Abstract

The results of modeling and optimization of a composite scintillator for recording thermal neutrons are presented. The interaction of thermal neutrons and γ-quanta with composites consisting of fragments of a glass scintillator containing 6Li was observed. The aim of the research was to determine the structure of a composite with high sensitivity to thermal neutrons and to provide effective suppression of signals from γ‑quanta. During the simulation, the optimal structural parameters of the composite were determined, such as the size of the fragments and the concentration of glass. According to the presented simulation results, optimized composites under thermal neutron irradiation can provide a neutron detection efficiency of at least 50% with a sensitivity to γ-quanta at the level η < 10–6.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The general requirements for neutron detectors are a high efficiency of neutron registration, low sensitivity to γ-radiation, as well as the ability to maintain high count rates and ensure stability in long exposures. Lithium-containing glass scintillators are particularly attractive for this purpose. The cross-section of the (n, α)-reaction on the 6Li nucleus for thermal neutrons is 940 b at a neutron energy of 0.025 eV, which provides a detection efficiency of 91% at a scintillator thickness of 2 mm. The speed of such scintillators is determined by the short decay time of the main component, which as a rule, does not exceed 60 ns.

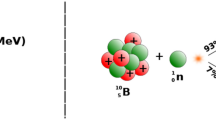

A significant drawback of such scintillators is their inherent γ-sensitivity, which can distort the results of neutron flux measurements in the presence of background γ- radiation. The γ-radiation interacts with the scintillator material mainly through Compton scattering with the formation of recoil electrons, while as a result of the capture of a neutron by a 6Li nucleus, heavy charged particles with a short range arise:

The energy yield of reaction (1) significantly exceeds the possible energy losses of electrons that occur from the interaction of γ-quanta with the scintillator material. However, due to the high specific energy losses of heavy charged particles, the scintillator flash is “quenched” by a factor of approximately 0.32 [1], which corresponds to the electron equivalent of the released energy Tee = 1.53 MeV. In this case, the number of scintillation photons generated in the event of neutron capture in lithium glass can be compared with the number of scintillation photons produced by electrons during γ-interaction. As a result, pulses from some γ-quanta may exceed the preset detection threshold in amplitude and will be incorrectly identified as neutron capture in the detector. A Pulse Shape Discrimination (PSD) can reduce this effect; however, it complicates the detector system and the effectiveness of the method is limited for high count rates and in a wide dynamic range of signal amplitudes [2].

One approach to reducing this unwanted γ-sensitivity is to embed fragments of a glass scintillator containing 6Li, into an organic matrix. In such a structure, the short-range products of the neutron capture reaction (Rα = 6 μm, Rt = 36 μm [3]) completely leave their energy in the scintillator, while the energy release of electrons with large ranges will largely occur on the neutral matrix material. In this way, one can separate the amplitude distributions from γ-quanta and neutrons. The size and distance between the grains of the glass scintillator can be chosen so that the properties of the detector will correspond to the conditions of a particular experiment. Scintillators of this kind are commonly referred to as heterogeneous or composite scintillators (composites).

Composite materials, which include scintillator grains surrounded by organic material, can provide good separation of the neutron and γ-distribution in pulse amplitude, while the detector has a higher count rate than detectors based on 3He. The need for neutron detectors with low sensitivity to γ-quanta has led to the appearance of a number of works in the field of research on composite scintillators [4–10].

Despite the conceptual simplicity of the approach, the actual response characteristics of the composite material can strongly depend on the composition of the organic matrix, the size of the scintillator grains and the distances between them, as well as on the optical properties of various components. Therefore, using simulation, it is necessary to study and limit the range of admissible parameters of the heterogeneous scintillator and determine the possible configurations of the composite. With an optimal configuration, the ranges of neutron capture products should fit into a separate fragment of the scintillator, and the distance between glass grains in the composite and their concentration should provide a high efficiency of neutron detection and low sensitivity to γ quanta. The refractive indices of organic and inorganic materials should be similar in order to ensure the minimum amount of reflections due to differences in refractive index.

