMIXTURES ON THE CONDENSATION RATE

During condensation in channels, the negative effect due to the presence of noncondensable admixtures may be significant even though the initial concentration of inert gas is low. This is because steam is condensed and removed from the vapor–gas flow, whereas air remains therein, and its relative fraction increases. Concurrently, the vapor–gas flow velocity slows down, as a result of which the condensation rate becomes significantly lower.

In air-cooled condensation installations, noncondensable admixtures bring about the danger of tubes becoming frozen at low negative environment temperatures. For certain kinds of condensers, such as installations for capturing moisture from flue gases (combustion products), mass transfer in the vapor–gas medium is the main process limiting the throughput of these installations [3].

In calculating heat transfer taking into account the effect of noncondensable admixtures, the following relation for heat fluxes on both sides of the phase interface boundary is used:

where \({{t}_{w}}\) is the wall temperature monitored by the condenser cooling system, \({{t}_{s}}\) is the saturation temperature at the phase interface boundary, \({{{\alpha }}_{{vg}}}\) is the heat transfer coefficient at the phase interface boundary on the vapor–gas flow side, \({{t}_{\infty }}\) is the temperature in the vapor–gas flow core, r is the vaporization (condensation) heat, β is the mass transfer coefficient, \({{c}_{{v0}}}\) is the steam condensation near the interphase boundary, and \({{c}_{{v\infty }}}\) is the vapor concentration in the vapor–gas flow core. The brackets with interrogation signs denote the sought unknown quantities.

If we exclude superintense evaporation/condensation processes from consideration and limit ourselves to moderate pressure levels, we obtain

where \({{p}_{s}}\) is the saturation pressure; \({{p}_{{vg}}}\) is the vapor–gas mixture pressure; \({\text{S}}{{{\text{t}}}_{D}}\) is the Stanton diffusion number (a dimensionless mass transfer coefficient); b1 is the permeability parameter; \({{R}_{v}}\) and Rg are the gas constants of vapor and gas; and Ψ(b1) is the correction factor that takes into account the stream field distortion under the effect of mass cross flow.

Relations (11)–(13) form the basis of an engineering technique for calculating heat and mass transfer under evaporation and condensation conditions (see, e.g., [7]).

DIFFERENTIAL MODEL

The variations of vapor–gas mixture parameters (steam quality, temperature, and pressure) over the channel length z are described by the mass, energy, and momentum conservation equations and stem from the flow interactions at interface boundaries as described above. On the whole, the mathematical description can be characterized as a 1D differential model, in which the state variables (steam quality, temperature, and pressure) and also transfer rates (condensation rate, heat flux density, and friction stress) are the sought functions of the longitudinal coordinate z.

The system of differential equations is integrated using the implicit control volume method, which makes it possible to ensure stable computation with a relatively large longitudinal step. In view of the fact that the mathematical description is nonlinear in nature and is realized according to an implicit numerical scheme, the nonlinear algebraic equations must be solved at each step along the longitudinal coordinate z.

The mass flowrates of the vapor and condensed phases vary as a consequence of condensation:

where Gf, Gv, and Gg are the condensate, vapor, and gas flowrates; and πd is the channel’s wetted perimeter.

The variation of the vapor–gas mixture temperature \({{t}_{{vg}}}\) is described by the enthalpy conservation equation

where \({{H}_{{vg}}}\) is the vapor–gas mixture enthalpy flux; \({{h}_{{vs}}}\) is the specific vapor enthalpy at the saturation line; d is the channel diameter; \({{h}_{g}}\) is the gas specific enthalpy in the vapor–gas mixture flow; and \({{h}_{v}}\) is the vapor specific enthalpy in the vapor–gas flow.

The flux densities on the right-hand side of (15) are related to the control boundary drawn in the gas phase infinitesimally close to the phase interface boundary. The expressions for enthalpy as a function of temperature are written in accordance with the adopted assumption about remoteness from the thermodynamically critical state.

The pressure losses in the vapor–gas flow are calculated using the momentum equation for one-dimensional current with a variable flowrate

where f is the channel cross-section area; τs is the tangential stress at the phase interface boundary; ρu is the vapor–gas flow mass velocity in the channel; and \({{u}_{s}}\) is the velocity at the phase interface boundary.

The change of pressure in two closely located control sections due to the dynamic effect and friction will make

where \({{G}_{{mix}}}\) is the total mass flowrate of a two-phase mixture; Xvg is the steam quality; and ρvg is the vapor–gas mixture density.

In this equation, the gravity effects for a vapor–gas flow are neglected because they are nonessential for the considered applications and coolant parameter ranges.

