Abstract—

The surface of the MA8 magnesium alloy, modified by laser treatment, was found to acquire superhydrophilic properties and high bactericidal activity against Escherichia coli K12 C600. The main mechanisms of bactericidal action were disruption of the integrity of the bacterial outer membrane, which was perforated by nanoparticles on a textured surface, and alkalization of the dispersion medium when it interacted with the metal. The proposed method opens up new prospects for metal protection against biocorrosion by creating superhydrophilic coatings with high bactericidal properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

The interest of the scientific community in the study of the behavior of magnesium and its alloys in different media and in development of novel magnesium-based materials for biomedicine has increased drastically in recent years. Such interest is fostered by the biocompatibility of magnesium, the possibility of using it in implants and other biodegradable devices and, finally, the attractive mechanical properties of magnesium alloys. One more highly valuable property of magnesium-based materials is their antibacterial potential, because infections are among the most serious adverse events associated with implantation of any device. Therefore, considerable efforts are made to study the bactericidal properties of the material with simultaneous analysis of its degradation rate. Previously, by the example of copper alloys we have shown that superhydrophilic surfaces obtained by laser texturing have a considerable antibacterial potential (Emelyanenko et al., 2019, 2020). As regards magnesium, aqueous suspensions of magnesium oxide or magnesium and magnesium alloy particles as fillers of polymer matrices used to control bacterial contaminations have been described so far (Li et al., 2018). One of the major problems of using the bactericidal properties of metals and their oxides is the poorly controllable distribution of particles in a liquid medium and their rapid sedimentation.

In the present work, we describe the method for preparing MA8 magnesium alloy plates decorated with micro- and nanoparticles of magnesium oxide providing for highly efficient decontamination of drops of bacterial (Escherichia coli K12 C600) cell suspension. The observed kinetics of decontamination on magnesium surfaces makes magnesium alloys with described coatings a promising material for the surfaces frequently touched by infected patients in healthcare facilities. Such surfaces are door handles, tumbler switches, flush handles, etc. Due to easy fabrication of these coatings and relatively low cost of magnesium alloys, the designed coatings may be considered an efficient and economically sound method of controlling hospital infections.

MATERIALS AND METHODS

The method for laser processing of MA8 alloy sheets and plates, resulting in formation of multimodal roughness on the surface and in a considerable increase in effective surface area, has been developed to investigate the antibacterial activity of magnesium alloys. The method was based on the raster scan of surface with a nanosecond laser beam at a wavelength of 1.064 µm. The samples were processed with a 20 W Argent-M laser station (Russia) equipped with an ytterbium fiber laser with surface contact patches of 40 µm in diameter and a RAYLASE MS10 2 laser beam deflection unit (Germany). Preliminary experiments were conducted to choose the mode of laser processing of the surface: pulse frequency, 20 kHz; pulse duration, 200 ns; raster scan density, 50 lines/mm; laser beam motion velocity, 200 mm/s.

The described laser processing mode resulted in formation of a highly porous superhydrophilic surface, where complete capillary soaking of a drop of bacterial suspension under study occurred within several seconds. The 10 × 10 × 1 mm plates were used to compare the antibacterial activities of surfaces of the initial magnesium alloy (referred to as control in our experiments) and of the superhydrophilic coating.

In the present work, we studied the bactericidal activity of magnesium plates against the suspension containing E. coli K12 C600 cells (В-7158; Obolensk State Collection of Pathogenic Microorganisms and Cell Cultures (GKPM-Obolensk)). Bacterial suspension was prepared as follows: an overnight E. coli culture was inoculated into meat peptone broth (MPB; Medgamal), followed by 18-h incubation at 37°C. Bacterial cell suspensions with the initial titer of 5 × 107 CFU/mL were used in the experiments.

The required number of control and superhydrophilic plates, according to the experimental protocol, were placed into sterile weighing bottles under moist conditions. The latter were provided by placing filter paper moistened with normal saline solution along the side walls of the weighing bottle. Saturation with water vapor prevented water evaporation from the suspension and maintained the “wet” suspension–substrate contact. Bacterial contamination of the plate was measured after a certain period of time (15 and 30 min, 1, 2, 4, 6, 8, and 24 h). For quantitative assessment of the bactericidal effect after a fixed time of contact between the plate and the suspension drop, the plate was placed into a test tube with 1 mL of sterile normal saline solution and stirred on a shaker at 250 rpm for 10 min. The resultant bacterial suspension was used to prepare tenfold dilutions, which were plated (0.1 mL per petri dishe) on the Mueller–Hinton agar (HiMedia Laboratories Pvt. Limited); bacterial titer was determined after 24-h incubation in a thermostat at 37°C. Different plates were used for each time interval, and each experiment was repeated at least two times.

