Abstract

It is shown that the 1% Pt/CeO2–ZrO2 (1% Pt/CZ) catalytic system allows selective hydrogenation of citral with a 94% conversion and a selectivity towards unsaturated alcohols of 59% at room temperature and atmospheric pressure. The effect of addition of alkali to the reaction mixture on the yield of the target products is studied, and the optimum conditions of the reaction are determined.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

The popularity of the processes of conversion of bioavailable materials is constantly growing. In processing natural substrates, we can obtain valuable compounds that are subsequently used in different fields of science and industry. Citral is a naturally occurring aldehyde. It was found in substantial quantities in the essential oils of lemongrass, lemon, lime, lemon balm, and verbena [1]. Citral belongs to the class of monoterpene acyclic carbonyl compounds and has two C=C bonds in its structure. One of the double bonds is conjugated with the carbonyl group, while the other is isolated. Therefore, we can obtain a wide range of possible products via the conversion of citral. Among the other hydrogenation products, the products of selective reduction of the carbonyl group (isomeric alcohols nerol and geraniol) are of the greatest value, since they are widely used in pharmaceuticals, perfumes, food industry, and organic synthesis [2]. In addition, the selective reduction of the C=O bond presents a challenge for researchers, since the hydrogenation of the C=C bond is thermodynamically more favorable than reduction of the carbonyl group [3].

Due to the complexity and high practical importance of the selective hydrogenation of the citral carbonyl group conjugated with the C=C bond, a great number of works are devoted to the selective preparation of isomeric alcohols nerol and geraniol. Non-noble metal catalysts are rarely used in this reaction, since such catalytic systems require harsh conditions to carry out the hydrogenation reaction. Under such conditions, the C=C bond is inevitably hydrogenated, resulting in low selectivity towards desired products [4, 5].

Systems with noble metals known for their activity in hydrogenation reactions would seem to be the ones most attractive and promising for the above reaction. Anantan et al. studied catalytic systems containing platinum, gold, palladium, and ruthenium supported on TiO2 [6]. The maximum yield of unsaturated alcohols (65%) was observed using platinum-containing catalysts. However, this result was achieved at a temperature of 90°C and a pressure of 100 atm—rather harsh conditions for carrying out the reaction in the presence of noble metals. High selectivity towards unsaturated alcohols was observed using a Pd–Sn bimetallic catalyst. However, the observed increase in selectivity when Pd was doped with tin was mainly due to a reduction in catalytic activity, since high selectivity with respect to unsaturated alcohols (>80%) was achieved at conversion below 20% [7]. At the same time, monometallic palladium systems are highly active under the chosen reaction conditions (140°C, 70 atm), but products of selective carbonyl group hydrogenation do not form [7]. Carrying out the reaction at a lower temperature or pressure results in a considerable drop in the yield of nerol and geraniol. The use of a Pt–Fe/MWCNT bimetallic catalytic system allows to obtain nerol and geraniol with a yield of 60%. However, increased hydrogen pressure and an elevated temperature (20 atm, 80°С) are also required to achieve citral conversion of more than 50% [8]. High selectivity in the formation of nerol and geraniol was noted for a Pt/MWCNT catalytic system doped with Fe and Ga, which allowed to perform the reaction at atmospheric pressure and a temperature of 80°C, but at very low loads on the catalyst (<20). This greatly limits practical use of the process [9].

The problem of selective nerol and geraniol production with a high yield but without the use of high pressure and temperature is therefore of considerable scientific and practical interest. In this work, we show for the first time that the selective production of unsaturated alcohols via citral hydrogenation is quite possible using catalysts with platinum contents of 0.25–1 wt % at room temperature and atmospheric pressure.

EXPERIMENTAL

Synthesis of Catalysts

The synthesis of CeO2–ZrO2 (CZ) mixed oxide supports was performed via the coprecipitation of metal precursors [10–12]. As initial materials, we used ZrO(NO3)2 · 8H2O (99.5%; up to 4% of Hf; Acros) as the precursor of zirconium oxide, and (NH4)2Ce(NO3)6 (98+%, Alfa Aesar) as a precursor of cerium oxide.

