Abstract

Unique features of metal nanoparticles (NPs) are attracting the attention of researchers from various fields of science, including biomedicine, microbiology, biotechnology, and agriculture. The biological activity of NPs depends on their size characteristics, composition, physicochemical properties, and method of preparation. Chemical, biological, and physical methods are used to obtain NPs. In this review, we discuss the main methods for the chemical synthesis of metal-based NPs. The advantages and disadvantages of the most commonly used reducing agents are described. Particular attention is paid to the effect of the synthesis conditions on the NP properties. The potential use of polysaccharides, in particular, chitosan, as a reducing and stabilizing agent of an NP suspension is considered.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Metal nanoparticles (NPs) are a dispersed system in which a particle of a metal or its oxide is a dispersed phase and a liquid, as a rule, is the dispersion medium. In accordance with modern concepts in the field of nanotechnology, NPs are structures with sizes from 1 to 100 nm (in one dimension). They have a large ratio of interface area to volume, i.e., a large specific surface area, which grows with decreasing particle size [1]. This feature of NPs underlies their unique properties, such as their high reactivity and the appearance of surface plasmon resonance (SPR), i.e., resonant oscillations of electrons upon the excitation of a surface plasmon by an external electromagnetic wave. Metal NPs are used to develop biosensors [2, 3], show antitumor activity in cell cultures [4, 5], possess antiviral activity [6, 7], are characterized by nonspecific toxicity for bacteria [8, 9] and microscopic fungi [10–12], are used as drug carriers [13, 14], have a stimulating effect on plant growth, and increase plant resistance to stress [15–17].

Taking into account the potential for the widespread use of NPs, special attention is directed to the study of their toxicity to humans, animals, and plants, as well as their impact on the environment. The toxicity of metals can vary depending on the degree of their oxidation, the solubility of the compounds or the morphology of particles, the presence of ligands capable of forming complex compounds with the metal, the environmental conditions, the exposure time, and the method of application [18, 19].

Nanoparticles are described by such fundamental characteristics as their shape, size, polydispersity, surface charge, time and degree of agglomeration, elemental composition, surface chemical composition, surface area, crystal structure, etc. These parameters are largely determined by the method of NP synthesis.

METHODS OF NANOPARTICLE FORMATION

At present, metal NPs are obtained with several approaches:

(1) NP preparation via the destruction of larger structures with physical methods (sputtering, grinding, laser ablation, etc.);

(2) the preparation of metal NPs with microorganisms;

(3) the formation of NPs containing metals in reduced or ionized form with polymers;

(4) the preparation of NPs of metals and metal oxides with reducing agents.

The last two approaches are chemical and do not require the use of specialized equipment, which makes them relatively inexpensive and may be interesting from the point of view of further practical use. This review is devoted to methods for the synthesis of NPs of metals and metal oxides with reducing agents. The potential use of polysaccharides, in particular, chitosan and its derivatives, as a reducing agent and stabilizer for a NP suspension is discussed.

NANOPARTICLE SYNTHESIS WITH REDUCING AGENTS

Agents such as hydrazine hydrate, sodium borohydride, reducing agents containing the borane group BH3, alcohols, formaldehyde, ascorbic acid, citrates, and others are used to synthesize NPs via the reduction of metals from their salts. Further, we will consider the reagents most often used for the synthesis of metal NPs.

HYDRAZINE HYDRATE

Hydrazine hydrate is a strong reducing agent and is widely used to isolate metals from solutions of their salts. Using a combination of hydrazine hydrate and its mixture with sodium citrate as a reducing agent, spherical silver NPs of various diameters from 9 to 30 nm were obtained [20]. Aggregation and the formation of two fractions of NPs differing in size were observed. The appearance of the SPR peak at 418 nm indicated the formation of metallic NPs. The crystal structure of the particles corresponded to the face-centered cubic structure of Ag. When sodium citrate was added, the optical absorption peak shifted to the 412 nm region with the formation of a shoulder in the 540 nm region. A study on the effect of NP size on antibacterial activity against a number of bacteria (Staphyloccoccus aureus, Escherichia coli, and Pseudomonas aeruginosa) showed that silver NPs 9 nm and 11 nm in size have a tenfold lower minimum inhibitory concentration (MIC) than the 23- and 30-nm particles.