Statistical data processing was performed with Microsoft Excel 2010 and Statistica 8.0. The differences were considered statistically significant at a confidence level >0.95, according to the requirements for medical and biological research.

The morphology of bacterial cells contacting the superhydrophilic surface of magnesium alloy and the texture of superhydrophilic plates were studied in secondary electrons using a scanning electron microscope of the Helios Nanolab 600 setup (FEI, United States).

RESULTS AND DISCUSSION

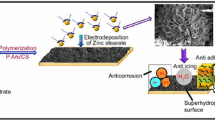

Figure 1a shows the morphology of the superhydrophilic coating on magnesium alloy, the bactericidal properties of which have been studied in the present work.

The surface obtained after laser processing was characterized by multimodal roughness formed by nanoparticles and their microaggregates. According to the Derjaguin–Wenzel law, such roughness, in combination with hydrophilicity of the initial magnesium alloy, makes the surface superhydrophilic.

As was stated above, the contact between a drop of bacterial suspension and such surface resulted in capillary soaking of the texture with the bacterial suspension. At the same time, due to 100% humidity in the weighing bottle, the fluid remained in the pores throughout the experiment, and bacterial cells in the system under study were present both in the planktonic form and in the form of cells deposited on the surface of texture walls. On the control magnesium alloy plate, the suspension remained as a drop, almost unvaried during the observation.

The histogram (Fig. 2) shows the time variation of the titer of viable E. coli cells in suspensions contacting the superhydrophilic and control plates; the dashed line indicates the titer of the initial suspension. These findings demonstrate that even a short-term contact between bacterial cells and magnesium alloy surface and procedures of cell isolation from the substrate cause a significant decrease in the titer relative to the titer of the suspension initially applied onto the substrate. However, at a longer contact, the bactericidal effect of the superhydrophilic magnesium plate developed much earlier compared to the control. For example, after 4 h the bacterial titer was about 102 CFU/mL, i.e., 5 orders of magnitude lower than the initial one, and could actually be considered as a safe concentration. After a 24-h contact with the bacterial suspension, the superhydrophilic plate was completely decontaminated. The viability of bacterial cells applied to the control plate was much higher, and the bacterial titer remained at a level of 104 CFU/mL even after an 8-h contact. After 24 h, the concentration of viable cells remained at a level of 102 CFU/mL, indicating considerable bactericidal properties even of the initial MA8 alloy plate.

Let us now dwell on the mechanisms of bactericidal activity of the magnesium alloy, both for the smooth plate and for the superhydrophilic plate, with its multimodal surface causing a significant increase in the effective surface area relative to the geometric or apparent area.

Bacterial cells deposited onto such a surface as a result of sedimentation die because of a combination of different factors. On the one hand, the outer membrane integrity is impaired as a result of its perforation by nanoparticles deposited on the metal surface during laser treatment (Tripathy et al., 2017; Boinovich et al., 2018). It is followed by cell deformation, the loss of intracellular fluid, and bacteriolysis (Fig. 1b). On the other hand, the interaction between magnesium and corrosion-active medium (here, meat peptone broth) leads to hydrogen release and dramatic alkalinization of the liquid medium. Previously we have shown (Emelyanenko et al., 2019, 2020) that the proteins of MPB are adsorbed on metal surface and stimulate corrosion. As it has been noted in some studies (Luque-Agudo et al., 2020; Lin et al., 2021), the increase in pH of the medium is one of the basic elements of toxic effect of magnesium. This mechanism leads to the death of both the planktonic bacteria and those on the alloy surface. Here, it would be important to emphasize that the former of the above mechanisms plays a key role only in case of a surface with multimodal roughness, while the mechanism associated with pH increase is important for both smooth and rough surfaces. However, the rate of alkalinization is proportional to the area of contact between the substrate and the corrosion medium and, therefore, will be higher for the superhydrophilic surface, resulting in acceleration of bactericidal effect. The experimental studies of pH evolution in suspension contacting the control and superhydrophilic plates (Emelyanenko et al., 2021) confirm the analysis presented above.

Finally, the third important mechanism of bacterial cell death near the surfaces of magnesium alloy is an increase in the concentration of magnesium ions in the liquid medium, which leads to osmotic effects within a cell (Luque-Agudo et al., 2020). Our recent studies of the concentration of magnesium ions in bacterial suspensions (Emelyanenko et al., 2021) have shown that, as a rule, the concentration of magnesium ions in a liquid medium is of the same order of magnitude as the typical intracellular concentrations (Jahnen-Dechent and Ketteler, 2012; Luque-Agudo et al., 2020), which allows us not to consider the mechanism associated with osmotic cell effects as exerting a substantial influence on the death of bacteria in a dispersion medium for the system under discussion.

