Abstract

Acetyl xylan esterases (AXEs) hydrolyze the specific ester linkages between acetic acid and xylose units, leading to the deacetylation and depolymerization of xylan. The AXE from the soil-psychrophilic Paenibacillus sp. R4 strain (PbAcE), was produced in recombinant Escherichia coli with 1 mM isopropyl β‑d-1-thiogalactopyranoside. The final dry cell weight and production of purified PbAcE were 17 g/L and 657 mg/L using 7-L bioreactor and, 6 g/L and 500 mg/L using 30-L fermenter, respectively. The hydrolysis activity of PbAcE was approximately 27 U/mg when p-nitrophenyl was used as the substrate. PbAcE was the most active at pH 8.0 and it maintained more than 80% activity from pH 4.0 to pH 11.0 compared to the maximum value under the given conditions. Furthermore, PbAcE deacetylated cephalothin and chromomycin A3 antibiotics. The current study demonstrates that the production of PbAcE was successful, and the results may encourage further application studies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Acetyl xylan esterases (EC 3.1.1.72; AXEs) are enzymes that catalyze the specific hydrolysis of the ester linkages between acetic acid and xylose units, in the process of xylan deacetylation [1]. As monomers hydrolyzed from xylan can be used as materials to produce valuable products such as biofuels [2], and acetylation is the most common substitution of plant xylan, it has attracted attention in the research for efficient AXEs. AXEs have been classified into 9 carbohydrate esterase (CE) families [3], and the CE7 family which is identified as composed of AXEs and cephalosporin-C deacetylases. This enzyme family has deacetylation activity against cephalosporin antibiotics and is efficiently used as starting material for the semisynthesis of β-lactam antibiotics [4–8].

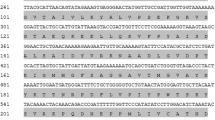

A new cold-active esterase was isolated from psychrophilic Paenibacillus sp. R4 strain, which was isolated from active-layer soil in Council, Alaska [9]. This acetyl xylan esterase (PbAcE) belongs to the CE7 family and is present as a hexamer (234 kDa) with a central substrate-binding tunnel. PbAcE has the canonical catalytic triad Ser-His-Asp and typical esterase α/β hydrolase folds. PbAcE has a shorter loop and different residue composition near the substrate-binding site compared with other mesophilic and thermophilic homologs. Moreover, weak inter-subunit interactions and different active site loop conformations may enhance the flexibility and low-temperature activity of PbAcE. This enzyme hydrolyzes glucose pentaacetate and xylan acetate, reversibly producing acetyl xylan from xylan. Similar to other enzymes in CE families, PbAcE also shows activity toward p‑nitrophenyl acetate and α-naphtyl acetate. PbAcE strongly prefers a short acyl chain of esters, no longer than C6. In addition, PbAcE has strong activity against cefotaxime and 7-aminocephalosporanic acid (7-ACA), an antibiotic substrate. PbAcE is considered a cold-active enzyme that retains high catalytic activity at low temperatures, while other members of the CE7 family demonstrate moderate or high temperature optima [4, 6, 10]. Despite the high potential of cold-active enzymes for industrial applications, only PbAcE has been characterized. This is the first report of the mass production of cold-active acetyl xylan esterase in the CE7 family. The aim of this study was to achieve a production level of recombinant PbAcE from laboratory-scale fermentation. Moreover, we investigated specific characteristics of PbAcE for its further applications, including its properties in different pH ranges and substrate specificity toward several antibiotics.

MATERIALS AND METHODS

Microorganisms, plasmids, and media. The PbAcE gene was cloned into the expression vector pET-28a (Novagen, USA) as described previously [1]. Escherichia coli BL21 (DE3) strain was used for the expression. Recombinant E. coli was cultured in Luria-Bertani (LB) medium consisting of (g/L): tryptone—10.0, yeast extract—5.0, and sodium chloride—10.0. Modified R medium contained (g/L): ((NH4)2HPO4—4.0, K-H2PO4—13.5, Na-citrate—1.7, tryptone—10.0 g/L, yeast extract—20.0, lactose—20.0, glycerol—50.0, MgSO4∙7H2O—1.2 (pH 6.8–7.2) supplemented with 5 mL/L trace metal solution consisting of (g/L): FeSO4∙7H2O—10.0, CaCl2∙2H2O—2.0, ZnSO4∙7H2O—2.25, MnSO4∙5H2O—0.5, CuSO4∙5H2O—1.0, (NH4)6Mo7O24∙7H2O—0.1, Na2B4O7∙10H2O—0.23 g/L and 35% HCl—5.0 mL. Modified R medium was used for 7- and 30-L cultures.