The authors of [21] found that an increase in the concentration of hydrazine hydrate from 2 to 10 mM led to a broadening of the SPR peak that corresponded to the appearance of silver NPs of various structures; a decrease in NP stability was also observed. To prevent aggregation, polyvinylpyrrolidone was added to the reaction mixture. At a hydrazine concentration of 6 mM, NPs 10–15 nm in size were obtained. It was shown that silver NPs have a face-centered cubic structure, and their planes are predominantly oriented. An increase in the concentration of silver nitrate from 2 to 4 mM led to the formation of a second absorption peak in the region of 656 nm, which, according to the authors, indicates a change in the morphological characteristics of the particles. During the determination of the antibacterial activity of silver NPs against E. coli and S. aureus by diffusion in agar, it was shown that particles with a high concentration of silver nitrate and hydrazine hydrate did not show a visible antibacterial effect, while the formation of a lysis zone was observed at lower concentrations. The authors explain this effect also by a change in the particle morphology, which affected the ability of particles to diffuse.

Saikova et al. [22] studied the effect of the reaction conditions on the characteristics of copper NPs. The ultraviolet (UV) spectra of the product of the reduction of copper sulfate with hydrazine hydrate at a temperature of 20–80°С are broad absorption bands with a maximum at a wavelength of λ = 600 nm, which is characteristic of the ammonium–copper complex. Upon heating to 90–100°С, the formation of a red colloid with a SPR peak in the region of λ = 590 nm was observed; this indicated the formation of metallic copper. Microwave treatment led to a shift in the SPR peak to 580 nm and was accompanied by an increase in intensity. To avoid the formation of copper(I) oxide or hydroxide during reduction, the reaction was carried out under alkaline conditions in the presence of complexing agents that maintain the level of copper ions in solution. The addition of complexing agents increased the particle yield, which was reflected by an increase in SPR intensity in the presence of tartrate ions. The presence of strong alkalis in the reaction mixture led to a shift in the reaction towards the formation of copper(I) oxide. An increase in the copper salt content led to the formation of a “copper mirror” on the walls of the reaction vessel and was accompanied by a decrease in SPR intensity; in this case, the optical absorption in the red region increased significantly.

The effect of surfactants depended on their nature and concentration. Sodium dodecyl sulfate promoted the formation of smaller NPs and reduced the proportion of oxidized particles. The addition of cetyltrimethylammonium bromide led to a sharp decrease in SPR intensity and, hence, the yield of copper NPs. Their yield increased significantly with the addition of polyvinylpyrrolidone at a concentration of 0.0001 M, but a further increase in the concentration led to a decrease in the yield of copper NPs, which is associated with the coordination of oxygen atoms in polyvinylpyrrolidone with copper(II) ions.

To prevent the formation of copper(II) oxide and to stabilize the suspension, a solution of low-molecular-weight chitosan was added to the reaction mixture before the introduction of hydrazine hydrate to copper sulfate [23]. The size of the obtained particles was 100–200 nm. Particles up to 5 nm in size were obtained based on copper chloride; however, the reaction mixture was multicomponent and contained hydrazine hydrate, as well as polyvinyl alcohol (stabilizer), trisodium citrate (dispersing agent), and glycerol (solvent) [24]. Both types of particles showed high fungicidal activity.

It should be noted that hydrazine hydrate is an extremely toxic substance for living organisms, including mammals; therefore, the synthesis of metal NPs with this reagent requires compliance with increased safety measures. For the same reason, its presence in the composition of the NP suspension can make a significant contribution to the biological activity of the obtained NP preparations. The colloids obtained with this reducing agent tend to aggregate and precipitate [21]. To ensure a stable synthesis of metal NPs and a high yield with the use of hydrazine hydrate, the selection of stabilizers and optimization of the synthesis conditions are required.

