Abstract

Using the positron annihilation spectroscopy method, the accumulation of vacancy-type defects in steels Kh16N15М3 and Kh16N15М3T1 alloyed with phosphorus has been studied at early stages of irradiation at a temperature of 573 К. The obtained data have showed that vacancies in the steels interact with phosphorus atoms at this temperature with the formation of immobile and low-mobile vacancy—impurity complexes, which results in the accumulation of vacancy-type defects. In the steel Kh16N15М3Т1 under irradiation, the formation of nanosized particles of intermetallic Ni3Ti precipitates occurs, which intensify recombination of point defects and reduce their accumulation as compared to the steel Kh16Н15М3. As this occurs, the presence of phosphorus in the steel Х16Н15М3Т1 likewise leads to the intensification of the accumulation of vacancy defects.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Structural materials used in nuclear reactors operate under severe conditions combining high temperature, corrosion action of heat carriers, mechanical stresses, vibrations, and intense neutron irradiation. Materials under these conditions degrade intensively, which markedly limits their employment and can sometimes lead to emergency situations. Modern problems facing the nuclear energetics (increase in the degree of burn-up of fuel, minimization of radioactive wastes, etc.) and the development of new types of reactors place further heavy demands on the useful life of structural materials. Therefore, there is a pressing need for the development of materials with improved characteristics including mechanical strength, adequate plasticity, good radiation stability, and corrosion resistance [1, 2].

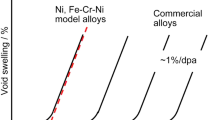

Austenitic stainless steels and alloys are among the materials that are most promising considering the above indicated requirements. These alloys were studied from the technological viewpoint, possess good service characteristics, are comparatively inexpensive, and their radiation damageability was investigated well enough. However, austenitic steels and alloys are subjected to radiation-induced swelling (increase in the linear dimensions upon irradiation), which is the main factor limiting their use. Void swelling is caused by the accumulation of vacancy-type defects in steels [1–4], which, in turn, relates to different effectiveness of interaction of point defects with microstructural features, in particular, with sinks such as dislocations, grain boundaries, etc.

One of the main methods of reducing void swelling in steels is their alloying with a small amount of impurities. Interacting with point defects, atoms of alloying elements form, together with them, vacancy—impurity and interstitial atom-impurity complexes and thus affect the behavior of point defects [5]. Titanium and phosphorus are currently considered promising alloying elements that enable the swelling of steels to be reduced [6–8]. Thus, when titanium interacts with vacancies, it affects their mobility and, hence, the swelling of steels. In addition, in steels alloyed with titanium at a level of 1 at % the decomposition of the solid solution takes place with the formation of second-phase precipitates (intermetallic precipitates, titanium carbides) that are sinks or centers of intensified recombination for point defects [5, 8–12].

The addition of phosphorus into austenitic stainless steels likewise retards void swelling under irradiation [6, 7]. However, mechanisms of retarding the evolution of porosity in steels upon addition of phosphorus have not been studied sufficiently. Three main mechanisms of the phosphorus effect were considered in the literature. Phosphorus in austenitic alloys is subdimensional impurity and, hence, at lowered temperatures can interact with interstitial atoms [6]. In this case the density of interstitial loops and their thermal stability increase noticeably. These loops, in turn, are sinks for migrating vacancies, reducing thereby vacancy supersaturation. The authors of [13] also showed that phosphorus in austenitic alloys is a rapidly diffusing impurity. In steels, as this takes place, the interaction of phosphorus atoms with vacancies is possible, which leads to an enhancement in the effective coefficient of their diffusion, increasing the probability of annealing of vacancies at sinks, and, as a result, decreases vacancy supersaturation. In addition, in steels alloyed with phosphorus, needle-shaped phosphides of Fe2P and Fe3P types may be formed in the process of irradiation at elevated temperatures [6]. These phosphides are incoherent to the matrix of steels. The matrix—precipitate interfaces of these phosphides contain misfit dislocations that are effective sinks for point defects.

