Abstract

Changes in the structure and phase composition of the high-strength Ti–5Al–5Mo–5V–3Cr alloy after quenching in water and in air from the temperatures of heating corresponding to the β field (in the range of 860–1000°C) and upon subsequent continuous heating have been studied using the methods of optical, scanning, and transmission electron microscopy, X-ray diffraction, microprobe, and thermal analyses, and hardness. It has been shown that the temperature of heating to a significant extent influences the structure of the Ti–5Al–5Mo–5V–3Cr alloy after cooling. In the case of a significant overheating above the temperature of the polymorphic transformation (Tpt +100–150°C), a large amount of vacancies arise, which activate the diffusion processes and promote the appearance of “precipitates” upon cooling in air in the form of single or intersecting packets of very thin plates (with a thickness of 3–5 μm) enriched in Al, Mo, Cr and with a bcc lattice similar to that of the β matrix. Upon subsequent continuous heating, this leads to the inhibition of the decomposition of the metastable matrix β solid solution with the formation of intermediate phases by a homogeneous mechanism and activates the diffusion β → α transformation (as compared to quenching in water), which occurs by the heterogeneous mechanism of decomposition.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The titanium alloy Ti–5Al–5Mo–5V–3Cr (VST5553) developed in the PAC “VSMPO-AVISMA Corporation” [1] is applied widely in the production of stamped forgings for the aircraft chassis [2] due to enhanced strength, compared to the Ti–10V–2Fe–3Al alloy, after a strengthening heat treatment [3] and due to a high resistance to the propagation of cracks after the treatment by the BASCA regime [4, 5]. Due to the high hardenability [6], the alloy in the production process can be subjected to a treatment for the metastable β solid solution with heating into the β region and the subsequent quenching both in water and in air. However, to date, data on the phase composition formed in the alloy in the course of quenching and subsequent heating remain complete, since they are mainly obtained after quenching in water [7–9] and media with a higher cooling rate as compared to air [10]. There are almost no investigations on the formation of the structure of the VST5553 alloy as a result of a mild quenching in air and on the processes of the subsequent decomposition of the fixed metastable β solid solution upon heating. Therefore, in this work we studied the influence of quenching parameters (heating temperature, holding time, cooling environment (water or air)) on the stability of the β solid solution in the Ti–5Al–5Mo–5V–3Cr alloy with respect to the decomposition both upon quenching and subsequent continuous heating.

EXPERIMENTAL

As the material for the investigation, we used the Ti–5Al–5Mo–5V–3Cr alloy with the temperature of the polymorphic α + β → β transformation Tpt = 855°C. Samples with a size of 15 × 20 × 20 mm were cut out from a pressed workpiece. The workpiece was obtained by the deformation in the β region, cooled in air, and aged at 600°C. The quenching operation consisted in heating the β field to 860, 900, 950, and 1000°C, holding at these temperatures for 30 min or 2 h, and then cooling in water or air.

The investigations were performed using the following techniques: optical microscopy (OM), scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD) phase analysis, electron microprobe analysis (EMPA), thermal and durometric analyses. For a metallographic analysis, an Olympus JX51 optical microscope at a magnification of 1000 was used. The β-grain size and the volume fraction of the precipitates were determined by the random-intercepts method and grid method [11], respectively. The SEM study was carried out using a JSM6490LV device with a special Oxford Inca attachment for the EMPA. The TEM studies were carried out using a JEM-2100 microscope at an accelerating voltage of 160 kV. The phase composition of the samples was determined using a Bruker Advance-D8 diffractometer in Cu Kα radiation in the range of angles 2θ = 33°–67°. The thermal analysis was carried out using an STA 449 C Jupiter device from the Netzsch firm, recording the thermograms in the 20°С to 1000°C range, with the heating rate of 20 K/min in the flowing atmosphere of high-purity argon. The Rockwell hardness (HRC) was measured on a Wilson hardness tester (5 measurements per sample).

RESULTS AND DISCUSSION

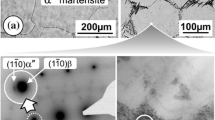

The analysis of the microstructure of the alloy in the initial state showed that the deformation in the β field with subsequent air cooling provides the development of recrystallization processes and the formation of almost equiaxed β grains (Fig. 1a) with an average size of 230 ± 20 μm.

The aging at 600°C promotes processes of decomposition of the metastable β solid solution fixed upon cooling from the temperatures of deformation and favors the formation of dispersed α particles in the bulk of β grains, which allows us to obtain an alloy hardness at a level of 42 HRC, characteristic of this aging temperature [12]. According to XRD data, the lattice parameters were determined to be a = 0.292 nm, c = 0.466 nm, c/a = 1.59 for the α phase and a = 0.321 nm for the β phase. The same lattice parameter for the β phase was obtained after the aging at 600°C in [5].