Production of PbAcE in E. coli. Laboratory-scale production of PbAcE was performed using a 7-L jar bottom magnet-drive fermenter (KF-7L model, Kobiotech, Korea). The seed culture grown in 200 mL LB medium was inoculated into a 7-L fermenter containing 3.8 L modified R medium with 40 mL trace metal solution and 50 μg/mL kanamycin at 37°C. Cells were grown to OD600 of 2–6, at which point PbAcE expression was induced by the addition of 1 mM isopropyl-1-thio-β-D-galactopyranoside (IPTG) upon temperature downshift to 25°C. The temperature was monitored using thermocouple at the vessel base, and pH was monitored using an InPro® 3030 pH sensor (Mettler-Toledo GmbH, Switzerland). Dissolved oxygen (DO) was monitored with a sterilizable, polarographic DO electrode InProc® 6800 Series O2 Sensors (Mettler-Toledo GmbH, Switzerland). During fermentation, the DO level was maintained at more than 30% air saturation by increasing the agitation speed and air-flow supply. Antifoam was added to the fermentation medium prior to inoculation and whenever foaming was observed. Throughout the fermentation processes, 10 mL of culture medium was taken out periodically to measure the optical density, dry cell weight (DCW), and protein expression level. The expression of PbAcE was confirmed using SDS-PAGE and hydrolysis assays.

Purification of PbAcE. Cultured cells were centrifuged (19 000 × g for 20 min at 4°C) and resuspended in lysis buffer (50 mM Na2HPO4 pH 8.0, 300 mM NaCl, 5 mM imidazole). The cells were lysed by ultrasonic treatment using Vibra-cell processor (VCX 500 model, Sonics & Materials, USA) for 20 min on icy water (2 s/1 s on/off cycle), and then centrifuged (19 000 × g, 50 min, 4°C) to collect the supernatant as soluble fractions. The supernatant was then loaded onto a Ni-NTA resin (Elpisbio, Daejeon, Korea) pre-equilibrated with NPI-5 buffer (50 mM Na2HPO4 pH 8.0, 300 mM NaCl, 5 mM imidazole), and washed with NPI-30 buffer (50 mM Na2HPO4 pH 8.0, 300 mM NaCl, 30 mM imidazole). The bound PbAcE was eluted with NPI-300 buffer (50 mM Na2HPO4 pH 8.0, 300 mM NaCl, 300 mM imidazole). The final eluate was buffer-exchanged with 50 mM Tris-HCl buffer (pH 8.0) and concentrated on a 10-kDa centrifugal filter (Amicon Ultra Centrifugal filter, Millipore, USA). Concentrated PbAcE was collected and analyzed using SDS-PAGE. The purity of the protein was determined by densitometric evaluation of the SDS gel using ImageLab 3.0 software (Bio-Rad, USA). The concentration of purified PbAcE was determined according to the Bradford method using BSA as the protein standard.

Characterization of PbAcE. Enzyme activity was determined using p-nitrophenyl acetate (pNP-C2) as the substrate. Soluble PbAcE was collected after cell lysis and tested for specific activity. The reaction was performed in 50 mM Tris-HCl buffer (pH 8.0) and the absorbance was determined at 405 nm. One unit of enzyme activity was defined as the amount of enzyme that releases one μmol of p-nitrophenol per min.