It should be emphasized that the right-hand sides of differential equations (14)–(17) contain cross flows of mass, momentum, and energy, which are defined as implicit (and nonlinear) functions of variable velocities, pressures, and concentrations—a circumstance that predetermines that the computation procedures are complex and iterative in nature. For example, the temperature ts at the phase interface boundary is varied by means of the effective algorithm ZeroTs for numerically solving nonlinear algebraic equations until conjugation conditions (11)–(13) become satisfied.

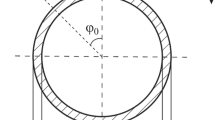

The dependence of thermal–hydraulic characteristics on the object orientation in space is an important specific feature of the problem, which generates the need of using special model descriptions. An essentially 3D flow of condensate emerges even if the orientation of long tubes deviates only slightly from the vertical direction. An attempt to obtain exact solutions encounters difficulties due to significantly different characteristic linear scales, and approximate models ensuring correct limiting transitions and reasonable interpolation in intermediate situations become of issue.

Such approximation can be set up using a simple scheme that takes into account the gravity and friction effects at the film surface. It is assumed that shear and the gravity force longitudinal projection act in the longitudinal direction (along the tube axis), whereas the corresponding gravity force projection (normal with respect to the tube axis) is only of issue in the transverse direction. The longitudinal two-phase flow consists of an axial vapor–gas stream and a condensate film, which moves along the tube axis under the combined effect of friction at the interface boundary and longitudinal gravity component. Motion of condensate moves transversely over the tube inner circumference only under the effect of gravity with a reduced gravity force value equal to its projection on the normal to the tube axis. This transverse stream produces a near-bottom flow in the inclined tube, which tends to increase along the tube length. It should be noted that the model stream transforms naturally into limiting condensation conditions inside a vertical or horizontal tube. It is also obvious that the limiting case with condensation of vapor quickly moving inside a tube irrespectively of its orientation is realized in a correct way.

The computer program’s user interface (Fig. 1) offers the possibility of accessing the database and the graphic demonstrations of computation results in an interactive manner. The diagram placed in the center shows the characteristic distribution of vapor–gas flow temperature, phase interface surface, and dew point under full condensation conditions in the channel inlet segment. The operation mode shown in this figure models operation of the NPP steam generator as a condenser of vapor–gas mixture in the PHRS under a hypothetical beyond-design-basis accident.

Simulation of simple film condensation limiting modes using a full computer model is a reasonable methodological requirement for its implementation by means of software. For the representative set of special test configurations (a tube slightly inclined to a horizontal plane with a low velocity of vapor flow at the inlet, a large-diameter vertical tube, and a high-velocity vapor flow in a tube oriented at different slope angles), full agreement between the computer model and well-known simple asymptotic solutions has been obtained. It should be emphasized that these computations demonstrate that the described model of vapor–gas mixture condensation in tubes has been correctly implemented by means of software.

COMPARISON OF COMPUTATION RESULTS WITH EXPERIMENTAL DATA

The computer model structure includes service functions for accumulating data arrays and comparing them with the simulation results. As an example, we present comparison with the materials reported in [10], the authors of which obtained a representative amount of experimental data on vapor–gas mixture condensation in a vertical tube.

The following parameters were varied in wide ranges in the experiments: pressure (0.5–2.1 MPa), vapor–gas flow velocity at the inlet (3–15 m/s), air concentration (0.2–0.6), and cooling intensity parameters (26 modes). The longitudinal (local) distributions of the vapor–gas flow and wall temperatures Tvg and Tw and also the condensate flowrate (and, thereby, the steam quality Xv) were measuredFootnote 1.

Based on comparison between the distributions of Tvg and Xv obtained experimentally and using the computer program, the empirical coefficients appearing in modified Wallis formula (7) were adjusted. It should be noted that the variation of vapor–gas mixture temperature over the channel length is governed by the heat transfer intensity from the vapor–gas flow to the condensate film surface under the effect of the local temperature difference (Tvg–TsSurf). As regards the steam quality, its variation is governed by the condensation rate, i.e., by the totality of heat and mass transfer processes in the vapor–gas flow and condensate film. As was shown from an analysis of the data array presented in [10], it is advisable to decrease the empirical coefficient in formula (7) from 24 to 6, which would correspond to the effect of usual (sand) roughness. In the case of using a smaller Wallis constant value, better agreement between the calculated and experimental data on the vapor–gas flow temperature is obtained, with the agreement of the steam quality data still remaining satisfactory (Fig. 2).

