Abstract

This paper presents an experimental study of diffusion jet combustion of gas at different flow rates of CH4–N2 and a constant flow rate of coal. Blow-off curves for a diffusion flame for different nozzle diameters are obtained. It is shown that an increase in the the nozzle diameter causes a decrease in the minimum residual flow rate of the fuel gas at which stable combustion is possible. As coal is supplied, the residual flow rate of the fuel gas also becomes slightly lower. The fluorescence of OH, which makes it possible to analyze the position and dynamics of the flame front is recorded.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

In the long term, coal remains one of the most important thermal power resources due to large world reserves and competitive low prices [1]. In Russia, the development of electricity production from fossil fuels is largely associated with an increase in the efficiency of existing coal-fired power plants, also during coal gasification with synthesis gas production [2]. At the same time, an important urgent task is to reduce the amount of harmful substances formed, especially soot and NOx [3, 4]. This problem is solved by optimizing the flame combustion aerodynamics in pulverized coal boilers in order to increase energy efficiency and reduce emissions into the environment.

The coal fuel flame combustion process was investigated using advanced diagnostic methods allowing for noninvasive measurements of the velocity, composition, and temperature of gas and particle concentration with further verification of computer models [5–7]. In [8], modern optical methods [laser Doppler velocimetry (LDV) and OH planar laser-induced fluorescence (OH PLIF)], Mie scattering photographs, a pyrometer, and measurement methods were used to profoundly examine the structure of a gas (methane) jet with combustion, containing coal particles (the average particle size was 25 \(\mu\)m, and the average mass size was 33 \(\mu\)m). In [8], there were mean velocity and particle diameter distributions, CO2 and O2 concentrations, and spatial correlations between the intensity of an OH fluorescence signal and Mie scattering, and it was concluded in that study that the combustion reaction occurred at the periphery of a cluster of sprayed coal particles in the upper flow region and penetrated into the cluster if the combustion process proceeded downstream.

Combustion of pulverized coal in the flame of an axisymmetric turbulent jet is a relatively simple (from the standpoint of the problem geometry) model for describing processes in the combustion chambers of real burners with a more complex geometry. Nevertheless, in this formulation, the main physicochemical processes affecting the flame loss, the fuel burnout rate, and the formation of harmful emissions can be considered in detail. However, the number of such paper is small. The turbulent combustion of a diffusion flame of a gas (propane) jet containing fine (less than 150 \(\mu\)m) coal particles (anthracite, brown coal, and bituminous coal) and the CO2 and O2 temperature and concentration distributions are given in [9]. It is established that, in the presence of coal particles, a heat flux from a jet becomes more intense. At the same time, no significant effect of these particles on flame loss is revealed.

These papers are used to verify numerical modeling methods [10], but the results obtained are limited by a small Reynolds number (Re = 2544), a fixed temperature, and the composition of a carrying phase.

Over the past 30 years, numerical modeling of the combustion of pulverized coal has been widely used for designing and optimizing power plants of various types and for improving and providing feasibility of new methods [11]. Many numerical methods and models have been developed (see, e.g., [12–17]). The studies given in [11–17] are supplemented by numerous experimental works carried out in laboratory and semi-industrial conditions [18–22]. However, there are practically no quantitative data in the literature on the characteristics of turbulent pulsations of the dispersed phase and on the features of clustering in a flow with an inhomogeneous density due to combustion.

The goal of this study is to use modern methods of optical diagnostics of turbulent reacting flows to obtain new experimental data on the dynamics of micromilling particles of coal fuel in a turbulent shear flow (jet) during the combustion of a pulverized coal flame.

EXPERIMENTAL TESTBED AND THE MEASUREMENT PROCEDURE

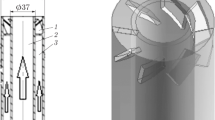

The burner testbed is an open circuit connected to cylinders with combustible gas (methane) and transport gas (nitrogen), whose flow rate is controlled by float rotameters. The schematic diagram of the device is shown in Fig. 1, which also illustrates the connection of the nozzle unit to the fuel and transport lines.

