Abstract

In this paper the nano gold doped in TiO2 were prepared, and characterized by scanning electron microscopy with energy dispersive analysis, powder X-ray diffraction, IR spectrometry and electrochemical methods. It was found that the citric acid oxidation could be catalyzed by Au@TiO2 under irradiation with full-spectrum solar light.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Titanium dioxide (TiO2) is an n-type semiconductor material. Because of the high photostability, photo-sensitivity and larger specific surface area TiO2 has been used in lots of fields such as paint industry, biomedicine, environmental engineering, photocatalysis, photovoltaic cells, dye sensitized solar cells and lithium ion batteries [1]. Several chemical methods have been employed to prepare anatase TiO2 including sol–gel process [2, 3], hydrothermal treatment [4, 5], chemical vapor deposition [6]. However, these methods are very expensive and tedious. Nano-Au and its composites are extensively used in the fields of catalysys, electricity, magnetism, semiconductor, optical, biological and information storage applications [7, 8]. Taking account of the advantages of nano-Au and porous-TiO2, the depositing nano-Au on matrix of sorbent TiO2 will be a promising composite.

In present work, a simple and cheap method for the nano TiO2 and nano Au@TiO2 was proposed, and the photocatalytic electrochemical behavior of citric acid was studied using a glassy carbon electrode (GCE) modified by the Au@TiO2.

EXPERIMENTAL

HAuCl4·4H2O was purchased from Aldrich. Titanium foil (0.1 mm) was obtained from Guoyao Co., Ltd. (China). Phosphate buffer solution (PBS) was prepared by dissolving 0.1 mol KCl and 0.1 mol Na2HPO4 in 1000 mL of double-distilled water and adjusted desired pH values with 6 mol L–1 HCl or 1 mol L–1 NaOH; 0.5 M Na2SO4–0.2 M NaF aqueous solution was prepared for the synthesis of TiO2. Double-distilled water was used throughout. All reagents were of analytical grade.

For all electrochemical experiments a CHI660D Electrochemical Analyzer (CHI, USA) was employed. Three-electrode electrochemical cells were used; a 3 mm GCE modified by Au@TiO2 was used as working electrode. A platinum wire and the Ag/AgCl (3 M KCl) electrode served as the counter electrode and the reference electrode, respectively. The full spectrum solar light of 50 W and a quartz beaker were used for the photocatalytic study.

The synthetic material was characterized by scanning electron microscopy (SEM) (QUANTA FEG 450, USA.) with energy dispersive spectrometer (EDS) (QUANTAX 400, Bruker, Germany). Powder X-ray diffraction (XRD) patterns were recorded on an ARL/ X‘TRA X-ray diffractometer (Switzerland) with rotating anode with CuKα radiation source (l = 1.54056 Å). IR spectra were measured on a NICOLET NEXUS470 spectrometer in the frequency range 4000–400 cm−1.

TiO2 was prepared by anodic oxidation of 0.1 mm × 2 cm × 3 cm titanium foil in the aqueous solution containing 0.5 M Na2SO4–0.2 M NaF. Prior to any electrochemical treatment, the titanium foil was sonicated in ether, ethanol and then in distilled water for 10 min, respectively. To obtain the white H2TiO3, the anodic oxidation of titanium foil at 30 V for 6 h was carried out in a stirred electrochemical cell working at room temperature. The H2TiO3 was washed with distilled water and ethanol, respectively, dried in air at 60°C for 24 h, and heated at 400°C in a muffle furnace for 3 h, thus the TiO2 was obtained. NaBH4 (0.150 g) was dissolved in 10 mL of mixed solution containing 1.0 mg mL–1 HAuCl4, 0.005 M Na2CO3, and 1.0 mg mL–1 TiO2. The mixture was stirred with a magnetic stirrer for 10 min to ensure that the NaBH4 completely dissolved; the red and white Au@TiO2 was soon produced, and followed by centrifugal separation, washing with distilled water and absolute alcohol, respectively, and then dried in vacuum at 40°C for 6 h. The modifier suspension was prepared by dispersing the 5.0 mg Au@TiO2 in 5.0 mL of ethanol under sonication for 10 min. The Au@ TiO2 modified GCE was prepared by casting 2 μL of the mentioned above red and white suspension on the surface of GCE using a micropipette and left to dry at room temperature.

