Abstract

The effect of temperature in the range from 350 to 650°С on the morphology of L63 brass (37 wt % Zn) during selective anodic dissolution in the eutectic salt melt of lithium, cesium and potassium chlorides is studied. Anodic polarization is accompanied by a change in the state of electrode surface due to the passage of the electronegative alloy component (zinc) into a corrosive medium and to the vacancy-induced rearrangement of the electropositive component (copper). Microscopy, gravimetry, chemical analysis, and hydrostatic weighing are used to estimate the laws of formation of a developed anode surface under galvanostatic conditions of the electrochemical dissolution of the bimetallic alloy. An increase in the temperature leads to a decrease in the selectivity of alloy dissolution, the porosity, and the developed surface of the materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The chemical and electrochemical dissolution of copper and its alloys is used for size etching in various industries. The dissolution of brass as a binary alloy can be selective or uniform depending on conditions. Selective dissolution, where the electronegative alloy component passes to a corrosion medium and the electropositive element forms an individual phase with a developed surface structure, is of particular interest.

Although the selective dissolution of alloys was studied in many works, all processes were investigated in low-temperature electrolytes, in particular, acid and salt solutions [1–16]. The available data on the high-temperature selective dissolution in molten salts are very scarce.

The use of molten salts as an electrolyte during the selective anodic dissolution of metallic materials makes it possible to exclude oxygen and hydrogen depolarization in aqueous solutions and to intensify dissolution significantly due to a high temperature.

The influence of various factors, which operate during the selective dissolution of metallic materials in a molten salt electrolyte in the course of producing a porous material, on the process should be carefully studied. Copper alloys, which have a high electrical and thermal conductivity with active components such as zinc, are promising objects for studying selective dissolution and the synthesis of structures with a developed surface and metallic conduction.

The brass components have different thermodynamic properties: their standard electrode potentials with respect to a reference hydrogen electrode are \(E_{{{{{\text{Cu}}} \mathord{\left/ {\vphantom {{{\text{Cu}}} {{\text{Cu}}}}} \right. \kern-0em} {{\text{Cu}}}}}}^{{2 + }}\) = +0.34 V and \(E_{{{{{\text{Zn}}} \mathord{\left/ {\vphantom {{{\text{Zn}}} {{\text{Zn}}}}} \right. \kern-0em} {{\text{Zn}}}}}}^{{2 + }}\) = –0.76 V. Therefore, there are thermodynamic prerequisites for the initial selective dissolution of alloys. An important circumstance is the fact that the components in such systems form a continuous series of solid solutions and their atomic radii are close. These circumstances allow the surface layer of an alloy to exist for a long time at a high defect concentration and facilitate the interdiffusion of the components in this layer [17].

The purpose of this work is to estimate the influence of the temperature factor on the electrode surface during anodic polarization.

EXPERIMENTAL

We performed experiments in a high-temperature electrochemical cell at temperatures of 350, 500, and 650°C in a molten mixture of lithium, cesium, and potassium chlorides (45.3 : 54.4 : 15.3 wt %) in air. Anode samples consisted of a 0.5-mm-thick copper–zinc foil with a surface area of 4 cm2. They were processed by abrasive paper, degreased, and dried with an alcohol–acetone mixture. The chloride eutectic was charged in a crucible and heated to a given temperature, and a sample was introduced into the melt. A copper plate with an area of 8 cm2 served as an auxiliary electrode, and a chlorine–silver electrode with channels served as a reference electrode.

The experiments were carried out in the galvanostatic anodic polarization mode at a geometric current density of 110 A/m2 for the time it took for the entire zinc in the sample dissolved. This time was calculated by Faraday’s law.

After the experiments, samples were washed with a 0.05 M hydrochloric acid solution to remove chloride salts.

The melt after an experiment was analytically studied. The sample surfaces were analyzed with a JSM‑5900 LV (Jeol, Japan) scanning electron microscope, and the data obtained were used to determine the average pore size [18]. We applied gravimetric measurements and chemical analysis methods to determine the selectivity factor [19] and hydrostatic weighing to determine the porosity [20].

RESULTS AND DISCUSSION

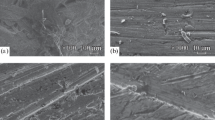

Figures 1–3 show the sample surfaces after selective dissolution at temperatures of 350, 500, and 650°C, respectively, at a geometric current density of 110 A/m2 for an anode plate made of L63 brass.

As follows from microscopic investigations, the pore size increases and the developed anode surface decreases with increasing temperature. At 350°C, the samples have a highly developed structure with an average pore (channel) size of 1.5 μm. At 650°C, a channel-connected structure is absent. Table 1 presents the average pore size at various temperatures.

As follows from local elemental analysis data, 1.2–2.4 wt % zinc are retained on the sample surfaces.

