Abstract

Thermodynamic analysis is performed for the oxygen solutions in titanium-containing melts of the Ni–Co system. The equilibrium constants of the reactions of titanium with oxygen, activity coefficients at infinite dilution, and interaction parameters in melts of various compositions at 1873 K are determined for the first time. The titanium contents at the equilibrium points between the oxide phases TiO2, Ti3O5, and Ti2O3 are determined. The dependences of the oxygen solubility on the titanium content in the studied melts are calculated. The deoxidation ability of titanium decreases with an increase in the cobalt content to 40% and then increases as the cobalt content in the melt further increases. The titanium contents at the minimum points on the curves of the oxygen solubility and the corresponding minimum oxygen contents are determined.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Superalloys based on the Ni–Co system are widely used in modern engineering [1–4]. Oxygen is one of the detrimental impurities in these alloys and exists in the metal in the both diluted form and nonmetallic inclusions. The presence of oxygen deteriorates service properties of the alloys. Titanium is often used as an alloying element to provide the optimum level of mechanical characteristics for manufacturing nickel–cobalt superalloys [1, 4]. The study of the influence of titanium on the oxygen solubility in alloys is of significant interest for the practice of manufacturing alloys of the Ni–Co system. The influence of titanium on the oxygen solubility in melts of the Ni–Co system can be evaluated, since data on the thermodynamics of oxygen solutions in liquid nickel and cobalt are available [5, 6].

The following oxides can be formed as a result of the deoxidation of nickel–cobalt alloys with titanium depending on the titanium content in the melt: (Ni, Co)O · TiO2, TiO2, Ti3O5, Ti2O3, and TiO. At 1873 K oxide NiO · TiO2 is formed at the titanium content in liquid nickel lower than 9.0 × 10–8% [7], whereas oxide CoO · TiO2 is formed at the titanium content in liquid cobalt lower than 1.9 × 10–6% [8]. Therefore, the formation of oxide (Ni, Co)O · TiO2 is not considered in this work.

The deoxidation of nickel–cobalt melts with titanium, the product of which is oxide TiO2,

can be presented as the sum of the reactions

where R is the gas constant, T is temperature, \(\gamma _{i}^{^\circ }\) is the activity coefficient of the ith element at infinite dilution, and Mi is the molecular weight of the component i.

A 1% solution having the properties of an ideal dilute solution was chosen as a standard state for titanium and oxygen dissolved in a nickel–cobalt melt. The corresponding pure components were chosen as standard states for nickel and cobalt forming a concentrated solution (nickel–cobalt melt).

The Gibbs energy for reaction (1) was calculated using the equation \(\Delta G_{{\left( 1 \right)}}^{^\circ }\) = \(\Delta G_{{\left( 2 \right)}}^{^\circ }\) + \(\Delta G_{{\left( 3 \right)}}^{^\circ }\) + \(\Delta G_{{\left( 4 \right)}}^{^\circ }\). The equilibrium constant of reaction (1) can be calculated using the equation lnK = \({{ - \Delta G_{T}^{^\circ }} \mathord{\left/ {\vphantom {{ - \Delta G_{T}^{^\circ }} {RT}}} \right. \kern-0em} {RT}}\). The molecular weight of melts of the Ni–Co system can be calculated by the equation MNi–Co = MNiXNi + MCoXCo [9]. The activity coefficients \(\gamma _{{{\text{Ti}}\left( {{\text{Ni-Co}}} \right)}}^{^\circ }\) and \(\gamma _{{{\text{O}}\left( {{\text{Ni-Co}}} \right)}}^{^\circ }\) can be calculated by the equation [10]

where Xi is the molar fraction, and \(\varepsilon _{i}^{j}\) is the interaction parameter of the first order when the contents of the components i and j are expressed in molar fractions [11].