SODIUM BOROHYDRIDE (NаBH4)

Sodium borohydride is often used as a reducing agent. Dong et al. [25] found that, at low temperatures, the reduction of silver nitrate with NaBH4 in the presence of sodium citrate is completed in 1 min, and further reduction of silver nitrate does not occur even after 50 h. When 2 × 10–7 M NaBH4 was added at a low temperature, almost no precursor consumption was found. After heating to 70°C, the silver nitrate was gradually consumed, and almost no silver nitrate remained after 4 h. The amount of NaBH4 in the reaction mixture affected the particle morphology. The spherical and rod-like silver NPs obtained at a low concentration of NaBH4 (2 × 10–7 M) were similar to those obtained by reduction with sodium citrate in the absence of sodium borohydride. Triangular silver nanoprisms accompanied by some spherical NPs were obtained at a medium concentration of NaBH4 (5 × 10–6 M). Small, spherical NPs prevailed in the product at a high concentration of NaBH4 (5 × 10–4 M).

Polish researchers studied the effect of oxygen on the formation of silver particles in a similar system (silver nitrate as a precursor, sodium citrate as a stabilizer, and sodium borohydride as a reducing agent) [26]. At low NaBH4 concentrations, silver NPs obtained at a natural oxygen concentration were approximately five times larger than silver NPs synthesized in an inert argon atmosphere. With an increase in the NaBH4 concentration at the natural concentration of oxygen in the air, the average size of NPs decreases; conversely, in an inert medium, an increase in the concentration of the reducing agent led to an increase in NP size.

SODIUM CITRATE

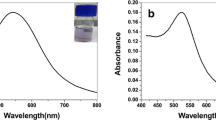

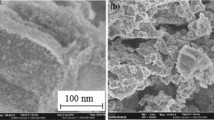

When silver NPs were obtained at 85°C with the citrate method and the UV spectra of the colloid were analyzed, the presence of several peaks and broadening of the absorption band were revealed [27]. The authors attributed this to the large NP variation in size and shape. This assumption was confirmed via scanning electron microscopy.

Sreelekha et al. compared the “green” method to obtain silver particles with a plant extract and synthesis with sodium citrate [28]. The SPR peak of chemically synthesized NPs was detected at a wavelength of 446 nm, whereas the optical absorption of synthesized NPs increased with time in both the case of green and chemical synthesis. For chemically synthesized silver NPs, a bathochromic shift of the absorption maximum was observed simultaneously with a decrease in the absorption intensity after 1 week, which the authors attributed to the increase in particle size. It was concluded that NPs synthesized with the citrate-reduction method were less stable than NPs synthesized with the green method. The observed effect is likely to be due to the stabilizing components contained in plant extracts, as well as the competitive mechanism of interaction between metals and components of plant extracts, which have different binding specificities [29]. The effect of tannic acid, a polyphenolic compound contained in plant extracts, on the synthesis of silver NPs by the reduction of silver nitrate with the citrate method was studied in [29]. With the addition of tannic acid, a narrower optical absorption peak was observed and homogeneous spherical silver NPs formed; without it, NPs were characterized by an inhomogeneous shape, which was shown by transmission electron microscopy. With an increase in the polyphenol concentration from 0 to 2 × 10–6 mol/L, the average size of silver NPs decreased from 98 ± 53 to 16 ± 5 nm.

It should be noted that the citrate method for NP synthesis is also widely used to synthesize gold NPs used in the development of sensors, as well as in biomedical research [30, 31]. Nanoparticles obtained with sodium citrate as a reducing agent are more narrowly dispersed than particles obtained via reduction with sodium borohydride, but they have a larger size [32].

