Abstract

Experimental data presented in the literature on the depth of processing of polymer films using low-temperature plasma are considered. Changes in the chemical composition and structure along the depth of the samples have been studied using the modern experimental techniques of X-ray photoelectron spectroscopy, secondary ion mass spectrometry, and transmission electron microscopy; precision etching was carried out with an Ar+2500 cluster beam; and the pit depth was measured by profilometry. It has been found that the thickness of the modified layer is ≤50 nm and depends relatively little on the polymer nature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

At present, polymer materials are widely used in various industries; however, the surface of polymers with many valuable properties, as a rule, is hydrophobic with low contact and adhesive properties, while a significant improvement in these characteristics is necessary for practical use. One of the most promising and environmentally friendly methods for changing the surface properties of polymer materials is low-temperature plasma treatment. This method is extensively used, and a wide variety of industrial units are produced [1–6].

One of the important advantages of this method of polymer modification is that the surface of the material and a thin near-surface layer, the thickness of which ranges from several tens of nm to ~1–2 μm, is subject to changes in the structure and morphology [7–11]. The bulk properties of the modified polymer are not altered in this case. It should be noted that there are very few experimental studies in the scientific literature that confirm this finding, most of them having appeared only in the last decade, which is apparently associated with the development of sophisticated experimental methods for studying surfaces.

This review considers the main experimental techniques and the results of modern studies on the thickness of a polymer layer modified in a low-temperature plasma.

METHODS FOR DETERMINING THE THICKNESS OF PLASMA-MODIFIED POLYMER LAYER

Transmission Electron Microscopy in Combination with Secondary Ion Mass Spectrometry and X-ray Photoelectron Spectroscopy [12]

The first work in which the thickness of a plasma-modified polymer layer was determined was the study of a 20-μm thick polyethylene terephthalate (PET) film modified in an argon RF discharge at a pressure of 6.67 Pa and a discharge energy of 5.22–23.3 J/m2. It was established by XPS that under plasma treatment, the ester group is converted into carboxyl and hydroxyl groups and the formation of primary and secondary amines is also possible. The O/C ratio for the modified films is lower than that of the untreated film and increases with increasing Ar pressure. The thickness of the layer with significantly changed composition is from 3 to 7 nm, as determined by secondary ion mass spectrometry (SIMS) using an ATOMIKA instrument (A-DIDA 3000, cesium ions), and decreases with increasing argon pressure. The interface between the modified layer and the bulk of the film is not sharp. To identify the modified layer by transmission electron microscopy (Hitachi H-600 instrument, energy 100 kV), a reaction with osmic acid vapor was carried out, which leads to coloring the layer; cross sections of the films were used for experiments. The thickness of the modified layer was clearly visible and amounted to ~20 nm. The authors believe that it this value which most accurately characterizes the thickness of the plasma-treated PET film layer.

Combination of X-ray Photoelectron Spectroscopy and Atomic Force Microscopy [13]

The thickness of the modified layer of a polytetrafluoroethylene (PTFE) film was determined using a combination of X-ray photoelectron spectroscopy (XPS) and atomic force microscopy (AFM); ion etching was performed directly in the XPS instrument. During etching, the XPS spectra were periodically recorded; as a result, the dependence of atomic concentrations of elements on the etching time was obtained. To determine the film etching rate, ion etching was carried out in the same mode, but with a mask applied to cover half of the sample. The depth formed by ion etching was measured by AFM, and the etching rate was determined as the ratio of the depth to the etching time. Based on the obtained value of the etching rate, the dependence of the atomic oxygen concentration in the film on the etching time was converted into the ratio of the atomic oxygen concentration over depth. The object of the study was a PTFE film of a 50 µm thickness (GOST 24222-80, Plastpolimer, St. Petersburg), processed on the anode in a direct-current discharge at a plasma gas (air) pressure in the reaction chamber of ~20 Pa, a discharge current of 50 mA, and a time of 60 s. An HI Quantera X-ray photoelectron spectrometer, a Veeco Dimension V atomic force microscope, and an argon gun (2 keV) for etching were used. An analysis of the AFM profiles showed that the etch rate was 15 ± 5 nm/min on average. It was found that the signal from oxygen atoms at an etching depth of 40–50 nm approaches the detection limit, which is 0.1%; the thickness of the modified PTFE film layer was 40–50 nm.

Combination of Time-of-Flight Secondary Ion Mass Spectrometry and X-ray Photoelectron Spectroscopy [14]

The processing depth and surface structure of low-density polyethylene (LDPE) films modified in an atmospheric-pressure discharge was studied using time-of-flight secondary ion mass spectrometry (ToF-SIMS) combined with X-ray photoelectron spectroscopy.

