Abstract

The reduction of metals by carbon and carbon monoxide in the FeS–Ni3S2–CaO system on continuous heating to 1250°C is studied using thermogravimetric and differential thermal analyses combined with mass spectrometry of gases. The formation of the oxysulfides CaFeSO and Ca3Fe4S3O6 along with sulfide phases is revealed in the FeS–CaO and FeS–Ni3S2–CaO systems on heating in an inert atmosphere. The chemism of the carbothermic reduction of sulfides FeS, Ni3S2, and Fe4.5Ni4.5S8 in a mixture with calcium oxide is determined. The reduction products are shown to be calcium sulfide and metals, and an additive of calcium oxide inhibits the evolution of sulfur-containing gases. The reduction of nickel sulfide by carbon and carbon monoxide is activated if iron sulfide is introduced into a reaction mixture along with calcium oxide. Iron sulfide favors the formation of intermediate iron–calcium oxysulfides with enhanced reactivity. In the temperature range from 750 to 1170°C, the experimental data on the carbothermic reduction of metals in the FeS‒Ni3S2–CaO system are described by a one-step Avrami–Erofeev model, in which the process is determined by the step of nuclei formation and growth. The kinetic parameters of the process are found to be E = 520 kJ/mol, log A = 18.2 s–1, and n = 0.87 (E is the activation energy, A is the preexponential factor, and n is the reaction order). The data obtained are useful for the development of technologies for the direct isolation of valuable metals from sulfide raw materials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

The phase transitions in calcium-containing oxide–sulfide systems are interesting for understanding the processes that occur during the pyrometallurgical processing of sulfide ores and concentrates of nonferrous metals. The data on the interaction of chalcogenides with calcium oxide on heating in a reductive medium favor the development of technologies for the direct production of metals from sulfide concentrates. The results of studying the thermal transformations during heating of iron sulfides and nonferrous metal sulfides together with calcium oxide are important for a more complete and unambiguous elucidation of the mechanism of metal reduction.

The published data mainly concern binary systems [1, 2]. The data on the influence of calcium oxide on the fusibility of iron, copper, zinc, and lead sulfides are available [1]. The phase equilibria in the Fe–Ca–S–O system and the carbothermic reduction of pyrrhotine in a mixture with calcium oxide were considered [2, 3]. The role of calcium oxide in the reduction of metal sulfides by carbon is related to the formation of an ion-exchange medium and the inhibition of the evolution of sulfur to the gas phase. The possibility of the reduction of the metal by graphite and coke from nickel sulfides (Ni3S2 and NiS) in mixtures with CaO under the isothermal conditions (800–1124°C) was shown [4, 5].

According to the well-known data [3, 4], the reduction of iron from an FeS–CaO mixture occurs at lower temperatures at higher rates and higher completeness of the process compared to the reduction of nickel from the NiS–CaO mixture. One of the causes is the formation of phases of iron–calcium oxysulfides CaFeSO and Ca3Fe4S3O6, whereas nickel does not form these compounds [6–8]. It can be assumed that FeS additives to an Ni3S2–CaO mixture make it possible to intensify the reduction processes due to a decrease in both the melting points in oxide–sulfide systems and the temperatures of interaction leading to metal formation. To substantiate these statements, it seems important to evaluate the influence of iron sulfide additives to an Ni3S2–CaO mixture on the carbothermic metal reduction mechanism.

The purpose of this work was to evaluate the phase transitions in the FeS–CaO and FeS–Ni3S2–CaO systems on heating in inert (argon) and reductive (carbon monoxide) media and to determine the mechanism and kinetic parameters of the carbon reduction of metals.

EXPERIMENTAL

The initial nickel sulfide was synthesized by smelting of an NP-1PEN metallic nickel powder and elemental sulfur (special purity grade 16-5) in graphite crucibles. Samples of iron sulfide FeS and pentlandite Fe4.5Ni4.5S8 were prepared by sintering of iron carbonyl and nickel powders with sulfur at 700–750°C for 400 h followed by annealing at 700°C for 100 h. The synthesized sulfides had the structures of troilite (FeS) and heazlewoodite (Ni3S2). The pentlandite sample composition (%) 32.6 Fe, 34.2 Ni, 33.2 S) mainly consisted of the Fe4.4Ni4.6S8 sulfide and a minor amount of a monosulfide solid solution (mss, (Fe0.8Ni0.1)S).Footnote 1 Calcium oxide was prepared by the calcination of chemically pure calcium carbonate at 950°C for 30 min. The sizes of the divided reagents were as follows: <120 μm for nickel sulfide and pentlandite and 63 μm for iron sulfide and calcium oxide. The compositions of the mixtures used in the experiments are presented in Table 1. The taken amount of KG-1 graphite (99% C) was 8.2–9.5% of the sum of the weights of metal sulfides and calcium oxide, which corresponded to 120% of the stoichiometrically necessary amount for the complete reduction of the metals.