In earlier works [6, 11, 12], the optimization of composite scintillators was carried out for detectors used to control the movement of fissile materials. In this case, it was assumed that the detector was irradiated with fast neutrons. In this work, a composite consisting of lithium glass fragments fixed in an organic matrix was investigated as a thermal neutron detector. Various organic polymers have been considered as matrix materials. The article presents a study by the Monte Carlo method of the characteristics of the response of a composite scintillator depending on the size of the scintillator grains and their concentration in a mixture with various organic polymers under irradiation with thermal neutrons and γ-quanta.

DESCRIPTION OF THE COMPOSITE MODEL

The 40 × 2 mm composite scintillator was disk shaped and was a neutral matrix with randomly placed scintillator grains. In calculations performed for a homogeneous glass scintillator, the dimensions of the latter were equal to those of the composite. NE 912 lithium glass (Nuclear Enterprises) was used as a scintillator. The scintillator grains had a cubic shape; the dimensions of the cube edge varied from 200 to 800 µm. It was assumed that thermal neutrons fall normally to the end of the scintillator and have an energy distribution corresponding to the Maxwell–Boltzmann distribution with a temperature of 25 meV. In studies of γ‑sensitivity, a 60Co point source was located along the axis of the disk at a distance of 16 mm from the end of the scintillator. The passage of scintillation photons and the response of the photodetector were not considered in the work; only the value of the transferred energy in the scintillator material was recorded.

Various organic polymers with a refractive index close to lithium glass can be considered as a matrix material. In our case, the calculations were made for a silicone compound, epoxy resin, and an acrylic. When modeling the composite, the characteristics of the materials listed in Table 1 were used.

To calculate the spectra of the energy transferred to the scintillator upon exposure to thermal neutrons and γ-quanta, a computer program for simulating the Monte Carlo method was developed. The program used Geant4 version 10.06.p01 [13] and a number of standard packages of physical processes: the package of electromagnetic processes G4EmStandardPhysics_option4 and the package of inelastic processes (including for neutrons up to 20 MeV (Low Energy Nuclear Data)) G4HadronPhysicsQGSP_BERT_HP.

THE EFFICIENCY OF THE COMPOSITE TO NEUTRONS

When a composite is irradiated with thermal neutrons, the energy release in scintillator fragments depends on their size and concentration. The shape of the energy release spectrum upon interaction with neutrons was calculated for a homogeneous glass scintillator and a composite with glass grains that were 400 μm in size at a concentration of 35%. The results of the experiment are shown in Fig. 1. On the right side of the graph, one can see a peak with an energy of 4.8 MeV, which corresponds to the total energy of the products of the reaction of neutron capture by a nucleus 6Li. In the region bounded on one side by the peak of total absorption and on the other by the energy of 2.05 MeV, the range of one of the charged particles goes beyond the scintillator. The left boundary of the region is determined by the energy of the α-particle and corresponds to the situation where the capture of a neutron occurs at the interface and the range of the triton lies entirely in the volume of the neutral matrix.

When calculating the efficiency, a neutron was considered registered if the paths of secondary particles fit completely in the scintillator grain. This approach provided a reliable estimate from below of the composite efficiency to neutrons and made it possible to significantly save the time spent on modeling. The detection efficiency was determined as the ratio of the number of registered neutrons to the total number of neutrons that crossed the volume of the composite. The concentration of the glass scintillator was determined as the volume fraction of glass in the total volume of the composite and varied in the calculations from 20 to 35%. The calculation result is shown in Fig. 2.

According to Fig. 2, the detection efficiency first increases with an increase in the fragments of the glass scintillator; it reaches a maximum value in the range of grain sizes from 400 to 500 μm and gradually decreases with their further increase. The decrease in efficiency in the region of small grain sizes is associated with an increase in the number of events in which the products of the neutron capture reaction cross the boundaries of glass fragments. With an increase in the grain size above the optimal value at a fixed glass concentration, the area of the zones where there is no glass and the neutron flies through the composite without crossing a single fragment of the scintillator increases. The presence of a pronounced “plateau” on the efficiency dependences in the grain size range of 400–500 µm makes it possible to use the simplest method of grinding with subsequent sorting on sieves for the manufacture of glass scintillator powder.