ASCORBIC ACID

Particles of different shapes were obtained with the use of different copper salts: rods (based on copper acetate, 250–350 nm in length and 40–60 nm in thickness), triangular plates (based on copper chloride, 150–250 nm), and spherical (based on copper sulfate up to 100 nm) [33]. It was shown that these particles contained copper in the form of oxide. The resulting NPs inhibited the growth of both gram-positive and gram-negative bacteria.

Nanoparticles based on copper chloride were synthesized with ascorbic acid in [34]; their size was about 2 nm. The obtained NPs proved to be stable for 2 months of storage.

The study of the effect of the pH of the reaction medium, the concentration of the stabilizing agent polyvinylpyrrolidone, and the reaction time with ascorbic acid showed that NPs did not form in an alkaline medium, and the NP size increased from 120 to 330 nm as the pH decreased from 7.0 to 3.0. This was accompanied by a shift of the maximum absorption spectrum in the visible region from 584 to 600 nm [35]. The reaction duration did not affect the number of formed particles for more than 3 h, and an increase in the concentration of polyvinylpyrrolidone led to their enlargement. Inhibition of the growth Fusarium oxysporum and Phytophthora capsici by copper NPs was increased with increases in the incubation time and decreases in the particle size.

The copper and silver NPs were obtained with ascorbic acid as a reducing agent [36]. It was shown that the samples had characteristic SPR peaks for silver NPs (420 nm) and copper NPs (550 nm). With an increase in the concentration of the precursor in the reaction mixture, the NP size also increased; upon an increase in the concentration of the stabilizer chitosan, the particle size decreased. Bimetallic Ag–Cu NPs exhibited a synergistic antibacterial effect in comparison with the antibacterial activity of silver NPs or copper NPs. At the same time, the preparation obtained via the mixing of ready-made metal particles did not show synergy, in contrast to bimetallic NPs.

POLYOL SYNTHESIS

The advantage of polyols as reducing agents is that they have high boiling points and dissolve metal salts well. In addition, polyhydric alcohols possess coordinating properties that allow surface functionalization and colloidal stabilization of NPs.

Polyvinylpyrrolidone and ethylene glycol were used as reducing agents in [37]. The authors studied the effect of the time, reaction temperature, and concentration of the silver precursor on NP formation. It was found that polyhedral plates with a size of about 300 nm and a high polydispersity formed at very short reaction times and at low temperatures. With an increase in time to 2 min and temperature to 120°C, a decrease in particle size and the formation of spherical NPs 10 nm in size with low polydispersity were observed. An increase in the reaction time by more than 2 min led to a gradual increase in size. The optimal temperature to obtain a homogeneous NP suspension was 120°C, while no particle nuclei formed at a temperature of 60°C, and the number of aggregates increased at temperatures of 150–160°C. An increase in the concentration of silver nitrate in the reaction mixture from 1.0 to 20 mM led to an increase in NP size from 11 nm to 20 nm without changes in the polydispersity and was accompanied by a bathochromic shift in the absorption maximum in the UV spectrum.

During the reduction of copper acetate with ethylene glycol (EG) in the presence of Tween 80 as a stabilizer, copper (Cu0) NPs were obtained under conditions of natural oxygen concentration [38]. When the reaction mixture was heated to 190–200°C, the metal was completely reduced, and it was found that the synthesized NPs were formed by phase-pure copper without any impurities, e.g., CuO, Cu2O, and Cu(OH)2.

Ethylene glycol (EG), diethylene glycol (DEG), and tetraethylene glycol (TEG) were used to obtain nanosized zinc oxide (ZnO) via the heating of zinc acetate at 160°C [39]. According to the hypothesis, glycols as chelating agents form complexes of growing NPs, as a result of which the growth of grains is limited and particle agglomeration is hindered. The size of the synthesized ZnO NPs correlated with the glycol chain length: with an increase in the glycol chain length, the average size of ZnO particles also increases: 19.62, 38.84, and 68.57 nm for ZnO/EG, ZnO/DEG, and ZnO/TEG, respectively. The shape of ZnO NPs also changed depending on the chain length of the reducing agent, from spherical for ZnO/EG, spherical and rod for ZnO/DEG to diamond-like structure for ZnO/TEG.