Thermal analysis methods were used to estimate the temperature and the thermal characteristics of the transformations occurred on heating of the reaction mixtures. The experiments were carried out on a NETZSCH STA 449 C Jupiter instrument designed for combined thermogravimetry (TG) and differential scanning calorimetry (DSC) in platinum crucibles under the conditions of continuous heating to 1000°C followed by cooling to 200°C at a rate of 10°C/min in an argon flow (70 cm3/min). The experiments on the reduction of metals from sulfides were conducted on continuous heating of the samples (50 mg) to 1200–1250°C at a rate of 5–30°C/min in a flow (50–60 cm3/min) of an Ar–CO (60%) gas mixture or in argon using graphite as one of the reactants. In this case, the sample holder was applied for differential thermal analysis (DTA). The composition of the gas phase in the carbothermic reduction experiments was examined on a QMS 403C Aêolos quadrupole mass spectrometer combined with a thermoanalyzer. The kinetic parameters of the carbothermic reduction were calculated using the NETZSCH Thermokinetics 3.0 software [9]. X-ray diffraction analysis (XRD) of the samples was carried out on a DRON diffractometer (Cu Kα radiation, graphite monochromator in the exit beam) followed by identification of the measurement results using the PDF 2012 database [10].

RESULTS AND DISCUSSION

The endothermic effects with the onset/maximum at 144/151 and 273/317°C caused by the phase transitions of troilite [11] were revealed by thermal analysis of the equimolar mixture of FeS and CaO in an argon flow (Fig. 1). The exothermal effect with the maximum at 866°C corresponds to the interaction of FeS with CaO accompanied by the formation of iron–calcium oxysulfides. The endothermic effects at 861/863 and 943/945/968°C are, most likely, due to melting of the formed phases, namel, eutectic Fe1 –xS–Ca3Fe4S3O6 and oxysulfides Ca3Fe4S3O6 and CaFeSO [1, 2]. The effect of phase crystallization at 931/924°C was revealed on cooling a sample. The XRD results obtained for the cooled reaction products confirmed the formation of the oxysulfides CaFeSO and Ca3Fe4S3O6 [1–3, 12–14]. The CaS, CaO, FeS, and Ca2Fe2O5 phases were identified along with the oxysulfides. The formation of the oxysulfides is the result of the following reactions:

The DSC curve for the 2FeS–Ni3S2–2CaO system heated to 920°C in an argon flow exhibits the endothermic effects characteristic of the phase transitions of FeS (140/149 and 286/317°C) and the effects caused by the β transition of a solid solution Ni3S2–(Fe,Ni)9S8 [15] with the onset/maximum phase transition temperatures at 502/526°C and the phase transition of pentlandite at 608/615°C (see Fig. 1b) [16]. The effects revealed in the temperature range from 817 to 843°C are attributed to melting of the sulfide and oxysulfides. The range of metal crystallization with the onset/maximum temperatures at 831/803°C was determined on cooling. The thermal effect at 469/458°C corresponds to the phase transition of a sulfide solid solution. The following phases were found in the cooled heating products by XRD: Ni3S2, CaS, Fe4.75Ni4.25S8, Ca3Fe4S3O6, Ca2Fe2O5, and FeS (traces).