Thus, the phosphorus effect on the retardation of swelling may be due to several causes, and this effect will depend on the irradiation temperature and phosphorus content. In addition, the presence of other coadditions likewise can exert an influence on it. Among other factors, there is an opinion that the stability and effectiveness of phosphides can be enhanced through the addition of titanium [7, 15–17]. Structure and phase transformations that take place upon the thermal action on austenitic steels alloyed with phosphorus and titanium are known. However, the processes of arising complex phosphides and their stability have not been studied until now. In addition, no radiation-induced structure and phase transformations in these steels were investigated.

Investigations of the behavior of point defects at early stages of irradiation (to 1 dpa (displacements per atom)) allow us to determine features of interaction of radiation defects with alloying elements and microstructural properties of steels. At these stages small defect accumulations arise in the form of nuclei of loops or three-dimensional clusters which, as the size grows, transform correspondingly into dislocation loops or voids. Thus, the structure of defect accumulations formed at early stages determines properties and defect structure arising in the material upon irradiation to high doses (1 dpa and more). In this case, the initial microstructure of the material formed before irradiation remains unaltered at low doses, which simplifies the understanding of the occurring processes.

One of the most effective methods for investigating the behavior of defects at early stages of irradiation is positron annihilation spectroscopy (PAS). Positrons are well-known probes for vacancy-type defects [13]. In addition, the PAS possesses a high sensitivity to defects both in their sizes (from 0.1 to 3 nm) and in the concentration (10–3–10–6 per atom). Owing to the high sensitivity and selectivity to vacancy-type defects, the PAS allows us to study the behavior of radiation defects at the initial stage of the radiation damageability (to 10–3 dpa).

The most effective method of creating defects for studying their interaction with microstructural elements of steels and alloys is electron irradiation. The electron irradiation, as distinct from neutron or ion irradiation, generates freely migrating point defects (vacancies and interstitial atoms). This allows us to study the interaction of different-type defects with impurities and imperfections of the crystal lattice of steels.

The purpose of this work is to investigate the influence of phosphorus and titanium on the accumulation of vacancy defects in austenitic stainless steels at early stages of irradiation at a temperature of 573 К.

EXPERIMENTAL

We investigated austenitic steels of types Fe16Cr15Ni3Mo (SS) and Fe16Cr15Ni3Mo1Ti (SSTi) alloyed with phosphorus in different concentrations and melted in a vacuum induction furnace. The phosphorus content in the steels is listed in Table 1. The concentrations were chosen so as to span the widest concentration range, yet below the solubility limit of phosphorus in steels. Steel ribbons were rolled to a thickness of 150–200 µm and were cut into plates of 10 × 10 mm2 in size. The resultant samples after electrolytic polishing were annealed at a temperature of 1323 K in an atmosphere of purified flowing helium for 0.5 h and then were rapidly water-quenched at a rate of ≈500 К/s

The steel samples were irradiated with 5-MeV-energy electrons on a linear accelerator at a temperature of 573 К. To provide homogeneous irradiation, scanning of an electron beam was performed over the sample surface. The temperature during irradiation was maintained with an accuracy of ≈5 K. The maximum fluence was 5 × 1022 electrons/m2, which corresponds, according to calculations within the modified Khinchin—Pease model [18], to the damaging dose ~5 × 10–4 dpa.

Vacancy defects formed under irradiation were diagnosed using the method of angular correlation of annihilation radiation (ACAR) which is one of the PAS procedures [13, 19]. The ACAR method was performed on a spectrometer with a resolution of 1 mrad × 160 mrad. Radionuclide 68Ge with activity ~400 MBq was used as a source of positrons. Each ACAR spectrum contained about 5 × 105 counts of coincidences. All measurements were conducted at room temperature. ACAR spectra represent dependences of the coincidence-reading rate on the angle θ, where θ is the deviation of the spreading angle of annihilation γ quanta from 180°. The angle θ = pz/m0c, where pz is the transverse component of the electron—positron pair momentum, m0 is the rest mass of electron, and c is the light velocity in vacuum. Since a positron in samples is thermalized, the magnitude of θ is determined by the momentum of annihilating electron. Thus, the ACAR spectrum describes the pulse distribution of annihilating electrons. The procedure of processing ACAR spectra was presented in detail in [19].

