Abstract

La2O2S:Tb3+ hollow nanofibers were successfully fabricated by sulfurization of the relevant La2O3:Tb3+ hollow nanofibers via double-crucible method. The morphology and properties of the products were investigated in detail by X-ray diffraction (XRD), scanning electron microscopy (SEM) and fluorescence spectrometry. La2O2S:Tb3+ hollow nanofibers were pure hexagonal phase with space group P\(\bar {3}\)m1 and were hollow-centered structure with the mean diameter of 160.03 ± 17.74 nm. Emission spectra indicate that La2O2S:Tb3+ hollow nanofibers emit green light at 544 nm attributed to 5D4 → 7F5 energy levels transition of Tb3+ ions. CIE analysis demonstrated that the light emitted by La2O2S:Tb3+ hollow nanofibers corresponds to the green region, and color-tuned luminescence can be obtained by changing concentration of Tb3+ ions. The obtained material could be applied in the field of optical telecommunication and optoelectronic devices. The possible formation mechanism of La2O2S:Tb3+ hollow nanofibers was also proposed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Rare earth (RE) compounds were intensively used in high-performance luminescence and display devices, optic communication, energy storage, new energy resource etc., especial the RE as hosts. It is expected that smaller size phosphors can improve luminescent quantum efficiency (QE), and display resolution [1–3]. Thus, nanocrystals doped with RE ions have attracted a large amount of interest. In the earlier years, the photoluminescent properties of RE ions in zero-dimensional nanoparticles have been extensively investigated, including the local symmetry, electronic transition processes, surface effects etc. [4–6]. Moreover, in comparison with zero-dimensional nanoparticles, the shape anisotropy of one-dimensional structure provided a better model system to investigate the dependence of electronic transport, optical properties on size confinement and dimensionality. Among these one-dimensional nanomaterials, hollow nanofiber is a new kind of one-dimensional nanomaterials with special morphology. It has attracted increasing interest of scientists owing to its anisotropy, large length-to-diameter ratio, unique optical, electrical and magnetic performances [7–9]. Research on the fabrication and properties of hollow nanofibers has become one of the popular subjects of study in the realm of nanomaterials.

The lanthanide (La-Lu) oxysulfides are known as wide-gap (4.6–4.8 eV) materials suitable for activation with doping ions [10–13]. In addition, compared with the lanthanide oxides, oxysulfides are more efficient phosphors with a broader excitation band. Therefore, the lanthanide oxysulfides become a very important host of inorganic materials which have high potential for applications in various fields, such as color television picture tubes, radiographic imaging, field emission displays, and long-lasting phosphorescence. RE oxysulfides are more biocompatible than RE oxide, may be used as biological probes and labels. Some researchers have prepared the La2O2S nanocrystals by combustion and solid state methods [14–17].

In recent years, electrospinning technology has been extensively explored as a simple and versatile method for forming inorganic superfine nanofibers using polymer/inorganic composite as the precursor [18–20]. The morphology of materials can be controlled by adjusting experimental conditions, such as the viscosity of spinning solution, relative air humidity, the structure of spinneret, spinning voltage, and the distance between the spinneret and the collector. Advantages of this novel process for fabricating 1D nanostructures include, but is not limited to, low cost, high efficiency and convenient assembly. It has been reported that the nanofibers were successfully synthesized via electrospinning [21–25].

In this study, pure hexagonal phase La2O2S:Tb3+ hollow nanofibers were prepared through calcining the electrospun PVP/[La(NO3)3 + Tb(NO3)3] composite nanofibers, and then La2O2S:x%Tb3+ (x is the molar ratio of Tb3+ to (La3+ + Tb3+), x = 1, 3, 5, and 7) hollow nanofibers were fabricated by sulfurization of La2O3:x%Tb3+ hollow nanofibers via a double-crucible method we newly proposed for the first time. The samples were systematically characterized, and a possible formation mechanism of La2O2S:Tb3+ hollow nanofibers was also presented.

EXPERIMENTAL

Chemicals

Polyvinyl pyrrolidone (PVP) (K15, Mw = 10 000, AR) was bought from Tiantai Chemical Co. Ltd. Yttrium oxide (La2O3, 99.99%) and terbium oxide (Tb4O7, 99.99%) were purchased from Kemiou Chemical Co., Ltd. N,N-dimethylformamide (DMF, AR) and Sulfur powder (S, AR) were purchased from Sinopharm Chemical Reagent Co. Ltd. Nitric acid (HNO3, AR) was bought from Beijing Chemical Works. All chemicals were directly used as received without further purification.