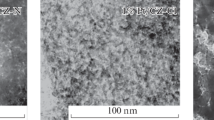

Catalyst with a platinum content of 1 wt % was synthesized via the pH-controlled deposition of precursor H2PtCl6. The resulting catalyst was reduced in a hydrogen flow over 2 h at a temperature of 250°С [10–12].

Catalytic Testing

The liquid-phase hydrogenation of citral was carried out at P = 1 atm and T = 25°C. The catalyst (13 or 25 mg) was placed in a two-necked flask, and the system was purged with hydrogen for 30 min. A solution of 0.3 mmol of citral in 1.5 mL of EtOH was then poured into the reactor using a feed valve. Depending on the content of platinum in the catalyst, the amount of Pt in the reaction mixture was 0.8–0.2 mol %. The reaction mixture was stirred with a magnetic stirrer at a speed of 1400 rpm. At the end of each experiment, the liquid phase was separated from the catalyst via centrifugation and the supernatant was sampled to analyze the reaction products.

The liquid reaction products were analyzed using a Chromatek Crystal 5000.2 gas chromatograph with a flame-ionization detector and a FFAP capillary column (0.2 mm × 25 m). The column temperature was raised stepwise from 80 to 190°С. The peaks were identified using experimentally determined retention times for individual compounds (citral, citronellal, citronellol, nerol, geraniol, and ethanol). The structure of the obtained compounds was confirmed by 1H and 13С NMR spectroscopy.

RESULTS AND DISCUSSION

Figure 1 shows the general scheme of the citral hydrogenation reaction.

The reaction can proceed by two parallel routes. Since the hydrogenation of the C=C bond is thermodynamically more favorable than reduction of C=O, mainly citronellal (3) is formed. It is then hydrogenated to produce citronellol (4) [13]. At the same time, citronellol (4) is also a product of the hydrogenation of unsaturated alcohols nerol and geraniol (2). To prevent further hydrogenation of the desired compounds and increase their yield, the reaction was performed at room temperature and atmospheric pressure on Pt/CZ catalysts. The activity of these catalysts under mild conditions was confirmed earlier by our research group on the example of hydrogenation of other carbonyl [10, 11] and nitroaromatic compounds [12].

Figure 2 shows the results of citral hydrogenation on catalysts with different platinum contents. In addition to nerol and geraniol, we observed the formation of citronellal and citronellol. The catalyst with an active metal content of 0.25 wt % showed relatively low activity under the chosen conditions. The conversion in this case did not exceed 10%. When the content of platinum was doubled, however, the conversion rose to 94% with a selectivity toward nerol and geraniol of around 40%. The 1% Pt/CZ catalyst exhibited the best activity at room temperature and atmospheric pressure, where conversion exceeded 98% with selectivity of more than 46%.

Some researchers have noted the important role played by the presence of alkali in the reaction medium [14, 15]. The authors argue in particular that the presence of such compounds as NaOH or Na2CO3 in the solution ensure a considerable increase in selectivity torwards the product of C=C bond hydrogenation. At the same time, other researchers believe that presence of OH groups on the surface of support promotes better adsorption of citral and thus its selective hydrogenation due to polarization of the C=O bonds [16, 17]. We performed a series of experiments to study the effect of alkali concentration in the reaction mixture on the yield of target products (Table 1).

From Table 1, we can see that increasing the NaOH content from 3 to 10 mol % had a positive effect on the yield of desired products. The citral conversion become almost 2 times higher. However, further raising the concentration of alkali in the solution lowered the conversion and selectivity. We suggest that this is associated with the formation of acetals by the base-catalyzed reaction between the substrate and the solvent. This phenomenon was described earlier in works on the hydrogenation of various carbonyl compounds in alcohol media [18, 19]. When the alkali content was increased to more than 10 mol %, the fraction of acetals also increases. This in turn decreases the rate of aldehyde hydrogenation (Fig. 3). In addition, the presence of alkali in a high concentrations can block the active sites of the catalyst.