RESULTS AND DISCUSSION

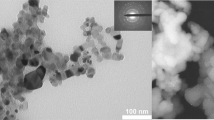

SEM is applied to confirm the formation of a layer of the film on the surface of bare GCE. The SEM imagines of Au@TiO2 and TiO2 on the surface of GCE and H2TiO3 are shown in Fig. 1, the faveolate Au@TiO2, TiO2, and H2TiO3 were observed.

EDX data are shown in Fig. 2 and Table 1, respectively. It could be seen that the mole ratios of O and Ti for Au@TiO2 on the carbon carrier were 2.21 : 1, the molecular formula could be deduced as TiO2, and some Na+ ions absorbed on TiO2 were found.

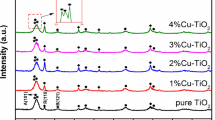

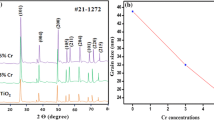

XRD pattern of the Au@TiO2 (a), TiO2 (b), and H2TiO3 (с) are shown in Fig. 3, the characteristic diffraction angles of 25.1°, 37.9°, 48.2°, 54.2°, 55.2°, 62.9°, 68.9°, 69.8°, and 75.2° corresponding well with (101), (004), (200), (105), (211), (204), (116), (220), and (115) planes of TiO2 were observed, which were ascribed to those of TiO2 anatase (JCPDF no. 21-1272). The peaks appeared at 44.4° and 78.9° for Au@TiO2 could be assigned to (200) and (311) crystalline plane diffraction peaks of gold (JCPDS no. 04-0784), respectively. The characteristic diffraction angles for Au@TiO2 were similar to those of TiO2, however only the characteristic diffraction angles of 25° for H2TiO3 was found. Based on the Scherrer formula [9]: Dhkl = kλ/β\(\cos \theta \), where k is Scherrer constant (0.89), λ is wavelength of CuKα (0.154062 nm), θ is Bragg diffraction angle (deg), β is the peak width at half height of the diffraction peaks (rad). The Dhkl values for TiO2 and Au were ∼3.0 nm. Therefore, the TiO2 deposited Au nanoparticles in size observed from the SEM images was evidently the clusters constructed by nano-Au@TiO2 crystalline.

IR spectra of H2TiO3 are shown in Fig. 4, the band at 3417 cm–1 could be assigned to the stretching vibration of –OH, and the bands of 1631 and 1547 cm–1 corresponding to the stretching vibration of Ti–O were also found. The bands of 1124, 975 and 806 cm–1 could be assigned to the bending vibration of Ti–O. The similar stretching vibrations of Ti–O and the –OH of absorbed water were found in Au@TiO2 and TiO2, and the bending vibration of Ti–O disappeared duo to the adsorption of nano Au.

The cyclic voltammograms (CVs) of K3Fe(CN)6–K4Fe (CN)6 on the electrode can be used to detect the cleanliness and the surface area of electrode, and the reversibility and the catalytic properties of the modified materials. The CVs of modified GCE in the K3Fe(CN)6–K4Fe(CN)6 system were shown in Fig. 5. The surface area of GCE could be estimated in a reversible process, the following Randles–Sevcik formula at 298 K [10] has been used: ip = 2.69 × 105n3/2Ac0\(D_{0}^{{1/2}}\)ν1/2, where, ip refers to the anodic peak current, n is the electron transfer number, A is the microscopic surface area of the electrode, D0 is the diffusion coefficient of K3Fe(CN)6, c0 is the bulk concentration of K3 Fe(CN)6 and ν is the scan rate. The CVs of bare GCE in the K3Fe(CN)6–K4Fe(CN)6 showed a good reversible process, and from the slope of the plot of oxidation current (ipa) versus ν1/2, the microscopic areas of bare GCE were 0.904 cm2. Compared with the redox of Fe(CN)\(_{6}^{{3 - /4 - }}\) at the GCE in Fig. 5, the oxidation currents of Fe(CN)\(_{6}^{{4 - }}\) at the Au@TiO2 were more than that of Fe(CN)\(_{6}^{{4 - }}\) at GCE and TiO2/GCE, and the oxidation peak shifted to negative direction; and the oxidation currents of Fe(CN)\(_{6}^{{4 - }}\) at the TiO2 were less than that of Fe(CN)\(_{6}^{{4 - }}\) at GCE, and the oxidation peak shifted to positive direction due to the poor conductivity of TiO2. These results showed that the oxidation of the Fe(CN)\(_{6}^{{4 - }}\) could be catalyzed by the nano gold in the Au@TiO2.