The optimal pH was investigated with an assay containing 5 μg of PbAcE and 250 μM pNP-C2. Enzyme activity was determined in a pH range of pH from pH 5.0 to pH 10.0 at 25°C. Following buffers were used including 50 mM citrate phosphate (pH 5.0–7.0), 50 mM Tris-HCl (pH 7.0–9.0), and 50 mM N-cyclohexyl-2-aminoethanesulfonic acid (CHES, pH 9.0–10.0). The PbAcE activity was monitored after 3-min incubation by measuring OD348, which is the pH-independent isosbestic wavelength of p-nitrophenol and p-nitrophenolate [2]. The esterase pH stability was determined by measuring the residual activity after incubating the enzyme at 4°C for 24 h in 50 mM citrate-phosphate (pH 4.0–8.0), 50 mM Tris-HCl (pH 7.0–9.0), and 50 mM glycine-NaOH (pH 8.0–12.0) buffers.

The hydrolase activity of PbAcE toward antibiotic-related compounds was evaluated using a colorimetric assay with phenol red [9]. The substrates consisted of 7-ACA, cefotaxime sodium salt, cephalothin sodium salt, ketoconazole, fusidic acid sodium salt, paclitaxel, daunorubicin hydrochloride, chromomycin A3, cephalomannine, and sulfacetamide. These substrates were diluted in DMSO to a final concentration of 20 mM. Reaction mixture containing each of the above substrates was incubated with 5 μg of PbAcE in 50 mM Tris-HCl buffer (pH 8.0).

RESULTS AND DISCUSSION

Production of PbAcE in laboratory-scale fermenter. PbAcE was produced by E. coli in a 7-L jar fermenter. The cell concentration increased steadily and DCW reached 17 g/L 24 h after IPTG induction (Fig. 1a). The enzyme production in the soluble fraction of the cell extract at 0, 5, 10, 19, and 24 h after induction was determined using activity measurement and SDS-PAGE. As shown in Fig. 1b, the expression of PbAcE reached the maximum level at 10 h after IPTG induction. As the number of cells grew, the concentration and activity of PbAcE per culture volume increased, with a maximum at 19 h after induction (Fig. 1a).

Production of PbAcE in pilot-scale fermenter. The same culture conditions described for laboratory-scale fermenter were used in pilot-scale fermentation with a 30-L bioreactor to determine the amount of recombinant PbAcE produced (Fig. 2). The DCW reached 6 g/L, which was lower than that of the 7-L fermenter.

Purification of PbAcE and activity assay. Cell samples were collected from the culture medium, lysed, and subjected to affinity chromatography. Soluble PbAcE was purified and analyzed using SDS-PAGE (Fig. 3a). The procedure yielded 657 and 500 mg/L of PbAcE from 7-L and 30-L fermenter, respectively (Fig. 3b). However, the recombinant PbAcE from the 7-L and 30-L fermenter showed the same level of hydrolysis activity, which was approximately 27 U/mg.

Comparison of the expression and activity of recombinant PbAcE from 7-L and 30-L fermenters. (a) Purification of recombinant PbAcE using Ni-NTA affinity chromatography. Lane M: protein markers; lane 1: expressed PbAcE before purification; lane 2: His-tagged purified PbAcE from 7-L fermenter; lane 3: His-tagged purified PbAcE from 30-L fermenter. (b) Concentration (solid bar; mg/L) and hydrolysis activity (solid circle, U/mg) of purified PbAcE from 7-L and 30-L fermenters. The tests were performed at 25°C using p-NA (C2) as the substrate. All measurements were performed in triplicates.

Previous studies have reported that recombinant AXEs are well expressed with hydrolysis activity toward p-nitrophenyl acetate. PbAcE showed a hydrolysis activity of 27 U/mg, which is comparable to other AXEs, such as AfAXE [11] and AoAXE [13] (Table 1). We observed the same specific activity of PbAcE from the two scales of fermentation; however, the production efficiency of the 30-L fermenter was lower than expected. Using a pilot-scale bioreactor, the relative surface aeration for gas exchange decreases, leading to a lower DO level. This limiting factor might affect cell growth and the production of secondary metabolites [16]. High and appropriate agitation speeds may generate and improve DO levels and dispersion.