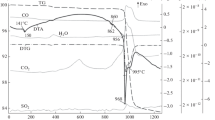

Heating of the FeS and CaO components taken in the equimolar ratio at a rate of 10°C/min in a flow of a 40% Ar–60% CO gas mixture is accompanied by an increase in the sample weight by 1.56% in the temperature range 200–626°C (Fig. 2). This is probably due to the decomposition of CO to form CO2 and elemental carbon deposited on the measuring cell, crucible, and sample [17]. Further heating (to 1000°C) of the reaction mixture is characterized by a decrease in the weight by 5.6% of the initial weight, which corresponds to 50.4% reduction of iron. The data of differential thermogravimetry (DTG) indicate the maximum rate of the mass loss in a range of 670–780°C (maximum at 733°C). The weight changing rate is stabilized during further heating of the sample up to melting of the oxysulfides (960°C), and the process is retarded due to partial blocking of the reaction surface by the reaction products. The DTA curve exhibits endothermic effects caused by the phase transition of FeS, the decomposition of Ca(OH)2 (360/390°C) and CaCO3 (550°C), the formation of oxysulfide and reduction of iron (combined effect with the onset/maximum temperatures 696/738°C), and melting of the oxysulfide phases (957/964°C). The presence of minor amounts of Ca(OH)2 and CaCO3 in the sample is due to the high activity of CaO in the environment (air) in which the experiment was prepared. The decreased temperatures of the decomposition of calcium carbonate are caused, most likely, by its reaction with iron sulfide. According to XRD data, CaS, CaFeSO, and Fe are the products of thermal treatment of the mixture (up to 1000°C) in a reductive medium.

These results show that the reduction of iron in an FeS–CaO mixture by carbon monoxide is described by the overall scheme

The intermediate steps of reaction (3) are reactions (1) and (2) along with the following processes:

According to [7, 8], the metals from oxysulfides Ca3Fe4S3O6 and CaFeSO are reduced by carbon monoxide at appreciable rates in the temperature range 500–800°C. Therefore, the formation of intermediate oxysulfides during heating a mixture of FeS and CaO is determining for the reduction of iron in the system considered.

The reduction of the metals by carbon monoxide from the 2FeS–Ni3S2–2CaO mixture on heating at a rate of 10°C/min begins from 530°C and is accompanied by an intensive mass loss at temperatures higher than 700°C (Fig. 2). The heating of the sample to 1100°C results in the mass loss by 6.5% and the formation of pentlandite Fe4.75Ni4.25S8 along with CaS and a Ni–Fe alloy in the products, indicating that the amount of CaO is insufficient for full binding of sulfur. The exothermic effect at 779/808°C is due to the formation of the oxysulfide phases. The reduction of the metals in a CO flow for the considered reagent ratio can be described by the reaction

On heating a 2FeS–Ni3S2–4CaO mixture at a rate of 10°C/min in a flow of an Ar–CO gas mixture (see Fig. 2), reduction starts at about 560°C and is accompanied by the mass loss reaching 9.58% at 1120°C, which corresponds to 95.9% reduction of the metals (nickel, iron). The maximum weight changing rate corresponds to a temperature range of 850–950°C. The endothermic effects on the DTA curve are characteristic of the phase transitions of FeS, Ni3S2, and Fe4.75Ni4.25S8 and melting of the oxysulfide (931/938°C). According to XRD data (Fig. 3), the cooled reaction products contain CaS, an Ni–Fe alloy, and traces of Fe4.75Ni4.25S8 and CaO.

According to [18], the mass loss reaches 16% in the temperature range 900–1050°C for the equimolar FeS–CaO mixture with graphite additives. The reduction of iron proceeds via the formation of intermediate low-melting oxysulfide phases. Carbon dioxide is formed beginning from 800°C and carbon monoxide is formed above 950°C. Very insignificant evolution of SO2 is observed on heating an FeS–CaO mixture with graphite, whereas no gases such as COS and CS2 form. The major condensed products on heating an FeS–CaO mixture with graphite to 1250°C are represented by CaS and Fe at low residual quantities of the initial components (CaO, FeS, and C). Since the carbothermic reduction of iron from iron sulfide is thermodynamically poorly probable and the introduction of calcium oxide activates the process, the overall reaction takes the form [18]

Thus, the carbothermic reduction of iron from iron sulfide in the considered temperature range occurs only in the presence of calcium oxide, which acts as an ion-exchange medium.

