Abstract—

As a result of heterosegregation, we have obtained a gallium nitride phase, including oriented micro- and nanocrystallites, on the surface of gallium arsenide. The mechanism underlying the growth of crystallites of the surface phase has been analyzed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The formation of surface phases as a result of autosegregation changes the properties and performance parameters of materials. At the same time, varying the surface phase composition and structure, one can obtain new, desired phases and modify the working surface of catalysts, sensors, and electrochemical anodes.

Recent years have seen significant advances in the study of surface autosegregation, including factors that determine changes in the concentration of particular components, assessment of the susceptibility to segregation and its degree for various compounds, the temperature and other segregation ranges, and model concepts of the nature of autosegregation [1]. There has been considerably less work on phase formation processes due to surface reactions of segregants with foreign components (heterosegregation). In particular, the use of heterosegregation makes it possible to ensure targeted synthesis of polyfunctional surface structures.

Gallium nitride is an important material, next to gallium arsenide, for creating a new generation of light-emitting devices in the visible (white, blue, and violet) and near-IR spectral regions, photodetectors in this range, and high-power, high-frequency, and high-temperature radiation-hard transistors [2–4].

In a previous study [5], we examined the feasibility of using heterosegregation processes for the preparation of surface phases, using GaN synthesis on a GaAs single crystal as an example. Reacting liquid gallium and nitrogen gas, we obtained gallium nitride on the gallium arsenide surface in the form of various, including oriented, morphological species, which is basic to the development of new, simple approaches to the synthesis of gallium nitride in the technology of epitaxial heterostructures. The new phase resulted from autosegregation on the gallium arsenide surface, where a liquid gallium layer was formed, through which nitrogen gas or argon with nitrogen and hydrogen additions was passed at temperatures from 970 to 1050°C.

In this paper, we report further developments in the synthesis of gallium nitride micro- and nanocrystallites on the surface of gallium arsenide and examine the mechanism of surface phase growth.

EXPERIMENTAL

Preparation and treatment of a gallium arsenide matrix surface. Gallium nitride was synthesized on the surface of a gallium arsenide single crystal using high-temperature reaction of nitrogen gas with a freshly prepared surface of a liquid gallium layer, which resulted from gallium arsenide surface autosegregation [6].

The samples for this study had the form of polished {001} sections of Czochralski-grown GaAs single crystals. The samples were annealed in a Labotherm programmed resistance furnace. Annealing in a nitrogen atmosphere was carried out at a temperature of 1050°C for 1 or 3 h. Measurements were made at room temperature after the samples were furnace-cooled. The gas flow rate was varied from 5 to 10 L/h.

Characterization techniques. The elemental composition of surface microlayers was determined by X-ray microanalysis using an INCA X-ray microanalysis system in combination with a JEOL JSM 7500 F high-resolution scanning electron microscope and an upgraded ZAF correction program. The electron probe energy was 20 keV. Normalization was performed using the CoKα radiation from a metallic cobalt standard. The composition was determined as the gallium/arsenic and gallium/nitrogen atomic ratios. The analytical accuracy in the concentration ratios on a morphologically homogeneous surface was ±(0.01–0.1). On morphologically inhomogeneous surfaces, we performed local measurements. The area of local regions for measurements on the crystals was 5 × 5 to 40 × 40 μm2. If the particle size of surface phases was comparable to or less than the electron probe diameter (several microns), the Ga/As and Ga/N ratios were determined with an accuracy of ±0.1.

The surface morphology of polished sections of the crystals was examined by high-resolution scanning electron microscopy on a JEOL JSM 7500 F, which ensured a resolution of a few nanometers, using a cold field emission cathode. The electron probe energy was ≤20 keV.

In morphological characterization, we also employed a Nikon Eclipse MA100 optical digital inverted metallurgical microscope (ODM method) with a resolution of 0.3 μm, which operated in reflection mode.

RESULTS AND DISCUSSION

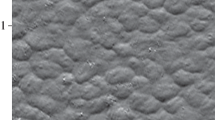

Morphology and chemical composition of the as-prepared gallium arsenide surface. The as-prepared surface was atomically smooth down to a resolution of ~10 nm (HREM) and contained very few inclusions. According to X-ray microanalysis data, the surface of the unannealed crystal (microlayers) had deviations from the ideal stoichiometry (Ga/As = 0.95–1.13), probably due to processing. No nitrogen was detected in the surface layer.

