Abstract

The heat capacities of four samples of butyl methacrylate–methacrylic acid copolymers with 7.6 to 37.3 mol % acid are measured in the temperature range of 6 (80)–330 K. The thermodynamic characteristics (enthalpy, entropy, and Gibbs function) of the above copolymers are calculated. The isotherms of thermodynamic functions in the studied range of temperatures and copolymer compositions are plotted and analyzed. The ordering of the system (the entropy factor), rather than the energy of intermolecular interaction (the enthalpy factor), is found to make the main contribution to the change in the Gibbs function. BMA–MAA copolymer with 7.6 mol % acid is shown to be the best for use as a matrix for transdermal administration of drugs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

The design of macromolecular therapeutic systems, particularly transdermal ones (TTSes) that can deliver drugs at specific doses to a target organ in strictly scheduled time intervals is a promising field of the application of polymers in medicine [1–11]. Such therapeutic systems of the new generation are protracted and do not induce shock, and drugs are not exposed to destructive action in the gastrointestinal tract. Having such properties as nontoxicity, resistance to biological media, and the capability of withstanding sterilization with no appreciable change in properties is a prerequisite for the applicability of a polymer material in any area of medicine. The material also should not display sensibilizing, carcinogenic, mutagenic, and teratogenic action. These requirements are met by many types of polymers, including acrylic ones [4–6, 12, 13]. However, each material must be selected on a case-by-case basis. Physicochemical and especially thermodynamic characteristics are required along with the above properties of a material. The study of these allows us to optimize the composition of a copolymer so that it meets specified requirements even better and can be used to solve a particular problem [4, 14–16].

The aim of this work was to study the thermodynamic characteristics (heat capacity, enthalpy, entropy, and Gibbs function) of butyl methacrylate (BMA) copolymers with methacrylic acid (MAA) as a function of temperature and composition, in order to select the best composition of the polymer system for use as a TTS matrix on the basis of the resulting data.

EXPERIMENTAL

BMA–MAA copolymers with 7.6–37.3 mol % MAA were synthesized via suspension polymerization according to the patented procedure in [4, 17]. The authors of that work failed to obtain copolymers containing more than ∼40 mol % MAA, due to the physical instability of the suspension. Our proposed procedure allows the synthesis of MBA–MAA copolymers with deep conversion of monomers (99.5–99.8%), free of residual BMA monomer, and containing negligible amounts of water (less than 0.5 wt %). The resulting copolymer is therefore nontoxic. Such copolymers can be used in medicine to create binders for TTSes. Synthesis was performed via the suspension polymerization of monomers in an aqueous medium at pH 3 using an initiator (benzoyl peroxide) in two steps: 2 h at 343 K and 2.5 h at 353 K, using the stabilizer (0.3–0.6 wt %) sodium methacrylate (84 wt %)–methacrylic acid (16 wt %) copolymer at an initiator concentration of 1.5 wt %. The polymer was then washed several times with distilled water and dried. The composition of the copolymer was determined via titration of the carboxyl groups of MAA as recommended in [18]. The molecular weight of the copolymer varied from 88 000 to 100 000, depending on the content of MAA. X-ray diffraction showed the random BMA–MAA copolymers were completely amorphous. The molar weight of the repeating unit of copolymers (conv. mol) was calculated using the equation

where X1 and X2 are the molar fractions of BMA and MAA, respectively, and M1 and M2 are the molar weights of the repeating units of BMA and MAA, respectively.

The BMA and MAA monomers were purified via fractionation under reduced pressure. Chromatographic data showed that the content of the main component in the taken monomer fractions was 99.9 wt %. Refractive indices nD at 293 K for BMA and MAA were 1.4240 and 1.4314, which coincided with reliable literature data [19].