The calculated equilibrium constants of reaction (1), the activity coefficients \(\gamma _{{{\text{Ti}}}}^{^\circ }\) and \(\gamma _{{\text{O}}}^{^\circ }\) for nickel and cobalt, and the activity coefficients \(\gamma _{{{\text{Ti}}\left( {{\text{Ni-Co}}} \right)}}^{^\circ }\) and \(\gamma _{{{\text{O}}\left( {{\text{Ni-Co}}} \right)}}^{^\circ }\) at 1873 K calculated for the nickel–cobalt alloys are presented in Table 1. The following values of interaction parameters were used in the calculations: \(\varepsilon _{{{\text{Ti}}\left( {{\text{Ni}}} \right)}}^{{{\text{Co}}}}\) = 0.98 [6], \(\varepsilon _{{{\text{O}}\left( {{\text{Ni}}} \right)}}^{{{\text{Co}}}}\) = –1.4 [5], \(\varepsilon _{{{\text{Ti}}\left( {{\text{Co}}} \right)}}^{{{\text{Ni}}}}\) = –1.7 [6], and \(\varepsilon _{{{\text{O}}\left( {{\text{Co}}} \right)}}^{{{\text{Ni}}}}\) = –0.25 [5].

The oxygen content in the melt equilibrium with the specified titanium content can be calculated using the equation

where \(e_{{i\left( {{\text{Ni-Co}}} \right)}}^{j}\) is the first-order interaction parameter when the contents of the components i and j are expressed in wt %, \(r_{{i\left( {{\text{Ni-Co}}} \right)}}^{j}\) is the second-order interaction parameter when the component contents are expressed in wt % [11, 12].

Oxide TiO2 at 1873 K is solid (Tm = 2185 K [13]) and, hence, \({{a}_{{{\text{Ti}}{{{\text{O}}}_{{\text{2}}}}}}}\) = 1. The value of [% O] in the right hand of Eq. (5) can be expressed via the ratio (K(1)/[% Ti]fTi\(f_{{\text{O}}}^{2}\))1/2. For [% O] → 0, fO → 1. Since the value of [% O] is negligible, [% O] can be accepted to be (K(1)/[% Ti]fTi)1/2. This replacement will not contribute an appreciable inaccuracy to the calculations. Then Eq. (5) takes the form

The interaction parameters for the melts of various compositions used in the calculations are presented in Table 1. The interaction parameters \(e_{{{\text{Ti}}}}^{{{\text{Ti}}}}\), \(e_{{\text{O}}}^{{{\text{Ti}}}}\), \(e_{{{\text{Ti}}}}^{{\text{O}}}\), and \(e_{{\text{O}}}^{{\text{O}}}\) for the melts of the Ni–Co system were determined by the equation \(\varepsilon _{{i\left( {{\text{Ni-Co}}} \right)}}^{j}\) = \(\varepsilon _{{i\left( {{\text{Ni}}} \right)}}^{j}{{X}_{{{\text{Ni}}}}}\) + \(\varepsilon _{{i\left( {{\text{Co}}} \right)}}^{j}{{X}_{{{\text{Co}}}}}\) [9].

The second-order interaction parameter in nickel is \(r_{{{\text{O}}\left( {{\text{Ni}}} \right)}}^{{{\text{Ti}}}}\) = 0.036 [7], and data on the second-order interaction parameter in cobalt \(r_{{{\text{O}}\left( {{\text{Co}}} \right)}}^{{{\text{Ti}}}}\) are lacking. Since the first-order interaction parameters \(e_{{\text{O}}}^{{{\text{Ti}}}}\) are close (\(e_{{{\text{O}}\left( {{\text{Ni}}} \right)}}^{{{\text{Ti}}}}\) = –0.510 [7], \(e_{{{\text{O}}\left( {{\text{Co}}} \right)}}^{{{\text{Ti}}}}\) = –0.492 [6]) in nickel and cobalt, we can accept that \(r_{{{\text{O}}\left( {{\text{Co}}} \right)}}^{{{\text{Ti}}}}\) = \(r_{{{\text{O}}\left( {{\text{Ni}}} \right)}}^{{{\text{Ti}}}}\) = 0.036.