Effect of pH on PbAcE activity and stability. The optimum pH for PbAcE was determined at 25°C using p-NP (C2) as the substrate (Fig. 4a). PbAcE was the most active in Tris-HCl buffer at pH 8.0, which is comparable to other CE7 esterases, such as AXEs from the Namib Desert hypolith metagenome study [17]. In terms of pH stability (Fig. 4b), PbAcE remained relatively stable over a wide range of pH values ranging from 5.0 to 11.0. PbAcE lost approximately 20% activity when pH values were 4.0 and 11.0, but when the pH value increased to 12.0, we observed a dramatic drop in its activity. Among CE7 family members, the pH stability of PbAcE is considerably higher than those reported for characterized CE7 esterases, such as AXE from Lactobacillus antri, which is stable in the pH range between 6.0 and 11.0, and AXE from Bacillus halodurans, stable in a pH range from 7.0 to 10.0 [18].

Effect of the pH on PbAcE activity (a) and stability (b). The tests were performed at 25°C using p-NA (C2) as the substrate. PbAcE activity was determined in different buffers: 50 mM citrate phosphate buffer (1), 50 mM Tris-HCl buffer (2), 50 mM CHES buffer (3) and 50 mM glycine-NaOH buffer (4). The highest activity was considered 100%. All measurements were performed in triplicates.

Activity test for antibiotic modification. PbAcE belongs to the CE7 family, which shows deacetylation activity against cephalosporin antibiotics. In a previous study, PbAcE showed high hydrolase activity toward cefotaxime and 7-ACA, and moderate activity toward cephalosporin C [9]. In this study, we used cefotaxime and 7-ACA antibiotics as positive controls. In addition, we investigated the specific activity of PbAcE against 8 other antibiotics (ketoconazole, fusidic acid sodium salt, sulfacetamide, cephalothin sodium salt, paclitaxel, daunorubicin hydrochloride, chromomycin A3, and cephalomannine).

Among these compounds, only 2 had deacetylation activity showing a change of color of the phenol red solution as the acetyl groups were released (Fig. 5). In the case of sulfacetamide, we observed a color change in both reactions with buffer and PbAcE due to the self-degradation of the compound in the solvent. Cephalothin sodium salt, which is a cephalosporin antibiotic, was significantly deacetylated by PbAcE at a concentration of 20 mM after 5 min incubation at room temperature. PbAcE exhibited intermediate activity against chromomycin A3, an anthraquinone antibiotic glycoside, by increasing the incubation time to 7 h at room temperature. These deacetylated compounds can be valuable materials for further studies on whether the specific antibiotic activity is improved or for the production of semisynthetic antibiotics.

Colorimetric assay of PbAcE with antibiotic-related compounds. The hydrolytic activity of PbAcE was revealed toward 7-aminocephalosporanic acid (7-ACA), cefotaxime sodium salt, cephalothin sodium salt, and chromomycin A3. Acetic acid released in the enzyme reaction changed the color the solution from red to yellow.

To the best of our knowledge, the present work is the first detecting study an esterase against cephalothin and chromomycin A3 in the CE7 family. Cephalothin is a first-generation cephalosporin that is used as an antibiotic prodrug material [19]. Taking into account specific hydrolysis activity, PbAcE can be used in the semisynthesis process for the cephalosporin core as the β-lactam component. Meanwhile, chromomycin A3 does not belong to the cephalosporin family and has a long-chain carbon backbone, whereas PbAcE prefers short chains [9]. However, the acetyl group in L-chromose B (sugar E) might interact with the substrate-binding site by partly passing through the hexamer tunnel of PbAcE. PbAcE has a more open and larger cleft area located near the catalytic triad than those of BsAcE and TmAcE [8, 9, 20]; therefore, it offers a wider variety of substrates.

* *

We have successfully performed large-scale production of PbAcE using 7-L and 30-L fermenters. None of the other AXEs in the CE7 family was studied for large production, even though they have interesting properties for industrial application. PbAcE has high stability over a broad pH range, together with high thermal and chemical stability, and it has considerable economic and industrial benefits. The large quantities of PbAcE produced may encourage further biotechnological applications, such as the development of novel antibiotics.

REFERENCES

Biely, P., Mastihubova, M., Tenkanen, M., Eyzaguirre, J., Li, X.L., and Vrsanska, M., J. Biotechnol., 2011, vol. 151, no. 1, pp. 137–142.

Dodd, D. and Cann, I.K., Global Change Biol. Bioenergy, 2009, vol. 1, pp. 2–17.