Morphology and chemical composition of the gallium arsenide surface after annealing in nitrogen. Gallium autosegregation. Gallium nitride formation. Starting at an annealing temperature of 500°C, we observed activation of gallium arsenide dissociation, arsenic diffusion to the surface, and arsenic sublimation on the gallium arsenide surface. As a result, annealing produced oriented individual particles on the order of 10 nm in size (HREM) on the gallium arsenide surface, which were identified as gallium (Ga/As = 1.10 ± 0.03 on a gallium–gallium arsenide heterophase surface according to X-ray microanalysis data). Annealing at a temperature of 600°C led to misorientation and an increase in the particle size of the gallium to ~30 nm. The Ga/As ratio was 1.5 ± 0.1 (HREM and X-ray microanalysis data). Annealing at 750°C increased the particle size of the gallium to ~200 nm. The Ga/As ratio was 2.4 ± 0.1 (HREM and X-ray microanalysis data). After annealing at higher temperatures and cooling, X-ray microanalysis showed that the surface morphology of the single-crystal gallium arsenide had the form of a continuous metallic gallium film with separate crystalline gallium oxide grains (the result of the presence of oxygen impurities in the gaseous atmosphere), faceted or rounded, ranging in size from below a micron to several microns. After annealing at 1050°C, most of the matrix surface was free of arsenic because of the formation of a thick layer of segregated gallium. As a result, the surface of gallium arsenide annealed at 1050°C in nitrogen had the form of a metallic gallium matrix (partially oxidized) with separate isotropic crystalline gallium oxide grains. A parallel process was gallium nitride formation.

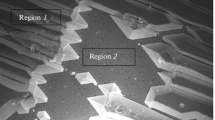

Annealing in a nitrogen atmosphere at 1050°C for 1 h produced a new phase on the gallium arsenide surface, which grew from a liquid gallium matrix and had the form of a network of light-colored gallium nitride microcrystallites with orthogonal orientations (HREM) (Fig. 1a).

Surface morphology of gallium arsenide after annealing at 1050°C for 1 h in flowing nitrogen (HREM): (a) network of light-colored gallium nitride microcrystallites with orthogonal orientations in a gallium matrix (dark areas); (b) nanoneedles on the end faces of the gallium nitride microcrystallites.

At higher magnifications (HREM), it is seen that some of the gallium nitride microcrystallites are tilted relative to the surface and that the end faces of the gallium nitride microcrystallites have needle-like nanocrystallites of submicron length, on the order of a few tens of nanometers in cross-sectional dimensions, on their surface (Fig. 1b). Separate areas of the gallium matrix, which appears dark, contain agglomerates of unoriented light-colored nano- and microcrystallites in the form of filaments, needles, plates, and ribbons.

X-ray microanalysis data demonstrate that, after annealing at 1050°C, on most of the matrix surface all structures in the form of light-colored crystallites growing from the gallium matrix contain gallium and nitrogen. If an electron probe is directed to such crystallites, we obtain Ga/N ≈ 1, which corresponds to gallium nitride (Table 1).

Increasing the 1050°C annealing time to 3 h changes the morphology of the surface layer, producing associates consisting of microcrystallites up to 2 μm in diameter and above 50 μm in length, which crystallize inside large gallium droplets (HREM) (Fig. 2). In between on the matrix surface are located partially oriented nanoparticles in the form of needles, filaments, individual isotropic nano- and microcrystallites, and intergrowths. Local X-ray microanalysis measurements indicate the presence of gallium and nitrogen in the composition of all these structures, confirming gallium nitride formation. Thus, after annealing at 1050°C the matrix consists of metallic gallium, which contains a gallium nitride phase in the form of oriented microcrystallites and separate agglomerates of gallium nitride nano- and microcrystallites in the shape of ribbons, plates, needles, and filaments, as well as unoriented microcrystallites.