When positrons are trapped by vacancy defects or dislocations, changes in the shape of ACAR spectra occur, since the electron structure of defects differs from that of steels. These changes are characterized by the standard parameter S, whose magnitude is defined as a ratio of the area under a low-momentum (pz ≤ 3 × 10–3m0c) part of the spectrum to the total area under the spectrum. The low-momentum region of the spectrum corresponds to annihilation of positrons with valence electrons. The changes in this region of the ACAR spectrum and, correspondingly, in the parameter S are determined by the concentration of trapping centers for positrons as follows:

where λf is the rate of positron annihilation in the free (Bloch) state, μd is the rate of positron trapping by vacancy-type defects, С0 is the concentration of vacancy defects, and Sf and Sd are the S values characterizing positron annihilation from the free state and the state trapped by defects, respectively.

The structure of irradiated samples was investigated with the help of transmission electron microscopy (TEM). The samples in the form of 5 × 5 mm plates 0.2 mm thick were thinned in a mixture of orthophosphoric acid and chromium anhydride and were studied on a JEM 200CX electron microscope at an accelerating voltage of 160 kV.

RESULTS AND DISCUSSION

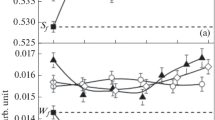

Figure 1 displays dependences of the parameter S on the electron fluence for samples of SS-series steels with different phosphorus content. This figure also indicates the value Sf = 0.526 corresponding to positron annihilation from the free (Bloch) state. As can be seen from the figure, the initial (before irradiation) S value for a steel sample with the minimum phosphorus content coincides with the Sf value. This points to the fact that there is a lack of defects (vacancies, vacancy clusters, dislocations, etc.) capable of positron trapping. In the other two steel samples, the initial S values exceed the Sf value, which indicates the presence of some amount of defects capable of positron trapping. Vacancy defects in this steel at a temperature of 1323 К are effectively annealed [18]. At the same time, positrons can be trapped by dislocations. In all the samples, according to the TEM data, dislocations are present: these supposedly were formed during rolling and retained after annealing and quenching. The density of dislocations present in samples is shown in Table 2. As we can see from the tabular data and Fig. 1, S values in the initial (before irradiation) state correlate with the density of dislocations present in samples.

In all the samples, with growth of fluence to Φ = 2 × 1022 m–2 a sharp increase in the parameter S was observed, which is due to the formation of vacancy-type defects therein. The results of our investigations of these steels and model alloys showed [18, 19] that in steels upon irradiation at a given temperature two-dimensional vacancy accumulations (nuclei of vacancy loops) are formed. Positron trapping by vacancy loops results in the growth of the parameter S. When the fluence increases further, growth of the parameter S decreases markedly. At these fluences the concentration of vacancy accumulations reaches the value at which they effectively absorb migrating interstitial atoms. As this occurs, there is a quasistationary state in which the rate of formation of defects and the rate of their disappearance are close to each other. As a result, the rate of accumulation of vacancy defects and, correspondingly, the rate of growth of the parameter S depending on the fluence decreases substantially. It should be noted that when the fluence Φ ≥ 2 × 1022 m–2, growth of the parameter S for samples directly depends on the phosphorus content. Thus, the greatest growth is observed for a steel sample containing 0.1 wt % Р. For a sample with the minimum phosphorus content, with growth of the fluence even a small decrease in the parameter S occurs.

Figure 2 shows dependences of the parameter S on the electron fluence for samples of SSTi-series steels with different phosphorus content. In the initial (before irradiation) state, S values for steel samples containing 0.005 wt % Р and 0.06 wt % Р exceed the Sf value, which is caused by the presence therein of a considerable amount of dislocations (see Table 2).

With growth of the fluence, the S value for the sample containing 0.005 wt % phosphorus remains almost unaltered. Dislocations present in the sample seem to effectively absorb vacancies. For the sample containing 0.06 wt % Р, the parameter S increases up to Φ = 2 × 1022 m–2 and then decreases. For the sample with high (0.1 wt %) phosphorus content, the parameter S at Φ ≥ 2 × 1022 m–2 continues to grow.