The experimental testbed is equipped with nozzles of the same internal geometry. Nonswirling jet flows with shock profiles at the nozzle cut are created using a bell-shaped Vitoshinskii nozzle having a preliminarily included section with embedded perforated plates for adjusting the flow in front of the nozzle. Diameters \(d\) of the bell-shaped nozzles used in the experiments are equal to 10, 15, and 23 mm. Coal is supplied by a screw feeder into a transport gas (nitrogen) line. Before the beginning of the experiment, the coal feeder is calibrated. A stirred mixture of propellant and nitrogen is fed into the nozzle. The stirring takes place in a long pipe (\(L_2 = 500\) mm and \(d_2 = 22\) mm), and methane is supplied via a needle directed toward the flow.

Experiments are carried out using bituminous long-flame coal from the Kuznetsk deposit with the following features and elemental composition: the mass fraction of water in an analytical sample is \(\mathrm{W}_a = 2\)%, the ash content in a dry state is \(\mathrm{A}_{d} = 21\)%, and the volatile yield is \(\mathrm{V}_{\mathrm daf} = 41\)%; the mass fractions of carbon, hydrogen, oxygen, nitrogen in a dry ash-free state are \(\mathrm{C}_{\mathrm daf} = 74.5\)%, \(\mathrm{H}_{\mathrm daf} = 4.9\)%, \(\mathrm{O}_{\mathrm daf} = 17.7\)%, and \(\mathrm{N}_{\mathrm daf} = 2.2\)%, respectively; the mass fraction of total sulfur in a dry state is \(\mathrm{S}_{\mathrm daf} = 0.6\)%.

The spectral dimensions of coal particles are measured using an optical-digital method, a Levenhuk digital microscope equipped with a built-in five-megapixel camera, and an image processing software package. It is established that 50% of particles have a diameter \(d_1<50\) \(\mu\)m, and the rest of the particles are 50 – 100 \(\mu\)m (Fig. 2).

The experiments are carried out for the following values of the main parameters: the coal flow rate is 0.2 kg/h, the N2flow rate is 3.0 – 7.7 liters/min, the CH4 flow rate is 1.2 – 3.3 liters/min, and the temperature is 291 K. The flow rates of N and CH4 are chosen so as to ensure that the coal particles are heated enough and that the velocity of the carrier flow is sufficiently high for transporting the particles to the nozzle. In all the experiments, the coal flow rate remains constant, and the feed system becomes clogged if the flow rate is increased.

The fluorescence of OH is recorded, which makes it possible to analyze the position and dynamics of the flame front. The OH PLIF system consists of a tunable pulsed dye laser and a pulsed neodymium laser (pump YAG laser) and an intensified chamber. A collimating optical device used to convert a laser beam into a laser sheet. A tunable laser excites the fluorescence of OH during the transition Q\(_1\) (8) of band \(\mathrm{A}^2\Sigma \pm \mathrm{X}^2\Pi\) (1–0). The average value of pulse energy with a wavelength of 283 nm is approximately 12 mJ. The OH fluorescence intensity is recorded using a video camera equipped with a UV lens and a bandpass optical filter (the transmission wavelength is \(310 \pm 10\) nm).

(a) Flame blow-off curves in the absence of coal supply for \(d=10\) (1), 15 (2), and 23 mm (4) and in the presence of coal supply for \(d=15\) mm (3); (b, c) the characteristic photographs of the flame for a nozzle diameter \(d=15\) mm in the absence and presence of coal supply, respectively, at different instances.

MEASUREMENT RESULTS

Figure 3a shows blow-off curves for the diffusion flame for different nozzle diameters. An increase in the nozzle diameter reduces the minimum residue Re of the flow rate \(Q\) of fuel gas CH4 in the absence of coal supply in the case where stable combustion is possible. A mild decrease in the residue is also observed in the case where the nozzle diameter is 15 mm in the presence of coal supply.