The carbothermic reduction of nickel sulfide Ni3S2 in the presence of CaO was evaluated under the conditions of continuous heating of the mixture to 1250°C. The measurement results showed (Fig. 4) that the Ni3S2–2CaO mixture with an additive of 8.2% carbon changed the weight at the temperature higher than 790°C. Heating of the mixture up to 1250°C is accompanied by the mass loss by 8.5%, and the TG curve indicates that the process is not completed. The endothermic effects (DTA) are associated with the phase transition (553/563°C) and melting (786/792°C) of Ni3S2 [11, 19] and with the reduction of sulfide (1000/1019°C). As found by XRD, CaS and Ni, as well as the unreacted initial components Ni3S2, CaO, and C, were among the reduction products. The change in the sample weight is accompanied by the evolution of CO and CO2 and a minor amount of SO2, the detection of which is provided by the high sensitivity of the mass spectrometer. It should be mentioned that no SO2 formation was revealed by chromatography on heating the Ni3S2–CaO system in a reductive medium [4]. Based on these data, we can describe the carbothermic reduction of nickel from nickel sulfide in the presence of calcium oxide by the following overall reaction:

The following reactions accompanied by the SO2 evolution are possible along with reaction (5):

The carbothermic reduction of the metals by graphite in the 2FeS–Ni3S2–4CaO system is developed above 730°C (see Fig. 4b) and is accompanied by a decrease in the sample weight, an endothermic effect, and the evolution of carbon oxides (CO and CO2). As in the previous experiments, the decrease in the sample weight at 400–450 and 600–750°C is related to the decomposition of Ca(OH)2 and CaCO3. An insignificant amount of SO2 in the gas was detected at 1050°C, and no formation of COS and CS2 was revealed. The solid reaction products are represented by CaS, Fe–Ni, an insignificant amount of Fe9Ni9S16, and unreacted CaO and C (see Fig. 3). The overall reaction of the metal reduction takes the form

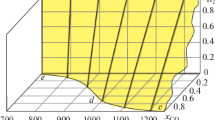

The kinetic parameters were determined and the reaction model of the metal reduction process was evaluated on the basis of the data on the weight change of the 2FeS–Ni3S2–4CaO mixture with graphite on heating with a rate of 5, 10, and 20°C/min in the temperature range 750–1170°C. The calculation results show (Fig. 5) that the one-step Avrami–Erofeev model [20, 21] with the rate-determining step of nuclei formation and growth describes the experimental data at a correlation coefficient of 0.9987. The kinetic equation takes the form

where A is the preexponential factor, E is the activation energy (kJ/mol), T is temperature (K), R is the gas constant, α is the conversion equal to the ratio of the current weight change to the maximum change, n is the reaction order, and τ is the experiment time. The kinetic parameters of the carbothermic reduction of the metals were determined to be as follows: E = 520 ± 11 kJ/mol, logA = 18.2 ± 0.4 s–1, and n = 0.87 ± 0.01.

The previously conducted thermal analysis of the synthesized pentlandite sample (Fe4.5Ni4.5S8) [22] on heating (20°C/min) in an argon flow revealed the endothermic effect on the DSC curves at the following onset/maximum temperatures: 278/293 (weak peak), 479/485, 616/624, and 857/864°C. The effects at 278 and 479°C were clarified by ordering of the superstructures and the β transformation of the monosulfide solid solution Fe0.8Ni0.1S. At 616°C, pentlandite undergoes transition into the high-temperature modification in the cubic crystal system, which is stable up to 857°C [16]. A liquid phase is formed and the monosulfide solid solution is retained in the sample above this temperature.

The reduction of the metals from the synthesized pentlandite Fe4.5Ni4.5S8 was evaluated for its mixture with CaO (see Table 1, mixture 5). Under the conditions of reduction with graphite (Fig. 6) on heating at a rate of 10°C/min, the sample weight changes by 14.4% (1100°C). The DTA curve exhibits the effects characteristic of the phase transitions of pentlandite (615 and 855°C) and the formation (864°C) and melting (932/938°C) of the oxysulfide. The combined endothermic effects with the onset at 1021°C and maxima at 1030 and 1063°C are the consequence of melting of the sulfide phases and the development of reduction processes accompanied by CO and CO2. Insignificant evolution of SO2 was observed in a range of 800–1000°C. The products of the carbothermic reduction of the metals in an Fe4.5Ni4.5S8–8CaO mixture on heating to 1250°C were CaS and a Fe–Ni solid solution (see Fig. 3), and trace amounts of C, Fe9Ni9S16, and CaO were additionally found, which is consistent with [23]. Based on these results, we can present the carbothermic reduction of the metals in the pentlandite mixture with calcium oxide by the overall reaction