Preparation of PVP/[La(NO3)3 + Tb(NO3)3] Composite Nanofibers via Electrospinning

In the typical procedure of preparing La2O3:5%Tb3+ hollow nanofibers, 1.14 g of La2O3 and 0.07 g of Tb4O7 were dissolved in dilute HNO3 at elevated temperatures to form RE(NO3)3⋅6H2O (RE = La3+ and Tb3+). The rare earth nitrates were dissolved in 9.8 g of DMF, and then 7.8 g of PVP was added into the above solution. The solution was magnetically stirred for 10 h to form homogeneous transparent precursor solution. Subsequently, the precursor solution was electrospun at room temperature under a positive high voltage of 13 kV, the distance between the capillary tip and the collector (aluminium foil) was fixed to 16 cm, and relative humidity was 50–60%. PVP/[La(NO3)3 + Tb(NO3)3] composite nanofibers were obtained on the collector. Other series of La2O3:x%Tb3+ (x = 1, 3, and 7) hollow nanofibers were prepared by the similar procedure except for different doping molar concentration of Tb3+.

Fabrication of La2O3:Tb3+ Hollow Nanofibers

The above PVP/[La(NO3)3 + Tb(NO3)3] composite nanofibers were calcined at 700°C for 8 h with a heating rate of 1 K/min. Then the calcination temperature was decreased to 200°C at a rate of 1 K/min. Finally, samples were naturally cooled down to room temperature and La2O3:Tb3+ hollow nanofibers were obtained.

Synthesis of La2O2S:Tb3+ Hollow Nanofibers

La2O3:Tb3+ hollow nanofibers were loaded into a small crucible. A few carbon rods were put into a big crucible, and then the small crucible was placed into the big crucible. Next, sulfur powder was loaded into the space between the two crucibles, and then the big crucible was covered with its lid. We call this process a double-crucible method. Finally the crucibles were heated at 800°C for 4 h under argon atmosphere, and then the temperature was decreased to 200°C at a rate of 1 K/min followed by natural cooling down to ambient temperature. Thus, La2O2S:Tb3+ hollow nanofibers were obtained.

Characterization Methods

The X-ray diffraction (XRD) measurement was performed using a Rigaku D/max-RA XRD diffractometer with CuKα radiation (0.15418 nm wavelength). The field emission scanning electron microscope (FESEM, XL-30, FEI Company) was used to characterize the morphologies and sizes of the products. The distribution histograms of diameters were plotted using Image-Pro Plus 6.0 and Origin 8.5 softwares. The excitation and emission spectra of samples were recorded with a HITACHI F-7000 fluorescence spectrophotometer using a Xe lamp as the excitation source.

RESULTS AND DISCUSSION

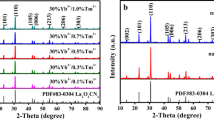

Crystal Structure

The XRD patterns of La2O2S:Tb3+ hollow nanofibers are shown in Fig. 1. The XRD analysis of La2O2S:Tb3+ hollow nanofibers demonstrates that the characteristic diffraction peaks of the samples can be easily indexed to those of the pure hexagonal phase with primitive structure of La2O2S (PDF no. 71-2098), and the space group is P\(\bar {3}\)m1. No peaks of any other phases or impurities are detected, indicating that crystalline La2O2S:Tb3+ material was prepared via sulfurization of crystalline La2O3:Tb3+.

Morphology

Figure 2 shows the representative SEM images of the PVP/[La(NO3)3 + Tb(NO3)3] composite nanofibers, La2O3:Tb3+ hollow nanofibers and La2O2S:Tb3+ hollow nanofibers. From the SEM image of Fig. 2a, it can be noticed that the PVP/[La(NO3)3 + Tb(NO3)3] composite nanofibers have uniform diameter with good dispersivity. Figure 2b shows the SEM image of as-prepared La2O3:Tb3+ hollow nanofibers. It can be clearly seen that the morphology of nanofibers is hollow-centered structure obtained by calcination of the respective electrospun PVP/[La(NO3)3 + Tb(NO3)3] composite nanofibers. After annealing and sulfurization at 800°C, as-formed La2O2S:Tb3+ hollow nanofibers have relatively smooth surface, as revealed in Fig. 2c. From Fig. 2c, one can see that the sample exhibits hollow-centered fibrous structure. It reveals that La2O2S:Tb3+ hollow nanofibers retain their 1D morphology. From above analyses, we can safely conclude that the sulfurization technique we proposed here can retain the morphology of the precursor nanofibers.

