Abstract

To determine the mechanism of a heterogeneous catalytic reaction, a spectrokinetic method was used based on the comparison of simultaneously measured rates of transformation of surface complexes using in situ IR spectroscopy and the rate of formation of reaction products. Based on the of systemic studies of intermediates of heterogeneous catalytic reactions by this method, general patterns are found that shed light on the essence of the catalytic action. It is found that the main function of the catalyst is the preparation of a new reagent from the molecule in the gas phase (during adsorption). The transformation of this regent into the products on the surface occurs via a route that is fundamentally different from the route of transformation of the initial molecule in a gas-phase reaction. It was also found that, if the initial adsorption forms of the reactants in the reaction under study are the same for a certain group of catalysts, then the mechanism (as a sequence of steps) of this reaction on these catalysts is the same. The individual properties of different catalysts within such a group are manifested in the difference in the ratio of the rates of steps, i.e. in determining the limiting step.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The development of theory in heterogeneous catalysis is hampered by the lack of information on the detailed mechanism of catalytic reactions. The mechanism of the catalytic reaction is usually [1] meant to be the set of elementary steps, leading to the formation of products. Intermediate complexes (intermediates) are substances involved in elementary steps. The determination of the mechanism of a catalytic reaction consists in determining the nature of intermediates and the sequence of their conversion into reaction products.

Currently, basic information on the complexes formed on the catalyst surface during the reaction is obtained by the methods of molecular spectroscopy. In particular, infrared spectroscopy, in contrast to electron spectroscopy, can be used directly under the conditions of a catalytic reaction (elevated temperatures, the presence of a gas phase). This method has helped accumulate information on the properties of surface complexes [2, 3]. However, the question of whether the observed surface complexes have any relation to the studied reaction remains open. To establish the true role of surface complexes in the reaction, some criterion is necessary.

In this work, we use as a criterion the comparison of simultaneously measured rates of consumption of surface compounds with the rate of product formation [4, 5]. If these rates are equal, then there are serious grounds for stating that the observed surface compound is intermediate in the reaction.

EXPERIMENTAL

Comparison of the rates of consumption of surface compounds and the formation of products was carried out on the basis of spectrokinetic measurements involving several stages [6, 7]:

(1) simultaneous measurement of the spectral and catalytic properties of the system;

(2) identification of bands in the spectra;

(3) quantitative processing of spectral data;

(4) quantitative comparison of the reaction rate calculated by the surface coverage, with the reaction rate determined from the concentration of products.

Each stage is considered in detail in [8].

Figure 1 shows a schematic diagram of an experimental setup for spectrokinetic measurements. The spectral cell is central to this scheme. Tough requirements are imposed on its design: the cell should also have the functions of a catalytic gradientless reactor in which conventional kinetic measurements can be carried out. The designs of reactors of this sort are described in [6–8]. Their main features are a small volume and the absence of cold parts. “Windows” are mounted by mechanical pressing of well-polished surfaces or with glue. To check the lack of gradients in the designed structures in each specific catalytic system, theoretical and experimental evaluations were performed. The theoretical estimates include the calculation of the Peclet criterion (Pe); the experimental estimates are a comparison of the same parameters determined in steady-state and non-steady-state conditions.

The reaction mixture before and after the cell/reactor was analyzed either by chromatography or using infrared, chemiluminescent, or magnetic gas analyzers.

Spectrokinetic measurements are possible both in steady-state and non-steady-state conditions.

When the rate of transformation of the surface complex (Wsc) (spectral measurements) and the reaction rate (Wr) measured experimentally quantitatively coincide, the surface compounds under consideration are intermediate in the reaction.

It is possible that a comparison of Wsc and Wr made in this way will not always show their coincidence. Let us consider the most typical options for these two rates.

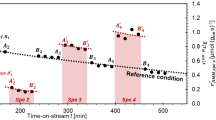

1.Wsc = Wr. Below is an example of a quantitative comparison of the reaction rate calculated by surface coverage (spectral measurements) with the rate measured experimentally under the condition of NOx reduction by propane in excess oxygen on Cu/ZSM-5 [8]. Under the reaction conditions, an absorption band at 1630 cm–1 was detected in the transmission spectra. According to the literature data [9], this absorption band refers to antisymmetric vibrations in the Cu–O–N=O complex. The extinction coefficient ε was determined by heating the sample in a thermal desorption mode with an analysis of the amount of released NOx molecules; ε = 3.4 × 10–18 cm2/molecule.

Under the reaction conditions at 300°С, the absorbance (D) of a band at 1630 cm–1 is 0.05. This means that there are \({{N}_{{{\text{N}}{{{\text{O}}}_{x}}}}}\) = DSε–1 = 3 × 1016 complexes on the sample (where S is the geometric surface area of the sample, S = 2 cm2). If NOx is converted via this complex, the reaction rate of its consumption will be Wsc = k\({{N}_{{{\text{N}}{{{\text{O}}}_{x}}}}}\) = 1.8 × 1017 molecule/min.