THE GAMMA SENSITIVITY OF THE COMPOSITE

In this work, the γ-sensitivity was defined as the ratio of the number of γ-quanta that released energy in the scintillator in excess of the specified detection threshold to the total number of γ-quanta that crossed the sensitive volume of the detector. To illustrate the capabilities of the composite scintillator to suppress the γ-sensitivity of the detector, we calculated the spectra of energy release from γ-quanta of the 60Co source in homogeneous and composite scintillators with the same dimensions. The calculations were performed for a composite scintillator with a glass concentration of 35% and a grain size of 400 μm. The calculation result is shown in Fig. 3.

As seen in Fig. 3, the spectrum of gamma quanta is noticeably shifted towards low energies. The number of events that exceed the electronic equivalent of the energy released during neutron capture (Tee = 1.53 MeV), for glass is approximately 2 orders of magnitude higher than for a composite.

The experimental energy spectra for neutron registration are well described by the normal distribution with mathematical expectation Tee and standard deviation σ. The threshold for neutron registration is set at the level L = Tee – kσ, where the coefficient k, depending on the specific conditions of the experiment, may lie within 2 ≤ k ≤ 4. The standard deviation for a specific detector based on a composite depends on a number of conditions: the optical characteristics of the components, the parameters of the photodetector, signal processing methods, etc. In our case, in the process of modeling the reaction of the composite to γ-quanta, the conditional detection threshold was set at the level R = 0.8Tee = 1.22 MeV. The results of calculating the γ-sensitivity of the composite depending on the size of the glass grains for different values of the glass concentration are shown in Fig. 4.

To select the glass concentration in the composite in accordance with the experimental conditions (the level and energy distribution of the γ-background, the requirements for the neutron detection efficiency, etc.), one can use the data in Fig. 5. This figure shows the dependences of the neutron detection efficiency and γ-sensitivity for a composite with grains of 400 μm at various glass concentrations. It can be seen that an increase in the glass concentration in the composite leads to a rapid increase in the γ-sensitivity. Therefore, the study of the properties of the composite at glass concentrations exceeding 35% was considered inappropriate. By choosing the working composition of the composite, it is possible to obtain a scintillator that meets various requirements for operation in mixed fields of neutron and γ-radiation. To be able to take the energy resolution of the detectors when choosing the glass concentration into account, we calculated the dependence of the γ-sensitivity for a composite with 400 μm grains on the detection threshold as a percentage of Tee. The calculation result is shown in Fig. 6.

The main function performed by the matrix material of a heterogeneous scintillator is to absorb the energy released by γ quanta in the bulk of the composite. Therefore, it is of interest to compare composites with matrices of various organic compounds with similar optical properties. The calculation results for various compositions of the composite in comparison with a homogeneous glass scintillator of similar geometry are presented in Table 2.

Analysis of the data presented in the table allows us to conclude that, in the energy approximation, the choice of the matrix material from the considered set of compounds affects the quality of the composite insignificantly, and the optical characteristics of the material will determine the properties of the detector. The final choice of the composition is possible after experimental studies of composites based on various organic compounds.

CONCLUSIONS

Simulation and optimization of a composite scintillator designed for registration of thermal neutrons that provide low sensitivity to γ-quanta have been carried out. The considered model of the composite consists of cubic fragments of lithium glass placed in a neutral organic matrix. The characteristics of the composite at various sizes of fragments and concentrations of lithium glass were determined using simulation in the Geant4 environment. The optimal configuration of the composite determined in the calculations is achieved at a glass volume concentration of 35% and a grain size in the range of 400–500 µm. Compared to a homogeneous glass scintillator of similar dimensions, the neutron detection efficiency of such a composite decreases from 91 to 56%, and the sensitivity to γ-quanta can be reduced by two orders of magnitude, to 4 × 10–7. Various materials are considered for use as a neutral matrix of the composite: acrylic, epoxy resin, and a silicone compound. It was found that in the energy approximation both the neutron detection efficiency and the γ-sensitivity of the composite are practically independent of which of the considered substances was used as the matrix material. Based on the results of this work, prototypes of various configurations will be built for experimental verification.

