Abstract

The Cu–Ce–La system is of interest for the production of both rare-earth-added bronzes and amorphous alloys. In this work, we investigate the phase composition, the microstructure, and the microhardness of 13 as-cast Cu–Ce–La samples corresponding to the copper angle of the Cu–Ce–La phase diagram. The experimental samples are studied by optical microscopy, scanning electron microscopy, electron microprobe analysis, atomic emission analysis with inductively coupled plasma, X-ray diffraction, and differential thermal analysis. The Vickers microhardnesses of the samples are measured. The microstructure of the samples is characterized by the presence of a eutectic, which is observed at Cu-based solid-solution grain boundaries and, according to electron microprobe analysis data, contains copper, lanthanum, and cerium. The X-ray diffraction analysis data also indicate the presence of the Cu6Ce and Cu6La compounds along with the Cu-based solid solution. The volume fraction of the eutectic component is determined (it is equal to the fraction of the area corresponding to the eutectic in the section of a sample). As the Ce and La contents increase, the fraction of the eutectic component increases. According to thermal analysis data, the ternary eutectic equilibrium takes place along with the binary eutectic equilibria. Significant correlation between the fraction of eutectic component in the microstructure and the hardness of the experimental samples is shown to exist. As the fraction of eutectic in the microstructure increases, microhardness HV also increases. The obtained results are of interest for materials scientists for analyzing the effect of rare-earth metal additions on the phase composition, the microstructure, and the mechanical characteristics of copper alloys.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Bronzes alloyed with rare-earth elements (in particular, with cerium and lanthanum) are of interest, on the one hand, owing to an adequate combination of the mechanical properties, high heat resistance, and electrical conductivity [1–9]. On the other hand, rare-earth-containing copper alloys are the basis for manufacturing rapidly quenched amorphous alloys [10–18].

However, information about the phase equilibria in the Cu–Ce–La system is very scarce. The results of investigations of the properties of the CexLa1 – xCu alloys are only reported in a number of studies [19‒21].

Data of the phase equilibria in the binary Cu–Ce, Cu–La, and Ce–La systems are reported in detail in [22–35].

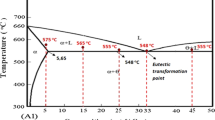

The Cu–Ce system is characterized by the formation of five compounds; these are Cu6Ce, Cu5Ce, Cu4Ce, Cu2Ce, and CuCe, among which only Cu6Ce and Cu2Ce are formed congruently [22–26]. In the composition range of interest (copper-enriched compositions), the nonvariant eutectic transformation L ↔ (Cu) + Cu6Ce takes place. According to [22], the eutectic point corresponds to 17.90 wt % Ce and 876°C; according to [24], the eutectic transformation occurs at 17.54 wt % and 892°C. The authors of work [25] indicate the eutectic point corresponding to 17.9 wt % Ce and 879°C. It should be noted that the cerium solubility in solid copper is only 0.2 wt % [26] and does not exceed 0.05 wt % at 300°C.

According to [27, 28], the Cu–La system is characterized by the formation of only four compounds, namely, Cu6La, Cu5La, Cu2La, and LaCu. The authors of recent work [29] experimentally studied the structure and properties of the LaCu13 compound. Two new compounds were also prepared in studying the Cu–La phase diagram [30]. The compounds were identified to be Cu4La and X phase [30]. The structure of X phase coincides with that of LaCu13; the phase is stable only at high temperatures. The existence of the Cu4La compound was confirmed in [31], whereas the formation of X compound was called into question. According to recent data of [32], the thermodynamic evaluation of data on the X compound was performed, and its composition as shown can be described by formula Cu37La3. As follows from the data available in the literature, the system is considered to be characterized by the following six compounds: Cu37La3, Cu6La, Cu5La, Cu4La, Cu2La, and CuLa. Among these compounds, only Cu6La and Cu2La form congruently [33]. The eutectic transformation typical of the copper-rich compositions is L ↔ (Cu) + Cu6La and occurs at 17.78 wt % and 865°C [28].