After selecting the optimum composition of the reaction medium and the catalyst that exhibited the best activity at a room temperature and atmospheric pressure, we investigated the time dependences of the citral conversion and selectivity towards different hydrogenation products (Fig. 4).

Conversion of 94% and selectivity towards desired products of 59% were achieved in 2 h. It should be noted that at different hydrogenation times, the selectivity toward nerol and geraniol formation remained unchanged. These unsaturated alcohols did not undergo further hydrogenation of the C=C double bond, and the formation of citronellol proceeds exclusively via hydrogenation of intermediate product citronellal (Fig. 1). The maximum yield of nerol and geraniol achieved at room temperature and atmospheric pressure, was 55%.

CONCLUSIONS

Monometallic catalysts based on Pt nanoparticles supported on CeO2–ZrO2 oxide showed high activity and selectivity in the hydrogenation of citral to unsaturated alcohols at room temperature and atmospheric pressure. The maximum citral conversion of 94% with a selectivity towards the mixture of nerol and geraniol of 59% was achieved at a Pt content of only 0.2 mol %. It was shown that adding NaOH to the reaction mixture in amounts of up to 10 mol % has a positive effect on the yield of the desired products. However, further increase in alkali concentration impairs conversion and selectivity as a result of base-catalyzed interaction between the aldehyde and ethanol with formation of acetals.

REFERENCES

S. Clarke, Essential Chemistry for Aromatherapy, 2nd ed. (Churchill, Livingstone, 2008).

S. Gryglewicz, A. Sliwak, J. Cwikta, et al., Can. J. Chem. Eng. 94, 1328 (2016).

E. Bailón-García, F. Carrasco-Marín, and A. F. Pérez-Cadenas, Catal. Commun. 82, 36 (2016).

E. Asedegbega-Nieto, B. Bachiller-Baeza, A. Guerrero-Ruiz, et al., Appl. Catal., A 300, 120 (2006).

J. Court, J. Jablonski, and S. Hamarthibault, Stud. Surf. Sci. Catal. 78, 155 (1993).

S. A. Ananthan, R. Suresh, K. Giribabu, et al., Chem. Sci. Trans. 2 (S1), 111 (2013).

A. Vicente, G. Lafaye, C. Especel, et al., J. Catal. 283, 133 (2011).

P.-F. Qu, J.-G. Chen, Y.-H. Song, et al., Catal. Commun. 68, 105 (2015).

J. P. Stassi, V. I. Rodríguez, M. J. Yañez, et al., Catal. Lett. 147, 1903 (2017).

K. V. Vikanova and E. A. Redina, Russ. J. Phys. Chem. A 92, 2355 (2018).

K. V. Vikanova, E. A. Redina, G. I. Kapustin, N. A. Davshan, and L. M. Kustov, Russ. J. Phys. Chem. A 93, 231 (2019).

E. A. Redina and K. V. Vikanova, Russ. J. Phys. Chem. A 92, 2374 (2018).

J. P. Stassi, V. I. Rodríguez, M. J. Yañez, et al., Catalysts 3, 853 (2013).

V. Satagopan and S. B. Chandalia, J. Chem. Technol. Biotechnol. 59, 257 (1994).

K. C. Tin, N. B. Wong, R. X. Li, et al., J. Mol. Catal. A 137, 113 (1999).

H. J. Jiang, H. B. Jiang, D. M. Zhu, et al., Appl. Catal., A 445–446, 351 (2012).

S. I. Fujita, Y. Sano, B. M. Bhanage, et al., J. Catal. 225, 94 (2004).

U. K. Singh and M. A. Vannice, Appl. Catal., A 213, 1 (2001).

A. B. Merlo, B. F. Machado, V. Vetere, et al., Appl. Catal., A 383, 43 (2010).

Funding

This work was supported by the Russian Science Foundation, grant no. 17-73-20282.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Polyakov

Rights and permissions

About this article

Cite this article

Vikanova, K.V., Redina, E.A. Selective Hydrogenation of Citral on Pt-Containing Catalysts at Room Temperature and Atmospheric Pressure. Russ. J. Phys. Chem. 93, 2566–2569 (2019). https://doi.org/10.1134/S0036024419120318

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024419120318