Due to the wide range of polyhydric alcohols differing in their characteristics, the synthesis process can be adapted for any metals and NPs with different characteristics can be obtained [40].

SODIUM HYDROXIDE

Sodium hydroxide can be used to obtain NPs consisting of metal hydroxides and oxides. For example, NPs of cobalt oxide Co3O4 were obtained from cobalt acetate [41]. Cobalt hydroxide obtained as a result of interaction with NaOH was oxidized by atmospheric oxygen to cobalt oxide. Co3O4 NPs had a cubic shape. The intensity of the cubic structure of NPs increased with increasing NaOH concentration. Agglomerates and irregular CoO(OH) particles formed at high concentrations of sodium hydroxide (0.7 M NaOH). It was shown that NP agglomeration led to a decrease in the catalytic activity of NPs in the Fenton degradation of methylene blue.

The effect of counterions in copper salts on NP formation during reduction with sodium hydroxide was studied [33]. Micrographs obtained via scanning electron microscopy indicate the formation of fibrous NPs of various lengths and thicknesses. The length of nanofibers increased in the following order: copper acetate, copper chloride, and copper sulfate. Based on the presence of an oxygen peak in the energy dispersive X-ray spectrum, the authors came to the conclusion that the obtained NPs contained precisely copper oxide.

Copper(II) oxide NPs of about 23 nm in size that were synthesized with NaOH had antimicrobial properties with the following MICs: 31.25 μg/mL for E. coli; 125 μg/mL for Pseudomonas aeruginosa; and 62.5 μg/mL for S. aureus [42].

PLANT EXTRACTS

At present, green methods, i.e., solutions of plant extracts, are used to synthesize metal NPs [43, 44]. Plants contain many active, natural compounds such as alkaloids, flavonoids, saponins, steroids, tannins, etc. Since the plant extract contains a variety of secondary metabolites, it acts as a reducing and stabilizing agent. Various parts of plants can be used to obtain extracts: leaves, stems, roots, flowers, bark, fruits, and seeds of various plants. For example, extracts obtained from pomegranate seeds [45], ginger and garlic roots [46], rose petals [47], and others have been used. Copper NPs with a size of 20–30 nm with a small negative zeta potential were obtained with lemon juice [48]. The particles were also characterized by the appearance of a SPR peak in the region of 615 nm. The resulting NPs did not contain copper oxide and had a crystal structure typical of metallic copper. It has been shown that they stimulate the growth of shoots and roots of the pigeon pea and promote an increase in the dry biomass of the plant in comparison with the control.

This approach has been actively used in recent years as an alternative, efficient, inexpensive, and environmentally friendly method to produce NPs. However, when this approach is used to produce NPs, it is difficult to determine the true activity of the obtained NPs due to the presence of many biologically active substances in plant extracts. Another disadvantage of this approach is the complexity of standardization due to the significant dependence of biochemical processes in plants on the environmental conditions, which affects the chemical composition of the obtained extracts.

NANOPARTICLE SYNTHESIS IN THE PRESENCE OF POLYSACCHARIDES

Physical and chemical methods for the synthesis of metallic NPs usually lead to the formation of reaction by-products; in addition, instability of the final product is observed at physiological pH values [49]. The factors listed above can limit the use of metal NPs in practice.

One strategy to overcome the listed disadvantages of NPs and enhance their biological activity is the modification of metal NPs with polysaccharides. Polysaccharides, e.g., starch, cellulose, chitin, chitosan, cyclodextrin, alginate, carrageenan, and their derivatives, are widely used in the field of biomedicine. These polymers have a variety of properties and can be isolated from a variety of sources of plant, animal, and microbial origin.