The quenching of the alloy from the temperature above Tpt in the interval of 860–1000°С leads to a coarsening of the initial β grains, which occurs the more actively, the higher the temperature (Figs. 1b, 1c) and the longer the holding time (Fig. 2a).

After the 2-h holding at 1000°C, the size of the initial β grains increased from 230 to 530 μm, i.e., by almost a factor of 2.5 (Fig. 2a). The replacement of the cooling environment from water to air upon quenching does not lead to a significant change in the size of β grains at the same heating temperatures and holding times, but changes in the structure in the bulk of grains (Figs. 1c, 1d) are observed.

After quenching in water, no precipitates of the second phases are present in the β grains (Fig. 1c). The quenching of the alloy in air leads to the appearance of the second phase in β grains (Fig. 1d). The distribution of precipitates in β grains is nonuniform: there are grains with both a large number of precipitates and almost without precipitates. With increasing heating temperature and holding time upon quenching in air, the volume fraction of precipitates in the alloy is increased and the precipitates occur in a larger number of β grains (Fig. 2b).

No lines of other phases except for the β solid solution have been revealed in the X-ray diffraction patterns of the samples cooled both in water and in air (Fig. 3), but after cooling in air, the β-phase lines begin to bifurcate, likely, as a result of the formation of two β solid solutions of different chemical compositions (Fig. 3b). Based on the XRD data obtained, the calculation of the lattice parameters of the fixed β solid solutions was carried out (Fig. 4).

After quenching in water, the lattice parameter of the metastable β phase remains almost unchanged in the range of the investigated temperatures (Fig. 4), likely, because of the identity of the chemical composition of β phase upon heating into the β region and because of the suppression of the diffusion processes in the alloy after cooling. In the case of the alloy subjected to soft quenching in air, the lattice parameters for the two β solid solutions were calculated on the basis of the bifurcation of the β-phase lines in the X‑ray diffraction patterns (Fig. 4).

The bifurcation of the lines indicates the formation of concentration isostructural decomposition of the β solid solution due to the development of diffusion processes upon slow cooling. On this basis, we believe that the precipitates found in the structure are regions of a β solid solution with chemical compositions differing from that of the matrix β phase due to the processes of segregation of the alloying elements in it. The processes of the phase separation of the β solid solution upon cooling were previously fixed in the alloys of systems Ti–Al–V [13], Ti–Al–Cr–V [14], Ti–Al–Mo [15], and Ti–Al–Mo–V–Cr–Fe [16] as an intermediate stage before the formation of second phases with a crystal lattice different from the β phase.

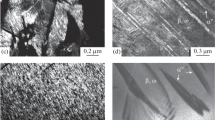

The investigation of the revealed isostructural β precipitates by SEM has shown that they can be oriented in a certain way in the grain body and represent either single plates (Fig. 5a) or packets (3–5 μm thick) of thin plates (Fig. 5b).

The EMPA method (Table 1) showed that the chemical composition of the microregions with multicomponent precipitates (marked by arrows 1, 2, 3 in Fig. 5a) is characterized by the enrichment in the α stabilizer (in aluminum) and in β stabilizers (in molybdenum, chromium, and partly in iron), and is depleted of vanadium as compared to the chemical composition of the β matrix (marked with arrows 4, 5 in Fig. 5a). The simultaneous enrichment of the regions of the β solid solution in aluminum and β stabilizers was observed in the VT22I alloy with the alloying system close to that of the Ti–5Al–5Mo–5V–3Cr alloy [17]. The authors of [17] associated this phenomenon with the process (fixed by TEM) of ordering of the A7B type in the β solid solution, where A are the atoms of titanium, and B are the atoms of aluminum and of β stabilizers. In this work, no superlattice reflections indicating the ordering process were revealed according to the electron diffraction patterns taken from the β solid solution using the TEM method (Fig. 6). The differences observed between the structures of the VT22I and VST5553 alloys are likely connected with the higher aluminum content in the VST5553 alloy as compared to VT22I, which does not make it possible to obtain the stoichiometric composition necessary for ordering in the microvolumes of the precipitates formed upon the phase separation.