The value of k was determined from the data in Fig. 2. Curve 1 in Fig. 2 is the change in the absorbance of the absorption band of the nitrite complex over time when replacing the flow of the reaction mixture with a flow containing propane. This expedient is aimed at stopping the process of formation of the nitrite complex in order to measure the rate of its consumption. Processing curve 1 in the coordinates of a first-order equation gives a value of k equal to 6 min–1.

The experimentally measured rate of NOx conversion on this sample is Wr = 1.9 × 1017 molecule/min. A good coincidence of the rates proves that the observed complex is intermediate in NOx reduction by propane. That is, the description of the reaction mechanism in this case corresponds to the following simplified scheme:

2.Wsc < Wr. In this case, the observed surface complex is not related to the studied reaction. It can be an intermediate in another reaction, the rate of which in this case is not measured. As an example, let us compare the rates of conversion of the carboxylate complex to CO2 in the oxidation of CO on copper oxide deposited on Al2O3 (Fig. 3) [10].

Under the reaction conditions, absorption bands at 1600 and 1380 cm–1 were detected in the IR spectra. The assignment of these absorption bands is made on the basis of literature data [2, 3]. These absorption bands belong to antisymmetric and symmetric vibrations of the surface carboxylate group. The extinction coefficient of vibrations ε in the carboxylate complex was determined in [11]: ε = 6 × 10–19 cm2/molecule. Under the reaction conditions at 340°С, the absorbance D at 1600 cm–1 is 0.12. This means that there are Nсоо = DSε–1 = 4 × 1017 complexes on the surface. If СО2 is formed via this complex, the rate of its formation СО2 is Wsc = kNcoo = 5 × 1016 molecule/min. The value of k is determined from data in Fig. 3. The processing of curve 2 in the coordinates of the first-order equation gives k = 0.13 min–1.

The experimentally measured reaction rate on this sample is Wr = 2.6 × 1019 molecule/min. These data indicate that the contribution of the oxidation of carboxylates to the overall reaction of CO oxidation is negligible.

The mismatch of the rate can also take place for the intermediate complex X (or Y) in the case of the reaction occurring according to the following scheme:

In this situation, the determination of the role of the complex X (or Y) in the reaction under study can be made on the basis of the comparison of the characteristic time of transformation of the complex and the characteristic reaction time. If these values coincide, we have grounds for stating that the observed complex is intermediate in the reaction. Note that the measurement of characteristic times (to determine the expenditure constant of the surface complex) is an integral part of the spectrokinetic experience.

3.Wsc > Wr. In this case, it is obvious that the observed surface complex either is completely unrelated to the studied reaction or it is also converted in some other reactions the rate of which we do not measure. Then, it is necessary to measure the rates of all reactions occurring in this system. A spectrokinetic example of such a relation between the rates was found using the example of NOx reduction by hydrocarbons in an excess of oxygen [12]. The rate of conversion of intermediate nitrate complexes is greater than the rate of NOx reduction due to the decomposition of nitrates to NO.

We would like to note that the method of comparing the rates encounters some experimental difficulties in the case of low-active samples. In order to determine the reaction rate, it is necessary to carry out experiments at elevated temperatures. Surface coverages decrease with increasing temperature. The success of the experiment will be determined by the possibility of combining the temperature ranges in which the spectral and catalytic properties of the system are measured.

One can also encounter difficulties when comparing velocities on highly active catalysts. These are mainly related to the low temporal resolution of spectral equipment. As follows from literature data [13, 14], the characteristic times of heterogeneous reactions are in the range from 10–2 to 102 s. It is possible to study reactions with characteristic times of more than 1 s by non-steady-state methods of molecular spectroscopy.

Spectrokinetic measurements can be carried out on the basis of transmission [15], diffuse reflectance [16], and emission [17] spectroscopy.

Note that transmission spectroscopy is used most often. However, its capabilities are limited by the need to press the sample and a significant intrinsic absorption of the catalysts. Finally, due to the long optical path in the cell, transmission is likely to impose absorption bands of molecules in the gas phase and surface compounds.

Diffuse reflectance spectroscopy has no disadvantages mentioned above. Its sensor captures light scattered by a powdered sample. For the quantitative description of diffuse reflectance spectra, the Kubelka–Munk formula is used, which relates the fraction of light reflected by an infinitely thick medium with the extinction coefficients ε and scattering s.

It is obvious that the processes occurring on the surface of bulk metals are inaccessible for studying using the methods listed above. Emission spectroscopy is the most suitable for this problem [18]. This is the only spectral method in which sample heating does not prevent the measurement, but rather is the necessary condition. Moreover, the characteristic spectrum of metal complexes is measured against the background of the noncharacteristic radiation of the metal itself.

