Abstract

We have designed and developed an experimental setup to measure the Seebeck coefficient of a variety of samples at cryogenic temperatures and under magnetic fields up to 7 T employing the physical property measurement system (PPMS). The measurement technique uses a low frequency ac thermal gradient generated by two thin film heaters in thermal contact with the sample. Heaters and temperature sensors are all fitted on a standard PPMS sample puck. The validity of this method is tested by measuring the thermoelectric power of several superconductors and thermoelectric samples. We have used this technique to measure the thermoelectric power of various topological insulator single crystals (Pb0.8Sn0.2Te, Bi2Te3, Bi2Se2.1Te0.9, and Sb2Te3). The developed hardware and software control is suitable for studying the thermoelectric power of small samples (length 2 mm) in a commercial cryomagnetic system (PPMS) and it allows for studying superconductor, semiconductor, thermoelectric, or topological insulator material in wide temperature (2–300 K) and magnetic field (0–7 T) ranges.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 INTRODUCTION

The Seebeck effect that describes the conversion of thermal energy into electrical energy has become a focus of study in many research areas, such as in thermoelectrics, superconductivity, and semiconductors [1–5]. It is also known as thermoelectric power or thermopower and is estimated by calculating the ratio of the thermoelectric voltage (ΔV) to the temperature gradient (ΔT) across the sample, i.e., S = ΔV/ΔT. This effect is the opposite of the Peltier effect [6], in which a temperature gradient arises across the sample if an electrical voltage is applied to it. The power factor (ZT), which is a dimensionless quantity, describes the efficiency of a thermoelectric material and is defined as ZT = S 2σT/k, where S, σ, and k represent the Seebeck coefficient, electrical conductivity, and thermal conductivity, respectively. This implies that precise electrical and thermal transport measurements are crucial for estimating the power factor of thermoelectric materials. For simple semiconductors or single-band metals, the Seebeck coefficient is positive for the p-type and negative for the n-type conduction. Thus, the sign of the Seebeck coefficient could be taken as a preliminary probe to identify the nature of the bulk charge carriers, as a complement to Hall measurements. Since the electrical voltage of the sample is zero in the superconducting state, the Seebeck coefficient is zero and it can be used to identify the critical temperature in superconductivity research [7, 8]. Compared to electrical conductivity, the Seebeck coefficient is less sensitive to impurity or grain boundary scattering processes of charge carriers and thus provides a more accurate definition of the critical temperature of the superconducting state.

Recently, thermoelectric power under magnetic fields, magnetothermopower, has become a sensitive tool with which to study topological insulator, Dirac, and Weyl materials [9–14]. Thermoelectric power under high field also shows the quantum oscillations. By analyzing the oscillations, one can estimate the various physical parameters that characterize the Fermi surface and their topological nature. Thus, a precise magnetothermopower measurement setup would also be a useful tool for studying topological insulators, Weyl, and Dirac systems. Motivated by this, we have designed and adapted a Seebeck measurement setup based on the dual heaters technique under magnetic fields to the physical properties measurement systems (PPMS, Quantum Design).

There are several techniques that are used for determining the thermoelectric power of a material [15–23]. However, ac thermoelectric power measurement technique is among the more popular due to its nearly perfect compensation of spurious dc voltages, fast measurements, and small temperature gradient along the sample [21–23]. Here, we present an experimental setup, based on the ac technique developed by Choi et al. [20], that can be used to measure precise thermoelectric power of a small sample in a broad temperature range (2–400 K) and under magnetic fields up to 7 T. Using this method, we have successfully measured the thermoelectric power of small (millimeter sized) single and polycrystalline samples of superconductor, thermoelectric, and topological insulator materials.