Heat capacity (\(C_{p}^{^\circ }\)) was measured in the range of 80–330 K on a vacuum adiabatic calorimeter designed at the Verkin Institute for Low Temperature Physics and Engineering of the National Academy of Sciences of Ukraine, Kharkiv [4, 16, 20, 21]. The temperature was measured with a platinum resistance thermometer. The energy equivalent of the calorimeter was determined by measuring the heat capacity of a calorimetric ampule filled with helium up to a pressure of 8.5 kPa. It did not exceed 40% of the heat capacity of the calorimeter with a substance in the studied range of temperatures. To verify the procedure, we determined the heat capacity of reference K-1 benzoic acid (Mendeleev Institute for Metrology, St. Petersburg). The difference between our data and those of [22] was 0.3% at T = 80–330 K. The rise in temperature in measuring heat capacity was 1–3 K, so we did not correct for the curvature of function \(C_{p}^{^\circ }\) = f(T). The deviation of the experimental data from the averaging curves was no more than 0.3%.

Heat capacity \(C_{p}^{^\circ }\) in the range of 6–80 K was measured on a BKT-3.07 vacuum adiabatic calorimeter with discrete heating and an automated system for maintaining the adiabaticity of measuring conditions [23, 24]. The calorimeter was designed and manufactured by AOZT Termis (Mendeleevo, Moscow oblast, Russia). The temperature was measured with a RIRT-2 iron-rhodium resistance temperature sensor (R0 ≈ 100 Ω). The absolute error of temperature measurements was ±5 × 10–3 K. The energy equivalent of the calorimeter was determined by measuring the heat capacity of an ampule filled with helium up to a pressure of 16 kPa. The heat capacities of references samples of K-1 benzoic acid and 11-4 high-purity copper were measured to verify the operational reliability of the calorimetric setup. The deviation of the obtained heat capacities from the instrument ratings and data in metrological works was 2% in the range of 6–20 K and did not exceed 0.5% in the range of 40–80 K.

We measured he heat capacities of four BMA–MAA copolymer samples (Table 1). The thermodynamic functions of substances H°(T) − H°(0) and S°(T) − S°(0) were calculated by integrating curves \(C_{p}^{^\circ }\) = f(T) and \(C_{p}^{^\circ }\) = f(\(\ln T\)), respectively, and Gibbs function G°(T) − G°(0) was calculated using the Gibbs–Helmholtz equation. To calculate the thermodynamic functions of samples 1 and 2 (Table 1), their curves \(C_{p}^{^\circ }\) = f(T) were extrapolated from 6 to Т → 0 K using Debye’ equation [4, 16, 25]:

where n = 1 and ΘD are ad hoc parameters (Table 1).

The heat capacities of samples 3 and 4 were measured from 80 K (Table 1), so their thermodynamic functions were calculated by extrapolating obtained dependences \(C_{p}^{^\circ }\) = f(T) of the above substances from 80 to Т → 0 K according to the Kelley–Parks–Huffman procedure [4, 16, 26]:

where \(C_{{p,{\text{ref}}}}^{^\circ }\) is the heat capacity measured in the range of 6–80 K for the reference substance associated with the one studied (sample 2), and T is temperature, K.

Coefficients A and B in Eq. (3) were selected so that the solution to this equation coincided with the experimental \(C_{p}^{^\circ }\) values of the substance in the range of 80–100 K with an error of no more than 0.3% (Table 1).

RESULTS AND DISCUSSION

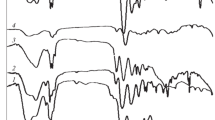

Our experimental data are presented in Fig. 1 and Tables 2–5. Figure 1 also gives the heat capacities of PBMA (curve 1) and PMAA (curve 6) homopolymers. \(C_{p}^{^\circ }\) and the thermodynamic functions of PMAA have been studied since 1967 [27–30]. In [28, 30], \(C_{p}^{^\circ }\) of PMAA was measured in a vacuum adiabatic calorimeter with a batch energy supply in the range of 60–300 K and an error of 0.3%. In [29], it was measured in the range of 298–463 K in an adiabatic calorimeter with a continuous energy supply (heating rate, ~1 K min−1) that had an error of 0.5% [31]. However, these articles never mention the content of residual water in the studied PMAA samples. Ur’yash et al. [27] measured \(C_{p}^{^\circ }\) = f(T) for PMAA (content of residual water, 2.5 wt %) in a vacuum adiabatic calorimeter in the range of 80–325 K. The content of water was calculated from thermochemical data while determining the enthalpy of combustion of PMAA. In [27], the heat capacity of anhydrous PMAA in the range of 80–325 K was calculated from existing data by assuming that \(C_{p}^{^\circ }\) is summed additively from the heat capacities of the polymer and water [32]. These data are shown in Fig. 1 (curve 6). To calculate the thermodynamic functions of PMAA, its \(C_{p}^{^\circ }\) = f(T) was extrapolated from 80 to T → 0 K with Eq. (3). The reference value was \(C_{p}^{^\circ }\) of sample 2. We obtained A = 0.548326 and B = −0.0000227.

