Abstract—

The results of a study of the characteristics of a thick gas electron multiplier based on a fiberglass plate with a 0.8–2.0-mm-thick double-sided copper coating in which 1 mm holes were drilled at a spacing of 1.5 mm are presented. The gas filling of the multiplier is a mixture of Ar + 5% isobutane. The energy resolution for the 55Fe line is 21%, the spatial resolution is 0.7 mm, the temporal resolution is better than 10 ns, and stable operation is provided up to an irradiation intensity of ~105 mm–2.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The gas electron multiplier (GEM) was invented by F. Sauli at the Center for European Nuclear Research in 1966 [1]; it is a representative of the class of microstrip detectors, i.e., it is a wireless structure. The GEM eliminates or minimizes surface leakage currents due to the fact that electron multiplication occurs in small holes. This solution made it possible to overcome the main drawback of all gas detectors to a considerable extent, namely, it eliminated the influence of the positive space charge, which is especially manifested at high gas amplification coefficients. Such a symbiosis of the best qualities of wire coordinate detectors, microstrip gas chambers and microchannel plates allowed a significant improvement in the loading capabilities of gas detectors, their temporal and spatial resolutions, and also provides flexibility and simplicity of design. One should take the positive factors of the lack of freon and explosive additives in the gas supply into account, which becomes a serious advantage of a GEM in the operation of gas detectors from an environmental point of view.

One of the main advantages of the classic GEM is its excellent spatial resolution [2], which is a consequence of the small size of the holes and the small spacing between them. However, in some applications, such as a ring-imaging Cherenkov detector (RICH) and two-phase temporary projection cameras using liquefied inert gases, a spatial resolution of fractions of a millimeter is sufficient. For these purposes, a simpler version of the GEM was developed, that is, the thick gas electron multiplier (TGEM) [3].

The design of the TGEM is similar to that of the detector on microchannel plates. Holes are drilled on conventional equipment for a conventional printed circuit board that is metalized on both sides and has a thickness of 0.4–2.0 mm. The typical size of the diameter of the hole is chosen equal to the thickness of the board and the distance between the holes is usually approximately two hole diameters. This type of detector can be made larger than 0.5 × 0.5 m. Another advantage of a TGEM is that it is a self-supporting structure that does not require special equipment for stretching and tensioning plates in the production of large areas of GEM or TGEM.

TGEM DESIGN

A detailed description of GEM and TGEM elements, as well as detectors developed on their basis for experiments in various studies, was given in [4]. The simplest and most affordable method of producing a wireless coordinate gas detector under normal laboratory conditions based on the results of this work related to the design of TGEM was shown in [5].

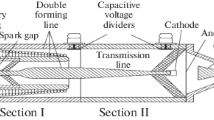

In the standard version, a TGEM, like a GEM, is a foil-coated fiberglass plate with many holes on both sides (Fig. 1). The holes have the shape of a double cone and are arranged in the form of a hexagonal matrix. A 1.5 mm spacing is used and the diameter is 1.0 mm (1.2 mm with a chamfer for metal).

When a potential difference is applied between the metal surfaces of the electrodes, a strong electric field with a strength of 10 to 40 kV/cm is formed in the holes, which is sufficient to initiate electron reproduction.

Primary electrons formed, for example, by α radiation in the gas gap above the upper TGEM electrode (Fig. 2), drift along the lines of force and focus into the holes in which Townsend avalanche electron multiplication occurs under the influence of a strong electric field (Fig. 3). Thus, each hole is an independent proportional counter. In this case, the avalanche electrons can leave a hole in the gas gap for further propagation in the subsequent cascade of the multiplier.

The main advantage of this device is the absence of the influence of the space charge of positive ions, which quickly resolves within the length of the hole and does not take part in the formation of the signal. Due to this fact, no breakdown occurs in the electronics when reading the signal from the signal electrode, which is separated from the amplification section by the induction gap. In this case, the transverse size of the signal induced at the read electrode is sufficiently large, which allows improvement of the spatial resolution by finding the center of gravity of the induced charge.

Figure 4 shows a comparison of the maximum achievable gas amplification factors for various hole devices: a GEM, glass capillary plates (CP) and a TGEM (CP G10), taken from [6], for various types of exposures (X-rays, γ rays, and α particles). The gas mixture consisted of Ar + 20% CO2 using GEM, Ar + 5% CH4 when using glass capillary plates, and Ar + 5% isobutane using TGEM. The flows of particles and quanta in these tests had the following intensities: γ rays, 109 mm–2; X-rays, 105 mm–2; and α particles, 100 mm–2.