Model concepts of the GaN growth process will be presented on the basis of the mechanism underlying melt growth of crystals [7]. Figure 3 shows a schematic of the process, where the growth kinetics proceed from right to left. The formation of a new phase begins at high temperatures (~1000°C) as a result of nitrogen diffusion through a liquid gallium layer and occurs on the interface between a liquid droplet and the surface of the single crystal. The resulting nuclei of the new phase grow in an oriented manner inside the droplet along the normal to the substrate or at an angle to it, and a part of the droplet remains on the end face of the growing nanocrystallite throughout. The growth stops when all the material of the droplet is consumed. Under such conditions, the arrival of liquid gallium at the end face of the resultant anisotropic microcrystallite or the presence of residual liquid gallium on it initiates the growth of “nanoneedles” on the surface of the end face.

Schematic of the growth of gallium nitride micro- and nanocrystals on gallium arsenide: heating from tR to 1050°C and cooling to tR in flowing nitrogen (GaAs, single-crystal gallium arsenide substrate; GaL, liquid gallium droplets at high temperatures; GaS, crystallized gallium droplets after high-temperature annealing and cooling; GaN, anisotropic gallium nitride micro- and nanocrystals).

The orthogonal orientations of the growing crystallites are determined by the symmetry of the single-crystal substrate. Note that the orienting effect of the substrate depends on both the annealing temperature and time and is optimal in the case of annealing at 1050°C for 1 h. If a new phase nucleates inside a liquid gallium layer in defect-rich areas of the matrix, where the substrate has a reduced orienting effect, the growth direction of the crystallites is disordered, and we observe the formation of various unoriented forms of the gallium nitride phase: separate microcrystals, ribbons, plates, needles, and filaments.

CONCLUSIONS

As a result of heterosegregation, we have obtained a gallium nitride phase on the surface of gallium arsenide from liquid gallium and nitrogen gas in the form of various morphological species, including oriented ones. The mechanism underlying the growth of crystallites of the surface phase has been analyzed.

REFERENCES

Tomashpolsky, Yu.Ya., Poverkhnostnaya avtosegregatsiya v khimicheskikh soedineniyakh (Surface Autosegregation in Chemical Compounds), Moscow: Nauchnyi Mir, 2013.

Akchurin, R.Kh. and Marmalyuk, A.A., Gallium nitride—a promising electronic material: 1. Fundamental properties of gallium nitride, Materialovedenie, 1999, no. 9, pp. 950–962.

Okumura Hajime, Present status and future prospect of widegap semiconductor high power devices, Jpn. J. Appl. Phys., 2006, pp. 7565–7580.

Khanna, S.M., Webb, J., Tang, H., Houdayer, A.J., and Carlone, C., 2 MeV proton radiation damage studies of GaN films through low temperature photoluminescence spectroscopy measurements, IEEE Trans. Nucl. Sci., 2000, vol. 47, pp. 2322–2328.

Tomashpolsky, Yu.Ya., Matyuk, V.M., and Sadovskaya, N.V., Heterosegregation on the surface of a gallium arsenide single crystal: gallium nitride phase formation in nitrogen- and argon-gas flows, J. Surf. Invest.: X-Ray, Synchrotron Neutron Tech., 2015, no. 3, pp. 581–589. doi 10.1134/S1027451015030350

Tomashpolsky, Yu.Ya., Sadovskaya, N.V., and Grigorieva, G.A., Nanoscale peculiarities of the thermally stimulated surface autosegregation of covalent crystals: gallium arsenide, J. Surf. Invest.: X-Ray, Synchrotron Neutron Tech., 2013, vol. 7, no. 5, pp. 900–906.

Chernov, A.A., Givargizov, E.I., Bagdasarov, Kh.S., et al., Obrazovanie kristallov (Crystal Formation), vol. 3 of Sovremennaya kristallografiya (Modern Crystallography), Vainshtein, B.K., Chernov, A.A., and Shuvalov, L.A., Eds., Moscow: Nauka, 1980.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Tomashpolsky, Y.Y., Matyuk, V.M. & Sadovskaya, N.V. Growth of Gallium Nitride Micro- and Nanocrystallites on the Surface of Gallium Arsenide. Inorg Mater 54, 1099–1102 (2018). https://doi.org/10.1134/S0020168518110146

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168518110146