Abstract

The finite element method and the results of delayed fracture tests of Charpy specimens are used to determine the local strength of grain boundaries in 18Kh2N4VA steel at various contents of phosphorus, antimony, and tin impurities. The embrittlement of grain boundaries is attributed to the adsorption enrichment of grain boundaries in impurities in initial austenite, which leads to weakening of the intergranular cohesion. Phosphorus is found to have the highest susceptibility to intergranular segregation: during the same heat treatment, its grain-boundary concentration is higher than that in steel with antimony or tin. However, the segregation of antimony is more dangerous than the segregation of phosphorus, since, at its lower intergranular concentration, the local strength of grains of quenched steel decreases as in the case of phosphorus segregation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The strength of grain boundaries substantially determines the resistance of steel against brittle failure. The strength of grain boundaries of martensitic steels is known to depend on the segregation of embrittling impurities generated as a consequence of the precipitation of impurity atoms onto boundaries during heat treatment. The most dangerous (embrittling) impurities are phosphorus, antimony, and tin.

The embrittlement of grain boundaries by segregation is the accompanying cause of delayed brittle failure of martensitic steels [1–4]. Residual internal microstresses and the intergranular segregation of embrittling impurities decrease the effective surface failure energy and increase the chance of thermal fluctuation nucleation and brittle crack propagation by the delayed fracture mechanism [5, 6].

The level of stresses at the point of crack nucleation at a grain boundary depends on external factors (load, geometry of stress concentrator, loading rate) [7] and internal factors (steel structure, grain size, chemical composition of steel, including impurities, residual microstresses and segregation of impurities on grain boundaries) [8–11]. Earlier, we developed an approach to determine the local stresses in the area of crack nucleation at a grain boundary, i.e., to determine the local strength of a grain boundary.

This work is aimed at quantitative estimation of the decrease in the local strength of grain boundaries in 18Kh2N4VA steel containing martensite during delayed fracture as a function of the volumetric and grain-boundary concentration of phosphorus, tin, and antimony.

EXPERIMENTAL

The object of research was 18Kh2N4VA steel (0.18 C, 0.25 Si, 0.45 Mn, 4.11 Ni, 1.51 Cr, 1.07 W at %). After addition of impurities to a blend, their actual content in ingots was as follows (at %): phosphorus: 0.003; 0.016, and 0.026; antimony: 0.0005 and 0.007; and tin: 0.012 (according to spectral analysis). Two heat-treatment schedules were applied: quenching from 1000°C in water and heating to 1000°C with subsequent isothermal holding at 860°C, 1 h and quenching in water. The strength of the boundaries of initial austenite grains was varied by addition of various contents of impurities and their precipitation at grain boundaries upon isothermal holding at 860°C, 1 h.

The tests for delayed fracture were performed by concentrated three-point bending using Charpy specimens (10 × 10 × 55 mm, notch: 2.0 mm, expansion angle: 45°, bending radius: 0.25 mm) by loading to preset level and holding to failure [7]. The time before initiation of crack nucleation (τr) was detected by acoustic emission [7]. The yield strength, the curvature of rheological curve, and the strengthening coefficients were detected during tensile tests of smooth specimens with a diameter of 4.3 mm (after similar heat treatment).

The maximum local tensile stresses in front of the notch top were determined using the finite element method. Figure 1 shows the map of deformation of a Charpy specimen during three point bending test with a finite element grid. To simulate plastic area where microcrack is nucleated at grain boundary under conditions of deformation confinement, a finite element grid was condensed (Fig. 2), and the local stresses in it were predicted at element grid nodes, including those in front of the stress concentrator tip [7]. For further consideration, the nodes were selected lying in the symmetry plane of the Charpy specimen in front of the notch top.

