Abstract

A mechanism for the degradation of n-heptane and the formation of the products of its plasma-chemical transformation by microwave discharge treatment has been proposed. Chemical reactions resulting in reactive species, namely free radicals that form lower hydrocarbons and polyaromatic structures are presented. The product composition of the gas, liquid, and solid phases has been studied using gas chromatography–mass spectrometry analysis of the precipitate obtained by evaporation of the liquid phase after the treatment of n-heptane.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Technologies based on the application of low-temperature plasma are widely used in various branches of engineering and industry, including petroleum chemistry, metallurgy, materials science, microelectronics, and medicine, and continue to actively develop. The use of methods of nonthermal activation of chemical reactions makes it possible to affect molecules more intensively due to the excitation of internal degrees of freedom. Therefore, it becomes possible to carry out reactions that are impossible or difficult to perform using thermal or thermal catalytic methods [1]. The interest of researchers in the use of electrical discharges to stimulate chemical reactions in liquids is due to a high product formation rate and high efficiency of physicochemical processes proceeding in the course of plasma-induced reactions. The high rate can be explained by the fact that plasma is created in a gas bubble inside a liquid, the surface of which is located near the high-temperature zone [2]. This ensures a high rate of flow of liquid molecules into the minireactor, which is a plasma-containing bubble. Because of the intensive supply of molecules from the liquid surface, high concentrations of active species (radicals, excited atoms, and charged particles) involved in plasma-chemical processes are ensured.

Currently, almost all types of electrical discharges, including microwave discharges, are used to produce plasma. However, the use of the microwave discharge for carrying out plasma-chemical reactions in liquid media has been studied scarcely. The mechanisms of transformation of liquid hydrocarbons are even less understood. The majority of studies dealing with the products of transformation of aqueous solutions of organic compounds by the action of dielectric barrier discharge and direct-current discharge focus on the environmental aspects [3–5]. Few reports have been devoted to the study of the conversion of liquid alkanes. The hydrocarbons described in the literature on discharge treatment are hexane [6], heptane [7, 8], n-C5–C8 alkanes and cyclohexane [9], and dodecane [10]. In this connection, the description of a possible mechanism for the conversion of n-heptane in a microwave discharge is a relevant task.

RESULTS AND DISCUSSION

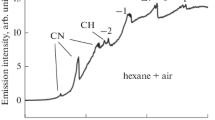

The results of the experiments performed in this study were obtained using a setup with coaxial introduction of microwave field into the reaction chamber [11]. The discharge treatment of n-heptane results in the formation of solid, liquid, and gaseous products. The solid products were found to contain amorphous carbon and damaged graphene. The gas phase was composed of about 98% hydrogen and acetylene. The liquid products determined by gas chromatographic–mass spectrometric (GC–MS) analysis of the residue, obtained by evaporating the liquid phase, are presented in Table 1. These are mostly bi- and polyaromatic compounds, which may be the precursors of soot formation.

In n-heptane subjected to microwave discharge treatment, two competing reactions, the dehydrogenation and the cleavage (cracking), occur in approximately equal proportions:

The cracking reaction proceeds via the radical chain mechanism, the bond breaking in the n-heptane molecule being homolytic:

The place of rupture in the molecule is determined by the bond dissociation energy, with the rupture at moderate temperature being closer to the middle of the molecule, i.e. by the weakest bonds:

The cleavage proceeds through the following stages:

A. Chain initiation.

B. Chain propagation. Radicals formed with the carbon number of C3 and higher instantaneously decompose under the action of the discharge. There is a homolytic rupture of the C–C bond and the C–H bond in the β-position with respect to the carbon atom carrying the unpaired electron.

The formation of acetylene is possible in two cases: n the pyrolysis of methane and by the dehydrogenation of the vinyl radical; the hydrogen atom is detached in both cases.

C. Chain termination. The concentration of radicals in the system increases with the progress of cracking reactions, and the probability of their colliding with each other increases. As a result, in the chain termination step, low-molecular product molecules accumulate.

The sequential cleavage of the C–H bonds in the β-position of the n-heptane molecule leads to the formation of unsaturated organic structures, which participate in the cyclization reaction. Almost all cleavage steps are accompanied by the formation of the hydrogen atom, which subsequently forms molecular hydrogen, which prevails in the gaseous products and amounts to 93.5 vol %.

A large amount of polyaromatic hydrocarbons are found in the products of plasma-chemical conversion of n-heptane. The formation of high-molecular0weight polyaromatic compounds is similar to the coking reaction, in which aromatic hydrocarbons condense under the action of radical initiators. Preliminarily, the naphthenic cycle is produced from the aliphatic structure followed by dehydrogenation and the formation of an aromatic structure.

The mechanism of formation of polyaromatic hydrocarbons is based on the reaction of polycondensation proceeding through the radical chain mechanism.