Taking into account the values of interaction parameters at 1873 K, Eq. (6) takes the following form:

(a) for Ni,

(b) for Ni–20% Co

(c) for Ni–40% Co,

(d) for Ni–60% Co,

(e) for Ni–80% Co,

(f) for Co,

The further increase in the titanium content results in the situation where the product of deoxidation of the melts of the Ni–Co system with titanium is oxide Ti3O5. In this case, the deoxidation reaction

can be presented as the sum of the reactions

The Gibbs energy for reaction (7) was calculated using the equation \(\Delta G_{{\left( 7 \right)}}^{^\circ }\) = \(\Delta G_{{\left( 8 \right)}}^{^\circ }\) + \(\Delta G_{{\left( 9 \right)}}^{^\circ }\) + \(\Delta G_{{\left( {10} \right)}}^{^\circ }\). The calculated equilibrium constants for reaction (7) at 1873 K are presented in Table 1.

The oxygen content in the melt equilibrium with the specified titanium content can be calculated by the equation

Oxide Ti3O5 at 1873 K is solid (Tm = 2050 K [13]) and, hence, \({{a}_{{{\text{T}}{{{\text{i}}}_{{\text{3}}}}{{{\text{O}}}_{{\text{5}}}}}}}\) = 1. The value of [%O] in the right hand of Eq. (11) can be expressed via the ratio \({{\left( {{{{{K}_{{\left( 7 \right)}}}} \mathord{\left/ {\vphantom {{{{K}_{{\left( 7 \right)}}}} {{{{\left[ {\% {\text{Ti}}} \right]}}^{3}}f_{{{\text{Ti}}}}^{3}f_{{\text{O}}}^{5}}}} \right. \kern-0em} {{{{\left[ {\% {\text{Ti}}} \right]}}^{3}}f_{{{\text{Ti}}}}^{3}f_{{\text{O}}}^{5}}}} \right)}^{{1{\text{/5}}}}}\). For [%O] → 0, fO → 1. Since the value of [% O] is negligible, [% O] can be accepted to be \({{\left( {{{{{K}_{{\left( 7 \right)}}}} \mathord{\left/ {\vphantom {{{{K}_{{\left( 7 \right)}}}} {{{{\left[ {\% {\text{Ti}}} \right]}}^{3}}f_{{{\text{Ti}}}}^{3}}}} \right. \kern-0em} {{{{\left[ {\% {\text{Ti}}} \right]}}^{3}}f_{{{\text{Ti}}}}^{3}}}} \right)}^{{1{\text{/5}}}}}\). Then Eq. (11) takes the form

Taking into account the obtained values of interaction parameters at 1873 K, Eq. (12) takes the following form:

(a) for Ni,

(b) for Ni–20% Co,

(c) for Ni–40% Co,

(d) for Ni–60% Co,

(e) for Ni–80% Co,

(f) for Co,

The combined solution of Eqs. (6) and (12) makes it possible to determine the equilibrium point TiO2 \( \rightleftarrows \) Ti3O5. Neglecting the terms containing the interaction parameters because of their low values, we have

or

The titanium contents at this point ([Ti]*1) for the melts of various compositions at 1873 K are given below.

Co, % | 0 | 20 | 40 | 60 | 80 | 100 |

[Ti]*1, % | 0.0458 | 0.0362 | 0.0270 | 0.0193 | 0.0135 | 0.0095 |

At higher titanium contents, the product of deoxidation of the melts of the Ni–Co system is oxide Ti2O3. In this case, the deoxidation reaction

can be presented as the sum of the reactions

The Gibbs energy for reaction (14) was calculated using the equation \(\Delta G_{{\left( {14} \right)}}^{^\circ }\) = \(\Delta G_{{\left( {15} \right)}}^{^\circ }\) + \(\Delta G_{{\left( {16} \right)}}^{^\circ }\) + \(\Delta G_{{\left( {17} \right)}}^{^\circ }\). The calculated equilibrium constants for reaction (14) at 1873 K are presented in Table 1.