Figure 3 shows the obtained distribution of local stresses as a function of the distance from the notch tip X upon variation of the applied load at an increment of 2 kN starting from an initial load of 8 kN. Based on the distribution of local tensile stresses for each applied load, maximum local tensile stresses σ11max were determined in front of the notch for each curve in Fig. 3. The excess of the yield strength by local tensile stress σ11max at the grid nodes depended on the degree of deformation confinement. The deformation confinement in front of the notch in the formed plastic area determined nonlinear interrelation between maximum local tensile stresses σ11max and nominal (volume averaged) stress σ. Here, the threshold maximum local tensile stresses characterize the local strength of the grain boundaries during delayed fracture.

RESULTS AND DISCUSSION

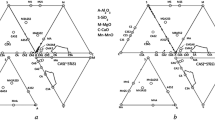

The curves of delayed brittle failure in the coordinates nominal stress σ–time to crack nucleation τr (without consideration for stress concentration) were plotted for 18Kh2N4VA steel containing various amounts of phosphorus, antimony, and tin (Figs. 4a, 5a, 6a). Since the nominal stresses do not reflect the actual local tensile stresses at the point of crack nucleation at a grain boundary, the obtained curves of delayed fracture were replotted in the σ11max–τr coordinates (Figs. 4b, 5b, 6b). Using electron fractography, we confirmed that a microcrack is nucleated and slowly propagates along grain boundaries. Transcrystalline fracture was observed at the stage of rapid crack propagation.

Time before crack nucleation as a function of (a) nominal and (b) local maximum stress in 18Kh2N4VA steel with a phosphorus content of (1) 0.003, (2, 4) 0.016, and (3, 5) 0.026% under various treatment conditions: (1–3) quenching from 1000°C in water; (4, 5) heating to 1000°C, isothermal holding in 1 h at 860°C, and quenching in water.

Time before crack nucleation as a function of (a) nominal and (b) local maximum stress in 18Kh2N4VA steel with antimony content of (1) 0.0005% and (2, 3) 0.007% after various treatment conditions: (1, 2) quenching from 1000°C in water; (3) heating to 1000°C, isothermal holding in 1 h at 860°C, quenching in water.

In all cases, a significant decrease in local strength was detected as a consequence of segregation of impurity at the boundaries of initial austenite grains. It was established that, upon increase in the content of intergranular concentration of phosphorus from 0.15 to 12.60%, the local strength of grain boundaries of 18Kh2N4VA steel decreases from 2320 to 700 MPa (see Table 1, Fig. 4, curves 1–3). Here, isothermal holding at 860°C, 1 h with subsequent quenching significantly increases the susceptibility of steel to delayed fracture in comparison with quenching from 1000°C. This is stipulated by an increase in the concentration of phosphorus atoms at grain boundaries by approximately 500 times.

An increase in the average antimony content from 0.0005 to 0.007% in the steel quenched from 1000°C leads to a decrease in the threshold local stress characterizing local strength of grain boundary from 2320 to 1380 MPa (see Fig. 5b). The susceptibility to delayed fracture of the steel with 0.007% antimony after isothermal holding at 860°C, 1 h and quenching increases in comparison with the steel with 0.0005% antimony. Isothermal holding of the steel with 0.007% antimony leads to a further decrease in the threshold stress from 1380 to 750 MPa. Here, at average antimony content of 0.007%, its concentration at the grain boundaries increases from 0.27 to 1.12% upon variation of the heat treatment schedule: quenching from 1000°C is replaced by heating to 1000°C with subsequent isothermal holding at 860°C, 1 h and quenching [10]. Isothermal holding leads to an increase in the concentration of antimony atoms at austenite grain boundaries by 160 times, which is by four times higher than that in the bulk after quenching from 1000°C (see Table 1) [10].

The segregation of tin exerts a weaker effect on the local strength of grain boundaries in comparison with antimony and phosphorus. Thus, the threshold local stress decreases from 1700 to 1150 MPa as a consequence of an increase in the tin concentration on grain boundaries from 0.48 to 1.53% (see Table 1, Fig. 6b). The decrease in intergranular cohesion along the boundaries of initial austenite grains as a consequence of the adsorption tin enrichment of grain boundaries in austenite leads to increased susceptibility of the quenched steel to delayed fracture.