2 MEASUREMENT PRINCIPLE

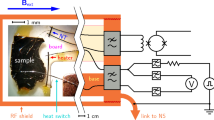

The thermoelectric power measurement hardware was built on a sample puck for the PPMS and equipped with heaters, temperature sensors, and thermal reference point to implement a high precision ac technique as described by Choi et al. [20] The sample was placed across two sapphire plates (as shown in Fig. 1). A sinusoidal temperature gradient of chosen amplitude and frequency is created across the sample using two thin film heaters H1 and H2. For most measurements we choose a gradient of 0.25 K and a frequency of 0.1 Hz. A sinusoidal current is applied separately to the heaters H1 and H2 using two Keithley 220 programmable current sources with a 90° phase offset between them. The heater currents are adjusted before each measurement to maintain the same temperature gradient. If I1 = I0sinωt and I2 = I0cosωt (with I0—amplitude and ω— angular frequency) are the current through H1 and H2, respectively, then total power

is constant with time. Here, R represents the heater resistance. This ensures that the average sample temperature is kept constant during the ac measurement.

(a) A schematic diagram of sample configuration for the Seebeck measurement. A sample is mounted on the sapphire plates. Two thermocouples TC1 and TC2 measure the temperature gradient across the sample. (b) The instruments setup for the thermoelectric power measurement. Two Keithley 220 current sources provide currents to the heaters (H1 and H2) to create the temperature gradient across the sample and a nanovoltmeter HP 34420A measures generated thermovoltage. (c) The sample mounting setup in the PPMS puck. (d) A photo of the modified PPMS puck (diameter 24 mm) in our setup showing the sample (YBCO), heaters (H1 and H2), and thermocouple reference. Two white patches on the sample surface are the indium contacts for holding two thermocouple wires (TC1 and TC2; see the text).

A sinusoidal temperature gradient of 0.25 K at a frequency of 0.1 Hz is created and measured using the two thermocouples attached to the sample over a time of about 90 s simultaneously; the sinusoidal thermovoltage of the same frequency is measured across the sample. The amplitudes of both waves are estimated through a nonlinear curve fitting routine. The Seebeck coefficient is then estimated by calculating the ratio of the amplitude of thermovoltage (ΔV) to temperature gradient (ΔT), i.e., S = ΔV/ΔT. Like the lock-in technique, this fitting method eliminates significantly the noise in the measured data, allowing for a precise determination of the Seebeck coefficient [20].

The Seebeck measurements were performed in the PPMS (Quantum Design) in the 2–300 K temperature range. Figure 1a shows the sample configuration used in this study for the Seebeck measurements. As shown in the figure, a sample is mounted across the two wedge-shaped sapphire plates using GE varnish. The minimum distance between these sapphire plates is less than 1 mm, implying that any sample having a length on the mm order can be measured using this setup. Two thin film heaters (H1 and H2) are installed on the sapphire plates using GE varnish. The high thermal conductivity values of the sapphire and GE varnish ensure that the sample is in good thermal contact with the heaters. Two Keithley 220 current sources provide sinusoidal currents (I1 and I2) to H1 and H2 separately and create a sinusoidal temperature gradient of 0.25 K across the sample. The phase shift between the currents, I1 and I2, is 90°. Two constantan-copper thermocouples (TC1 and TC2) measure the temperature gradient across the sample. The open wires of both thermocouples are thermally anchored at a reference point on the puck so that only the temperature difference between this point and the spot on the sample is measured by each thermocouple. The TC reference consists of insulating thermal copper grease; thermocouple wires are embedded inside and held in place by pressing with a rectangular sapphire plate to ensure a homogeneous thermal environment. The temperature of the TC reference is measured by a Cernox (CX) temperature sensor embedded in the copper grease. The high thermal conductivity of copper grease ensures good thermal contact between the ends of the thermocouple wires and the CX temperature sensor. The temperature of each point on the sample where the thermocouples are attached is then measured by using the reference temperature from the CX thermometer and the thermovoltage of each thermocouple averaged over the 90 s measurement time. The sinusoidally changing thermoelectric voltage of the sample is collected during the 90 s measurement time (typically 1000 data points) using the two copper wires of the constantan-copper thermocouples and the differential input of the voltmeter. The overall circuit diagram of our experimental setup is displayed in Fig. 1b. Two programmable current sources (Keithley 220) provide the ac current to H1 and H2. There are two HP 34420A nanovoltmeters with two input channels each, one for measuring the voltage of thermocouples TC1 and TC2 (in Ch1 and Ch2) and another for measuring the sample’s thermovoltage (in Ch1). The whole setup is built on the PPMS resistivity puck as sketched in Fig. 1c. Our modified PPMS puck is shown in Fig. 1d. The instruments and the puck are connected by the PPMS user bridge cable.