The above approach for comparing the rates of consumption of surface compounds and the formation of products shows that the spectrokinetic method is a promising experimental base for studying the mechanism of a heterogeneous catalytic reaction and the patterns of flow of surface steps. To identify the general patterns of transformation of complexes on the surface, we propose to study the same reaction on the widest possible range of catalysts by the spectrokinetic method.

RESULTS AND DISCUSSION

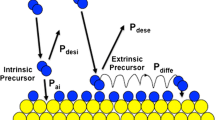

In chemistry, it is known that the reaction of dilute and concentrated nitric acid with metals produces different products. Similarly, in the interaction of olefins with sulfuric acid of varying degrees of dilution, different reactions take place. The explanation for this fact is quite simple: when the acid is dissolved, different ions are formed in the solution due to the solvation effect. That is, by diluting the acid to different extents, we prepare different reagents. This example is a clear analogy with heterogeneous catalysis. When the molecule is adsorbed on the surface of the catalysts, the initial reagent for the reaction is formed, which is fundamentally different in its properties and structure from the molecule in the gas phase.

A brilliant literature example is the reaction of CO oxidation. The high strength of the C–O bond (>1000 kJ/mol) and spin forbiddenness lead to the fact that the process in the gas phase is difficult to occur (reaction temperature is higher than 700°C).

In the presence of a metal catalyst, a σ-bond is formed between the occupied d orbitals of CO and unoccupied d orbitals of the metal. The bond is also formed due to the interaction of the occupied d orbitals of the metal with the vacant π* orbitals of CO. As a result, in the resulting CO–catalyst molecular complex, the electronic structure of the C–O bond and its strength change. The second component of the reaction, oxygen, is adsorbed dissociatively on metal catalysts. As a result, the interaction between the new reagents created by the catalyst—the carbonyl complex and atomic oxygen—takes place at a much lower temperature.

Below, on the basis of our own and literature data, we will try to prove that the formation of a new reagent during adsorption determines the route of the catalytic reaction.

On the group of catalysts under the conditions of the same reaction (initial reagents and products coincide), the formation of identical surface complexes-reagents is possible. We will show that, in this case, the studied reaction occurs via the same mechanism on different catalysts of this group. The individual properties of the catalysts in this case manifest themselves in the determination of the rate-limiting step.

If, on different catalysts, the adsorption of the same molecule leads to the formation of different reagents, then different reactions take place on them.

To check these considerations using the spectrokinetic method, each reaction was studied on the widest possible range of catalysts.

Low-Temperature Ammonia Oxidation

Low-temperature catalytic oxidation of ammonia to nitrogen is one of the main processes for reducing the concentration of ammonia in industrial waste gases. The intermediate compounds in this reaction were studied by us on oxide catalysts [15, 16, 19–21] and bulk metals (Pt, Fe) [17]. When ammonia interacts with catalysts characterized by Lewis acidity, a chemical bond with the catalyst is formed due to electron transfer to the coordination-unsaturated surface sites. As a result, a reagent appears that fundamentally differs in its electronic structure from the ammonia molecule in the gas phase. When this reagent interacts with adsorbed oxygen, reaction products are formed.

Using steady-state and non-steady-state spectrokinetic measurements by the methods of IR spectroscopy of transmission and diffuse reflectance [15, 16, 19–21], it was shown that intermediates in this reaction on Lewis oxides are NH3ads, N2Oδ–; N2Oδ–, NOδ+, and NH2ads.

Assuming that all the detected intermediates are involved in the reaction, we can suggest the following scheme for describing the process of low-temperature ammonia oxidation on the studied metal oxides:

where Z is the free site of the surface oxide. Oxides on which the corresponding surface compounds were observed experimentally are given in brackets.

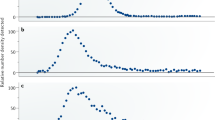

Based on the above scheme, calculations of product concentrations and surface coverages with intermediate compounds were carried out depending on the composition of the reaction mixture under steady-state conditions [19]. As the reference values of the rate constants, we used the estimates of k12, k6, and k10 obtained from non-steady-state spectrokinetic measurements.

The agreement of the calculated and experimental dependences with the assumptions made in the scheme is quite good (Fig. 4). Similar results were obtained in non-steady-state experiments [19].

Low-temperature ammonia oxidation on Fe2O3. Dependences of experimental (1, 3) and calculated (2, 4) values of the concentrations N2 and N2O for Fe2O3 at 240°С on the ammonia concentration in the reaction mixture at \({{C}_{{{{{\text{O}}}_{2}}}}}\) = 0.40 (a) and on the concentration of oxygen in the reaction mixture at \({{C}_{{{\text{N}}{{{\text{H}}}_{3}}}}}\) = 0.25 (b).