The use of polysaccharides as a modifier of the NP surface affects the biocompatibility and stability of the nanomaterial. It has been shown that the in vitro toxicity of copper NPs decreases as a result of their inclusion in the polysaccharide matrix. This simultaneously increased the parameters of the inflammatory process in the lungs of mice [50]. Polysaccharides successfully prevented the agglomeration of iron oxide NPs and promoted their protection from macrophages, increasing their half-life [51]. The so-called green methods for the polysaccharide-based synthesis of NPs, in which the polysaccharide is used as a reducing and stabilizing agent of the resulting NPs, are increasingly discussed in the scientific literature [52, 53].

Chitosan is a linear polysaccharide, a heteropolymer consisting of glucosamine and acetylglucosamine units linked by β-(1-4)-glycoside bonds. Chitosan is a product of the chemical modification of chitin with a certain degree of deacetylation (DD). As a rule, it is more than 50%; i.e., it is predominantly composed of glucosamine [54].

The main physicochemical characteristics of chitosan are the molecular weight (MW) and DD. It should be noted that the distribution of acetylglucosamine and glucosamine units in the polymer structure is also an important parameter of the polysaccharide [55]. Chitosan is soluble only in an acidic medium due to protonation of the amino group of the glucosamine units of the biopolymer. The average value of the dissociation constant of chitosan is pKa = 6.5 [56]. It follows from this that the amino groups of chitosan are in the protonated form at a pH of <6.5. With an increase in the pH of aqueous solutions, the polymer solubility is significantly reduced. This fact significantly limits the potential use of the biopolymer in solution under physiological conditions (pH close to neutral). Depolymerization and chemical modification of chitosan make it possible to overcome the problems associated with the polymer solubility and increase its biological activity.

The polycationic structure determines the special physicochemical properties of chitosan, which distinguish it from other biopolymers and polysaccharides [57]. Chitosan and chitooligosaccharides are characterized by bacteriostatic, fungicidal, chelating, antioxidant, immunomodulatory, and antitumor activities; they are also biocompatible, biodegradable, and have low toxicity [58].

NANOPARTICLE SYNTHESIS WITH CHITOSAN AND ITS DERIVATIVES

Chitosan and its derivatives can be used as reducing agents in the synthesis of metal NPs. The ability to synthesize silver NPs in a chitosan medium (η 200 Pa s, 85% DD) was demonstrated in [59]. In a chitosan solution at 95°C for 12 h, the formation of spherical silver NPs was observed. The SPR peak at 419–424 nm in the UV spectrum indicated the formation of metallic NPs. The main fraction of NPs, according to transmission electron microscopy (TEM), consisted of particles with a size of 6–8 nm. The amino groups of chitosan are capable of forming complexes with metal ions, due to which chitosan is a highly effective polymeric chelating agent for Ag+ ions. Thus, silver NPs form as a result of a process involving the complexation of Ag+ with amino groups and the subsequent reduction to Ag0,which is accompanied by chitosan oxidation. The study of the antibacterial activity of the synthesized silver NPs against E. coli, Staphylococcus aureus, and Bacillus subtilis showed that the MICs were 10, 10, and 48 μg/mL, respectively.

Carboxymethyl chitosan (95% degree of substitution) was used as a matrix for the synthesis of silver NPs under the action of light [60]. The formation of NPs was detected by the appearance of a characteristic peak in the UV spectrum. The SPR peak was absent in the control AgNO3-containing samples placed in the dark. Thus, it was shown that the formation of silver NPs proceeded only in light. The NP size was on the order of 30–100 nm (according to TEM data). X-Ray diffraction analysis of the nanocomposite showed the formation of polycrystalline metallic NPs.

A nanocomposite based on silver NPs and quaternized chitosan (MW 250 kDa, 85% DD) was proposed as a substrate for the development of a system to detect Sudan I and tricyclazole via surface-enhanced Raman scattering (SERS) [61]. [Ag(NH3)2]OH was used as a precursor. The synthesis proceeded in a solution of quaternized chitosan under the action of microwave radiation. Nanoparticles about 19 nm in size formed under optimal conditions (according to TEM data). It was shown that an increase in the degree of substitution of quaternized chitosan led to the formation of larger NPs. A decrease in the molecular weight of chitosan as a result of degradation of the polymer chain under more drastic synthesis conditions led to a decrease in nanomaterial stability and the formation of NP agglomerates. The resulting nanocomposite was stable in an aqueous medium for a month, but it was aggregated in ethanol.