Curve \(C_{p}^{^\circ }\) = f(T) for PMAA in the range of 295–306 K displayed a relaxation transition of endotermic nature that can be classified as a γ-transition (Tγ = 300.6 K) [4, 27] (Fig. 1, curve 6). This transition occurs in glass-like polymers and is associated with the start of vibrations of pendant groups in the polymer chain [16]. Another two relaxation transitions (β and α) were detected via DTA in PMAA [4, 27]. The latter was associated with the glass transition of PMAA (Tg), and the β-transition was due to vibrations in the regions of polymer macromolecules that were smaller than the segment in [16]. Extrapolating Tg of PMAA as a function of the content of water in the sample to a zero content of H2O allowed determination of Tg in anhydrous PMAA: 456 K [4, 27].

The first work on measuring the heat capacity of PBMA in a vacuum adiabatic calorimeter in the range of 93–433 K was published in 1971 [33]. These studies were continued by Wunderlich et al. [30] and Lebedev et al. [34] in the same calorimeter. In the latter work, \(C_{p}^{^\circ }\) = f(T) was measured in the range of 8–330 K with an error of ~1% around 10 K, 0.5% in the range of 10–30 K, and 0.2% in the range of 30–330 K. We also have DSC data obtained in the range of 240–400 K [35]. Figure 1 shows the \(C_{p}^{^\circ }\) values for PBMA from [30] (curve 1), since only this work gave numerical \(C_{p}^{^\circ }\) values of PBMA in the range of 80–450 K. The Tg values given in the literature for PBMA are 290 [30], 293 [34], and 312 K [35]. The Tg values obtained in [30] and [34] coincide with the error of its determination. Close Tg values were obtained for PBMA (295 K) via DTA [4, 36]. To calculate the thermodynamic functions of PBMA, its \(C_{p}^{^\circ }\) = f(T) was extrapolated from 80 to T → 0 K according to Eq. (3). The reference was \(C_{p}^{^\circ }\) of sample 1. The resulting values of the coefficients were A = 1.34178 and B = −0.002776.

The heat capacity of the copolymer with 7.6 mol % MAA (Fig. 1, curve 2; Table 2) grows monotonically in the range of 6–290 K. An anomaly of endotermic nature caused by devitrification of the copolymer (Tg1 = 306 K) was then observed. Several BMA–MAA copolymers were analyzed via DTA in [4, 36]. All copolymer samples with 7.6 to 37.3 mol % MAA displayed two (<20 mol % MAA) or three (>20 mol % MAA) intervals of devitrification with transition temperatures Tg1, Tg2, and Tg3. The obtained data thus testify to the multiphase nature of the random BMA–MAA copolymers. It is commonly assumed that random acrylic copolymers have one Tg. This is true for the methyl methacrylate (MMA)–MAA system [29], but several Tg have been observed for some acrylic copolymers. For example, one or two temperature ranges of devitrification were found in [37] for MMA–butyl acrylate and MMA–ethyl hexylacrylate copolymers, depending on the composition of the monomer mixture. Three Tg in hybrid alkyd–acryl water-based resins were recorded via DSC in [38].