For a nozzle diameter of 15 mm, Figs. 3b and 3c show the typical photographs of a flame during the diffusion combustion of CH4 in the presence and absence of coal supply. It can be seen that no ignition of coal particles is observed as coal is supplied near the base of the flame. Characteristic glow in the vicinity of the flame edge at a distance of 50 mm from the nozzle is observed, with most particles burning in the diffusion layer. A coal flame is significantly brighter than a pilot flame due to emission. The charcoal particles are shaped as strips because of the long exposure time of the video camera.

Figure 4 shows the instantaneous distribution of the laser-induced OH fluorescence intensity in the case of diffusion combustion of the CH4–N2 mixture (the intensity is normalized to a maximum value).

As the OH radical is formed during combustion in the flame front and also present in combustion products, being in a state of thermal equilibrium with water, it can be assumed that the inner boundary (located closer to the jet axis) of the presence region of the OH radical corresponds to the position of the flame front. The flame front propagates in a direction opposite to the flow of the CH4–N2 mixture, partially mixed with ambient air due to molecular and turbulent diffusion.

CONCLUSIONS

Modern optical methods are used to perform the experimental studies of the diffusion combustion of long-flame coal from the Kuznetsk deposit in a CH4–N2 gas jet. For the shaped nozzles with diameters of 10, 15, and 23 mm, the limiting flow rates of the carrier gas for a diffusion flame are obtained. In the case with no coal supply, with an increase in the flow rate of Re, and with a fixed flow rate of CH4, which exceeds the critical value, the flame cannot stabilize near the nozzle and is carried away by the flow. In the presence of coal supply, the flame loss is observed sooner. The coal particles are ignited at a distance of 50 mm from the nozzle.

The presented instantaneous distributions of the fluorescence intensity of the OH radical show that the flame front is stabilized asymmetrically relative to the jet axis at a certain distance from the nozzle and experiences pulsations near the flame stabilization point.

The testbed was modernized within the framework of the State Assignment of the Kutateladze Institute of Thermophysics of the Siberian Branch of the Russian Academy of Sciences. The experimental and numerical studies were carried out with the financial support of the Russian Foundation for Basic Research (Grant No. 19-08-00781).

REFERENCES

Forecast of Energy Development in the World and Russia 2016, Ed. by A. A. Makarov, L. M. Grigor’ev, and T. A. Mitrovaya (Analytical Center for the Government of the Russian Federation, Energy Research Institute of the Russian Academy of Sciences, Moscow, 2016) [in Russian].

N. A. Abaimov, E. B. Butakov, A. P. Burdukov, et al., “Investigation of Air-Blown Two-Stage Entrained-Flow Gasification of Micronized Coal," Fuel 271, 117487 (2020).

E. Croiset, “NOx and SO2 Emissions from O2/CO2 Recycle Coal Combustion," Fuel 80 (14), 2117–2121 (2001).

C. R. Choi and C. N. Kim, “Numerical Investigation on the Flow, Combustion. and NOx Emission Characteristics in a 500 MWe Tangentially Fired Pulverized-Coal Boiler," Fuel 88(9), 1720–1731 (2009).

D. K. Sharaborin, R. V. Tolstoguzov, V. M. Dulin, and D. M. Markovich, “On the Structure of an Impact Jet with Flow Swirling and Combustion," Fiz. Goreniya Vzryva 56 (2), 10–16 (2020) [Combust., Expl., Shock Waves 56 (2), 131–136 (2020)].

A. S. Lobasov, V. M. Dulin, Ar. A. Dekterev, and A. V. Minakov, “Turbulent Transport in a Swirling Jet with Vortex Core Breakdown. PIV/PLIF-Measurement and Numerical Simulation," Teplofiz. Aeromekh. 26 (3), 381–389 (2019) [Thermophys. Aeromech. 26 (3), 381–389 (2019)].

I. V. Litvinov, D. K. Sharaborin, and S. I. Shtork, “Reconstruction the Structural Parameters of a Precessing Vortex by SPIV and Acoustic Sensor," Exp. Fluids 60 (9), 139 (2019).

S. M. Hwang, R. Kurose, F. Akamatsu, et al., “Application of Optical Diagnostics Techniques to a Laboratory-Scale Turbulent Pulverized Coal Flame," Energy Fuels 19 (2), 382–392 (2005).