As shown in Fig. 1a, a HP 34420A nanovoltmeter measures the voltage across the copper wires Cu1 (of TC1) and Cu2 (of TC2) and the sample

The measured thermoelectric voltage of the sample has to be corrected for the contribution of the copper wires used for measurement, Cu1 and Cu2. The thermoelectric voltage across the copper wires was calibrated by using an YBa2Cu3O7 (YBCO) high temperature superconductor sample below its critical temperature; and at higher temperatures, high purity lead was employed, using the known thermoelectric power of lead.

For measurements in magnetic fields all thermometers and wires have to be calibrated to take into account any change of properties in magnetic fields. The CX temperature sensor at the reference point has a negligible field dependence up to the maximum field of 7 T. This was tested in a careful measurement after stabilizing the PPMS temperature and varying the external field. However, the constantan-copper thermocouples show a field dependence that cannot be neglected. They have been calibrated by applying a constant temperature gradient between the junction and the reference point using one of the thin film heaters. The response of the thermocouple was monitored until the temperature gradient in zero magnetic field became stationary and constant with time. The value of the applied current was adjusted such a way that it creates a constant temperature gradient of 0.5 K. The field correction to the thermoelectric voltage of the constantan-copper thermocouples was then measured at different magnetic field values and a numerical routine was developed to apply the correction in any future measurement. Similarly, the magnetic field dependence of thermovoltage across the copper wires Cu1 and Cu2 was carried out using a manganin foil as the reference sample. The thermoelectric power and its field dependence of the manganin foil had been calibrated previously by employing the thermal transport option (TTO) of the PPMS. The field correction of the copper wires has been implemented in the software controlling the measurement process and evaluating the thermoelectric signal of the sample to be measured. A nonlinear curve fitting procedure was used to determine the amplitude of both the thermal gradient and the thermoelectric voltage across the sample from the corresponding sinusoidal responses. The PPMS temperature controller is used to control the sample temperature. The instruments, including PPMS, are interconnected by the GPIB interface and data are collected in the computer using the Visual Basic program. All the measurements were performed in high vacuum, typically 10–6 Torr.

3 MEASUREMENT RESULTS

The experimental setup and algorithm were tested in zero magnetic field by measuring two known superconducting materials, Rb0.8Fe2Se2 single crystal and K0.4Ba0.6Fe2As2 polycrystal [25, 26]. The data are shown in Fig. 2a. Rb0.8Fe2Se2 shows a positive Seebeck coefficient at room temperature that turns negative with decreasing temperature below T = 210 K. However, K0.4Ba0.6Fe2As2 shows a positive Seebeck coefficient over the whole temperature range. For both samples, the thermopower shows a sudden jump to zero at the critical temperatures of TC = 31 K and 38 K, respectively. These transition temperatures are consistent with the corresponding resistivity measurements [25, 26].

(a) Temperature dependence of the Seebeck coefficient of K0.4Ba0.6Fe2As2 polycrystal and Rb0.8Fe2Se2 single crystal samples. The superconducting transition temperatures, TC = 31 K and 38 K are shown by the arrows. (b) Temperature dependence of the Seebeck coefficient for the Sb2Te2Se single crystal at 0 T (solid rectangle) and 7 T (solid circle). The open symbols (star— 0 T, triangle—9 T) represent previously reported data [24] obtained using the TTO option in PPMS (Quantum Design).

The thermoelectric power and its field dependence were measured for several topological systems. Sb2Te2Se is a good thermoelectric compound and its topological insulator nature has recently been proven by both experimental and theoretical studies [27, 28]. Figure 2b presents the Seebeck measurements at different temperatures in a semi-log plot for a Sb2Te2Se single crystal that was used in our previous study [28]. The Seebeck value at T = 300 K is S = 35 V K–1; it decreases with temperature and changes sign to negative at T = 140 K. However, it returns to the positive with further decrease in temperature below T = 10 K. The thermopower value in our measurements is consistent with previous data [24] (see Fig. 2b). In order to investigate the influence of magnetic fields, we have measured the thermopower of Sb2Te2Se under 7 T of applied field. The Sb2Te2Se sample shows a positive magnetothermopower and follows a similar temperature dependence as that previously measured at 9 T (the blue dashed line in Fig. 2b). It is important to note that the magnetothermopower of our Sb2Te2Se sample at 7 T is higher than that in the previous report [24] at 9 T. The magnetic field response of a sample depends on its crystalline quality. Thus, the higher magnetothermopower of our sample could be due to its better crystalline quality [residual resistivity ratio (RRR) = 3.5] as compared to the sample used in [24] (RRR = 2.3).