CONCLUSIONS

Using the developed procedure based on the finite element method, we determined the local stresses in the area of crack nucleation above the notch in a Charpy specimen during delayed fracture tests, which allowed us to quantitatively estimate the local strength of the grain boundaries of in quenched steel with various content of intergranular impurities. A lower intergranular concentration of antimony in comparison with phosphorus was found to result in approximately the same decrease in the local strength of grain boundaries. At the same time, under similar heat-treatment conditions, phosphorus more actively reaches the boundaries of initial austenite grains (higher intergranular concentration) in comparison with antimony. Antimony and tin impurities are less sensitive to segregation at the boundaries of initial austenite grains. However, despite a high phosphorus concentration at grain boundary in comparison with antimony, the antimony-induced decrease in the local strength of grain boundaries is more significant in comparison with phosphorus.

REFERENCES

M. R. Orlov, O. G. Ospennikova, and V. I. Gromov, “Delayed fracture of 38KhN3MA steel during long term operation,” Vestn. Mosk. Gos. Tekh. Univ., Ser. “Mashinostr.”, No. SP2, 5–12 (2011).

Y. Komatsuzaki, H. Joo, and K. Yamada, “Influence of yield strength levels on crack growth mode in delayed fracture of structural steels,” Eng. Fract. Mech., 75 (3, 4), 551–559 (2008).

Y. S. Chun, K.-T. Park, and C. S. Lee, “Delayed static failure of twinning-induced plasticity steels,” Scr. Mater. 66 (12), 960–965 (2012).

I. A. Krutikova, L. M. Panfilova, and L. A. Smirnov, “Analysis of the influence of various factors on delayed fracture of structural fasteners,” Vestn. Magnitogorsk. Gorno-Metall. Univ., No. 2, 68–74 (2012).

V. M. Mishin and G.A. Filippov, “Kinetic model of delayed fracture of steel,” Probl. Chern. Metall. Materialoved., No. 3, 28–33 (2008).

V. M. Mishin and V. I. Sarrak, “The role of residual internal microstresses in thermally activated crack nucleation during delayed fracture of high strength steels,” Fiz. Met. Metalloved., No. 1, 195–198 (1990).

V. M. Mishin and G. A. Filippov, “Criterion and physicomechanical property of resistance of steel against delayed fracture,” Deform. Razrushenie Mater., No. 3, 37–42 (2007).

V. M. Mishin and G.A. Filippov, “Microstructural factors that decrease the local strength of grain boundaries in martensitic steels,” Phys. Met. Metallogr., 119 (5), 504–509 (2018).

V. I. Sarrak, G. A. Filippov, O. N. Chevskaya, and D. A. Litvinenko, “Adsorption of phosphorus at austenite grain boundaries and propensity of quenched steel to delayed fracture,” Fiz. Met. Metalloved., No. 6, 1262–1270 (1979).

G. A. Filippov and O. N. Chevskaya, “Segregation of antimony atoms at grain boundaries in austenite and resistance against intercrystalline brittle failure of steel after quenching,” Probl. Prochn., No. 11, 94–98 (1982).

G. A. Filippov, V. N. Marchenko, D. A. Litvinenko, V. I. Sarrak, and O. N Chevskaya, “The influence of impurities on intercrystalline strength of 18Kh2N4VA steel after quenching and tempering,” Probl. Prochn., No. 2, 114–119 (1980).

ACKNOWLEDGMENTS

We are grateful to the personnel of the Center of High-Quality Steels, Central Research Institute for Ferrous Metallurgy, for the assistance in performing the experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by I. Moshkin

Rights and permissions

About this article

Cite this article

Filippov, G.A., Mishin, V.M. & Mishin, V.V. Effect of the Segregation of Embrittling Impurities on the Local Strength of Grain Boundaries in a Martensitic Steel. Russ. Metall. 2020, 449–453 (2020). https://doi.org/10.1134/S0036029520040072

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029520040072