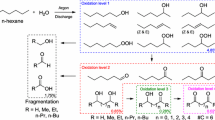

The C–H bond in the substrate heptane can break possible at the primary atom, leading to the formation of a primary carbon-centered radical followed by cleavage of the β-C–C bond and the formation of the lower radicals \({{{\text{C}}}_{4}}{\text{H}}_{9}^{\centerdot }\) and \({{{\text{C}}}_{3}}{\text{H}}_{7}^{\centerdot }\) (R1). Butyl \({{{\text{C}}}_{4}}{\text{H}}_{9}^{\centerdot }\) is stabilized via dehydrogenation along the β-C–H bond to form butadiene (R2). Simultaneously, butyl \({{{\text{C}}}_{4}}{\text{H}}_{9}^{\centerdot }\) is cleaved to give the ethyl radical \({{{\text{C}}}_{2}}{\text{H}}_{5}^{\centerdot }\) and the ethylidene biradical •C2H4•; ethylene (R3) is formed when the hydrogen atom is detached.

The butadiene and ethylene formed in the course of reactions (R2) and (R3) can participate in a transformation according to the diene synthesis scheme to form cyclohexene. Under the same conditions during the microwave discharge treatment, cyclohexene undergoes β-cleavage of the C–H bonds, which leads to the formation of the aromatic hydrocarbon benzene (R4). Simultaneously, butadiene and cyclohexene as a dienophile form decalin and then naphthalene (R5) via the subsequent dehydrogenation. Thus, the polycondensation of aromatic structures and the formation of β-phenylnaphthalene (R6) occur in this way.

The preparation of Biphenyl can also be produced via the diene synthesis reaction through the intermediates 4-vinylcyclohexene and styrene (R7). Styrene, being a dienophile as well, continues the diene synthesis with butadiene to produce cyclohexen-3-ylbenzene followed by dehydrogenation to form biphenyl (R8).

The majority of the detected polyaromatic entities: the bicyclic (naphthalene and diphenyl) and tricyclic (acenaphthene, acenaphthylene, phenanthrene, and anthracene) structures, are formed via the polycondensation type of reaction.

CONCLUSIONS

In summary, a sequential scheme for the transformation of n-heptane into products by the action of microwave discharge has been presented. It is worth noting that this paper describes the first cycle of the experimental study on the microwave discharge treatment of hydrocarbons; further, based on the results of this work, one can find new areas of application of microwave discharges.

REFERENCES

Fridman, A., Plasma Chemistry, New York: Cambridge University Press, 2008.

Lebedev, Y.A., Tatarinov, A.V., Epstein, I.L., and Averin, K., A, Plasma Chem. Plasma Process., 2016, vol. 36, no. 2, p. 535.

Bobkova, E.S. and Rybkin, V.V., Plasma Chem. Plasma Process., 2015, vol. 35, no. 1, p. P.133.

Bobkova, E.S., Borzova, A.A., Shishkina, A.I., and Rybkin, V.V., High Energy Chem., 2015, vol. 49, no. 5, p. 375.

Gushchin, A.A., Grinevich, V.I., Shulyk, V.Y., Kvitkova, E.Y., and Rybkin, V.V., Plasma Chem. Plasma Process., 2018, vol. 38, no. 1, p. P. 123.

Foglein, K.A., Babievskaya, I., Szabo, P.T., and Szepvolygi, J., Plasma Chem. Plasma Process., 2003, vol. 23, no. 2, p. 233.

Lebedev, A.Yu., Tatarinov, A.V., and Epshtein, I.L., Prikl. Fiz., 2016, no. 3, p. 11.

Epstein, I.L., Lebedev, Y.A., Tatarinov, A.V., and Bilera, I.V., J. Phys. D: Appl. Phys., 2018, vol. 51, p. 214007.

Kudryashov, S.V., Transformation of hydrocarbons of various classes in dielectric barrier discharge, Doctoral (Chem.) Dissertation, Tomsk, 2016.

Prantsidou, M. and Whitehead, J.C., Plasma Chem. Plasma Process., 2015, vol. 35, no. 1, p. 159.

Lebedev, A.Yu., Averin, K.A., Borisov, R.S., Garifullin, A.R., Bobkova, E.S., and Kurkin, T.S., High Energy Chem., 2018, vol. 52, no. 5, p. 306.

Novoselov, Yu.N., Ryzhov, V.V., and Suslov, A.I., Pis’ma Zh. Tekh. Fiz., 1998, vol. 24, no. 19, p. 40.

Ryabov, V.D., Oil and Gas Chemistry Textbook, Moscow: Forum, 2018.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Avdeeva

Rights and permissions

About this article

Cite this article

Bobkova, E.S., Stokolos, O.A. & Garifullin, A.R. Mechanisms of Heptane Degradation and Product Formation in Microwave Discharge. High Energy Chem 53, 336–340 (2019). https://doi.org/10.1134/S0018143919040039

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0018143919040039