These facts taken together suggests that the reaction mechanisms on the studied oxides are the same. It should be noted that the studied oxides are characterized by the same forms of adsorption of ammonia and oxygen on them. Therefore, it can be assumed that, on some set of catalysts the mechanism of the above reaction will be the same if the initial adsorption forms of the reactants on them are identical.

On oxides with Brønsted acidity (MoO3, Cr2O3), upon the adsorption of ammonia, a surface complex \({\text{NH}}_{4}^{ + }\) is observed. The spectrokinetic measurements have shown that this complex is intermediate in the reaction of N2O and N2 formation. In other words, the mechanism of ammonia oxidation on these samples is the same. However, it radically differs from that described above for oxides with pronounced Lewis acidity.

Another example that confirms the hypothesis is the oxidation of ammonia on bulk metals [17]. According to in situ emission IR spectroscopic data, the form of ammonia activation in this case is the surface NH2 complex, and nitrous oxide appears in the reaction products.

Interaction of СО and NO

The reaction of CO with NO is important from the standpoint of neutralizing the harmful emissions of gasoline engines. The main catalysts are supported platinum group metals. In this connection, the mechanism of the process on Pt, Pd, Rh, Ru, and Cu supported on alumina has been studied. Under reaction conditions, CO forms carbonyl complexes and NO forms nitrosyl complexes on the catalyst surface. Isocyanate and carbonate complexes were also identified as intermediates. A spectrokinetic study [8, 22–26] with a wide variation of the composition of the reaction medium and temperature allowed us to determine that the isocyanate complex is a key intermediate complex in the nitrogen formation. The NCO complex is formed by the interaction of the adsorbed nitrogen atom and the CO molecule, and decomposes as a result of reaction with the adsorbed NO molecule. With this in mind, the following mechanism of interaction between CO and NO is proposed:

Based on this mechanism, a satisfactory quantitative description of the dependence of the reaction rate and selectivity on the composition of the reaction medium on all tested catalysts (with a different set of constants) was obtained [26]. Note that the initial adsorption state of reactants in this process is the same for these catalysts and the reaction mechanism is the same.

A comparative study of the same reaction on bulk copper–cobalt spinel and on copper–cobalt spinel and copper oxide supported on alumina [27, 28] showed that carbon monoxide is activated in the form of carbonyl complexes, and nitric oxide is activated in the form of nitrite complexes. The reaction between them leads to the formation of N2O and CO2. In other words, when changing the form of activation of the reactants the reaction mechanism becomes different.

Selective Catalytic NOx Reduction by Hydrocarbons in the Presence of Oxygen

The most interesting data were obtained when studying the process of selective catalytic reduction of nitrogen oxides by hydrocarbons in the presence of oxygen (HC-SCR NOх). This reaction in the literature is paid great attention because it is necessary to neutralize the harmful emissions of diesel engines. HC-SCR NOх is the most effective on oxide catalysts [29–32] apparently because of the presence of oxygen does not prevent the activation of NOх (which is characteristic of supported metals). On the contrary, the presence of oxygen appears to be favorable for the formation of nitrate complexes.

A spectrokinetic study [33–51] allowed us to prove for a wide range of oxide catalysts—copper- and cobalt-substituted zeolites with the ZSM-5 structure [33–36, 47–50], zirconia of various modifications [37–43], columnar clays [44–46, 51] (nanosized particles of zirconia are fixed between the aluminosilicate layers of natural montmorillonite clays with supported active components), nickel–chromium oxide, iron–chromium oxide, copper–zinc–aluminum catalysts, and others—that nitrate complexes [35–42] are key intermediates in this process (Scheme 1, Scheme 2). The next step is the interaction of \({\text{NO}}_{3}^{ - }\) with the hydrocarbon to for, formation of nitroorganic complexes [8, 43–46].

It is interesting to note that the structure of the nitroorganic complexes is determined by the form of hydrocarbon activation. In particular, the interaction of a mixture of propylene and oxygen with the surface of bulk ZrO2 leads to the appearance of only an acetate complex. As a result, the acetate and monodentate nitrate complexes form a complex on the surface that is similar in structure to adsorbed nitromethane (Scheme 1).

Scheme 1 .

On ZrO2 in the form of columns in the composition of columnar clay, the main form of propylene activation is the isopropoxide complex. In this case, the isopropoxide and nitrate complexes form a complex similar in structure to the structure of adsorbed dinitropropane (Scheme 2).

Scheme 2 .

The dinitropropane complex is consumed in the interaction with surface NO2 complexes that arise during the decomposition of surface nitrates.

Overall, the data shows that the initial adsorption state of the reagents determines the sequence of steps: if NO forms nitrate in its activation and the hydrocarbon forms acetate, the reaction goes through the nitromethane complex; if NO forms nitrate in its activation and the hydrocarbon forms isopropoxide, then the reaction goes through the nitropropane complex. This statement is true for all studied systems.