The Ce–La system is characterized by the mutual continuous solid solubility in both liquid and solid [34, 35].

There a few studies related to the determination of the hardness of copper–rare-earth metal alloys in the literature. According to data of [1], the Vickers hardness equal to 1100 MPa can be reached in the copper–cerium alloys at a cerium content of 4 wt %. According to data of [2], the Vickers microhardness of the Cu–0.3 wt % Ce composition is 1042 MPa; at a cerium content of 2 wt %, the Vickers hardness is 893 MPa. For the copper–lanthanum alloys, the microhardness HV equal to 750 MPa can be obtained at a lanthanum content of 0.32 wt % [8].

Thus, the phase composition, microstructure, and mechanical properties of the ternary Cu–Ce–La alloys are poor understood, and taking into account the relevance of the system, call for further investigation.

The present study is aimed at investigating the phase composition and the microstructure of cast Cu–Ce–La alloys belonging to the copper angle of the phase diagram and at determining the effect of the parameters on their hardness.

EXPERIMENTAL

Table 1 gives the compositions of the samples used for an experimental investigation. As the object of study, we selected the copper angle of the Cu–Ce–La phase diagram; the cerium and lanthanum concentrations in the experimental samples did not exceed 6.5 wt % for each of the elements.

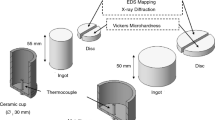

The samples were melted using electrolytic copper (99.99 wt % purity), metallic cerium (99.9 wt % purity), and metallic lanthanum (99.9 wt % purity). The required quantities of components were melted at 1400°C using a graphite crucible. The holding time at the given temperature was ~10 min. The melting was performed in a reducing atmosphere created inside the furnace. The samples were cooled in a protective atmosphere; the estimated cooling rate of experimental samples upon solidification did not exceed 10 deg/s. It should be noted that, in performing all experiments, the majority of factors (the solidification rate, segregation, limit solubility of rare-earth metals in the copper-based solid solution, etc.) affected the hardness of samples were unchanged.

The composition of samples was checked by determining the cerium and lanthanum on an OPTIMA 2100 DV (Perkin Elmer) atomic emission spectrometer using inductively coupled plasma.

X-ray diffraction (XRD) analysis was performed using sections of samples, a D8 ADVANCE multifunctional powder diffractometer (Bruker), and CuKα radiation.

The differential scanning calorimetry (DSC) was performed at heating and cooling rates of 10 deg/min using a STA 449 C synchronous thermal analyzer (NETZSCH).

The microstructure of sections of experimental samples was studied using an IM 7200 optical inverted microscope (MEIJI TECHNO CO., LTD). The volume fraction of the eutectic (percentage of the total section area) was determined using Thixomet PRO software. The sections also were studied by scanning electron microscopy (SEM) performed on a JSM-6460LV JEOL scanning electron microscope equipped with an energy dispersive spectrometer (Oxford Instruments), which is used to perform qualitative and quantitative electron microprobe analysis (EPMA).

The Vickers hardness (HV) was measured at a load of no less than 100 g using a FUTURE-TECH FM-800 tester and Thixomet PRO software; the measurements were performed for no less than ten points of each of samples.

RESULTS AND DISCUSSION

Table 1 shows the XRD and thermal analysis data (where T1 and T2 are the temperatures corresponding to the first and second thermal effects in the DSC curve, respectively). For samples 1, 2, 4, and 8, temperatures T1 are not given, since XRD did not allowed us to find other phases along with the copper-based solid solution likely because of small amounts of the formed intermetallics. When studying the phase composition of all samples, no phase, which can be identified as Cu37La3, was found. Figure 1 shows the XRD pattern for sample 13 characterized by the maximum cerium and lanthanum contents (see Table 1); Fig. 2 shows the DSC curve of sample 13.