We may assume there were two reasons for the emergence of several Tg in the BMA–MAA copolymers [4, 36]. The first could be the distribution of MAA over the aqueous phase and droplets of a BMA emulsion during the synthesis of the copolymer. The second could be inhomogeneity in the composition that emerges upon polymerization up to deep conversions [18, 39]. Suspension polymerization thus proceeds under the conditions described in [17] to yield a BMA–MAA copolymer where the adsorption of solution-polymerized molecules of BMA–MAA copolymer highly enriched with MAA occurs on the surfaces of its grains. All resulting grains of the BMA–MAA copolymer thus have copolymer shells highly enriched with MAA, the devitrification of which is matched by relaxation transition Tg3. Core–shell morphology is exhibited by, e.g., MMA/alkyd particles resulting from hybrid miniemulsion polymerization [40]. The shells are enriched by polyacrylate and the cores are enriched by alkyd.

DTA data show [4, 36] that samples with more than 20 mol % MAA are characterized by a third temperature range of devitrification with average temperature Tg2, which corresponds to devitrification of the copolymer fraction obtained at deep conversions, the composition of which differs from that of the copolymer obtained up to conversion of 90%.

The experimental heat capacities of the copolymer with 25.1 mol % MAA are described by curve 3 (Fig. 1) and given in Table 3. The heat capacity of this copolymer grew monotonically in the temperature range of 6–300 K. The more dramatic increase at 303 K is explained by incipient devitrification, the average temperature of which (according to DTA data) was Tg1 = 321 K [4, 36]. A similar pattern is observed for the BMA–MAA (28.5 mol %) copolymer sample, the heat capacity of which (Fig. 1, curve 4; Table 4) grew monotonically in the range of 80–303 K. A more dramatic increase corresponding to the start of devitrification was then observed as well. DTA data show [4, 36] its average temperature was Tg1 = 327 K. The heat capacity curve for the copolymer with 37.3 mol % MAA (Fig. 1, curve 5; Table 5) displays one physical transition with average temperature Tg1 = 299.5 K and the onset of the subsequent transition, the average temperature of which (according to DTA data) was Tg2 = 337 K [4, 36].

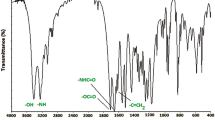

The average \(C_{p}^{^\circ }\) values and thermodynamic functions of the studied BMA–MAA copolymers as a function of temperature are given in Tables 6–10. Since devitrification did not end at 330 K (Fig. 1, curves 2–5), the thermodynamic functions in the temperature range of the relaxation transition were calculated from curves \(C_{p}^{^\circ }\) = f(T) for the studied samples. Analysis of the isotherms of the concentration dependence of \(C_{p}^{^\circ }\) for the BMA–MAA copolymers (Fig. 2a, Table 10) showed that at low temperatures where the copolymers were in a glass-like state throughout the range of compositions, this dependence of the isobaric heat capacity of the copolymer was close to linear and fell when the content of MAA in the copolymer was raised. The deviations from the additive dependence were in this case minor and comparable to the error in determining \(C_{p}^{^\circ }\). The transition of the systems into a high-elasticity state was accompanied by negative deviation from the corresponding linear dependences (e.g., the isotherm at T = 300 K, Fig. 2a). Of great interest are the isotherms of the concentration dependences of enthalpy (Fig. 2b), entropy (Fig. 2c), and the Gibbs function of heating (Fig. 2d). The enthalpy isotherms are additive at all temperatures (Table 10), since vitrification is an enthalpy-free transition [16, 20, 41]. The entropy isotherms of the copolymers (Fig. 2c, Table 10) display negative deviations from additive straight lines. These deviations range from 3 to 9%, which greatly exceeds the error in calculating entropy. At the same time, summand T[S°(T) − S°(0)] makes a greater contribution to the Gibbs function of heating than the enthalpy part of the Gibbs–Helmholtz equation at all the above temperatures. The corresponding isotherms of the Gibbs function therefore also have a negative deviation from linear dependences at 100–300 K (Fig. 2d, Table 10). In other words, it is the ordering of the system, rather than the energy of intermolecular interaction, that makes the main contribution to the change in the Gibbs function for all the studied BMA–MAA copolymers. The studied copolymers therefore differ from the MMA–MAA copolymers described in the literature [29], for which the heat capacity and enthalpy show negative deviation from additivity. This suggests that the increase in the intermolecular interaction upon raising the content of MAA makes the main contribution to the Gibbs function of the MMA–MAA system.