Catalytic Conversion of Methanol

The catalytic conversion of methane is important from the standpoint of producing hydrogen for fuel cells. The main form of methanol activation on various catalysts is methoxy groups. The mechanism of formation of methoxy groups depends on the properties of the catalyst [52–57]. These complexes can be formed by interaction with basic or acidic hydroxyl groups with O–H or C–O bond breaking in the alcohol molecule, respectively. As a result of spectrokinetic studies [52–57], it turned out that linear methoxy groups of the first type are converted into methyl formate due to the condensation reaction with the formate complex and then to CO and H2. Methoxy groups of the second type are intermediate in the formation of dimethyl ether.

In other words, the form of activation of the ethanol molecule during adsorption determines the route of its further transformation.

Theoretical Consideration

The above data indicate that the main function of the catalyst is to transform the molecule from the gas phase (during adsorption) into a fundamentally new reactant, on the nature of which the reaction route depends.

In addition, it was found that, on some set of catalysts, the mechanism of any reaction as a sequence of intermediate conversions is preserved if the initial adsorption forms of the reactants on it are the same. The individual properties of the catalysts in this set are manifested in the determination of the ratio of the rates of the steps, and, consequently, of the rate-limiting step.

Confirmations of this hypothesis can be found in the literature. In particular, the study of the mechanism of propylene oxidation to acrolein on oxide catalysts [58] showed that if the adsorption of propylene produces a π-complex of propylene, then the catalyst undergoes a process of mild oxidation of propylene to acrolein. If, upon adsorption, the π-complex of propylene is observed, then deep oxidation of propylene is carried out. The activation of propylene in the form of isopropoxide leads to the formation of acetone.

Methanol synthesis also provides the confirmation of the unambiguous correspondence of the reaction mechanism to the adsorption forms of reactants. In accordance with the ideas developed in [59], methanol synthesis occurs exclusively through CO2 rather than CO. That is, the formation of methanol requires the presence of a surface complex that forms only during CO2 adsorption.

Apparently, the presence of a compensation effect in catalysis (the proportionality of the entropy and enthalpy terms of the Gibbs activation energy) [1] can only be explained if the reaction mechanism is the same on different catalysts (i.e., if the measurements refer to the reaction step of the same nature on different catalysts).

The literature describes chemical reactions that occur only on one catalyst. These are ammonia synthesis on iron, maleic anhydride formation on vanadyl pyrophosphate, ethylene oxidation on silver, etc. These examples show that there may not exist several mechanisms of the same reaction. Neither may exist many forms of activation of reactants, otherwise other effective catalysts of these reactions would be found.

The mechanism of a heterogeneous catalytic reaction is usually understood as a sequence of steps, in each of which intermediate complexes (intermediates) are formed and consumed [1]. From the standpoint of quantum mechanics, to determine such a sequence, it is necessary to solve the Schrödinger equation for a very complex many-electron system. If the system can be described in the adiabatic approximation, the solution to this equation is a complex multidimensional potential energy surface. In terms of the potential energy surface (PES), the occurrence of a catalytic reaction means the movement of the imaging point from one potential well (from one intermediate) to another (to another intermediate) through the corresponding energy barrier [60].

On a complex multidimensional potential energy surface, there are infinitely many options for the transition of the system from the initial to the final state. It is reasonable to assume that the real route (the motion of the imaging point on the surface of potential energy) characterizes a certain principle of minimum. The most suitable for describing a reaction route is the minimum of action [61, 62]. In accordance with it, a route is realized for which the action (the integral of the difference between the kinetic and potential energy along this path in time) is minimal. Such a route has differential properties: the action is minimal bothe throughout the entire route and through each of its small sections. In other words, if for one of the catalysts it was possible to find a sequence of steps for the conversion of reactants into products (the nature and properties of the intermediate complexes are known), the same intermediate complexes, except for one unknown, are found for the other catalyst of this reaction, the structure of this unknown intermediate will be identical to the structure of the corresponding intermediate on the first catalyst. That is, a “loop” on PES is impossible. The presence of branching points on PES will then mean that another reaction occurs in the system with the formation of another product, and then we can talk about the selectivity of the process.

However, the application of the least-action principle is limited to quick reactions for well-known reasons [56]. In addition, based on this principle, it is difficult to associate the real route with the specific structure of intermediate complexes. On the other hand, back in 1938, Rice and Teller [63] substantiated the principle of least motion and formulated it as follows: The formation of reaction products occurs with as little motion of atoms and electrons as possible.