From the thermopower measurements of the super-conducting and topological samples, we have shown the validity of our experimental approach. We thus proceeded to implement this technique for other topological systems. Figure 3a shows the temperature dependence of the Seebeck coefficient of a Pb1 –xSnxTe (x = 0.2) single crystal. Theoretical and experimental studies have confirmed that Pb1 –xSnxTe undergoes a topological phase transition (topologically trivial to non-trivial) at a critical doping level xc = 0.25 [29, 30]. Here, we have measured the thermoelectric power of Pb1 –xSnxTe (x = 0.2) just below the critical doping. At room temperature, the value of the Seebeck coefficient is measured to be S = 50 V K–1. The S value decreases with temperature and becomes negative below T = 180 K. Its absolute value decreases with further decrease in temperature and becomes nearly zero at T = 10 K. The Pb1 –xSnxTe (x = 0.2) sample shows a positive magnetothermopower under the magnetic field of 7 T. We have also studied the magnetic field dependence of the Seebeck coefficient. Figure 3b shows the normalized Seebeck coefficient, S (B)/S (0), of a Pb1 –xSnxTe (x = 0.2) single crystal at different temperatures. The Seebeck coefficient shows the parabolic (upward) dependence on the magnetic field. The sign of curvature changes (upward to downward) as the temperature is lowered below T = 200 K. This is because of the sign change of the thermopower value around that temperature. It should be noted that at low temperatures (15 25 K), there is a signature of quantum oscillations at higher fields as shown in the inset to Fig. 3b. Higher magnetic fields (beyond the current field range up to 7 T) are needed to resolve these oscillations and study their properties. Similarly, Fig. 3c shows the thermopower of the single crystals Bi2Te3, Bi2Se2.1Te0.9 (BST), and Sb2Te3 at zero and 7 T applied fields. The topological nature of these compounds has already been confirmed by our previous measurements [31–35]. All of the above samples show the positive magnetothermopower. The data obtained on the topological samples here can be used to estimate various physical parameters characterizing the system using the Mott relation [36] (see [12] and references therein).

(a) Temperature dependence of the Seebeck coefficient for a Pb0.8Sn0.2Te single crystal under magnetic fields of 0 and 7 T. (b) Magnetic field dependence of the Seebeck coefficient of a Pb0.8Sn0.2Te single crystal at different temperatures. The curvature of the Seebeck curve changes while lowering the temperature below T = 200 K. Inset: Low temperature (15 and 25 K) curves showing a signature of quantum oscillations at higher fields. (c) Temperature dependence of the Seebeck coefficient for Bi2Te3, Bi2Se2.1Te0.9 (BST), and Sb2Te3 single crystals under magnetic fields of 0 (symbols with lines) and 7 T (dashed lines).

4 SUMMARY

In this work, we have adapted the ac technique for the precise measurement of the Seebeck coefficient of small samples to the Physical Property Measurements System for temperature and magnetic field control. Using this experimental setup, we have successfully measured the thermoelectric power of various topological insulator and superconducting compounds in cryogenic temperatures and in strong magnetic fields. The novelty of this experimental setup is that it is applicable to a very small (2 mm in length) and very thin (0.1 mm) sample of any shape, which might not be possible in other experimental techniques, such as the TTO option in PPMS (Quantum Design), in magnetic fields up to 7 T. Measurements of various samples, including iron pnictide superconductors and topological insulator compounds, in a wide temperature range and in magnetic fields have been presented. These results validate the developed hardware and prove the high precision of the method.