CONCLUSIONS

Analysis of the thermodynamic characteristics and DTA data [4, 36] for BMA–MAA copolymers with 7.6 to 37.3 mol % of the acid showed that BMA–MAA (7.6 mol %) copolymer with two temperature ranges of devitrification (Tg1 = 306 K and Tg3 = 419 K) is the one best suited to be a matrix for the transdermal administration of β-adrenoreceptor blocking agents, nitroglycerin, chlorpropamide, acetylsalicylic acid, and other drugs. This was confirmed by studies on the diffusion of drugs from TTSes into the bodies of patients that were performed at the RF Ministry of Health’s Shumakov Federal Research Center of Transplantology and Artificial Organs [6–8, 42].

REFERENCES

Artificial Organs, Ed. by V. I. Shumakov (Meditsina, Moscow, 1990) [in Russian].

Biocompatibility, Ed. by V. I. Sevast’yanov (Inform. Tsentr VNIIgeosistem, Moscow, 1999) [in Russian].

Progress in Biomedical Polymers, Ed. by C. G. Gebelein and R. L. Dunn (Springer, New York, 2013).

V. Uryash, S. Chuprova, and N. Kokurina, Thermodynamics and Thermal Analysis of Plasticized Copolymers Butyl Methacrylate with Methacrylic Acid, a Binder for Transdermal Therapeutic Systems (LAP Lambert Academic, Saarbrücken, 2021).

N. A. Plate and A. E. Vasil’ev, Vysokomol. Soedin. A 24, 675 (1982).

V. I. Sevast’yanov, L. A. Solomatina, A. A. Tikhobaeva, et al., Perspekt. Mater., No. 1, 46 (2004).

V. I. Sevast’yanov, L. A. Salomatina, N. V. Yakovleva, et al., Med. Tekh., No. 2, 3 (2000).

V. I. Shumakov, L. A. Salomatina, N. V. Yakovleva, et al., Vestn. Transplantol. Iskusstv. Organ., No. 4, 33 (1999).

M. I. Shtilman, Polymer Sci., Ser. A 52, 884 (2010).

A. E. Vasil’ev, I. I. Krasnyuk, S. Ravikumar, and V. N. Tokhmachi, Khim.-Farm. Zh. 35 (11), 29 (2001).

Biomaterials Science: An Introduction to Materials in Medicine, Ed. by B. D. Ratner, A. S. Hoffman, F. J. Schoen, and J. E. Lemons (Elsevier Academic, London, 2004).

N. A. Lavrov and T. S. Kryzhanovskaya, Plast. Massy, No. 2, 42 (1995).

M. Dittgen, M. Durrani, and K. Lehmann, S. T. P. Pharma Sci. 7, 403 (1997)

V. Kalous and Z. Pavliček, Biofyzikální chemie (SNTL, Prague, 1980).

G. M. Mrevlishvili, Low-Temperature Calorimetry of Biological Macromolecules (Metsniereba, Tbilisi, 1984) [in Russian].

V. Ur’yash and A. Gruzdeva, Thermodynamics of Biologically Active Substances (LAP Lambert Academic, Saarbrücken, 2017) [in Russian].

T. E. Knyazeva, V. A. Izvozchikova, and V. F. Ur’yash, RF Patent No. 2174522, Byull. Izobret., No. 28 (2001), p. 35.

T. E. Knyazeva, I. B. Myasnikova, and Yu. D. Semchikov, Polymer Sci., Ser. A 40, 859 (1998).

Yu. S. Lipatov, A. E. Nesterova, T. M. Grishchenko, and R. A. Veselovskii, Reference Book on Polymer Chemistry (Nauk. Dumka, Kiev, 1971) [in Russian].

I. B. Rabinovich, V. P. Nistratov, V. I. Tel’noi, and M. S. Sheiman, Thermodynamics of Organometallic Compounds (Nizhegor. Univ., Nizh. Novgorod, 1996) [in Russian].