On a given potential energy surface, let us choose from the set of possible routes the one that is characterized by the minimum motion of nuclei and electrons. This actual route is realized through a well-defined sequence of intermediate complexes. In other words, there is an unambiguous correspondence between the least motion of nuclei and electrons and the set of intermediate complexes through which this motion is realized. We turn to the same reaction on a different catalyst. Among the set of probable routes connecting the initial and final state of the system, there will be one that is defined as valid on the first catalyst. Since the initial and final states for the reaction are the same, and there is one-to-one correspondence between the least motion of nuclei and electrons and the set of intermediate complexes through which this motion is realized. Let us turn to the same reaction on a different catalyst. Of the set of probable routes connecting the initial and final state of the system, there will be one that is defined as valid on the first catalyst. Since the initial and final states for the reaction are the same, and there is one-to-one correspondence between the least motion of nuclei and electrons and the set of intermediate complexes, the same set of intermediate complexes will correspond to the least motion as on the first catalyst.

CONCLUSIONS

The analysis of the properties of intermediates in different reactions given in this paper suggests that the main function of the catalyst is to transform the molecule in the gas phase (during adsorption) into a fundamentally new reactant, the nature of which determines the reaction route.

It turns out that on some set of catalysts the mechanism of the studied reaction as a sequence of transformations of intermediates is preserved if the initial adsorption forms of the reactants on it are the same. The individual properties of the catalysts in this set are manifested in the determination of the ratio of the rates of the steps, and, consequently, of the limiting step.

On the basis of the proposed concept, it is possible to propose a method for studying the reaction mechanism that is different from the traditional one. It involves the study of the forms of activation of reactant molecules and intermediates on different catalysts in the same reaction. If the initial (adsorption) state of reactants on them is the same, then, taking into account the set of intermediates found on these catalysts, it is possible to construct a general sequence of steps that is valid for each catalyst.

This approach, in addition to information about the detailed mechanism of the catalytic process, can reveal more general patterns of catalysis because the study of the overall process is based on the study of individual elementary steps of the reaction. In this case, it is clear that, when comparing the parameters of the same elementary step of a catalytic process on catalysts of different structure and chemical composition, the probability that the kinetic parameters of the surface elementary steps will correlate with the physicochemical properties of catalysts increases. The promise of this approach is shown by the example of the reaction of low-temperature ammonia oxidation [19].

REFERENCES

Kiperman, S.L., Osnovy khimicheskoi kinetiki v geterogennom katalize (Fundamentals of Chemical Kinetics in Heterogeneous Catalysis), Moscow: Khimiya, 1979.

Finocchio, E., Busca, G., Lorenzelli, V., and Willey, R.J., J. Chem. Soc., Faraday Trans., 1994, vol. 90, p. 3347.

Davydov, A.A., IK-spektroskopiya v khimii poverkhnosti okislov (Infrared Spectroscopy in Chemistry of Surface Oxides), Novosibirsk: Nauka, 1984.

Krylov, O.V. and Matyshak, V.A., Russ. Chem. Rev., 1995, vol. 64, no. 2, p. 167.

Tamaru, K., Dynamic Heterogeneous Catalysis, London: Academic Press, 1978, p. 96.

Matyshak, V.A., Kinet. Katal., 1989, vol. 30, p. 168.

Matyshak, V.A., Kinet. Catal., 2007, vol. 48, p. 812.

Matyshak, V.A. and Krylov, O.V., Catal. Today, 1995, vol. 25, p. 1.

Larsen, S., Aylor, A.W., Bell, A.T., and Reimer, A.A., Proc. US–Russia Workshop on Environmental Catalalysis, Wilmington, Delaware, 1994, p. 21.

Ismailov, M.A., Akhverdiev, R.B., Gadzhi-Kasumov, V.S., and Matyshak, V.A., Kinet. Katal., 1992, vol. 33, p. 611.

Matyshak, V.A. and Krylov, O.V., Kinet. Catal., 2002, vol. 43, p. 391.

Sadykov, V.A., Paukshtis, E.A., Beloshapkin, S.A., Ukharskii, A.A., Il’ichev, A.N., Lunin, V.V., Matyshak, V.A., and Rozovskii, A.Ya., React. Kinet. Catal. Lett., 1999, vol. 66, p. 297.

Budar, M., Usp. Khim., 1974, vol. 43, p. 317.

Krylov, O.V. and Matyshak, V.A., Russ. Chem. Rev., 1994, vol. 63, p. 559.

Matyshak, V.A., Kadushin, A.A., Burkkhardt, I.S., and Shnabel’, K.-Kh, Kinet. Katal., 1985, vol. 26, p. 334.

Sil’chenkova, O.N., Ukharskii, A.A., and Matyshak, V.A., Kinet. Katal., 1994, vol. 35, p. 766.

Matyshak, V.A., Lefler, E., and Shnabel’, K.-Kh, Kinet. Katal., 1988, vol. 28, p. 1389.

Krylov, O.V. and Matyshak, V.A., Promezhutochnye soedineniya v geterogennom katalize (Intermediate Compounds in Heterogeneous Catalysis), Moscow: Nauka, 1996.