Lombard, V., Golaconda Ramulu, H., Drula, E., Coutinho, P.M., and Henrissat, B., Nucleic Acids Res., 2014, vol. 42, pp. D490–D495.

Levisson, M., Han, G.W., Deller, M.C., Xu, Q., Biely, P., Hendriks, S., et al., Proteins, 2012, vol. 80, pp. 1545–1559.

Degrassi, G., Kojic, M., Ljubijankic, G., and Venturi, V., Microbiology (Reading), 2000, vol. 146, Pt 7, pp. 1585–1591.

Tian, Q., Song, P., Jiang, L., Li, S., and Huang, H., Appl. Microbiol. Biotechnol., 2014, vol. 98, pp. 2081–2089.

Martinez-Martinez, I., Montoro-Garcia, S., Lozada-Ramirez, J.D., Sanchez-Ferrer, A., and Garcia-Carmona, F., Anal. Biochem., 2007, vol. 369, pp. 210–217.

Vincent, F., Charnock, S.J., Verschueren, K.H., Turkenburg, J.P., Scott, D.J., Offen, W.A., et al., J. Mol. Biol., 2003, vol. 330, pp. 593–606.

Park, S.H., Yoo, W., Lee, C.W., Jeong, C.S., Shin, S.C., Kim, H.W., et al., PLoS One, 2018, vol. 13, no. 10, article ID e0206260.

Drzewiecki, K., Angelov, A., Ballschmiter, M., Tiefenbach, K.J., Sterner, R., and Liebl, W., Microb. Biotechnol., 2010, vol. 3, pp. 84–92.

Chung, H.J., Park, S.M., Kim, H.R., Yang, M.S., and Kim, D.H., Enzyme Microb. Tech., 2002, vol. 31, pp. 384–391.

Degrassi, G., Okeke, B.C., Bruschi, C.V., and Venturi, V., Appl. Environ. Microbiol., 1998, vol. 64, pp. 789–792.

Koseki, T., Miwa, Y., Akao, T., Akita, O., and Hashizume, K., J. Biotechnol., 2006, vol. 121, pp. 381–389.

Hettiarachchi, S.A., Kwon, Y.K., Lee, Y., Jo, E., Eom, T.Y., Kang, Y.H., et al., Microb. Cell Fact., 2019, vol. 18, no. 122.

Blum, D.L., Li, X.L., Chen, H., and Ljungdahl, L.G., Appl. Environ. Microbiol., 1999, vol. 65, pp. 3990–3995.

Yang, S.T., Bioprocessing for Value-Added Products from Renewable Resources: New Technologies and Applications, Amsterdam: Elsevier, 2007, 1st ed.

Adesioye, F.A., Makhalanyane, T.P., Vikram, S., Sewell, B.T., Schubert, W.D., and Cowan, D.A., Appl. Environ. Microbiol., 2018, vol. 84, no. 8, article ID e02695-17.

Kim, M.J., Jang, M.U., Nam, G.H., Shin, H., Song, J.R., and Kim, T.J., J. Microbiol. Biotechnol., 2020, vol. 30, pp. 155–162.

Evans, L.E., Krishna, A., Ma, Y., Webb, T.E., Marshall, D.C., Tooke, C.L., et al., J. Med. Chem. 2019, vol. 62, pp. 4411–4425.

Singh, M.K., Shivakumaraswamy, S., Gummadi, S.N., and Manoj, N., Protein Eng. Des. Sel., 2017, vol. 30, pp. 559–570.

Funding

This research was a part of the project titled “Development of potential antibiotic compounds using polar organism resources (20200610, KOPRI Grant PM22030)”, funded by the Ministry of Oceans and Fisheries, Korea.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest. This article does not contain any studies involving animals or human participants performed by any of the authors.

Rights and permissions

About this article

Cite this article

Nguyen, D.L., Hwang, J., Kim, E.J. et al. Production and Characterization of a Recombinant Cold-Active Acetyl Xylan Esterase from Psychrophilic Paenibacillus sp. R4 Strain. Appl Biochem Microbiol 58, 428–434 (2022). https://doi.org/10.1134/S0003683822040123

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0003683822040123