S. R. Gollahalli, A. Prasad, and S. Gundavelli, “Lift-off Characteristics and Flame Base Structure of Coal Seeded Gas Jet Flames," Proc. Inst. Mech. Eng. A 210 (5), 373–382 (1996).

N. Mika Hashimoto, R. Kurose, and H. Shirai, “Numerical Simulation of Pulverized Coal Jet Flame Employing the TDP Model," Fuel 97, 277–287 (2012).

M. Muto, H. Watanabe, R. Kurose, et al., “Large-Eddy Simulation of Pulverized Coal Jet Flame. Effect of Oxygen Concentration on NOx Formation," Fuel 142, 152–163 (2015).

J. Watanabe, T. Okazaki, K. Yamamoto, et al., “Large-Eddy Simulation of Pulverized Coal Combustion Using Flamelet Model," Proc. Combust. Inst. 36, 2155–2163 (2017).

A. Clements, S. Black, J. Szuhánszki, et al., “LES and RANS of Air and Oxy-Coal Combustion in a Pilot-Scale Facility: Predictions of Radiative Heat Transfer," Fuel 151, 146–155 (2015).

O. T. Stein, G. Olenik, A. Kronenburg, et al., “Towards Comprehensive Coal Combustion Modelling for LES," Flow Turb. Combust. 90, 859–884 (2013).

O. T. Stein, G. Olenik, and A. Kronenburg, “LES of Swirl-Stabilised Pulverised Coal Combustion in IFRF Furnace N 1," Proc. Combust. Inst. 35, 2819–2828 (2015).

M. Rabac, B. M. Franchetti, F. Marincola, et al., “Large Eddy Simulation of Coal Combustion in a Large-Scale Laboratory Furnace," Proc. Combust. Inst. 35, 3609–3617 (2015).

M. Rietha, A. G. Clementsc, M. Rabaçald, et al., “Flamelet LES Modeling of Coal Combustion with Detailed Devolatilization by Directly Coupled CPD," Proc. Combust. Inst. 36, 2181–2189 (2017).

M. Yu. Chernetskii and A. A. Dekterev, “Mathematical Model for Heat Transfer and Combustion in a Pulverized Coal Flame," Fiz. Goreniya Vzryva 47 (3), 37–46 (2011) [Combust., Expl., Shock Waves 47 (3), 280–288 (2011)].

S. V. Alekseenko, A. P. Burdukov, A. A. Dekterev, et al., “Physical and Mathematical Simulation of Aerodynamics and Combustion in the Furnace Chambers of Power Installations," Teploenergetika, No. 9, 67–72 (2011) [Therm. Eng. 58, 779 (2011)].

A. V. Gil and A. V. Starchenko, “Mathematical Modelling of Physical and Chemical Processes of Coal Combustion in Chamber Furnaces of Boiler Aggregates Based on the Package of Applied Programs FIRE 3D," Teplofiz. Aeromekh. 19 (5), 655–671 [Thermophys. Aeromech. 19 (2012) (5), 503–519 (2012)].

M. Chernetskiy, A. Dekterev, N. Chernetskaya, and K. Hanjalic, “Effects of Reburning Mechanically-Activated Micronized Coal on Reduction of NOx: Computational Study of a Real-Scale Tangentially-Fired Boiler," Fuel 214 215–229 (2018).

M. Yu. Chernetskiy, V. A. Kuznetsov, A. A. Dekterev, et al., “Comparative Analysis of Turbulence Model Effect on Description of the Processes of Pulverized Coal Combustion at Flow Swirl," Teplofiz. Aeromekh. 23 (4), 615–626 (2016) [Thermophys. Aeromech.23 (4), 591–602 (2016)].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alekseenko, S.V., Butakov, E.B., Chikishev, L.M. et al. EXPERIMENTAL STUDY OF DIFFUSION COMBUSTION OF A FINE PULVERIZED COAL IN A CH4–N2 GAS JET. J Appl Mech Tech Phy 61, 757–762 (2020). https://doi.org/10.1134/S0021894420050090

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021894420050090