A Nyquist plot representing electrochemical impedance spectrum (EIS) is an effective way to measure the electron-transfer resistance. EIS measurements were carried out at bare, TiO2 and Au@TiO2 composite film modified GCE, respectively, and the results are shown in Fig. 6. The supporting electrolyte used was 0.1 KCl containing 5 mM Fe(CN)\(_{6}^{{3 - /4 - }}\). The semicircle portion observed at higher frequencies in a Nyquist plot corresponds to electron-transfer-limited process and diameter of the semicircle corresponds to interfacial electron-transfer resistance (Rct). Linear part of the spectra is characteristic of lower frequency range and represents diffusional-limited process. In Fig. 6, the EIS of GCE implied the redox of Fe(CN)\(_{6}^{{3 - /4 - }}\) at bare GCE was controlled by the diffusional-limited process. After a modification with TiO2 layer, the electron-transfer resistance reached a higher value (Ret = 1.34 kΩ), however, the modification of nano Au@TiO2 film modified electrode reached a lower value of electron-transfer resistance (Rct = 1.07 kΩ), indicated that the high conductivity of Au@TiO2 film increases the electrical properties of the redox processes.

The electrochemical response of the modified electrode in 0.1 M PBS of pH 6.0 in the light is shown in Fig. 7. No oxidation peaks of citric acid at bare GCE and TiO2/GCE were found. Compared with the CVs of citric acid at TiO2/GCE and GCE, the oxidation peak of citric acid at the Au@TiO2/GCE in absence of light was found at 0.700 V but 0.690 V in the light, and the currents were significantly more than that of citric acid in absence of light, indicating that the oxidation of citric acid could be catalyzed by the light. It could be seen from in Fig. 7 (inset) that the sharp reduction peak of O2 at Au@TiO2/GCE was found at 0.073 V, and the reduction currents of O2 at Au@TiO2/GCE were more than that at GCE and TiO2/GCE.

CONCLUSIONS

In present work, a simple and cheap method for the preparation of nano Au@TiO2 was proposed, and the prepared material was characterized by scanning electron microscopy with energy dispersive spectrometry, powder X-ray diffraction, IR spectrometry and electrochemical measurements. It was demonstrated that the citric acid oxidation could be catalyzed by the Au@TiO2 with the light significantly.

REFERENCES

S. Sakthivel, M. C. Hildago, D. C. Bahnemann, S. U. Geissen, V. Murugesan, and A. Vogelpohl, Appl. Catal. B 63, 31 (2006).

M. A. Behnajady, H. Eskandarloo, N. Modirshahla, and M. Shokri, Photochem. Photobiol. 87, 1002 (2011).

A. Wong, W. A. Daoud, H. Liang, and Y. S. Szeto, Mater. Lett. 117, 82 (2014).

H. Liu, X. Dong, T. Liu, X. Sun, and Z. Zhu, Mater. Lett. 136, 187 (2014).

A. F. Alkaim, T. A. Kandiel, F. H. Hussein, R. Dillert, and D. W. Bahnemann, Appl. Catal. A 466, 32 (2013).

A. A. Umar, S. Nafisah, S. K. M. Saad, S. T. Tan, A. Balouch, M. M. Salleh, and M. Oyama, Sol. Energy Mater. Sol. Cells 122, 174 (2014).

H. Onnemann and R. Richards, Eur. Inorg. Chem. 10, 2455 (2001).

D. P. Macwan, P. N. Dave, and S. Chaturvedi, J. Mater. Sci. 46, 3669 (2011).

V. Radmilovic, H. A. Gasteiger, and P. N. Ross, J. Catal. 154, 98 (1995).

P. T. Kissinger and W. R. Heineman, Laboratory Techniques in Electroanalytical Chemistry (Marcel Dekker, New York, 1984), Chap. 3.

Funding

The authors gratefully acknowledge the financial support of the Open Science Foundation for Jiangsu Province Key Laboratory for Chemistry of Low-Dimentional Materials (grant no. JSKC17009), the Open Science Foundation for Jiangsu Key Laboratory for Biomass-based Energy and Enzyme Technology (grant no. JSBEET1207), and the Science foundation of Huaiyin Normal University (grant no. 11HSGJBZ13).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, Y.Z., Heng, H.D., Di, K.Z. et al. A Facile Synthesis of Nano Gold Doped TiO2 and Its Photocatalytic Activity toward Citric Acid. Russ. J. Phys. Chem. 95, 2708–2713 (2021). https://doi.org/10.1134/S0036024421130215

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024421130215