REFERENCES

DiSalvo, F.J., Science, 1999, vol. 285, p. 703. https://doi.org/10.1126/science.285.5428.703

Bell, L., Science, 2008, vol. 321, p. 1457. https://doi.org/10.1126/science.1158899

Cyr-Choinire, O., Badoux, S., Grissonnanche, G., Michon, B., Afshar, S.A.A., Fortier, S., LeBoeuf, D., Graf, D., Day, J., Bonn, D. A., Hardy, W. N., Liang, R., Doiron-Leyraud, N., and Taillefer, L., Phys. Rev. X, 2017, vol. 7, p. 031042. https://doi.org/10.1103/PhysRevX.7.031042

Tapp, J.H., Tang, Z., Lv, B., Sasmal, K., Lorenz, B., Chu, P.C.W., and Guloy, A.M., Phys. Rev. B, 2008, vol. 78, p. 060505. https://doi.org/10.1103/PhysRevB.78.060505

Goldsmid, H. and Sharp, J., J. Electron. Mater., 1999, vol. 28, p. 869. https://doi.org/10.1007/s11664-999-0211-y

Martin, J., Tritt, T., and Uher, C., J. Appl. Phys., 2010, vol. 108, p. 121101. https://doi.org/10.1063/1.3503505

Lv, B., Deng, L., Gooch, M., Wei, F., Sun, Y., Meen, J. K., Xue, Y.Y., Lorenz, B., and Chu, C.W., Proc. Natl. Acad. Sci. U. S. A., 2011, vol. 108, p. 15705. https://doi.org/10.1073/pnas.1112150108

Gofryk, K., Griveau, J.-C., Riseborough, P.S., and Durakiewicz, T., Phys. Rev. B, 2016, vol. 94, p. 195117. https://doi.org/10.1103/PhysRevB.94.195117

Hor, Y., Qu, D., Ong, N., and Cava, R.J., J. Phys.: Condens. Matter, 2010, vol. 22, p. 375801. https://doi.org/10.1088/0953-8984/22/37/375801

Matusiak, M., Cooper, J., and Kaczorowski, D., Nat. Commun., 2017, vol. 8, p. 15219. https://doi.org/10.1038/ncomms15219

Qu, D.-X., Hor, Y.S., and Cava, R.J., Phys. Rev. Lett., 2012, vol. 109, p. 246602. https://doi.org/10.1103/PhysRevLett.109.246602

Liang, T., Gibson, Q., Xiong, J., Hirschberger, M., Koduvayur, S.P., Cava, R., and Ong, N., Nat. Commun., 2013, vol. 4, p. 2696. https://doi.org/10.1038/ncomms3696

Stockert, U., Reis, R., Ajeesh, M.O., Watzman, S.J., Schmidt, M., Shekhar, C., Heremans, J.P., Baenitz, C.M., and Nicklas, M., J. Phys.: Condens. Matter, 2017, vol. 29, p. 325701. https://doi.org/10.1088/1361-648X/aa7a3b

Fauque, B., Butch, N.P., Syers, P., Paglione, J., Wiedmann, S., Collaudin, A., Grena, B., Zeitler, U., and Behnia, K., Phys. Rev. B, 2013, vol. 87, p. 035133. https://doi.org/10.1103/PhysRevB.87.035133

Zhou, Z. and Uher, C., Rev. Sci. Instrum., 2005, vol. 76, p. 023901. https://doi.org/10.1063/1.1835631

Rouleau, O. and Alleno, E., Rev. Sci. Instrum., 2013, vol. 84, p. 105103. https://doi.org/10.1063/1.4823527

Ponnambalam, V., Lindsey, S., Hickman, N.S., and Tritt, T.M., Rev. Sci. Instrum., 2006, vol. 77, p. 073904. https://doi.org/10.1063/1.2219734

Liu, J., Zhang, Y., Wang, Z., Li, M., Su, W., Zhao, M., Huang, S., Xia, S., and Wang, C., Rev. Sci. Instrum., 2016, vol. 87, p. 064701. https://doi.org/10.1063/1.4952744

Fu, Q., Xiong, Y., Zhang, W., and Xu, D., Rev. Sci. Instrum., 2017, vol. 88, p. 095111. https://doi.org/10.1063/1.4990634