The analysis of the TEM data (Fig. 6) confirmed the XRD data, which indicated that there is only a β‑solid solution with a bcc lattice in the alloys cooled both in water and in air. Upon cooling in water, rather uniformly distributed single dislocations in the form of loops and a small number of dislocation clusters in the form of “bands” are observed in the β matrix (Fig. 6a), whereas, when cooled in air, the number of dislocation pileups of this form increases sharply and many bands intersect with each other (Fig. 6b, 6c). A specific feature of the electron diffraction patterns taken from such regions was the presence of diffuse scattering, which was seen in the form of streaks oriented along the directions 〈112〉β (Fig 6c). According to [18, 19], the observed configuration of streaks is associated with the appearance of a short-range order in atomic displacements in the β matrix leading to the formation of atomic configurations whose symmetry is characteristic of the hcp lattice of the α precipitates.

The average hardness values almost do not change after the different quenching modes and are ~31–32 HRC that are typical of the Ti–5Al–5Mo–5V–3Cr alloy quenched from the β field [12].

The comparison of the presented data obtained by various methods of the structural and chemical analysis shows that the fixed precipitates have a bcc lattice, i.e., are isostructural to the β matrix, but are enriched in the alloying elements (Al, Mo, Cr). On this basis we believe that these precipitates represent a new isostructural phase based on the β solid solution that appeared as a result of its decomposition with respect to the alloying elements upon the mild quenching in air. The decomposition process occurs more actively at higher heating temperatures in the β region. As an explanation, we propose the following. The increase of the temperature of heating for quenching, as is known [20], promotes the formation of a larger number of the equilibrium vacancies in the alloy, which activates the development of diffusion processes of decomposition of the β solid solution upon cooling, providing the formation of a larger volume fraction of precipitates (Fig. 2b). Because of the determining role of vacancies in the formation of precipitates, they are practically absent near the grain boundaries, which serve as efficient sinks for vacancies (Fig. 1d).

According to the known concentration dependence of the equilibrium vacancies on temperature С = exp(–E/kT) [20], where C is the concentration of vacancies in the alloy, E is energy necessary for the formation of 1 mole of vacancies in the alloy, k is the Boltzmann constant (8.617 × 10–5 eV/К), and T is the heating temperature in Kelvins, it was estimated how many times the concentration of vacancies increases when the quenching temperature rises from 860 to 1000°C.

It was found that at the values E = 1.35–2.70 eV typical of the titanium alloys based on the β phase [21], the С1000/С860 ratio lies in the range of 13–164; i.e., with an increase in the quenching temperature from 860 to 1000°C, the concentration of vacancies increases by 1–2 orders of magnitude; this affects, upon cooling in air, the rate of development of the decomposition processes with the formation of the precipitates.

To estimate the influence of the metastable state produced by quenching on the processes of the subsequent decomposition, the stepwise transformation of the matrix metastable β solid solution in the samples quenched from 1000°C in water and in air upon their continuous heating was studied by the differential scanning calorimetry (DSC) (Fig. 7).

In the heating thermograms, two exothermic effects were revealed in the temperature intervals of 140–300°C and 360–680°C. Based on the analysis of the literature data on the processes of decomposition of a metastable β solid solution in the titanium alloys upon heating [15, 22], the low-temperature exothermic effect in the range of ~140–300°C is due to the formation in the β matrix of the pre-precipitates of the intermediate ω phase (Vω) or of the low-temperature αl phase (Vαl). In our case, according to the electron-microscopic data (Fig. 6), which indicate the presence in the quenched alloys of atomic displacements similar to those in α-phase, these species can be the pre-precipitates of the αl phase (Vαl). It is known [22] that the formation of the Vαl pre-precipitates occurs by a homogeneous mechanism of decomposition. Therefore, an important role in this process should belong to the concentration of vacancies created in the material before the action of the continuous heating on this material. Since, upon the mild quenching of the samples in air, the processes that favor the formation of pre-precipitations have already been running, upon the subsequent heating they receive less development than in the samples quenched in water, where these processes were “frozen”, but yet, a greater amount of nonequilibrium vacancies are still retained. As a result, the intensity of the low-temperature effect is higher in the water-quenched samples (see Fig. 7).