The maximum achievable gas amplification depending on the voltage: 1–3, for GEM exposure γ beams (1), X-rays (2) and α-particles + X-rays (3); 4, 5, for glass capillary plates (CPs) when exposed to X-rays (4) and α‑particles (5); 6, 7, for thick gas electron multipliers (TGEM or G10 CP) when irradiated with X-rays (6) and α-particles (7).

The achieved gas amplification factors for TGEM are approximately 10 times higher than those for a GEM. This effect can be explained by the fact that the influence of a positive space charge on the process of electron multiplication in the amplification region decreases due to an increase in the Reter threshold [7], which occurs with an increase in the thickness of the amplification gap, where the critical charge density for which the streamer forms also increases.

A TGEM can have a higher coefficient of gas amplification by subjecting the edges of the holes to chemical etching or making them conical, as shown in [8].

Other modifications of the thick gas electron multiplier are metal and wire resistive TGEMs, as well as TGEMs with strip readout electrodes. In these devices, the maximum values of the gas amplification coefficient are increased and their reliability from the point of view of sparking is increased.

DISCUSSION

The energy, spatial, and temporal resolutions of these devices have been investigated in various works. Figure 5 from [9] shows the spectrum of the amplitudes of 55Fe pulses recorded in a double TGEM. As can be seen, the energy resolution is 21%, which is typical for gas position-sensitive detectors of this class. Figure 6 shows the results of the estimation of the spatial resolution [9], which was 0.7 mm (FWHM). This result is 5 times lower than that for a GEM, which is explained by the significantly large spacing between the holes in the TGEM. It follows that the use of a TGEM can be attractive in applications where moderate spatial resolution and high gas amplification are required, for example, as a UV photon detector.

The time resolution (Fig. 7) measured in [10] using a single TGEM was 8 ns during the detection of ultraviolet photons; the same results (7–8 ns) were obtained with charged particles.

Instability of the gas gain over time [4] was not detected up to a value of 105 mm–2.

CONCLUSIONS

It has been shown here that thick GEMs (TGEMs) have a rather high gas gain and, in combination with the corresponding radiation converters, can be used for detecting Cherenkov light, neutrons, X-rays, charged particles, etc. The use of TGEMs is being considered for dark matter research projects and neutrino experiments.

The absence of freon and explosive additives in the gas supply is a serious advantage of TGEM.

REFERENCES

Sauli, F., Nucl. Instrum. Methods Phys. Res.,Sect. A, 1997, vol. 386, p. 531.

Peskov, V., Cortesi, M., Chechic, M., and Breskin, A., J. Instrum., 2010, vol. 5, p. 11004. https://doi.org/10.1088/1748-0221/5/11/P11004

Buzulutskov, A.F., Instrum. Exp. Tech., 2007, vol. 50, no. 3, p. 287.

Periale, L., Peskov, V., Carlson, P., Francke, T., Pavlopolous, P., Picchi, P., and Pictropaolo, F., Nucl. Instrum. Methods Phys. Res.,Sect. A, 2002, vol. 78, p. 377. https://doi.org/10.1016/S0168-9002(01)01779-X

Razin, V.I., Marin, V.N., Ovchinnikov, B.M., and Reshetin, A.I., Preprint of Institute for Nuclear Research, Russ. Acad. Sci., Moscow, 2009, no. 1227/2009.

Ostling, J., Brahme, V., Danielson, M., Fonte, P., Francke, T., Iacobaeus, C., and Peskov, V., IEEE Trans. Nucl. Sci., 2003, vol. 50, no. 4, p. 809. https://doi.org/10.1109/TNS.2003.814562

Raether, H., Electron Avalanches and Breakdown in Gases, London: Butterworts, 1964.

Shalem, C., Chechic, R., Breskin, A., and Michaeli, K., Nucl. Instrum. Methods Phys. Res.,Sect. A, 2006, vol. 558, no. 2, p. 475. https://doi.org/10.1016/j.nima.2005.12.241

Cortesi, M., Alon, R., Chechik, R., Breshkin, A., Vartsky, D., and Dangendorf, V., J. Instrum., 2007, vol. 2, p. 09002.

Breskin, A., CERN Internal Report, Geneva, 2008.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Razin, V.I. A Thick Gas Electronic Multiplier. Instrum Exp Tech 63, 161–164 (2020). https://doi.org/10.1134/S0020441220020153

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020441220020153