Table 1 also presents data on the Vickers microhardness of the samples and the fraction of the eutectic component in the structure of samples. The statistic analysis of the data on HV and the fraction of the eutectic component shows a high degree of mutual correlation between these two parameters (coefficient of correlation is 0.975); this also is observed in the scattering graph (Fig. 3). As the fraction of the eutectic component increases, the Vickers hardness increases (from 890 MPa for sample 2 to 1490 MPa for sample 13).

Figure 4 shows the microstructure (SEM images) of the experimental samples (as the fraction of the eutectic component increases). The samples are characterized by a dendritic structure; the low-melting (bright gray in color) component is observed at grain boundaries of the Cu-based solid solution. Figure 4 shows that, as the fraction of eutectic increases, its layers become thicker and the Cu-based solid solution grains become smaller. A lamellar structure of the eutectic component is observed at a high magnification (Fig. 5).

Microstructure (SEM images) of experimental samples (as the fraction of eutectic component increases, see Table 1): (a) 2, (b) 5, (c) 3, (d) 7, (e) 12, and (f) 13.

Table 2 gives the compositions determined for the eutectic component by EPMA. The comparison of the data given in Tables 1 and 2 allows us to note that the cerium and lanthanum contents in the eutectic component depend on the sample composition. As the cerium concentration increases, the cerium content in the eutectic component increases, whereas the lanthanum content in the eutectic decreases and vise versa. According to XRD data (see Table 1), the Cu6Ce compound was not found in samples 3, 5, 6, and 7; however, according to the data given in Table 2, the eutectic component of these samples contains cerium. Taking into account the low cerium concentration in the low-melting component (see Table 2), we can assume that the Cu6Ce compound can be present in these samples; however, its content is insufficient to be detected by XRD. Moreover, according to data of [19], cerium can dissolve in the Cu6La intermetallic. A similar pattern is observed for the Cu6La compound in samples 10 and 11; moreover, according to [19], lanthanum exhibits terminal solubility in the Cu6Ce intermetallic.

The analysis of the data given in Tables 1 and 2 allows us to conclude that, along with the Cu-based solid solution, both binary and ternary eutectics are present in the samples. This is typical of the systems characterized by continuous solubility in liquid and terminal solubility in solid (for the system under study, the cerium and lanthanum solubilities in copper is no more than hundredths of a percent).

Upon solidification of experimental compositions, Cu-based solid solution crystals are the primary phase. After that, for the compositions characterized by the higher lanthanum content as compared to the cerium content, the binary eutectic corresponding to the Cu–La binary system is likely to form. In the case of compositions with the higher cerium contents, the eutectic typical of the Cu–Ce system forms. When the concentration of third component in the liquid reaches a certain value, the solidification finishes the formation of the ternary eutectic. Based on the DSC data for samples 9, 12, and 13 (see Table 1), the ternary eutectic equilibrium is realized at a temperature of 861 ± 3°C. Taking into account the possibility of the formation of solid solutions based on Cu6Ce and Cu6La [19], we can write the ternary eutectic transformation as L ↔ |Cu|ss + |Cu6Ce|ss + |Cu6La|ss.

CONCLUSIONS

The phase composition and the microstructure of the alloys corresponding to the copper angle of the Cu–Ce–La system were studied. According to the data obtained, the Cu6Ce and Cu6La intermetallics are present along with the copper-based solid solution. Cu-based solid solution grains were found to be in equilibrium with the eutectic component, the composition of which comprises cerium and lanthanum along with copper. The ternary eutectic transformation at 861 ± 3°C can be written as L ↔ |Cu|ss + |Cu6Ce|ss + |Cu6La|ss. The existence of the Cu37La3 compound was not confirmed. A significant positive correlation between the Vickers microhardness HV and the content of eutectic component in the microstructure of the experimental samples was demonstrated. The microhardness of the alloys varies from 890 to 1490 MPa.

REFERENCES

A. M. Korol’kov, E. V. Bezus, and L. M. Gurova, “Low-alloyed heat-resistant copper alloys with a high electrical conductivity,” Izv. Akad. Nauk SSSR. Met., No. 1, 150–155 (1967).