Sil’chenkova, O.N., Korchak, V.N., and Matyshak, V.A., Kinet. Catal., 2002, vol. 43, p. 363.

Sil’chenkova, O.N., Matyshak, V.A., and Korchak, V.N., Kinet. Catal., 1999, vol. 40, p. 526.

Matyshak, V.A., Sil’chenkova, O.N., Staroverova, I.N., and Korchak, V.N., Kinet. Katal., 1995, vol. 36, p. 736.

Matyshak, V.A., Slin’ko, M.M., Gazarov, R.A., Panchishnyi, V.I., Kadushin, A.A., and Krylov, O.V., Kinet. Katal., 1986, vol. 27, p. 167.

Matyshak, V.A., Gazarov, R.A., Panchishnyi, V.I., and Kadushin, A.A., Kinet. Katal., 1989, vol. 29, p. 1123.

Matyshak, V.A., Gazarov, R.A., Panchishnyi, V.I., and Kadushin, A.A., Kinet. Katal., 1989, vol. 29, p. 1130.

Matyshak, V.A., Gazarov, R.A., Panchishnyi, V.I., and Kadushin, A.A., Kinet. Katal., 1989, vol. 29, p. 1382.

Matyshak, V.A., Kinet. Katal., 1992, vol. 33, p. 1168.

Matyshak, V.A., Ismailov, M.A., Akhverdiev, R.B., Gadzhi-Kasumov, V., and Panchishnyi, V.I., Kinet. Katal., 1993, vol. 34, p. 117.

Matyshak, V.A., Panaiotov, D., Sklyarov, A.V. Vlasenko, A.G, and Mehandjiev, D., Appl. Catal., 1986, vol. 24, p. 37.

Iwamoto, M., Yahiro, H., Shundo, S., Yu-u, Y., and Mizuno, N., Shokubai, 1990, vol. 32, p. 430.

Iwamoto, M., In Proc. Meeting of Catal. Technol. for Removal of Nitrogen Monoxide, Tokyo, 1990, p. 1.

Held, W. and Koenig, A., GER Patent 3642018, 1987.

Held, W., Koenig, A., Richter, T., and Puppe, L., SAE Pap., 900496, 1990.

Sadykov, B.A., Lunin, V.V., Matyshak, V.A., Paukshtis, E.A., Rozovskii, A.Ya., Bulgakov, N.N., and Ross, J.R.H., Kinet. Catal., 2003, vol. 44, p. 379.

Sadykov, V.A., Baron, S.L., Alikina, G.M., Bunina, R.V., Ivanova, A.S., Veniaminov, S.A., Matyshak, V.A., Rozovskii, A.Ya., Lunin, V.V., Lunina, E.V., and Kharlanov, A.N., Catal. Lett., 1996, vol. 37, p. 157.

Sadykov, V.A., Bunina, R.V., Alikina, G.M., Ivanova, A.S., Kochubei, D.I., Novgorodov, B.N., Paukshtis, E.A., Fenelonov, V.B., Zaikovsii, V.I., Kuznetsova, T.G., Beloshapkin, S.A., Kolomiichuk, V.N., Moroz, E.M., Matyshak, V.A., Konin, G.A., Rozovskii, A.Ya., Tret’yakov, V.F., Burdeinaya, T.N., Davydova, M.N., Ross, J.R.H., and Breen, J.P., J. Catal., 2001, vol. 200, p. 131.

Matyshak, V.A., Il’ichev, A.N., Ukharskii, A.A., and Korchak, V.N., J. Catal., 1997, vol. 171, p. 245.

Matyshak, V.A., Konin, G.A., and Il’ichev, A.N., Top. Catal., 2001, vol. 17, p. 193.

Tret’yakov, V.F., Matyshak, V.A., Burdeinaya, T.N., and Zakorchevnaya, Yu.P., Kinet. Catal., 2003, vol. 44, p. 840.

Tret’yakov, V.F., Matyshak, V.A., Burdeinaya, T.N., and Zakorchevnaya, Yu.P., Kinet. Catal., 2003, vol. 44, p. 846.

Tret’yakov, V.F., Zakirova, A.G., Matyshak, V.A., Burdeinaya, T.N., Korchak, V.N., Glebov, L.S., and Lunin, V.V., Kinet. Catal., 2006, vol. 47, p. 873.

Burdeinaya, T.N., Matyshak, V.A., Tret’yakov, V.F., Zakirova, A.G., Korchak, V.N., and Lunin, V.V., Kinet. Catal., 2007, vol. 48, p. 84.

Tret’yakov, V.F., Burdeinaya, T.N., Zakorchevnaya, Yu.P., Zakirova, A.G., Bukhtiyarov, M.N., Matyshak, V.A., and Korchak, V.N., Kinet. Catal., 2005, vol. 46, p. 559.