The oxygen content in the melt equilibrium with the specified titanium content can be calculated by the equation

Oxide Ti2O3 at 1873 K is solid (Tm = 2110 K [13]) and, hence, \({{a}_{{{\text{T}}{{{\text{i}}}_{{\text{2}}}}{{{\text{O}}}_{{\text{3}}}}}}}\) = 1. The value of [% O] in the right hand of Eq. (18) can be expressed via the ratio \({{\left( {{{{{K}_{{\left( {14} \right)}}}} \mathord{\left/ {\vphantom {{{{K}_{{\left( {14} \right)}}}} {{{{\left[ {\% \,{\text{Ti}}} \right]}}^{2}}f_{{{\text{Ti}}}}^{2}}}} \right. \kern-0em} {{{{\left[ {\% \,{\text{Ti}}} \right]}}^{2}}f_{{{\text{Ti}}}}^{2}}}f_{{\text{O}}}^{3}} \right)}^{{1{\text{/3}}}}}\). For [% O] → 0, fO → 1. Since the value of [% O] is negligible, [% O] can be accepted to \({{\left( {{{{{K}_{{\left( {14} \right)}}}} \mathord{\left/ {\vphantom {{{{K}_{{\left( {14} \right)}}}} {{{{\left[ {\% \,{\text{Ti}}} \right]}}^{2}}f_{{{\text{Ti}}}}^{2}}}} \right. \kern-0em} {{{{\left[ {\% \,{\text{Ti}}} \right]}}^{2}}f_{{{\text{Ti}}}}^{2}}}} \right)}^{{1{\text{/3}}}}}\). Then Eq. (18) takes the form

Taking into account the obtained values of interaction parameters at 1873 K, Eq. (19) takes the following form:

(a) for Ni,

(b) for Ni–20% Co,

(c) for Ni–40% Co,

(d) for Ni–60% Co,

(e) for Ni–80% Co,

(f) for Co,

The combined solution of Eqs. (12) and (19) enables one to determine the equilibrium point Ti3O5 \( \rightleftarrows \) Ti2O3. Neglecting the terms containing the interaction parameters because of their low values, we have

or

The titanium contents at this point ([Ti]*2) for the melts of various compositions at 1873 K are given below.

Co, % | 0 | 20 | 40 | 60 | 80 | 100 |

[Ti]*2, % | 7.563 | 5.984 | 4.452 | 3.181 | 2.231 | 1.570 |

Titanium monoxide TiO is formed in the reaction of titanium and oxygen in the Ni–Co melts at the titanium contents substantially higher than those used for alloying these melts. Therefore, this region of titanium contents is not considered in the present work.

The dependences of the equilibrium constants of reactions (1), (7), and (14) on the composition of the alloy base at 1873 K are presented in Fig. 1. For clarity of data comparison, the values of equilibrium constants for these reactions are given for the interaction of titanium with one oxygen atom dissolved in the melt. It is seen that the equilibrium constant of reaction (1) increases with the cobalt content in the melt up to 50–60%. The equilibrium constants of reactions (7) and (14) increase with the cobalt content up to 35–45%. A smooth decrease in the equilibrium constants of all reactions is observed with the further increase in the cobalt content.

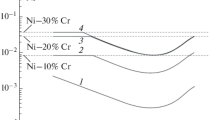

The dependences of the equilibrium oxygen concentrations on the contents of titanium and cobalt in the melt at 1873 K are shown in Fig. 2. According to the data presented, the deoxidation ability of titanium decreases with an increase in the cobalt content to 40% and then increases as the cobalt content in the melt further increases. The deoxidation ability of titanium is almost the same in the melts containing 20, 40, and 60% of Co.

The calculated equilibrium contents of titanium and oxygen in nickel and cobalt are presented in Fig. 3 in comparison with the published data [14, 15]. It is seen that the calculation results are satisfactorily consistent with the literature data.

The curves of the oxygen solubility in the nickel–cobalt melts pass through a minimum. The titanium contents to which the minimum oxygen contents correspond can be determined from the equation

where m and n are the coefficients in the formula of RmOn oxide.

For the melts of the Ni–Co system, the minimum falls onto the region of existence of oxide Ti3O5. In this case, Eq. (21) takes the form

The titanium contents at the minimum points calculated by Eq. (21a) and the corresponding oxygen contents are presented below

Co, % | [% Ti]' | [% O]min |

|---|---|---|

0 | 0.565 | 2.98 × 10–4 |

20 | 0.567 | 3.36 × 10–4 |

40 | 0.569 | 3.50 × 10–4 |

60 | 0.571 | 3.36 × 10–4 |

80 | 0.573 | 2.96 × 10–4 |

100 | 0.576 | 2.39 × 10–4 |

CONCLUSIONS

(1) Titanium has a high deoxidation ability in the melts of the Ni–Co system. The deoxidation ability of titanium decreases with an increase in the cobalt content to 40% and then increases as the cobalt content in the melt further increases.