Thus, the presented data on the effects of magnesium alloy plates on the planktonic form of E. coli cells and on bacterial cells deposited on the substrate show that the efficiency of bactericidal effect of magnesium is similar to that of copper (Emelyanenko et al., 2019), which is considered in the literature as one of the strongest bactericidal metals. However, extensive application of the antibacterial properties of copper is impeded by its toxicity for humans. The toxicity of magnesium alloys, which have an almost equally significant antibacterial effect as copper, has never been mentioned in the literature. The findings of the present work show that the antibacterial properties of the tested superhydrophilic coating considerably surpass those observed for the smooth control plate. This fact opens up further prospects for selecting the morphology of superhydrophilic coatings, which will considerably enhance the bactericidal effect of magnesium.

REFERENCES

Boinovich, L.B., Modin, E.B., Aleshkin, A.V., Emelyanenko, K.A., Zulkarneev, E.R., Kiseleva, I.A., Vasiliev, A.L., and Emelyanenko, A.M., Antibacterial effect of textured surfaces induced by extreme wettability and bacteriophage seeding, ACS Appl. Nanomater., 2018, vol. 1, pp. 1348–1359.

Emelyanenko, A.M., Kaminskii, V.V., Pytskii, I.S., Domantovsky, A.G., Emelyanenko, K.A., Aleshkin, A.V., and Boinovich, L.B., Antibacterial properties of superhydrophilic textured copper in contact with bacterial suspensions, Bull. Exp. Biol. Med., 2020, vol. 168, no. 4, pp. 488–491.

Emelyanenko, A.M., Kaminsky, V.V., Pytskii, I.S., Emelyanenko, K.A., Domantovsky, A.G., Chulkova, E.V., Aleshkin, A.V., and Boinovich, L.B., Antimicrobial activity and degradation of superhydrophobic magnesium substrates in bacterial media, bioRxiv, 2021.04.29.441950. https://doi.org/10.1101/2021.04.29.441950

Emelyanenko, A.M., Pytskii, I.S., Kaminskii, V.V., Chulkova, E.V., Domantovsky, A.G., Emelyanenko, K.A., Sobolev, V.D., Aleshkin, A.V., and Boinovich, L.B., Superhydrophobic copper in biological liquids: antibacterial activity and microbiologically induced or inhibited corrosion, Colloids Surf. B: Biointerfaces, 2020, vol. 185C, art. 110622.

Jahnen-Dechent, W. and Ketteler, M., Magnesium basics, Clin. Kidney J., 2012, vol. 5, suppl. 1, pp. i3–i14.

Li, L.Y., Cui, L.Y., Zeng, R.C., Li, S.Q., Chen, X.B., Zheng, Y.F., and Kannan, M.B., Advances in functionalized polymer coatings on biodegradable magnesium alloys–a review, Acta Biomater., 2018, vol. 79, pp. 23–36.

Lin, Z., Sun, X., and Yang, H., The role of antibacterial metallic elements in simultaneously improving the corrosion resistance and antibacterial activity of magnesium alloys, Mater. Des., 2021, vol. 198, art. 109350.

Luque-Agudo, V., Fernández-Calderón, M.C., Pacha-Olivenza, M.A., Pérez-Giraldo, C., Gallardo-Moreno, A.M., and González-Martín, M.L., The role of magnesium in biomaterials related infections, Colloids Surf. B: Biointerfaces, 2020, vol. 191, art. 110996.

Tripathy, A., Sen, P., Su, B., and Briscoe, W.H., Natural and bioinspired nanostructured bactericidal surfaces, Adv. Colloid Interface Sci., 2017, vol. 248, pp. 85–104.

Funding

The work was supported by the Russian Foundation for Basic Research, project 18-29-05008, and partially by the Ministry of Science and Higher Education of the Russian Federation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest. This article does not contain any studies involving animals or human participants performed by any of the authors.

Additional information

Translated by E. Makeeva

Rights and permissions

About this article

Cite this article

Kaminsky, V.V., Emelyanenko, A.M., Aleshkin, A.V. et al. Efficiency and Mechanisms of Bactericidal Effect of Superhydrophilic Magnesium Alloy Surface against Escherichia coli. Microbiology 90, 643–646 (2021). https://doi.org/10.1134/S002626172105009X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S002626172105009X