The results of chemical analysis, gravimetry, and hydrostatic weighing demonstrate that the dissolution selectivity and the porosity decrease with increasing temperature.

CONCLUSIONS

A decrease in the anodic polarization temperature in the galvanostatic electrolysis mode increases the selectivity of dissolution of an L63 copper–zinc alloy, the porosity, and the developed surface of the metallic material.

REFERENCES

M. Hakamada and M. Mabuchi, “Preparation of nanoporous Ni and Ni–Cu by dealloying of rolled Ni–Mn and Ni–Cu–Mn alloys,” J. Alloys and Compd. 485 (1–2), 583–585 (2009).

V. I. Larin and L. M. Egorova, “Study of behavior of α brass in solutions of various compositions,” Vestn. Khar’k. Natsional. Univ., Khimiya 17 (40) (870), 245–252 (2009).

E. B. Khobotova and L. M. Egorova, “Regularities of electrochemical dissolution of alloy L-62 in chloride solutions,” Elektronn. Obrab. Mater. 50 (1), 39–44 (2014).

F. Z. Chan, N. M. Tutukina, and I. K. Marshakov, “The tendency of brass to dezincing in chloride media,” Kondensirovannyye Sredy Mezhfazn. Granitsy 11 (4), 349–353 (2009).

I. K. Marshakov, Thermodynamics and Corrosion of Alloys (Voronezh, 1983).

I. K. Marshakov, A. V. Vvedenskii, V. Yu. Kondrashin, and G. A. Bokov, Anodic Dissolution and Selective Corrosion of Alloys (Voronezh, 1988).

G. Keshe, Corrosion of Metals: Physicochemical Principles and Chellenging Problems (Metallurgiya, Moscow, 1984).

O. A. Kozaderov, O. V. Sazhneva, O. V. Koroleva, and A. V. Vvedenskii, “Corrosion of metals: physicochemical principles and challenging problems,” Zashch. Met. 41 (4), 360–371 (2005).

O. A. Kozaderov, “Selective dissolution of homogeneous alloys in the regime of nonstationary solid-phase diffusion,” Kondensirovannyye Sredy Mezhfazn. Granitsy 10 (2), 109–121 (2008).

J. Zhang and C. M. Li, “Nanoporous metal: fabrication strategies and advanced electrochemical applications in catalysis, sensing and energy system,” Chem. Soc. Rev., No. 41, 7016–7031 (2012).

X. Li and Q. Chen, “Dealloying of nobel-metall alloy nanoparticles,” Nano Lett., No. 14, 2569–2577 (2017).

E. Seker, L. Michael, Reed and Matthew R. Begley, “Nanoporous gold: fabrication, characterization, and applications,” Materials 2, 2188–2215 (2009).

Q. Zhang, X. Wang, Qi Zhen, Yan Wang, and Z. Zhang, “A benign route to fabricate nanoporous gold through electrochemical dealloying of Al–Au alloys in a neutral solution,” Electrochim. Acta 54, 6190–6195 (2009).

Z. Zhang, Yan Wang, Zhen Qi, and W. Zhang, “Generalized fabrication of nanoporous metals (Au, Pd, Pt, Ag and Cu) through chemical dealloying,” J. Phys. Chem. C 113, 12629–12636 (2009).

N. A. Senior and R. C. Newman, “Synthesis of tough nanoporous metals by controlled electrolytic dealloying,” Nanotechnology 17, 2311–2316 (2006).

J. Snyder, P. Asanithi, A. B. Dalton, and J. Erlebacher, “Stabilized nanoporous metals by dealloying ternary alloy precursors,” Adv. Mater. 20, 4883–4886 (2008).

I. K. Marshakov, “Selective corrosion of alloys,” Sorosovskii Obrazovat. Zh. 6 (4), 56–62 (2000).

J. Goldstein, D. Newbury, P. Echlin, D. Joy, Ch. Fiori, and F. Livshin, Scanning Electron Microscopy and X-ray Microanalysis (Plenum, New York, 1981).

O. N. Bulgakova, E. A. Bannova, and N. V. Ivanova, Chemical Analysis Methods: A Textbook (Kemerov. Gos. Univ., Kemerovo, 2015).

A. P. Karnaukhov, Adsorption. Texture of Dispersed and Porous Materials (Nauka, Novosibirsk, 1999).

ACKNOWLEDGMENTS

This study was financially supported by the Russian Foundation for Basic Research (grant no. 17-03-00715).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Karfidov, E.A., Nikitina, E.V., Kazakovtseva, N.A. et al. Effect of the Temperature Factor on the Morphology of a Copper–Zinc Alloy during Anodic Polarization in a Molten Chloride. Russ. Metall. 2019, 101–103 (2019). https://doi.org/10.1134/S0036029519020095

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029519020095