Gold NPs were synthesized based on Au(III) chloride trihydrate; in this case, chitosan (MW ~ 1278 ± 8 kDa, DD 89 ± 2%) was used as reducing and stabilizing agent for the formation of NPs [62]. The synthesis was carried out via heating to 60°C with stirring for 4 h. An absorption maximum at ~525 nm was observed in the spectrum of colloidal gold NPs; this is characteristic of spherical NPs, which was confirmed by TEM data. As the NP concentration increased, the SPR absorption intensity and the colloid color intensity increased. The particle size was 10–20 nm. The use of phosphotungstic acid for staining chitosan made it possible to visualize the chitosan coating in the form of a homogeneous halo (approximately 3–4 nm). It was shown that this nanocomposite has a low cytotoxicity on macrophage cells. Gold NPs exhibited antibacterial activity against E. coli and S. aureus. Flow cytometry and scanning electron microscopy have shown that the predominant mechanism of antibacterial action is the destruction of the bacterial cell wall.

It was shown in [63] that cubic silver NPs can be synthesized in a medium with chitosan (MW 190–310 kDa, 75–78% DD) under the action of ultrasound. The treatment of a solution of chitosan and AgNO3 with ultrasound was carried out for 1 h at a temperature of 60–90°С. An increase in NP size was observed with an increase in the reaction temperature. Samples of the obtained NPs were analyzed via scanning electron microscopy (SEM) and electromotive force (EMF). The cubic structures were in the range of 120–450 nm. Starch was chosen as a control polysaccharide for NP formation. The presence of cubic structures was observed only in chitosan, which indicates a significant effect of the nature of the polysaccharide on the silver NP morphology.

CHITOSAN AND ITS DERIVATIVES AS A STABILIZING AGENT FOR METAL NANOPARTICLES

Trimethylchitosan (η 3.6 mPa s, 93.8% DD) was used as a stabilizing agent [64] in the synthesis of silver NPs with a positive surface charge. Glucose was used as a reducing agent. The process of NP synthesis at different concentrations of NaOH and glucose was studied. It was shown that the amount of NaOH had a significant effect on the rate of the process and the size of silver NPs. The formation of spherical NPs with average sizes within 60 nm was shown via transmission electron microscopy (TEM). According to the results of dynamic light scattering (DLS), the average particle size was 180 nm. Elemental analysis proved the presence of silver in the particles. The catalytic activity of the obtained NPs was studied via the reduction of nitrophenol with NaBH4. It was shown that the reaction rate increased linearly with an increase in the amount of catalyst. The antibacterial activity of the synthesized silver NPs against eight antibiotic-resistant bacterial strains, including one gram-negative and seven gram-positive strains, was assessed by the MIC value, which ranged from 3.6 to 12.25 μg/mL.

The fungicidal properties of chitosan NPs and a nanocomposite based on silver NPs and chitosan were studied in [65]. The NPs were synthesized via the reduction of AgNO3 with NaBH4 in a medium with chitosan. The TEM results showed the formation of spherical NPs with an average size of ~373 nm and a positive surface charge of 47.5 mV. The NP samples exhibited a fungicidal effect against F. oxysporum. It was found that the fungicidal effect of NPs is associated with an increase in the formation of reactive oxygen species (ROS) in the mycelium; in addition, NPs affected the synthesis of ergosterol, which is similar to the action of azole fungicides. At the same time, NPs did not possess significant cytotoxicity in the MTT assay at a concentration of up to 400 μg/mL on A549 human lung carcinoma cells.