Comparison between the computation results and experimental data of [5] for the operation mode with p = 0.498 MPa, air concentration equal to 0.594, vapor–gas flow velocity equal to 13.31 m/s, and wall temperature equal to 87–79°С.

This result is a problem statement rather than a final recommendation. We touch here the most complicated and topical problem of modeling a two-phase flow, namely, description of the structure of a phase interface boundary susceptible to strong disturbances under the conditions of intense cross flow of mass during phase transformations.

The obtained results can be generally appraised as follows: on the one hand, the simulated results are in satisfactory (within 20%) agreement with the experiment (see Fig. 2), and, on the other hand, the problem of special roughness produced by the liquid film still remains of issue. An essential difference of the characteristic temperatures from each other should also be pointed out, namely, the saturation temperature at the phase interface boundary (TsSurf) and the vapor–gas flow dew point temperature (Tdew), which are sometimes unduly considered to be identical with each other in analysis models.

ADEQUATE TURBULENT FILM MODEL

Sophistication of methods for calculating heat and mass transfer in film apparatuses is associated with selecting adequate turbulent film models, i.e., models with the minimal complexity oriented at applications encountered in engineering practice, which, however, take into account all effects that are of fundamental importance for the flow under consideration. In this regard, application of the Kolmogorov–Prandtl model involving one differential equation, namely, the turbulence kinetic energy conservation equation (known as the k-model, see [11]) is an efficient approach for solving the problem. With turbulent energy chosen as the directly calculated quantity, it becomes possible to model effects relating to droplet entrainment and specific roughness of the phase interface boundary (see, e.g., [12]).

Below, the results obtained from relevant computations are briefly outlined. The motion equation for a steady plane-parallel film flow is written as the equilibrium of gravity and shear forces, so that the velocity gradient \({\text{grad}}U\left( Y \right)\) is given by the following expression written in terms of dimensionless “wall variables” (or boundary layer dynamic variables):

where Rsw is the numerical parameter determining the ratio between the friction stress at the film surface (s) and at the wall (w), \({{u}_{{\tau }}}\) is the dynamic velocity, \({{N}_{{turb}}}\) is the relative turbulent viscosity, and \({{\nu }_{{turb}}}\) is the turbulent viscosity.

Thus, for a gravity film Rsw = 0, and for a shear film Rsw = 1. The friction stress at the wall τw is a positive quantity, which possibly tends to zero when the gravity is balanced by the oppositely directed shear. The relative turbulent viscosity \({{N}_{{turb}}}\) is calculated as a function of the local values of turbulent energy K and vapor–gas mixture turbulence scale \({{L}_{{vg}}}.\)

The determining system of differential equations for turbulent energy K, turbulent energy diffusion flux Jk, and flow velocity U written in dimensional variables is given by

where \({{C}_{D}}\) and\({{f}_{{\mu }}}\) are the turbulence model inner functional parameters.

The problem formulation is finalized by specifying the zero boundary conditions at the wall and the zero turbulent energy flux Jk at the phase interface boundary.

The computations of heat transfer and friction according to the model represented by (18) and (19) were carried out in two limiting cases (for the gravity and shear films) and also in the general case involving a combined effect of gravity and friction at the phase interface boundary. Figure 3 shows a comparison between the computation results with those obtained using the model [8]. The marked points connected by solid curves are in fact the results of calculations using the k-model represented by (18) and (19). The series of points with the same marking but without connection curves reflect the results of computations according to the model [8].

The obtained data are in satisfactory agreement with formula (2) (in its domain). With other values of the parameters, growing discrepancies are observed. In all cases, the k-model yields somewhat lower transfer intensities than computations with predefined turbulent transfer coefficients (based on measurements of single-phase flows in tubes). Discrepancies become more noticeable with extreme (essentially larger or smaller than unity) Prandtl number values, which is important for applications relating to film apparatuses with special coolants (organic or liquid metal). The same applies to diffusion processes in liquid films at very high values of the diffusion Prandtl number.

Solution of boundary problem (19) makes it possible to correctly take the flow structure and coolant properties into account and defines the distribution of turbulent transfer coefficients as the problem inner feature, due to which it can be regarded as an efficient tool for solving problems associated with turbulent films in miscellaneous technologies.

In what follows, we present, as a characteristic example, the results of computations carried out for a more complex model stream of coolant with recirculation under the conditions of oppositely directed gravity and friction at the phase interface surface (Fig. 4).

Such flow pattern precedes the “flooding” effect, with which the emergency mode, in which the flowing down liquid is repeatedly thrown upward, takes place instead of the normal condensate flowing down mode. Thus, the considered model may be useful for detecting special operating conditions in film apparatuses, in particular, for analyzing the NPP steam generator performance in the condensing mode when the passive heat removal system comes into operation.