Z. Zhang, G. Lin, S. Zhang, and J. Zhou, ”Effects of Ce on microstructure and mechanical properties of pure copper," Mater. Sci. Eng. A 457, 313–318 (2007).

H. Li, S. Zhang, Y. Chen, M. Cheng, H. Song, and J. Liu, “Effects of small amount addition of rare earth Ce on microstructure and properties of cast pure copper,” J. Mater. Eng. Perform. 24, 2857–2865 (2015).

M. Aindow, S. P. Alpay, Y. Liu, J. V. Mantese, and B. S. Senturk, “Base metal alloys with self-healing native conductive oxides for electrical contact materials,” Appl. Phys. Lett. 97, 152103 (2010).

B. S. Senturk, Y. Liu, J. V. Mantese, S. P. Alpay, and M. Aindow, “Effects of microstructure on native oxide scale development and electrical characteristics of eutectic Cu–Cu6La alloys,” Acta Mater. 60, 851–859 (2012).

J. B. Liu, L. Meng, and L. Zhang, “Rare earth microalloying in as-cast and homogenized alloys Cu–6 wt % Ag and Cu–24 wt % Ag,” J. Alloys Compd. 425, 185–190 (2006).

F. A. Guo, C. J. Xiang, C. X. Yang, X. M. Cao, S. G. Mu, and Y. Q. Tang, “Study of rare earth elements on the physical and mechanical properties of a Cu–Fe–P–Cr alloy,” Mater. Sci. Eng. B. 147, 1–6 (2008).

Y. Chen, M. Cheng, H. Song, S. Zhang, J. Liu, and Y. Zhu, “Effects of lanthanum addition on microstructure and mechanical properties of as-cast pure copper,” J. Rare Earths 32, 1056–1063 (2014).

J. Wu, S. Zhang, Y. Chen, H. Li, and J. Liu, “Effects of La microalloying on microstructure evolution of pure copper,” Mater. Sci. Forum. 898, 361–366 (2017).

A. Inoue, “Stabilization of metallic supercooled liquid and bulk amorphous alloys,” Acta Mater. 48, 279–306 (2000).

Q. K. Jiang, G. Q. Zhang, L. Y. Chen, J. Z. Wu, H. G. Zhang, and J. Z. Jiang, “Glass formability, thermal stability and mechanical properties of La-based bulk metallic glasses,” J. Alloys Compd. 424, 183–186 (2006).

R. Li, F. Liu, S. Pang, C. Ma, and T. Zhang, “The influence of similar element co-existence in (La–Ce)–Al–(Co–Cu) bulk metallic glasses,” Mater. Trans. 48, 1680–1683 (2007).

Q. S. Zeng, Y. C. Li, C. M. Feng, P. Liermann, M. Somayazulu, G. Y. Shen, H. Mao, R. Yang, J. Liu, T. D. Hu, and J. Z. Jiang, “Anomalous compression behavior in lanthanum/cerium-based metallic glass under high pressure,” PNAS 104, 13565–13568 (2007).

Q. S. Zeng, J. F. Liu, G. Q. Zhang, L. N. Wang, and J. Z. Jiang, “Synthesis of LaCe-based bulk metallic glasses with low glass transition temperature,” Intermetallics 15, 753–756 (2007).

Q. Yang, S. Pang, R. Li, and T. Zhang, “Effect of coexistence of similar elements La and Ce on formation of (La–Ce)–Al–Cu bulk metallic glasses,” Int. J. Mod. Phys. B. 23, 1235–1240 (2009).

L.Wu, S. Li, J. Fang, Q. Chen, and K. Peng, “Enhancement of the glass forming ability of La–Al–Cu glassy alloys by partial substitution of Al by Mg,” J. Alloys Compd. 504, S38–S40 (2010).

T. Wang, Y. Q. Yang, J. B. Li, and G. H. Rao, “Thermodynamics and structural relaxation in Ce-based bulk metallic glass-forming liquids,” J. Alloys Compd. 509, 4569–4573 (2011).

