Abstract

The results of studying the optical transmission and X-ray diffraction spectra of thin In2O3 films obtained by DC magnetron sputtering on Al2O3 (012) substrates are presented. The diffraction patterns contain a reflex corresponding to the (222) plane of cubic In2O3. Its position shifts from 30.3° to 30.6° with decreasing film thickness. The half-width of this reflex decreases with decreasing deposition time, which may indicate an increase in the grain size of the film material. According to measurements of optical transmission, at the interface between the film and the substrate, the presence of a transition layer with a band gap of 1.39 eV and a thickness of about 40 nm was established. The properties of this layer are independent of the deposition time.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 INTRODUCTION

In2O3 is a fairly well-known and well-studied semiconductor. Nevertheless, due to the unique combination of properties of high optical transparency (>80%) and high electrical conductivity, which, moreover, is very sensitive to the composition of the surrounding atmosphere, the interest of researchers in films of this material continues to this day. Doping of In2O3 with various impurities makes it possible to vary widely the properties of the films – electrical conductivity, sensitivity to various gases, etc. [1–3]. Due to their properties, films based on In2O3 have already found wide application as transparent conductors and are also promising materials for the creation of gas sensors. To ensure high sensitivity of the latter, it is important to have a developed surface on which reversible binding of the analyte occurs. The presence of a significant roughness on the surface of In2O3 films, which naturally forms during their growth, provides a large area of contact with the environment. The polycrystalline structure of films and the presence of mechanical stresses in them also increase the diffusion coefficients [4] and, accordingly, increase the sensitivity of sensors based on them.

The study of the optical transmission of thin films makes it possible to study not only the structure of the energy levels of the material, but also to determine the number and thickness of layers of multilayer coatings.

The magnetron sputtering method used by us is scalable and provides good reproducibility of film parameters.

2 EXPERIMENT

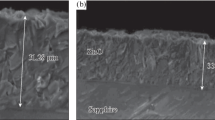

The investigated films were obtained on Al2O3 (012) substrates by dc-magnetron sputtering of an In2O3 target [5]. The deposition was carried out for 15, 35, 45, 60, 120, and 180 minutes at a current of 50 mA and a voltage of 300 V. The temperature of the substrates during the deposition was 600°C.

The films were studied by X-ray and spectrophotometric methods. X-ray measurements were carried out using Cuα radiation on a DRON-3 diffractometer equipped with a modernized system of automatic control and data recording. Optical transmission measurements were performed on a Shimadzu UV-2450 spectrophotometer in the wavelength range from 200 to 1000 nm.

3 RESULTS AND DISCUSSION

The obtained diffraction patterns of the films contain a reflection that shifts from 30.3° to 30.6° depending on the deposition time (Fig. 1). Its position is close to the position of the reflection corresponding to the (222) plane of the cubic In2O3 lattice (space group \(Ia\bar {3}\)), according to the data [6]. This, as well as the regular decrease in the intensity of the observed reflection with a decrease in the deposition time of the film, makes it possible to associate it with the (222) plane of the film material. The half-width of this reflex decreases with decreasing deposition time. This indicates that the average grain size of films with short deposition times is larger than films with long deposition times. A similar dependence of the grain size on the deposition time, according to the results of X-ray diffraction measurements, was also observed on similar films [7].

The rotation of the samples in the plane of their surface causes a sharp change in the intensity of the reflections of the Al2O3 substrate from zero to a maximum, which indicates a certain misorientation of the cut plane with the (012) Al2O3 plane. However, such a rotation has practically no effect on the intensity of the reflection near 30.6°, which once again confirms its belonging to the film material and speaks of the polycrystallinity of the films obtained.

The results of measurements of optical transmission show its anomalous decrease with decreasing wavelength. In addition, in the optical transmission curves of films with a long deposition time, an interference pattern is observed even in the low transmission region. To explain these results, a model of the investigated films was constructed (Fig. 2). According to this model, the films under study consist of three layers. The optical properties of the middle layer correspond to the cubic modification of In2O3 (space group \(Ia\bar {3}\)) according to [8]. The surface of the films is assumed to be rough and modeled as a homogeneous layer with optical properties calculated on the basis of the dielectric constant of the cubic modification of In2O3 and the filling factor of 0.5, in accordance with the Clausius–Mossotti equation. This is a common practice when simulating the rough surface of such films [9, 10].

However, the presence of only the indicated layers does not fully explain the observed optical transmission spectra. To fully explain them, a third layer is introduced into the model, located between the film and the substrate. It is obvious from the experimental data that it has a high extinction coefficient. The best description of the spectral dependence of the extinction coefficient of this layer is the law of fundamental absorption in a semiconductor with a band gap Eg = 1.39 eV for direct transitions:

where hν is the photon energy, A is a constant that does not depend on the photon energy. Since the value of the extinction coefficient of this layer is large (the imaginary part of the dielectric constant is much larger than the real one), the contribution of the refractive index to the reflection and transmission coefficients of this layer is small. Therefore, it is difficult to unambiguously determine its value from the measurement results. Therefore, any small number can be used as the refractive index of this layer, however, based on the assumption that its composition is somewhat similar to that of the film material, it was assigned the same spectral dependence of the refractive index as for the middle layer of the model. In addition, due to the high absorption, it is difficult to estimate the thickness d3 of this layer. The value of A was taken to be unity, since its contribution to the reflection and transmission coefficients of this layer cannot be unambiguously separated from the contribution d3.