The exothermic effect in the 360–680°C interval has a complicated form because of the superposition of two exoeffects, namely, one that occurs in the 360–520°C interval, and second, at higher temperatures, up to 680°C. The exoeffect fixed in the 360–520°C range, according to the data of papers devoted to the alloys of the same class [22, 23], is associated with the decomposition of β solid solution with the formation of the low-temperature αl (\(\alpha _{{{\text{iso}}}}^{''}\)) phase with an orthorhombic lattice according to an intermediate mechanism having features of a shear and a diffusion transformations. This exoeffect is gradually replaced by the second, more high-temperature exoeffect, which is characteristic, according to the data of [23], of the occurrence of the diffusion β → α transformation, with the formation of equilibrium α phase with an hcp lattice by heterogeneous mechanism of the nucleation at dislocations and grain boundaries. In this interval of temperatures, the dissolution of the previously precipitated nonequilibrium αl phase or its transformation into the equilibrium α phase can also occur. The retention of a higher concentration of nonequilibrium vacancies after the sharp quenching in water explains the greater integral intensity of the exothermic effect associated with the intermediate transformation by the homogeneous mechanism as compared to the magnitude of the effect of the diffusion transformation by a heterogeneous mechanism upon the mild quenching in air (see Fig. 7).

An increase in the holding time from 30 min to 2 h upon quenching in water appears to promote the retention of a larger amount of quenched vacancies because of a decrease in the length of β-grain boundaries which serve as sinks for vacancies in the larger grains (Fig. 2a). As a result, after a 2-h holding, the intermediate β → αl transformation occurs more completely by the homogeneous mechanism at temperatures of 360–520°C, and the diffusion β → α transformation by the heterogeneous mechanism at higher heating temperatures occurs less actively; and vice versa, after a 30 min-holding (Fig. 7).

The change in the time of holding at 1000°C from 30 min to 2 hs for the samples cooled in air promotes to decrease the intensity of the low-temperature exoeffect in the 140–300°C range and an increase in the magnitude of the exoeffect in the 360–680°C temperature range. We associate this change in the behavior of the exoeffects with the different concentration of vacancies arising upon the mild quenching in air after holding for 30 min and for 2 h. As it was established earlier (Fig. 2b), the amount of observed precipitates after the 2-h holding is more than after the 30-min holding; correspondingly, the concentration of the nonequilibrium vacancies retained upon cooling from 30-min holding is higher than that after the 2-h holding. Therefore, the low-temperature transformation after the 30-min holding occurs more actively, and the high-temperature transformation, on the contrary, is inhibited and this is seen in the behavior of the effects.

Based on the above data, the presence of precipitates found in the Ti–5Al–5Mo–5V–3Cr alloy after the mild quenching in air (Figs. 1, 2) and, apparently, the smaller amount of retained nonequilibrium quenched vacancies in the structure inhibit, upon the subsequent heating, the processes of the decomposition of the β solid solution in the low-temperature region by the homogeneous mechanism and activate the β → α transformation by the heterogeneous mechanism.

CONCLUSIONS

It has been shown that the heating temperature in the β region exerts a significant influence on the structure of the Ti–5Al–5Mo–5V–3Cr alloy after quenching. In the case of a significant overheating (to Tpt + (100–150 K)), there is a substantial increase in the number of vacancies, which activate the diffusion processes in the alloy, leading to the appearance of isostructural β precipitates in the form of single or the intersecting packages of thin plates (3–5 μm thick) upon quenching in air, but do not form their own crystal lattice during decomposition of the β matrix. This leads upon the subsequent continuous heating of the mildly quenched alloy to a retardation, as compared to the alloy quenched in water, of the processes of the decomposition of the β solid solution in the low-temperature region by a homogeneous mechanism and to the activation of the β → α transformation by a heterogeneous mechanism of decomposition.

REFERENCES

V. V. Tetyukhin, Yu. I. Zakharov, and I. V. Levin, RF Patent 2 169 204 (2001).

J. D. Cotton, R. D. Briggs, R. R. Boyer, S. Tamirisakandala, P. Russo, N. Shchetnikov, and J. C. Fanning, “State of the art in beta titanium alloys for airframe applications,” JOM 67, 1281–1303 (2015).

V. V. Tetyukhin, I. V. Levin, and A. V. Volkov, New Titanium Alloys of VSMPO-AVISMA Co., in Proceedings of the 1st Russian Conference “Blacksmiths of the Ural – 2005” (UGTU-UPI, Ekaterinburg, 2005), pp. 412–417 [in Russian]

R. D. Briggs, US Patent 7785429 (2010).

S. L. Demakov, D. V. Gadeev, A. G. Illarionov, and O. M. Ivasishin, “Effect of heat treatment on the structure and fracture behavior of titanium alloy VST5553,” Metalloved. Term. Obrab. Met., no. 8, 26–31 (2015).

J. C. Fanning, “Properties of TIMETAL 555 (Ti–5Al–5Mo–5V–3Cr–0.6Fe),” J. Mater. Eng. Perform. 14, 788–791 (2005).

S. Nag, R. Banerjee, R. Srinivasan, J. Y. Hwang, M. Harper, and H. L. Fraser, “ω-Assisted nucleation and growth of a precipitates in the Ti–5Al–5Mo–5V–3Cr–0.5Fe β titanium alloy,” Acta Mater. 57, 2136–2147 (2009).