For coolants characterized by the Prandtl number values essentially greater than unity, the near-wall region (Fig. 5) is of importance, the turbulent viscosity in which already becomes nonessential due to proximity of the wall; however, the turbulent thermal conductivity remains high compared with the molecular thermal conductivity. The same relates also to diffusion processes in liquid films characterized by very high values of the diffusion Prandtl number.

Possible cellular structures with countercurrent motion in films, i.e., with recirculation in cells, deserve special investigation. In this regard, both condensation and evaporation processes, e.g., those for evaporation cooling purposes, are of equal interest.

CONCLUSIONS

(1) The presented mathematical model and computer program for analyzing the vapor–gas mixture condensation processes in tubes meet the modern challenges in the field of providing scientific and engineering support to the power industry.

(2) The classic solutions presently available to problems connected with condensation processes are insufficient for designing and providing information support to complex condensation equipment of power installations for securing their normal operation.

(3) The use of purely empirical correlations derived from engineering practices is also insufficient for analyzing complex configurations and operation modes. The direct numerical simulation method involves many difficulties and, perhaps, is excessive in being implemented under real conditions.

(4) The presented development (the analysis model and its implementation by means of software) is a reasonable compromise able to provide information support in designing and operating condensing devices of a certain type.

FUNDING

This work was supported by the Russian Foundation for Basic Research, grant no. 16-08-00601 A.

Notes

Here and henceforth, the notation of variables is given in accordance with the computer program.

REFERENCES

V. P. Isachenko, Heat Transfer in Condensation (Energoizdat, Moscow, 1977) [in Russian].

G. F. De Santi and F. Mayinger, “Steam condensation and liquid holdup in steam generator U-tubes during oscillatory natural circulation,” Exp. Heat Transfer 6, 367–387 (1993).

A. S. Sedlov, A. P. Solodov, and D. Yu. Bukhonov, “Condensate production from exhaust flue gases at the experimental unit of PJSC ‘GRES-24’,” Energosberezhenie Vodopodgot., No. 5, 76–77 (2006).

A. V. Zheltoukhov, G. S. Taranov, M. B. Mal’tsev, and A. P. Solodov, “Calculation of the process of steam condensation from the vapor-gas mixture in the tubing of the VVER steam generator during SPOT operation,” Sb. Tr. OAO Atomenergoproekt, No. 11, 9–15. http:// www.gidropress.podolsk.ru/files/proceedings/mntk2011/ autorun/section3-ru.htm (2011).

J. Huhn, “Filmstroemungen bei sich ueberlagernden Einfluessen,” Waerme- Stoffuebertrag. 19, 133–144 (1985).

A. P. Solodov, D. V. Sidenkov, and I. I. Kutakov, “Physical and mathematical model, algorithm and program for computation of heat mass transfer and resistance in steam condensation in inclined tubes,” in Proc. Engineering Foundation Conf. on Condensation and Condenser Design, St. Augustine, FL, March 7–12, 1993 (Am. Soc. Mech. Eng., New York, 1993), pp. 569–580.

A. P. Solodov, “Differential model of heat and mass exchanger,” Teplovye Protsessy v Tekh., No. 8, 364–370 (2010).

D. A. Labuntsov, Physical Fundamentals of Power Engineering. Selected Papers on Heat Transfer, Hydrodynamics and Thermodynamics (Mosk. Energ. Inst., Moscow, 2000), pp. 177–197 [in Russian].

G. B. Wallis, One-Dimensional Two-Phase Flow (McGraw-Hill, New York, 1969).

R. Numrich, Die Partielle Kondensation Eines Wasserdampf/Luftgemisches im Senkrechten Rohr bei Drücken bis 21 Bar, Dissertation (Univ. Paderborn, Paderborn, 1988); VDI Fortschritt-Berichte, Reihe 3, No. 165.

M. Rahman, M. Lampinen, and T. Siikonen, “An improved k-equation turbulence model,” Int. J. Energy Power Eng., No. 8, 1895–1907 (2014).

A. P. Solodov, “Phase interface perturbations in phase transitions,” High. Temp. 55, 253–262 (2017). https://doi.org/10.1134/S0018151X17020195

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Filatov

Rights and permissions

About this article

Cite this article

Gorpinyak, M.S., Solodov, A.P. Vapor–Gas Mixture Condensation in Tubes. Therm. Eng. 66, 388–396 (2019). https://doi.org/10.1134/S004060151906003X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S004060151906003X