B. V. Lebedev and V. Ya. Lityagov, in Thermodynamics of Organic Compounds, Interschool Collection (Gor’k. Gos. Univ., Gorky, 1976), No. 5, p. 89 [in Russian].

A. A. Sklyankin and P. G. Strelkov, Zh. Prikl. Mekh Tekh. Fiz., No. 2, 100 (1960).

V. M. Malyshev, G. A. Mil’ner, E. L. Sorkin, and V. F. Shibakin, Prib. Tekh. Eksp., No. 6, 195 (1985).

R. M. Varushchenko, A. I. Druzhinina, and E. L. Sorkin, J. Chem. Thermodyn. 29, 623 (1997).

N. V. Karyakin, Principles of Chemical Thermodynamics, The Manual (Akademiya, Moscow, 2003) [in Russian].

K. K. Kelley, G. S. Parks, and H. M. Huffman, J. Phys. Chem. 33, 1802 (1929).

V. F. Ur’yash, N. Yu. Kokurina, V. N. Larina, and S. V. Chuprova, Polymer Sci., Ser. A 56, 32 (2014)

I. B. Rabinovich, B. V. Lebedev, and T. I. Melent’eva, Vysokomol. Soedin., Ser. A 9, 1699 (1967).

L. I. Pavlinov, I. B. Rabinovich, N. A. Okladnov, and S. A. Arzhakov, Vysokomol. Soedin., Ser. A 9, 483 (1967).

U. Gaur, Sukfai Lau, B. Wunderlich, and B. Wunderlich, J. Phys. Chem. Ref. Data 11, 1065 (1982).

M. M. Popov and G. L. Gal’chenko, Zh. Obshch. Khim. 21, 2220 (1951).

Thermodynamic Properties of Individual Substances, The Handbook, Ed. by V. P. Glushko (Nauka, Moscow, 1978), Vol. 1, Part 2, p. 310 [in Russian].

R. Hoffmann and W. Knappe, Koll.-Z. Z. Polym. 247, 763 (1971).

B. V. Lebedev, T. G. Kulagina, N. N. Smirnova, et al., Zh. Fiz. Khim. 69, 581 (1995).

V. A. Bershtein, V. M. Egorov, and V. A. Ryzhov, Vysokomol. Soedin., Ser. B 28, 268 (1986).

V. F. Uryash, T. E. Knyazeva, V. A. Izvozchikova, and N. Yu. Kokurina, in Advances in Condensed Matter and Materials Research, Ed. by F. Gerard (Nova Sci., New York, 2002), Vol. 3, pp. 169–175.

E. Yu. Ovchinnikov and Yu. P. Gorelov, Vysokomol. Soedin., Ser. B 30, 677 (1988).

A. A. Yousefi, M. Pishvaei, and A. Yousefi, Prog. Color Colorants Coat. 4, 15 (2011).

Yu. D. Semchikov, S. F. Zhil’tsov, and S. D. Zaitsev, Introduction to Polymer Chemistry, The Manual (Lan’, Nizh. Novgorod, 2012) [in Russian].

J. G. Tsavalas, Y. Luo, L. Hudda, and F. J. Schork, Polym. React. Eng. 11, 277 (2003).

D. F. Westrum, Jr. and J. P. Mccullough, in Physics and Chemistry of the Organic Solid State, Ed. by D. Fox, M. M. Labes, and A. Weissberger (Wiley, New York, 1965).

A. A. Tikhobaeva, L. A. Salomatina, and V. I. Sevast’yanov, Vestn. Transplantol. Iskusstv. Organov, No. 4, 50 (2003).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare they have no conflicts of interest.

Additional information

Translated by K. Utegenov

Rights and permissions

About this article

Cite this article

Ur’yash, V.F., Chuprova, S.V., Kokurina, N.Y. et al. Heat Capacity, Thermodynamic Functions, and the Glass Transition of Butyl Methacrylate–Methacrylic Acid Copolymers. Russ. J. Phys. Chem. 96, 248–258 (2022). https://doi.org/10.1134/S0036024422020285

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024422020285