Thus, the results of irradiation show that phosphorus intensifies the accumulation of vacancy defects in both steels at the given irradiation temperature. Vacancies in steels possess a high mobility at this temperature [18]. Intensification of accumulation of the vacancy-type defects appears to be caused by the interaction of phosphorus atoms with vacancies and by the formation of immobile or low-mobile vacancy—impurity atom complexes. The decrease in the mobility of vacancies reduces the probability of their recombination with interstitial atoms and annealing at sinks. In addition, these complexes trap migrating vacancies being thus centers for the formation of clusters. Two more possible processes presented in the introduction should be noted: these are the formation of the interstitial atom—phosphorus atom complexes and formation of phosphides. However, interstitial loops and incoherent precipitates arising in these cases are sinks for vacancies, and their presence should lead to a reduced accumulation of vacancy defects.

Influence of Titanium on the Accumulation of Vacancy Defects

Figure 3 displays dependences of the parameter S on the electron fluence for the samples of steels of SS- and SSTi-series with a content of 0.06 wt % Р. As we can see from the figure, the growth of the parameter S in a steel SSTi sample is appreciably suppressed as compared to the steel SS sample. From this it follows that the presence of titanium in steels leads to a substantial decrease in the accumulation of vacancy defects upon irradiation.

Dependences of the parameter S on the electron fluence for the samples of steels of SS- and SSTi-series with a content of 0.1 wt % Р are presented in Fig. 4. In the steel SSTi sample, as in the samples containing 0.06 wt % Р, the growth of the parameter S and, hence, accumulation of vacancy defects upon irradiation are suppressed as compared to the steel SS sample.

From the obtained data it can be assumed that in the SSTi steel upon irradiation, additional sinks or centers for recombination of point defects are formed. Our investigations of model Fe–Ni alloys showed [20, 21] that upon irradiation at a given temperature in alloys alloyed with titanium the radiation-induced formation of nanosized particles of Ni3Ti-type intermetallic precipitates occurs. These precipitates intensify recombination of point defects and, in so doing, markedly reduce the accumulation of vacancy defects in alloys [21]. The analogous effect can be seen in steels. The titanium content in the SSTi steel is 1 wt % (about 1.2 at %), which significantly exceeds the solubility limit of titanium in the steel [9]. Thus, in this case, upon irradiation, the occurrence of processes of decomposition of solid solution and formation of intermetallic precipitates are possible. These precipitates intensify recombination of point defects and reduce their accumulation as compared to the SS steel.

CONCLUSIONS

Using the PAS method, the accumulation of vacancy-type defects in steels Kh16N15M3 and Kh16N15М3Т1 alloyed with phosphorus was studied at the early stages of irradiation at a temperature of 573 К. The obtained data showed that at this temperature, vacancies in steels interact with phosphorus atoms with the formation of immobile or low-mobile vacancy—impurity complexes, which leads to an intensification of accumulation of the vacancy-type defects. In the steel alloyed with titanium, nanosized particles of intermetallic Ni3Ti precipitates are formed upon irradiation, and these intensify recombination of point defects and reduce their accumulation as compared to the steel not containing titanium. As this occurs, the presence of phosphorus in the steel alloyed with titanium likewise results in the accumulation of vacancy defects.

REFERENCES

S. J. Zinkle and Jeremy T. Busby, “Structural materials for fission & fusion energy,” Mater. Today 12, 12–19 (2009).

S. J. Zinkle and G. S. Was, “Materials challenges in nuclear energy,” Acta Mater. 61, 735–758 (2013).

F. A. Garner, “Recent insights on the swelling and creep of irradiated austenitic alloys,” J. Nucl. Mater. 122–123, 459–471 (1984).

J. F. Bates and R. W. Powell, “Irradiation-induced swelling in commercial alloys,” J. Nucl. Mater. 102, 200–213 (1981).

A. D. Braislford and R. Bullough, “Void growth and its relation to intrinsic point defect properties,” J. Nucl. Mater. 69–70, 434–450 (1978).

H. Watanabe, A. Aoki, H. Murakami, T. Muroga, and N. Yoshida, “Effects of phosphorus on defect behavior, solute segregation and void swelling in electron irradiated Fe–Cr–Ni alloys,“ J. Nucl. Mater. 155–157, 815–822 (1988).

H. Watanabe, T. Muroga, and N. Yoshida, “The temperature dependent role of phosphorus and titanium in microstructural evolution of Fe–Cr–Ni alloys irradiated in FFTF,” J. Nucl. Mater. 228, 261–274 (1996).