The results of mass spectrometric analysis of gases to detect CO and CO2 (see Figs. 4 and 6) were used for the calculation of coefficient b in reactions (4)–(7) of the metal reduction by graphite from FeS–CaO, Ni3S2–2CaO, 2FeS–Ni3S2–4CaO, and Fe4.5Ni4.5S8–8CaO mixtures. The SCO/\({{S}_{{{\text{C}}{{{\text{O}}}_{{\text{2}}}}}}}\) ratios were determined from the surface areas of the peaks under the ionic current curves of the gases formed upon the carbothermic reduction of the metals from the sulfide mixtures with calcium oxide (Table 2). Coefficients b for reactions (4)–(7) were estimated by the equation

where SCO/\({{S}_{{{\text{C}}{{{\text{O}}}_{{\text{2}}}}}}}\) are the surface areas of the peaks of the ionic current curves of CO and CO2 (arb. units). The found values of coefficient b made it possible to calculate the weight changes (TGcalc) for the complete reduction of the metals (Fe, Ni) from the considered systems and to compare them with the experimental values (TGexp). The degrees of reduction of the metals in the systems on heating to 1250°C at a rate of 10°C/min were estimated from the calculated weight changes. The calculations confirmed the increase in the degrees of reduction of the metals from 61 to 83% upon the introduction of iron sulfide into the Ni3S2–CaO mixture. The high degrees of reduction of the metals in the Fe4.5Ni4.5S8–8CaO system are due to the presence of the monosulfide solid solution in the system [24], pentlandite melting, and the formation of iron–calcium oxysulfide phases.

CONCLUSIONS

(1) The reactions in an FeS–CaO mixture on heating in argon yield iron–calcium oxysulfides Ca3Fe4S3O6 and CaFeSO, and pentlandite Fe4.75Ni4.25S8, Ca3Fe4S3O6, and CaS form in the reactions in a 2FeS–Ni3S2–2CaO mixture.

(2) Heating of FeS–CaO and FeS–Ni3S2–CaO mixtures in a reductive medium (Ar–CO) at the temperatures higher than 600°C results in the formation of a metal (Fe, Fe–Ni alloy) and calcium sulfide. An increase in the calcium oxide content in an FeS–Ni3S2–CaO mixture is accompanied by an increase in the degree of reduction of the metals.

(3) Iron sulfide activates the carbothermic reduction of nickel in an Ni3S2–CaO mixture due to the formation of iron–calcium oxysulfides with an enhanced reactivity.

(4) The carbothermic reduction of the metals in an FeS–Ni3S2–CaO mixture was described by a one-step Avrami–Erofeev model with the rate-determining step having the following kinetic parameters: E = 520 kJ/mol, logA = 18.2 s–1, and n = 0.87 (E is the activation energy, A is the preexponential factor, n is the reaction order).

(5) The high degree of the carbothermic reduction of the metals in the Fe4.5Ni4.5S8–CaO system is caused by the presence of low-melting phases and the formation of iron–calcium oxysulfides.

Notes

Hereafter, the component content is given in wt %.

REFERENCES

V. I. Yarygin, N. I. Kopylov, V. N. Novoselova, et al., “Influence of calcium oxide on the fusibility of iron, copper, zinc, and lead sulfides,” Izv. Akad. Nauk SSSR, Met., No. 6, 65–68 (1975).

A. Jha, U. O. Igiehon, and P. Grieveson, “Carbothermic reduction of pyrrhotite in the presence of lime for production of metallic iron. I. Phase equilibria in Fe–Ca–S–O system,” Scand. J. Met. 20, 270–278 (1991).

A. Jha and P. Grieveson, “Carbothermic reduction of pyrrhotite in the presence of lime for production of metallic iron. II. Kinetics and mechanism of reduction,” Scand. J. Met. 21, 50–62 (1992).

M. C. Bronson and H. Y. Sohn, “The carbothermal reduction of nickel in the presence of lime,” Met. Trans. 14, 605–615 (1983).

N. Machingawuta, A. Jha, and P. Grieveson, “Mechanism of carbothermic reduction of nickel sulfide mineral in the presence of lime,” Scand. J. Met. 18, 81–88 (1989).

V. M. Chumarev, A. I. Okunev, and R. I. Shakirzyanova, “Reduction of iron–calcium oxysulfide by carbon and carbon oxide,” Izv. Akad. Nauk SSSR, Met., No. 3, 10–15 (1977).