In the experiments, a 50-μm thick LDPE film (Goodfellow, UK) was used; the treatment was performed in an Ar/H2O or Ar/D2O RF discharge plasma (27.12 MHz, 80 W, 30–300 s). The ToF-SIMS study of the sample surface and molecular depth profiling were performed using an IONTOF TOF.SIMS 5 instrument (Münster, Germany) with a bismuth liquid metal ion gun (Bi-LMIG) or an argon gas cluster ion beam (Ar-GCIB). Primary ion sources were set at an angle of 45° to the surface, and secondary ions were collected from a reflecting time-of-flight analyzer located perpendicular to the sample surface. To calibrate positive-ion mass spectra, \({\text{CH}}_{3}^{ + }\), \({{{\text{C}}}_{{\text{2}}}}{\text{H}}_{5}^{ + }\), \({{{\text{C}}}_{{\text{5}}}}{\text{H}}_{{11}}^{ + }\), and C6H11+ were chosen, and negative-ion mass spectra were calibrated with CH−, \({\text{C}}_{2}^{ - }\), C3H−, and C4H−.

The study using the combined ToF-SIMS/XPS protocol, both on the surface and within the depth of first tens of nanometers, has shown that the treated LDPE is characterized by two different oxidation trends depending on the time and location of the samples. The procedure used made it possible to investigate the gradual transition of the functionalized polymer on the surface to the virgin material over a depth of up to ~18 nm.

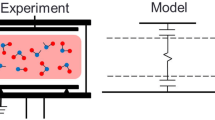

Single-Wavelength Ellipsometry and a Model of the Plasma Modification Process with Treated-Layer Thickness Determination [15]

To determine the thickness of the plasma-modified polymer layer, a model of the process was considered based on the experimental data obtained by Corbella et al. [15]. The objects of study were syndiotactic polypropylene (PP) films of 130 ± 5 nm thickness deposited on a silicon substrate. Modification was carried out in an argon RF discharge (13.56 MHz, 200–300 W). The change in the PP layer thickness due to etching in the discharge at different powers and substrate positions was measured by single-wavelength ellipsometry (λ = 632.8 nm). The cited authors considered the following ellipsometric model of the polymer surface exposed to plasma: a layer of amorphous carbon formed due to ion bombardment, a rough layer, and a layer modified by plasma UV radiation. With this approach, surface processes are described in terms of etching yield and crosslinking probability as a function of the incident energy fluxes of argon ions and ultraviolet photons, and the ion beam model is in good agreement with the results of plasma etching. The results obtained in the experiments indicate that the carbon layer makes ~3 nm, which is followed by the modified rough layer with a thickness of 5 to 20 nm depending on the conditions (time, discharge power in Ar) and, next, the virgin PP determined below the rough layer. The experiment shows that plasma treatment for 30 s is sufficient for the complete manifestation of the layers considered in the model.

Combination of ATR-FTIR Spectroscopy, Ellipsometry, and X-ray Photoelectron Spectroscopy [16]

To determine the layer thickness of films of aromatic polymers (polystyrene, poly(4-methylstyrene), and poly(α-methylstyrene) (thickness 400 μm)), polypropylene (PP), polymethyl methacrylate (PMMA), and polyvinyl alcohol (PVA) with a thickness of 200 μm modified in atmospheric-pressure plasma, a combination of XPS, ATR-FTIR spectroscopy, and ellipsometry was used. The plasma reactor was powered at a current frequency of 23 kHz with a power input of <0.1 W/cm2. It was shown that both long-lived active species generated in atmospheric-pressure plasma and UV radiation cause significant changes in the structure of the aromatic polymers at a depth of ≤20 nm. The destruction of aromatic rings and the formation of ether, ester, and organic nitrate groups were observed. The depth of processing of PP, PMMA and PVA under these conditions was several nanometers, but there was noticeable sputtering of polymer films.

Combination of X-ray Photoelectron Spectroscopy, Precision Etching with Argon Cluster Beam Ar+ 2500, and Profilometry [17, 18]

A combination of XPS and precision etching with an Ar+2500 cluster beam was used to determine the thickness of the modified layer of polyethylene terephthalate (PET) and polyvinyltrimethylsilane (PVTMS) films. The working XPS system was the PHI5500 VersaProbeII (ULVAC-PHI. INC, Kanagawa, Japan); for layer-by-layer etching, an Ar+2500 argon cluster gun with an Ar+2500 cluster ion source (GCIB) was used. To measure the depth of etch pits before and after treatment of the films in a direct-current discharge, measurements were made with a KLA-Tencor Alpha-Step IQ profilometer (USA).

The object of study was a commercial biaxially oriented PET film PETLAIN BT 1010 E (Superfilm, Turkey) with a thickness of 40 µm. The modification was carried out in a direct-current discharge at the anode and cathode; filtered air (~15 Pa, 50 mA, 50 s) was used as the plasma gas [17]. The film etching rate was experimentally determined, which was then used in experiments to measure the processing depth. The depth of treatment in plasma was found by restoring the concentrations of elements and peak ratios in the high-resolution C1s and O1s spectra to the values characteristic of the virgin film. It was found that the experimentally determined thickness of the modified layer of the PET film treated in dc discharge at the anode and at the cathode is ≤20 nm.