C. T. Rios, L. C. R. Aliaga, C. S. Kiminami, C. Bolfarini, and W. J. B. Filho, “Stability of an amorphous alloy of the Mm–Al–Ni–Cu system,” Mater. Res. 15, 757–762 (2012).

Y. Onuki, Y. Shimizu, M. Nishihara, Y. Machii, and T. Komatsubara, “Kondo lattice formation in CexLa1 ‒ xCu6,” J. Phys. Soc. Japan 54, 1964–1974 (1985).

K. Satoh, T. Fujita, Y. Maeno, Y. Onuki, and T. Komatsubara, “Low-temperature specific heat of CexLa1 –xCu6,” J. Phys. Soc. Japan 58, 1012–1020 (1989).

J. S. Kim and G. R. Stewart, “Specific heat of Ce1 ‒ xMxCu6 (M = La, Th, Y and Pr),” Phys. Rev. B 49, 327–331 (1994).

T. B. Rhinehammer, D. E. Etter, J. E. Selle, and P. A. Tucker, “The cerium–copper system,” Trans. Metall. Soc. AIME 230, 1193–1198 (1964).

P. R. Subramanian and D. E. Laughlin, “The Ce–Cu (cerium–copper) system,” Bull. Alloy Phase Diagr. 9, 322–331 (1988).

W. Zhuang, Z. Y. Qiao, S. Wei, and J. Shen, “Thermodynamic evaluation of the Cu–R (R: Ce, Pr, Nd, Sm) binary systems,” J. Phase Equilib. 17, 508–521 (1996).

H. Zhou, C. Tang, M. Tong, Z. Gu, Q. Yao, and G. Rao, “Experimental investigation of the Ce–Cu phase diagram,” J. Alloys Compd. 511, 262–267 (2012).

U. K. Duisemaliev, A. A. Presnyakov, K. S. Saparov, and N. A. Kozhamberdin, “Cerium solubility in copper and effect of cerium of the properties of brasses,” Metalloved. Term. Obrab. Met., No. 2, 36–43 (1970).

S. Cirafici and A. Palenzona, “The lanthanum–copper system,” J. Less-Common Met. 53, 199–203 (1977).

D. J. Chakrabarti and D. E. Laughlin, “The Cu–La (copper–lanthanum) system,” Bull. Alloy Phase Diagr. 2, 302–305 (1981).

J. M. Bloch, D. Shaltiel, D. Davidov, “Preparation and study of new intermetallic compounds with the NaZn13 structure: LaCu13, PrCu13,” J. Less-Common Met. 79, 323–327 (1981).

F. Meyer-Liautaud, C. H. Allibert, and J. M. Moreau, “New phases in the system La–Cu”, J. Less-Common Met. 110, 81–90 (1985).

H. Bolmgren and T. Lundström, “The ternary system La–Cu–B at 650°C and some remarks on the La–Cu system,” J. Less-Common Met. 163, 79–87 (1990).

Z. Du, Y. Xu, and W. Zhang, “Thermodynamic assessment of the Cu–La system,” J. Alloys Compd. 289, 88–95 (1999).

H. Okamoto, “Cu–La (copper–lanthanum),” J. Phase Equilib. 22, 594–595 (2001).

K. A. Gschneidner, Jr. and F. W. Calderwood, “The Ce–La (cerium–lanthanum) system,” Bull. Alloy Phase Diagr. 2, 445–447 (1982).

C. Guo, Z. Du, and C. Li, “A thermodynamic description of the Ce–La–Mg system,” Int. J. Mater. Res. 101, 1424–1431 (2010).

Funding

This study was supported by the Russian Foundation for Basic Research, project no. 16-38-60144mol_a_dk.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Kolchugina

Rights and permissions

About this article

Cite this article

Samoilova, O.V., Trofimov, E.A. Effect of the Phase Composition and the Microstructure on the Microhardness of As-Cast Cu–Ce–La Alloys. Russ. Metall. 2020, 83–88 (2020). https://doi.org/10.1134/S0036029520020111

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029520020111