Under the 95% confidence level, the diameters of PVP/[La(NO3)3 + Tb(NO3)3] composite nanofibers, La2O3:Tb3+ hollow nanofibers and La2O2S:Tb3+ hollow nanofibers analyzed by Shapiro-Wilk method are normal distribution. Distribution histograms of diameters of the samples are indicated in Fig. 3. As seen from Fig. 3, the diameters of PVP/[La(NO3)3 + Tb(NO3)3] composite nanofibers, La2O3:Tb3+ hollow nanofibers and La2O2S:Tb3+ hollow nanofibers are 459.19 ± 52.62, 189.57 ± 22.69, and 160.03 ± 17.74 nm, respectively.

Photoluminescence Properties

Figure 4 shows the excitation (monitored by 544 nm) and emission (excited by 260 nm) spectra of La2O2S:x%Tb3+ (x = 1, 3, 5, and 7) hollow nanofibers. The excitation spectra (Fig. 4a) exhibits one strong broad band in the range from 200 to 300 nm with a maximum at 260 nm, which is attributed to transition of the electron from the ground state to the split 5d energy levels, namely 4f 8 → 4f 75d1 energy levels transitions of Tb3+ [12, 15]. The emission spectra of La2O2S:x%Tb3+ (x = 1, 3, 5, and 7) hollow nanofibers is shown in the Fig. 4b. It is found from Fig. 4b that the green emission peaks consist of two main peaks at 489 and 544 nm, which originate from 5D4 → 7FJ (J = 6 and 5) energy levels transitions of Tb3+ ions, respectively. The weak emission peak at 587 nm is ascribed to the 5D4 → 7F4 energy level transitions of Tb3+ ions. Among these emission peaks, the green emission at 544 nm attributed to 5D4 → 7F5 energy levels transition of Tb3+ ions is the strongest one.

Figure 4 demonstrates the PL spectra of La2O2S:Tb3+ hollow nanofibers with different concentrations of Tb3+ ions. It is found that the spectral shape and locations of excitation and emission peaks do not vary with the concentration of Tb3+ ions, but the intensity of excitation and emission peaks strongly depend on the concentration of Tb3+ ions. The strongest excitation and emission spectra can be obtained when the molar concentration of Tb3+ is 5%. Obviously, the luminescence intensity of La2O2S:Tb3+ hollow nanofibers increases with increase in the concentration of Tb3+ from the beginning, reaches a maximum value at Tb3+ concentration of 5%, and then decreases with further increase in Tb3+ concentration.

PL decay curves for La2O2S:x%Tb3+ (x = 1, 3, 5, and 7) hollow nanofibers with different concentrations of Tb3+ shown in Fig. 5, are used to calculate the lifetime and to investigate the luminescence dynamics of these samples. The luminescence was excited at 260 nm and monitored at 544 nm. It can be seen that all the curves can be well fitted with a single-exponential function as It = I0exp(–t/τ), where It is the intensity at time τ, I0 is the intensity at t = 0, and τ is the decay lifetime. The fitting was performed using Origin 8.5 software, and the values of the parameter τ were obtained. The average luminescence lifetime for La2O2S:x%Tb3+ (x = 1, 3, 5, and 7) hollow nanofibers are 0.79, 0.89, 1.11, and 0.96 ms, corresponding to the Tb3+ concentration of 1, 3, 5, and 7%, respectively.

CIE Analysis

Generally, color is represented by the Commission Internationale de L’Eclairage (CIE) chromaticity coordinates and color ratios. The chromaticity coordinates and color ratios have been calculated from the emission spectra by the method described in previous report [24]. For the La2O2S:x%Tb3+ (x = 1, 3, 5, and 7) hollow nanofibers, the chromaticity coordinates (X, Y) are determined to be (0.2520, 0.5749), (0.2573, 0.5977), (0.2646, 0.6109), and (0.2791, 0.6386), respectively. Remarkably, the change in emission color of La2O2S:x%Tb3+ (x = 1, 3, 5, and 7) hollow nanofibers with the variation of concentration of Tb3+ is shown in Fig. 6. These results indicate that the luminescence color can be tuned by changing the concentration of doping activator ions. The obtained nanostructures could be a promising material for LEDs.