N. Clement, A. Lenain, and P. J. Jacques, “Mechanical property optimization via microstructural control of new metastable beta titanium alloys,” JOM 59, 50–53 (2007).

V. A. Bykov, T. V. Kulikova, L. B. Vedmid’, A. Ya. Fishman, K. Yu. Shunyaev, and N. Yu. Tarenkova, “Thermophysical properties of Ti–5Al–5V–5Mo–3Cr–1Zr titanium alloy,” Phys. Met. Metallogr. 115, 705–709 (2014).

N. G. Jones, R. J. Dashwood, M. Jackson, and D. Dye, “β Phase decomposition in Ti–5Al–5Mo–5V–3Cr,” Acta Mater. 57, 3830–3839 (2009).

A. M. Vasserman, V. A. Danilkin, O. S. Korobov, V. G. Kudryashov, N. M. Naumov, V. M. Polyakov, V. S. Sinyavskii, G. I. Fridman, and S. S. Khayurov, Methods of Control and Study of Light Alloys (Metallurgiya, Moscow, 1985) [in Russian].

N. Wain, X. J. Hao, G. A. Ravi, and X. Wu, “The influence of carbon on precipitation of α in Ti–5Al–5Mo–5V–3Cr,” Mater. Sci. Eng., A 527, 7673–7683 (2010).

E. L. Harmon and A. R. Troiano, “β-transformation characteristics of Ti alloyed with V and Al,” Trans. ASME 53, 43–53 (1961).

G. H. Narayanan and T. F. Archbold, “Decomposition of the metastable β-phase in all-beta-alloy TiV13Cr11Al3,” Met. Trans., no. 1, 2281–2290 (1970).

U. Zwicker, Titanium and Titanium Alloys (Springer, Berlin, 1974).

F. V. Vodolazskii, A. G. Illarionov, A. A. Popov, M. O. Leder, A. V. Zhloba, and A. V. Skidan, “A study of isothermal decomposition of β-solid solution in titanium alloy VST2,” Metalloved. Term. Obrab. Met., No. 8, 11–16 (2015).

A. G. Illarionov, A. V. Korelin, A. A. Popov, S. M. Illarionova and O. A. Elkina, “Formation of the structure, phase composition, and properties in high-strength titanium alloy upon isothermal and thermomechanical treatment,” Phys. Met. Metallogr. 119, 780–788 (2018).

I. V. Lyasotskii, V. S. Lyasotskaya, L. S. Krasnoyartseva, and E. A. Feoktistova, “Structural changes during heating of complex titanium alloy,” Fiz. Met. Metalloved. 49, 1307–1311 (1980).

Yu. D. Tyapkin, “Electron diffraction (application of the method of diffuse scattering of electrons in physical metallurgy),” Sb. “Itogi Nauki i Tekhniki”, Seriya “Metallovedenie i Termicheskaya Obrabotka” 11, 113–152 (1977) [in Russian].

M. A. Shtremel’, Strength of Alloys. Ch. 1. Lattice Defects (MISiS, Moscow, 1999) [in Russian].

C. J. Smithells, Metals Reference Book. (Butterworths, London, 1976; Metallurgiya, Moscow, 1980).

A. A. Popov, L. I. Anisimova, and V. D. Kibal’nik, “Investigation of the decomposition of the metastable β phase upon continuous heating of titanium alloys,” Fiz. Met. Metalloved. 52, 829–837 (1981).

P. Barriobero-Vila, G. Requena, S. Schwarz, F. Warchomicka, and T. Buslaps, “Influence of phase transformation kinetics on the formation of α in a β-quenched Ti–5Al–5Mo–5V–3Cr–1Zr alloy,” Acta Mater. 95, 90–101 (2015).

FUNDING

The work was supported by resolution no. 211 of the Government of the Russian Federation, contract no. 02.A03.21.0006, and by the state task within the framework of the basic theme no. 11.8386.2017/8.9 of the Ministry of Education and Science of the Russian Federation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by G. Salnikov

Rights and permissions

About this article

Cite this article

Illarionov, A.G., Narygina, I.V., Illarionova, S.M. et al. Influence of Quenching Parameters on the Stability of the β Solid Solution in a High-Strength Titanium Alloy. Phys. Metals Metallogr. 120, 476–482 (2019). https://doi.org/10.1134/S0031918X19050053

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X19050053