The contribution of reflection from the substrate in this system does not play a significant role; nevertheless, the dispersion of its refractive index was taken into account.

On the whole, the transmission for the selected model of the studied films was calculated by exact formulas—using the scattering matrix for a system of plane-parallel homogeneous isotropic layers [11]. The nonmonochromaticity of the probe radiation was also taken into account by averaging the transmittance in the wavelength range corresponding to the used spectral width of the spectrophotometer slit, 5 nm.

The thicknesses of all layers were selected manually until the calculated transmission spectra corresponded to the experimental ones (Table 1).

Comparison of the optical transmission spectra calculated within the framework of the proposed model with the measurement results is in good agreement over the entire investigated wavelength range, with the exception of the 300–400 nm of region (Fig. 3). According to [8], a sharp increase in the refractive index of In2O3 begins in this region, which is associated with the onset of fundamental absorption. Apparently, the band gap of In2O3 in the films studied by us is somewhat larger than in the films studied by the authors of [8]. This is not surprising, since this material is characterized by a certain spread in the values of the band gap depending on the production conditions [12].

The formation of a transition layer at the interface with the substrate, apparently, does not require a large violation of the stoichiometry of the film, since this is possibly associated with the smearing of the band gap due to a large number of defects in the crystal structure, as well as the formation of impurity levels inside the band gap. The thickness of this layer is practically independent of the deposition time, and, therefore, its appearance is entirely due to the influence of the substrate surface.

The thickness of the rough layer on the film surface is also practically independent of the deposition time and is mainly determined by the deposition mode.

4 CONCLUSIONS

The proposed model of the investigated films makes it possible to describe their optical transmission spectra. The structure and properties of the bulk of the films, on the whole, correspond to the structure and properties of such films presented in the literature. The results of X-ray diffraction studies indicate an increase in the grain size of In2O3 with a decrease in the film thickness. The shift of the reflection corresponding to the (222) plane with an increase in the deposition time, as well as the presence of a transition layer with a band gap of 1.39 eV at the film–substrate interface, are caused by the effect of the substrate on the structure of the film material.

REFERENCES

K. Arshak, and K. Twomey, Sensors 2, 205 (2002). https://doi.org/10.3390/s20600205

A. K. Yewale, K. B. Raulkar, A. S. Wadatkar, and G. T. Lamdhade, J. Electron. Devices 544 (2011).

D. Мanno, M. Di Giulio, T. Siciliano, E. Filippo, and A. Serra, J. Phys. D: Appl. Phys 34, 2097 (2001). https://doi.org/10.1088/0022-3727/34/14/303

Yu. M. Nikolaenko, A. N. Artemov, Yu. V. Medvedev, N. B. Efros, I. V. Zhikharev, I. Yu. Reshidova, A. A. Tikhii, and S. V. Kara-Murza, J. Phys. D: Appl. Phys. 34, 2097 (2001). https://doi.org/10.1088/0022-3727/34/14/303

Yu. M. Nikolaenko, A. B. Mukhin, V. A. Chaika, and V. V. Burkhovetskii, Tech. Phys. 55, 1189 (2010). https://doi.org/10.1134/S1063784210080189

H. E. Swanson, N. T. Gilfrich, and G. M. Ugrinic, Circ. Bureau Standards, No. 539 (Natl. Bureau of Standards, 1955), Vol. 5, p. 26.

Z. Ghorannevis, E. Akbarnejad, and M. Ghoranneviss, J. Theor. Appl. Phys. 9, 285 (2015), https://doi.org/10.1007/s40094-015-0187-3

A. Schleife, M. D. Neumann, N. Esser, Z. Galazka, A. Gottwald, J. Nixdorf, R. Goldhahn, and M. Feneberg, New J. Phys. 20, 053016 (2018). https://doi.org/10.1088/1367-2630/aabeb0

D. Lehmann, F. Seidel, and D. R. T. Zahn, SpringerPlus 3, 82 (2014). https://doi.org/10.1186/2193-1801-3-82

A. A. Tikhii, Yu. M. Nikolaenko, A. S. Kornievets, K. A. Svyrydova, Yu. I. Zhikhareva, and I. V. Zhikharev, J. Appl. Spectrosc. 86, 1053 (2019). https://doi.org/10.1007/s10812-020-00939-x

H. G. Tompkins and E. A. Irene, Handbook of Ellipsometry (William Andrew, USA, 2005).

Z. M. Jarzebski, Phys. Status Solidi A 71, 13 (1982). https://doi.org/10.1002/pssa.2210710102

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by N. Petrov

Rights and permissions

About this article

Cite this article

Tikhii, A.A., Nikolaenko, Y.M., Zhikhareva, Y.I. et al. Spectral and X-Ray Studies of Indium Oxide Films on Sapphire Substrates. Opt. Spectrosc. 128, 1667–1670 (2020). https://doi.org/10.1134/S0030400X20100252

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0030400X20100252