Formation Mechanism for La2O2S:Tb3+ Hollow Nanofibers

The formation mechanism for La2O2S:Tb3+ hollow nanofibers is proposed on the basis of the above experimental results, as shown in Fig. 7. PVP, La(NO3)3 and Tb(NO3)3 were mixed with DMF to form precursor solution with certain viscosity. Then, PVP/[La(NO3)3 + Tb(NO3)3] composite nanofibers were obtained via electrospinning. During calcination process, PVP chain was broken and volatilize. The La3+, Tb3+, and \({\text{NO}}_{3}^{ - }\) ions moved to the surface of the composite fibers upon evaporation of solvent DMF. With the increase in calcination temperature, nitrates were decomposed to NO2, La3+, and Tb3+ and form La2O3:Tb3+ crystallites. The crystallites were combined into nanoparticles, then some nanoparticles were mutually connected to generate hollow-centered La2O3:Tb3+ nanofibers. PVP acted as template during the formation of La2O3:Tb3+ hollow nanofibers. It was found from experiments that the average molecular weight of PVP and content of PVP in the precursor solution played important role in the formation of La2O3:Tb3+ hollow nanofibers. Next, La2O3:Tb3+ hollow nanofibers were sulfurized using sulfur powder. During the process, sulfur powder and La2O3:Tb3+ hollow nanofibers were separated by the small crucible, which prevented La2O3:Tb3+ hollow nanofibers from morphology damage. If La2O3:Tb3+ hollow nanofibers were directly mixed with sulfur powder, molten sulfur destroyed La2O3:Tb3+ hollow nanofibers. Carbon rods played an important role in the reduction via combination with O2 to produce CO, which react with oxygen species of La2O3:Tb3+ to give CO2 in the heating process. The double-crucible method we proposed here is actually a solid–gas reaction, which has been proved to be an important method, not only can retain the morphology of La2O3:Tb3+ hollow nanofibers, but also allows to fabricate single-phase La2O2S:Tb3+ hollow nanofibers at relatively low temperature. Reaction scheme describing the formation of La2O2S:Tb3+ hollow nanofibers can be written as follows:

CONCLUSIONS

In summary, pure hexagonal phase La2O2S:Tb3+ hollow nanofibers with space group P\(\bar {3}\)m1 were fabricated via sulfurization of the La2O3:Tb3+ hollow nanofibers. The morphology of the obtained nanofibers can be inherited from the precursor nanofibers under the sulfurization conditions via a double-crucible method we newly proposed. The diameter of La2O2S:Tb3+ hollow nanofibers analyzed by Shapiro–Wilk method obeys normal distribution and is 160.03 ± 17.74 nm. Emission spectra show that La2O2S:Tb3+ hollow nanofibers emit green light luminescence at 544 nm attributed to 5D4 → 7F5 energy levels transition of Tb3+ ions. The double-crucible method we proposed here is of great importance. This technique can be employed in fabrication of other pure-phase rare earth oxysulfide nanomaterials with various morphologies.

REFERENCES

C. H. Yan, Z. Yan, Y. Du, J. Shen, C. Zhang, and W. Feng, in Handbook on the Physics and Chemistry of Rare Earths (Academic, Burlington, 2011), Vol. 41, p. 275.

D. G. Mancebo, A. I. Becerro, T. C. Rojas, A. Olivencia, A. Corral, M. Balcerzyk, E. Cantelar, F. Cussó, and M. Ocaña, J. Colloid Interface Sci. 520, 134 (2018).

J. Shen, L. D. Sun, and C. H. Yan, Dalton Trans. 42, 5687 (2008).

N. Shrivastava, U. Rocha, D. Muraca, W. Silva, C. Jacinto, R. Kumar, and S. K. Sharma, Mater. Lett. 213, 358 (2018).

L. X. Lovisa, M. C. Oliveira, J. Andrés, L. Gracia, M. S. Li, E. Longo, R. L. Tranquilin, C. A. Paskocimas, M. R. D. Bomio, and F. V. Motta, J. Alloys Compd. 750, 55 (2018).