REFERENCES

Kuzmin, E.S., Bokuchava, G.D., Zimin, I.Yu., Kruglov, A.A., Kuchinskiy, N.A., and Malyshev, V.L., Instrum. Exp. Tech., 2021, vol. 64, no. 2, p. 195. https://doi.org/10.1134/S0020441221010279

Favalli, A., Iliev, M.L., Chung, K., Hurlbut, C., Martinez, H.P., Swinhoe, M.T., Zaitseva, N.P., and Ianakiev, K.D., IEEE Trans. Nucl. Sci., 2013, vol. 60, p. 1053. https://doi.org/10.1109/TNS.2013.2251900

Ziegler, J.F., Ziegler, M., and Biersack, J., Nucl. Instrum. Methods Phys. Res., Sect. B, 2010, vol. 268, p. 1818. https://doi.org/10.1016/j.nimb.2010.02.091

Ianakiev, K.D., Hehlen, M.P., Swinhoe, M.T., Favalli, A., Iliev, M.L., Lin, T.C., Bennett, B.L., and Barker, M.T., Nucl. Instrum. Methods Phys. Res., Sect. A, 2015, vol. 784, p. 189. https://doi.org/10.1016/j.nima.2014.10.073

Rich, G.C., Kazkaz, K., Martinez, H.P., and Gushue, T., Nucl. Instrum. Methods Phys. Res., Sect. A, 2015, vol. 794, p. 15. https://doi.org/10.1016/j.nima.2015.05.004

Mayer, M.F., Nattress, J., Trivelpiece, C., and Jovanovic, I., Nucl. Instrum. Methods Phys. Res., Sect. A, 2015, vol. 784, p. 168. https://doi.org/10.1016/j.nima.2014.09.023

Kazkaz, K., Bowden, N.S., and Pedretti, M., IEEE Trans. Nucl. Sci., 2013, vol. 60, p. 1416. https://doi.org/10.1109/TNS.2013.2249528

Shi, T., Nattress, J., Mayer, M., Lin, M.W., and Jovanovic, I., Nucl. Instrum. Methods Phys. Res., Sect. A, 2016, vol. 839, p. 86. https://doi.org/10.1016/j.nima.2016.09.041

Mayer, M., Nattress, J., Kukharev, V., Foster, A., Meddeb, A., Trivelpiece, C., Ounaies, Z., and Jovanovic, I., Nucl. Instrum. Methods Phys. Res., Sect. A, 2015, vol. 785, p. 117. https://doi.org/10.1016/j.nima.2015.03.014

Chernukhin, Y.I., Yudov, A.A., and Streltsov, S.I., Nucl. Energy Technol., 2015, vol. 1, p. 130. https://doi.org/10.1016/j.nucet.2016.01.005

Foster, A., Meddeb, A., Wilhelm, K., Nattress, J., Ounaies, Z., and Jovanovic, I., Nucl. Instrum. Methods Phys. Res., Sect. A, 2018, vol. 905, p. 29. https://doi.org/10.1016/J.NIMA.2018.07.018

Wiggins, B.W., Favalli, A., Iliev, M.L., Ianakiev, K.D., and Hehlen, M.P., Nucl. Instrum. Methods Phys. Res., Sect. A, 2019, vol. 915, p. 17. https://doi.org/10.1016/j.nima.2018.10.165

Geant4. A Simulation Toolkit. https://geant4.web.cern.ch/support/download.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kuzmin, E.S., Zimin, I.Y. Optimization of the Structure of a Heterogeneous Scintillator for Registration of Thermal Neutrons. Instrum Exp Tech 64, 657–662 (2021). https://doi.org/10.1134/S0020441221050201

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020441221050201