PVTMS films deposited on a silicon substrate were modified in a direct-current discharge at the anode; filtered atmospheric air (20 Pa, discharge current 50 mA, treatment time 30 s) served as the working gas. It was found that plasma treatment leads to a significant change in the chemical composition of the surface: the carbon content noticeably decreases, the oxygen content sharply increases, and the silicon coordination Si[4C] turns into Si[4O]. Layer-by-layer etching with a beam of argon cluster ions was used to study changes in the chemical composition of a PVTMS film with depth [18]. Etching was carried out until the C1s spectrum became similar to the spectrum of the initial polymer. As a result, it was found that the modified layer had a gradient structure and its depth was ~50 nm.

CONCLUSIONS

Experimental data obtained for films of polymers of various chemical natures using combination of modern instrumental research methods (X-ray photoelectron spectroscopy, secondary ion mass spectrometry, transmission electron microscopy, ellipsometry, ATR-FTIR spectroscopy, precision etching with Ar+2500 cluster beam, profilometry) indicate that the treatment of polymer films by low-temperature plasma leads to changes in the chemical composition at a depth of several nanometers to ≤50 nm.

REFERENCES

Oehr, C. and Wertheimer, M.R., Plasma Process. Polym., 2022, vol. 19, p. 2277025.

Tudoran, C., Roşu, M.-C., and Coroş, M., Plasma Process. Polym., 2020, vol. 17, no. 8, p. 2000046.

Weltmann, K.-D., Kolb, J.F., Holub, M., Uhrlandt, D., et al., Plasma Process. Polym., 2019, vol. 16, no. 1, p. 1800118.

Cvelbar, U., Walsh, J.L., Černák, M., de Vries, H.W., et al., Plasma Process. Polym., 2019, vol. 16, no. 1, p. 1700228.

Bekeschus, S., Favia, P., Robert, E., and von Woedtke, T., Plasma Process. Polym., 2019, vol. 16, no. 1, p. 1800033.

Iqbal, M., Dinh, D.K., Abbas, Q., Imran, M., Sattar, H., and Ahmad, A.U., Surfaces, 2019, vol. 2, p. 349.

Modification of Polymer Properties, Jasso-Gastinel, C.F. and Kenny, J.M., Eds., Norwich, NY: William Andrew, 2017.

Plasma Science and Technology—Progress in Physical States and Chemical Reactions, Mieno, T., Ed., Rijeka: InTech, 2016.

Desmet, T., Morent, R., De Geyter, N., Leys, C., Schacht, E., and Dubruel, P., Biomacromolecules, 2009, vol. 10, p. 2351.

Kutepov, A.M., Zakharov, A.G., and Maksimov, A.I., Vakuumno-plazmennoe i plazmenno-rastvornoe modifitsirovanie polimernykh materialov (Vacuum–Plasma and Plasma–Solution Modification of Polymer Materials), Moscow: Nauka, 2004.

Entsiklopediya nizkotemperaturnoi plazmy. Vvodnyi tom IV (Encyclopedia of Low-Temperature Plasma: Introductory Volume IV), Fortov, V.E., Ed., Moscow: Nauka, 2000.

Nakayama, Y., Soeda, F., Ishitani, A., and Ikegami, T., Polym. Eng. Sci., 1991, vol. 31, no. 11, p. P. 812.

Yablokov, M.Yu., Sokolov, I.I., Malinovskaya, O.S., Gilman, A.B., and Kuznetsov, A.A., High Energy Chem., 2013, vol. 47, no. 1, p. 32.

Cristaudo, V., Collette, S., Tuccitto, N., Poleunis, C., Melchiorre, L.C., Licciardello, A., Reniers, F., and Delcorte, A., Plasma Process. Polym., 2016, vol. 13, no. 11, p. 1106.

Corbella, C., Pranda, A., Portal, S., de los Arcos, T., Grundmeier, G.S., Oehrlein, G.S., and von Keudell, A., Plasma Process. Polym., 2019, vol. 16, no. 6, p. 1900019.

Luan, P. and Oehrlein, G.S., Plasma Process. Polym., 2019, vol. 16, no. 11, p. 1900053.

Piskarev, M.S., Skryleva, E.A., Senatulin, B.R., Gilman, A.B., and Kuznetsov, A.A., High Energy Chem., 2020, vol. 54, no. 4, p. 299.

Piskarev, M., Skryleva, E., Gilman, A., Senatulin, B., Zinoviev, A., Syrtsova, D., Teplyakov, V., and Kuznetsov, A., Coatings, 2021, vol. 11, p. 1317.

Funding

The work was supported by the Ministry of Science and Education of the Russian Federation, project no. FFSM-2021-0006.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflict of interest.

Additional information

Translated by S. Zatonsky

Rights and permissions

About this article

Cite this article

Gilman, A.B., Piskarev, M.S. & Kuznetsov, A.A. Thickness of the Modified Polymer Layer Formed by Low-Temperature Plasma Treatment. High Energy Chem 57, 440–443 (2023). https://doi.org/10.1134/S001814392305003X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S001814392305003X