Matyshak, V.A., Tret’yakov, V.F., Chernyshov, K.A., Burdeinaya, T.N., Korchak, V.N., and Sadykov, V.A., Kinet. Catal., 2006, vol. 47, p. 593.

Matyshak, V.A., Tret’yakov, V.F., Chernyshov, K.A., Burdeinaya, T.N., Korchak, V.N., and Sadykov, V.A., Kinet. Catal., 2006, vol. 47, p. 747.

Matyshak, V.A., Tret’yakov, V.F., Burdeinaya, T.N., Chernyshov, K.A., Sadykov, V.A., Sil’chenkova, O.N., and Korchak, V.N., Kinet. Catal., 2007, vol. 48, p. 74.

Matyshak, V.A., Sadykov, V.A., Chernyshov, K.A., and Ross, J., Catal. Today, 2009, vol. 145, p. 152.

Matyshak, V.A., Ukharskii, A.A., and Il’ichev, A.N., Mendeleev Commun., 1995, vol. 3, p. 118.

Matyshak, V.A., Baron, S.L., Ukharskii, A.A., Il’ichev, A.N., Sadykov, V.A., and Korchak, V.N., Kinet. Catal., 1996, vol. 37, p. 549.

Matyshak, V.A., Ukharskii, A.A., Il’ichev, A.N., Sadykov, V.A., and Korchak, V.N., Kinet. Catal., 1999, vol. 40, p. 105.

Sadykov, V.A., Paukshtis, E.A., Beloshapkin, S.A., Ukharskii, A.A., Il’ichev, A.N., Lunin, V.V., Matyshak, V.A., and Rozovskii, A.Ya., React. Kinet. Catal. Lett., 1999, vol. 66, p. 297.

Sadykov, V.A., Bunina, R.V., Alikina, G.M., Ivanova, A.S., Kuznetsova, T.G., Beloshapkin, S.A., Matyshak, V.A., Konin, G.A., Rozovskii, A.Ya., Tretyakov, V.F., Burdeynaya, T.N., Davydova, M.N., Ross, J.R.H., and Breen, J.P., J. Catal., 2001, vol. 200, p. 117.

Matyshak, V.A., Berezina, L.A., Sil’chenkova, O.N., Tret’yakov, V.F., Lin, G.I., and Rozovskii, A.Ya., Kinet. Catal., 2009, vol. 50, p. 111.

Matyshak, V.A., Berezina, L.A., Sil’chenkova, O.N., Tret’yakov, V.F., Lin, G.I., and Rozovskii, A.Ya., Kinet. Catal., 2009, vol. 50, p. 255.

Berezina, L.A., Matyshak, V.A., Korchak, V.N., Burdeinaya, T.N., Tret’yakov, V.F., Lin, G.I., and Rozovskii, A.Ya., Kinet. Catal., 2009, vol. 50, p. 775.

Matyshak, V.A., Sil’chenkova, O.N., Ismailov, I.T., and Tret’yakov, V.F., Kinet. Catal., 2009, vol. 50, p. 784.

Matyshak, V.A., Sil’chenkova, O.N., Ismailov, I.T., and Tret’yakov, V.F., Kinet. Catal., 2010, vol. 51, p. 428.

Matyshak, V.A., Sil’chenkova, O.N., Ismailov, I.T., and Tret’yakov, V.F., Kinet. Catal., 2012, vol. 53, p. 91.

Margolis, L.Ya., Okislenie uglevodorodov na geterogennykh katalizatorakh (Oxidation of Hydrocarbons on Heterogeneous Catalysts), Moscow: Khimiya, 1977.

Rozovskii, A.Ya., Kinet. Catal., 2003, vol. 44, p. 360.

Kondrat'ev, V.N. and Nikitin, V.V., Kinetika i mekhanizm gazofaznykh reaktsii (Kinetics and Mechanism of Gas Phase Reactions), Moscow: Nauka, 1977, p. 318.

Feynman, R.P. and Hibbs, A.R., Quantum Mechanics and Path Integrals, New York: McGraw-Hill, 1965.

Feynman, R.P., Leyton, R.B., and Sands, R.B., Lectures on Physics, Addison Wesley, 1963–1965, vol. 6. Ch. 19.

Rice, P.O. and Teller, E.J., J. Chem. Phys., 1938, vol. 6, p. 489.

Funding

This work was supported by grant 18-03-006270-a from the Russian Foundation for Basic Research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Andrey Zeigarnik

Rights and permissions

About this article

Cite this article

Matyshak, V.A., Sil’chenkova, O.N. Information on Intermediates Is the Basis for Understanding the Mechanism of Catalytic Action. Kinet Catal 60, 573–581 (2019). https://doi.org/10.1134/S0023158419040086

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0023158419040086