(2) The deoxidation ability of titanium is almost the same in the melts Ni–20% Co, Ni–40% Co, and Ni–60% Co.

(3) The curves of the oxygen solubility in the titanium-containing nickel–cobalt melts pass through a minimum, whose position shifts toward a little higher titanium content as the cobalt content in the melt increases. The further titanium additives result in an increase in the oxygen content in the melt.

REFERENCES

R. C. Reed, The Superalloys. Fundamentals and Applications (University Press, Cambridge, 2006).

J.-Y. Guedou, I. Augustine-Lecallier, L. Naze, P. Caron, and D. Locq, “Development of a new fatigue and creep resistant PM nickel base superalloy for disks applications,” in Proceedings of the 11th International Symposium on Superalloys “Superalloys 2008” (TMS, Pennsylvania, 2008), pp. 21–30.

Y. F. Gu, C. Cui, K. Harada, T. Fukuda, D. Ping, A. Mitsuhashi, K. Kato, T. Kobayashi, and J. Fujioka, “Development of Ni–Co-base superalloys for high-temperature turbine disk applications,” in Proceedings of the 11th International Symposium on Superalloys “Superalloys 2008” (TMS, Pennsylvania, 2008), pp. 53–62.

A. V. Logunov and Yu. A. Shmotin, Modern Nickel Superalloys for Disk Gas Turbines (Nauka Tekhn., Moscow, 2013).

T. Miki, “Dilute solutions,” in Treatise on Process Metallurgy, Vol. 1: Process Fundamentals, Ed. by S. Seetharaman (Elsevier, 2014), pp. 557–585.

L. N. Belyanchikov, “Estimation of interaction parameters, activity coefficients, and heats of dissolution of elements in cobalt-based alloys using the recalculation of their values in iron alloys,” Elektrometallurgiya, No. 4, 16–22 (2009).

A. A. Aleksandrov, V. Ya. Dashevskii, and L. I. Leont’ev, “Thermodynamics of Oxygen Solutions in Nickel Melts Containing Aluminum and Titanium,” Steel Transl. 46 (7), 479–483 (2016).

A. A. Aleksandrov, V. Ya. Dashevskii, and L. I. Leont’ev, “Solubility of Oxygen in Fe–Co Melts Containing Titanium,” Steel Transl. 47 (3), 178–187 (2017).

A. A. Aleksandrov and V. Ya. Dashevskii, “Thermodynamics of the oxygen solutions in chromium-containing Ni–Co melts,” Russ. Metall. (Metally), No. 7, 642–648 (2016).

M. G. Frohberg and M. Wang, “Thermodynamic properties of sulphur in liquid copper–antimony alloys at 1473 K,” Z. Metallkd. 81 (7), 513–518 (1990).

E. T. Turkdogan, Fundamentals of Steelmaking (Maney, Leeds, 2010).

S. Seetharaman, Fundamentals of Metallurgy (Woodhead, Cambridge, 2005).

N. P. Lyakishev and M. I. Gasik, Physical Chemistry and Technology of Electroferroalloys (ELIZ, Moscow, 2005).

S.-H. Seok, T. Miki, and M. Hino, “Ti deoxidation equilibrium in molten Fe–Ni alloys at temperatures between 1823 to 1923 K,” ISIJ Int. 49 (6), 804–808 (2009).

V. V. Averin, “Solubility of oxygen and nitrogen and activity of deoxidizer elements in the melts based on iron, cobalt, nickel, and chromium”, Extended Abstract of Doct. Sci. (Eng.) Dissertation (IMET AN SSSR, Moscow, 1968).

ACKNOWLEDGMENTS

This work was supported by the Russian Foundation for Basic Research, project. no. 16-33-60138 mol_a_dk.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Yablonskaya

Rights and permissions

About this article

Cite this article

Aleksandrov, A.A., Dashevskii, V.Y. Oxygen Solubility in Titanium-Containing Melts of the Ni–Co System. Russ. Metall. 2018, 1081–1087 (2018). https://doi.org/10.1134/S0036029518110034

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029518110034