Choi, E.S., Brooks, J.S., Qualls, J.S., and Song, Y.S., Rev. Sci. Instrum., 2001, vol. 72, p. 2392. https://doi.org/10.1063/1.1353192

Resel, R., Gratz, E., Burkov, A.T., Nakama, T., Higa, M., and Yagasaki, K., Rev. Sci. Instrum., 1996, vol. 67, p. 1970. https://doi.org/10.1063/1.1146953

Freeman, R.H. and Bass, J., Rev. Sci. Instrum., 1970, vol. 41, p. 1171. https://doi.org/10.1063/1.1684751

Kettler, W.H. and Rosenberg, M., Rev. Sci. Instrum., 1986, vol. 57, p. 3053. https://doi.org/10.1063/1.1139195

Wang, K., Graf, D., and Petrovic, C., Phys. Rev. B, 2014, vol. 89, p. 125202. https://doi.org/10.1103/PhysRevB.89.125202

Gooch, M., Lv, B., Deng, L.Z., Muramatsu, T., Meen, J., Xue, Y.Y., Lorenz, B., and Chu, C.W., Phys. Rev. B, 2011, vol. 84, p. 184517. https://doi.org/10.1103/PhysRevB.84.184517

Gooch, M., Lv, B., Lorenz, B., Guloy, A.M., and Chu, C.W., J. Appl. Phys., 2010, vol. 107, p. 09. https://doi.org/10.1063/1.3362932

Lin, H., Das, T., Wray, L.A., Xu, S.-Y., Hasan, M.Z., and Bansil, A., New J. Phys., 2011, vol. 13, p. 095005. https://doi.org/10.1088/1367-2630/13/9/095005

Shrestha, K., Marinova, V., Graf, D., Lorenz, B., and Chu, C.W., Phys. Rev. B, 2017, vol. 95, p. 075102. https://doi.org/10.1103/PhysRevB.95.075102

Tanaka, Y., Sato, T., Nakayama, K., Souma, S., Takahashi, T., Ren, Z., Novak, M., Segawa, K., and Ando, Y., Phys. Rev. B, 2013, vol. 87, p. 155105. https://doi.org/10.1103/PhysRevB.87.155105

Gao, X. and Daw, M.S., Phys. Rev. B, 2008, vol. 77, p. 033103. https://doi.org/10.1103/PhysRevB.77.033103

Shrestha, K., Marinova, V., Lorenz, B., and Chu, P.C.W., Phys. Rev. B, 2014, vol. 90, p. 241111. https://doi.org/10.1103/PhysRevB.90.241111

Shrestha, K., Chou, M., Graf, D., Yang, H.D., Lorenz, B., and Chu, C.W., Phys. Rev. B, 2017, vol. 95, p. 195113. https://doi.org/10.1103/PhysRevB.95.195113

Shrestha, K., Graf, D.E., Marinova, V., Lorenz, B., and Chu, C.W., Philos. Mag., 2017, vol. 97, p. 1740. https://doi.org/10.1080/14786435.2017.1314563

Shrestha, K., Marinova, V., Graf, D., Lorenz, B., and Chu, C.W., J. Appl. Phys., 2017, vol. 122, p. 125901. https://doi.org/10.1063/1.4998575

Shrestha, K., Graf, D., Marinova, V., Lorenz, B., and Chu, C.W., J. Appl. Phys., 2017, vol. 122, p. 145901. https://doi.org/10.1063/1.4997947

Ziman, J.M., Electrons and Phonons: The Theory of Transport Phenomena in Solids, Oxford: Clarendon Press, 1960.

ACKNOWLEDGMENTS

This work is supported in part by the U.S. Air Force Office of Scientific Research Grant FA9550-15-1-0236, the T.L.L. Temple Foundation, the John J. and Rebecca Moores Endowment, and the State of Texas through the Texas Center for Superconductivity at the University of Houston.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Shrestha, K., Gooch, M., Lorenz, B. et al. Experimental Setup of Ac Thermoelectric Power Measurements in a Cryocooler PPMS System and Its Implementation to Superconductors, Topological Insulator, and Thermoelectric Materials. Instrum Exp Tech 62, 298–303 (2019). https://doi.org/10.1134/S002044121902026X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S002044121902026X