R. I. Gulyaeva, E. N. Selivanov, and A. N. Mansurova, “Kinetics of the calcium oxysulfides reduction by carbon monoxide,” Def. Dif. Forum 283–286, 539–544 (2009).

V. P. Mar’evich, R. I. Gulyaeva, V. M. Chumarev, E. N. Selivanov, and O. N. Bezryadnova, “Solid-phase interactions of zinc and nickel sulfides with iron–calcium-containing oxysulfides,” in Proceedings of All-Russia Conference on Solid State Chemistry and Functional Materials (Yekaterinburg, 2004), p. 251.

J. Opffermann, NETZSCH Thermokinetics 3.0. Version2006.08. www.therm-soft.com.

Centre for Diffraction Data (ICCD) (2012).

D. J. Vaughan and J. R. Craig, Mineral Chemistry of Metal Sulfides (Cambridge Earth Science Series) (Cambridge Univ. Press, Cambridge, 1978).

J. Trifonow and D. Mirew, “Uber die Rolle des Kalkes bei der Entchwefelung von Eisen und Stahl,” Arch. Eisenguttenwesen, No. 7, 337–341 (1933/34).

E. N. Selivanov, V. M. Chumarev, R. I. Gulyaeva, V. P. Mar’evich, A. D. Vershinin, A. A. Pankratov, and E. S. Korepanova, “Composition, properties, and thermal expansion of Ca3Fe4S3O6 and CaFeSO,” Neorg. Mater. 40 (8), 969–974 (2004).

N. I. Kopylov, V. A. Lata, and M. Z. Toguzov, Interactions and Phase States in Molten Sulfide Systems (Gylym, Almaty, 2001).

F. V. Chukhnov, N. A. Ostrovskii, and V. V. Lapin, Phase Equilibria Diagrams (Nauka, Moscow, 1974).

A. Sugaki and A. Kitakaze, “High form of pentlandite and its thermal stability,” Amer. Mineralogist 83, 133–140 (1998).

O. A. Esin and P. V. Gel’d, Physical Chemistry of Pyrometallurgical Processes (Metallurgizdat, Moscow, 1950), Part I.

E. N. Selivanov and R. I. Gulyaeva, “Carbothermic reduction of metals in the FeS–Cu1.96S–CaO system,” Russ. Metall. (Metally), No. 3, 216–222 (2019).

A. D. Vershinin, E. N. Selivanov, R. I. Gulyaeva, and N. I. Sel’menskikh, “Thermal expansion of Ni3S2 in an alloy with Ni,” Neorg. Mater. 41 (8), 1005–1010 (2005).

S. Vyazovkin, A. K. Burnhamb, J. M. Criadoc, L. A. Perez-Maquedac, C. Popescud, and N. Sbirrazzuoli, “ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data,” Thermochim. Acta 520, 1–19 (2011).

J. Opfermann, “Kinetic analysis using multivariate non-linear regression,” J. Therm. Anal. Calorim. 60, 641–658 (2000).

R. I. Gulyaeva, E. N. Selivanov, and A. D. Vershinin, “Synthesis of pentlandites with variable composition and phase transformations upon heating in inert atmosphere and air,” in Programme and Book of Abstracts of 13 Annual Conference Yucomat 2011 (Herceg Novi, Montenegro, 2011), p. 105.

A. Jha, S. Tang, and C. Andreas, “Phase equilibria in the metal–sulfur–oxygen system selective reduction of metal oxides and sulfides. I. The carbothermic reduction and calcination of complex mineral sulfides,” Met. Mater. Trans. B 27, 829–840 (1996).

V. A. Drebushchak, T. A. Kravchenko, and V. S. Pavlyuchenko, “Synthesis of pure pentlandite in bulk,” J. Crystal Growth 193, 728–731 (1998).

Funding

This work was carried out in terms of state assignment for the Institute of Metallurgy (Ural Branch, Russian Academy of Sciences) using the equipment of the Center for Collective Use Ural-M.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Yablonskaya

Rights and permissions

About this article

Cite this article

Selivanov, E.N., Gulyaeva, R.I. & Tyushnyakov, S.N. Mechanism and Kinetics of the Carbothermic Reduction of Metals in the FeS–Ni3S2–CaO System. Russ. Metall. 2020, 250–258 (2020). https://doi.org/10.1134/S0036029520030118

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029520030118