T. Okita, W. G. Wolfer, F. A. Garner, and N. Sekimura, “Effects of titanium additions to austenitic ternary alloys on microstructural evolution and void swelling,” Philos. Mag. 85, 2033–2048 (2005).

V. V. Sagaradze, B. N. Goshchitskii, V. L. Arbuzov, and Yu. N. Zuev, “Dispersion-hardening austenitic steel for fast-neutron reactors,” Metalloved. Term. Obrab. Met., No. 8, 13–20 (2003).

G. R. Odette, M. J. Alinger, and B. D. Wirth, Recent developments in irradiation resistant steels, Annu. Rev. Mater. Res. 38, 471–503 (2008).

C. David, B. K. Panigrahi, S. Balaji, A. K. Balamurugan, K. G. M. Nair, G. Amarendra, C. S. Sundar, B. Raj, “A Study of the effect of titanium on the void swelling behavior of D9 steels by ion beam simulation,” J. Nucl. Mater. 383, 132–136 (2008).

J. Arunkumar, S. Abhaya, R. Rajaraman, G. Amarendra, K. G. M. Nair, C. S. Sundar, and B. Raj, “Positron annihilation studies on D9 steel—Effect of Ti concentration,“ Phys. Status Solidi C 6, 2319–2321 (2009).

V. I. Grafutin and E. P. Prokop’ev, “Positron annihilation spectroscopy in materials structure studies,” Phys.–Usp. 45, 59–74 (2002).

F. A. Garner and W. G. Wolfer, “The effect of solute additions on void nucleation,” J. Nucl. Mater. 102, 143–150 (1981).

P. W. M. Jacobs, E. A. Kotomin, A. Stashans, E. V. Stefanovich, and I. Tale, “Quantum chemical simulations of hole self-trapping in corundum,” J. Phys.: Condens. Matter. 4, 7531–7544 (1992).

I. Shibahara, S. Ukai, S. Onose, and S. Shikakura, “Irradiation performance of modified 316 stainless steel for Monju fuel,“ J. Nucl. Mater. 204, 131–140 (1993).

V. D. Vijayanand, P. Parameswaran, M. Nandagopal, S. Panneer Selvi, K. Laha, and M. D. Mathew, “Effect of prior cold work on creep properties of a titanium modified austenitic stainless steel,” J. Nucl. Mater. 438, 51–57 (2013).

A. P. Druzhkov, V. L. Arbuzov, and D. A. Perminov, “Positron annihilation study of effects of Ti and plastic deformation on defect accumulation and annealing in electron-irradiated austenitic steels and alloys,” J. Nucl. Mater. 341, 153–163 (2005).

A. P. Druzhkov, D. A. Perminov, and N. L. Pecherkina, “Positron annihilation spectroscopy characterization of effect of intermetallic nanoparticles on accumulation and annealing of vacancy defects in electron-irradiated Fe–Ni–Al alloy,“ Philos. Mag. 88, 959–976 (2008).

A. P. Druzhkov, V. L. Arbuzov, D. A. Perminov, and K. V. Shal’nov, “Effect of precipitate particles of intermetallic compounds on the accumulation of radiation defects in austenitic Fe–Ni–Ti alloys,” Phys. Met. Metallogr. 96, 509–513 (2003).

D. A. Perminov, A. P. Druzhkov, and V. L. Arbuzov, “Role of intermetallic nanoparticles in radiation damage of austenitic Fe–Ni-based alloys studied by positron annihilation,” J. Nucl. Mater. 414, 186–193 (2011).

ACKNOWLEDGMENTS

This work was performed within a State Assignment of the Federal Agency of Scientific Organizations of the Russian Federation (theme Spin, no. 01201463330), supported by the Ural Branch of the Russian Academy of Sciences (project no. 18-10-2-22), and in part by the Russian Foundation for Basic Research (project no. 18-02-00270).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by I. Krasnov

Rights and permissions

About this article

Cite this article

Perminov, D.A., Druzhkov, A.P., Pecherkina, N.L. et al. Accumulation of Defects in Austenitic Stainless Steels with Phosphorus and Titanium Additions upon Electron Irradiation at 573 К Investigated Using Positron Annihilation Spectroscopy. Phys. Metals Metallogr. 120, 284–289 (2019). https://doi.org/10.1134/S0031918X19030098

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X19030098