Z. F. Li, T. Y. Yang, Q. Zhao, and M. Z. Zhang, Phys. Chem. Chem. Phys. 19, 16758 (2017).

Y. W. Liu, Q. L. Ma, M. Yang, X. T. Dong, Y. Yang, J. X. Wang, W. S. Yu, and G. X. Liu, Chem. Eng. J. 284, 831 (2016).

L. Han, Y. H. Hu, M. M. Pan, Y. F. Xie, Y. Y. Liu, D. Li, and X. T. Dong, CrystEngComm 17, 2529 (2015).

J. D. Guo, Y. Yang, W. S. Yu, X. T. Dong, J. X. Wang, G. X. Liu, and T. T. Wang, RSC Adv. 6, 111447 (2016).

G. D. Liu, Q. H. Zhang, H. Z. Wang, and Y. G. Li, Mater. Sci. Eng. B 177, 316 (2012).

M. Pokhrel, A. K. Gangadharan, and D. K. Sardar, Mater. Lett. 99, 86 (2013).

S. V. Yap, R. M. Ranson, W. M. Cranton, D. C. Koutsogeorgis, and G. B. Hix, J. Lumin. 129, 416 (2009).

Y. M. Yang, C. Mi, F. Yu, X. Y. Su, C. F. Guo, G. Li, J. Zhang, L. L. Liu, Y. Z. Liu, and X. D. Li, Ceram. Int. 40, 9875 (2014).

N. T. Lau, M. Fang, and C. K. Chan, Appl. Catal. B 79, 110 (2008).

J. Bang, M. Abboudi, B. Abrams, and P. H. Holloway, J. Lumin. 106, 177 (2004).

Y. Z. Huang, L. Chen, and L. M. Wu, Cryst. Growth Des. 8, 739 (2008).

J. J. Oh, B. K. Jin, W. J. Chung, D. W. Shin, and Y. G. Choi, Curr. Appl. Phys. 11, S15 (2011).

Y. T. Geng, P. Zhang, Q. T. Wang, Y. X. Liu, and K. Pan, J. Mater. Chem. B 5, 5390 (2017).

C. Luo, X. X. Wang, J. Q. Wang, and K. Pan, Compos. Sci. Technol. 133, 97 (2016).

N. Lv, J. L. Zhang, G. M. Li, X. Wang, and J. Z. Ni, J. Phys. Chem. C 121, 11926 (2017).

N. Lv, Z. G. Wang, W. Z. Bi, G. M. Li, and J. L. Zhang, J. Mater. Chem. B 4, 4402 (2016).

M. Gao, X. F. Lu, M. Q. Chi, S. H. Chen, and C. Wang, Inorg. Chem. Front. 4, 1862 (2017).

M. Q. Chi, S. H. Chen, M. X. Zhong, C. Wang, and X. F. Lu, Chem. Commun. 54, 5827 (2018).

L. B. Fan, Q. L. Ma, J. Tian, D. Li, X. Xi, X. T. Dong, W. S. Yu, J. X. Wang, and G. X. Liu, J. Mater. Sci. 53, 2290 (2018).

J. Tian, Q. L. Ma, W. S. Yu, X. T. Dong, Y. Yang, B. Zhao, J. X. Wang, and G. X. Liu, N. J. Chem. 41, 13983 (2017).

ACKNOWLEDGMENTS

This work was financially supported by the National Natural Science Foundation of China (NSFC 50972020, 51072026), Ph.D. Programs Foundation of the Ministry of Education of China (20102216110002, 20112216120003), the Science and Technology Development Planning Project of Jilin Province (grant nos. 20070402, 20060504), Key Research Project of Science and Technology of Ministry of Education of China (grant no. 207026), the Science and Technology Research Project of the Education Department of Jilin Province during the thirteenth five-year plan period (grant nos. JJKH20180580KJ, JJKH20180582KJ) and the Scientific Development Program of Jilin Province (grant no. 20170520152JH).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Bi, F., Li, J., Gai, G. et al. Fabrication and Luminescence Properties of La2O2S:Tb3+ Hollow Nanofibers. Russ. J. Phys. Chem. 95, 1418–1423 (2021). https://doi.org/10.1134/S0036024421070104

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024421070104