A water-soluble, N-methylated, chitosan thiomer (MCT) synthesized based on low-molecular-weight chitosan (MW 24.5 kDa, 74.9% DD) was proposed as a stabilizing agent for silver NPs [66]. It is known that thiol functional groups are capable of reversible oxidation and the formation of covalent bonds with metals. The sizes of the silver–MCT complex and the nanocomposite based on silver NPs and MCT were determined. The formation of spherical NPs 9–15 nm in size was observed; the NPs exhibited antibacterial properties against model microorganisms E. coli and S. aureus. The NPs also had the ability to inhibit the formation of bacterial biofilms on the surface of polystyrene.

CONCLUSIONS

Numerous studies have demonstrated a wide range of possibilities for the chemical synthesis of metal NPs with various properties. Metal NPs exhibit biological activity that significantly distinguishes them from precursors. Moreover, their properties (size, charge, and biological activity) can vary significantly depending on the synthesis conditions. In the considered works, metal NPs are largely inseparable from the dispersion medium that affects their surface properties. Thus, the consideration and study of new approaches and conditions for NP synthesis is an important task. For example, metal NPs can be modified with polysaccharides, including chitosan, which makes it possible to increase their stability, reduce their toxicity, and change the mechanism of action on biological objects. Chitosan and its derivatives can act as reducing and, at the same time, as stabilizing agents in the preparation of various NPs of metals.

REFERENCES

Sergeev, G.B., Nanokhimiya (Nanochemistry), Moscow: Mosk. Gos. Univ., 2003.

Wang, J., Munir, A., Li, Zh., and Zhou, H.S., Biosens. Bioelectron., 2009, vol. 25, no. 1, pp. 124–129.

Qiu, J., Wang, R., Liang, R., and Xia, X., Biosens. Bioelectron., 2009, vol. 24, no. 9, pp. 2920–2925.

Babaei, A., Mousavi, S., Ghasemi, M., Pirbonyeh, N., Soleimani, M., and Moattari, A., Life Sci., 2021, p. 119652. https://doi.org/10.1016/j.lfs.2021.1196525

Khandanlou, R., Murthy, V., Saranath, D., and Damani, H., J. Mater. Sci., 2018, vol. 53, no. 5, pp. 3106–3118.

Cai, L., Liu, Ch., Fan, G., Liu, Ch., and Sun, X., Environ. Sci. Nano, 2019, vol. 6, no. 12, pp. 3653–3669.

Vargas-Hernandez, M., Macias-Bobadilla, I., Guevara-Gonzalez, R.G., Rico-Garcia, E., Ocampo-Velazquez, R.V., Avila-Juarez, L., and Torres-Pacheco, I., Agriculture, 2020, vol. 10, no. 10, p. 444. https://doi.org/10.3390/agriculture10100444

Gold, K., Slay, B., Knackstedt, M., and Gaharwar, A.K., Adv. Ther., 2018, vol. 1, no. 3, art. 1700033. https://doi.org/10.1002/adtp.1700033

Zia, R., Riaz, M., Farooq, N., Qamar, A., and Anjum, S., Mater. Res. Express, 2018, vol. 5, no. 7, p. 075012.

Malandrakis, A.A., Kavroulakis, N., and Chrysikopoulos, C.V., Sci. Total Environ., 2020, vol. 703, art. 135557.

Abboud, M.A.L., Res. Sq., 2020, vol. 1, pp. 1–15. https://doi.org/10.21203/rs.3.rs-125001/v1

Chen, J., Wu, L., Lu, M., Lu, Sh., Li, Z., and Ding, W., Front. Microbiol., 2020, vol. 11, pp. 1–19. https://doi.org/10.3389/fmicb.2020.003656

Farooq, M., Novosad, V., Rozhkova, E., Wali, H., Ali, A., Fateh, A., Neogi, P., Neogi, A., and Wang, Zh., Sci. Rep., 2018, vol. 8, no. 1, p. 2907. https://doi.org/10.1038/s41598-018-21331-y

Beik, J., Shiran, M., Abed, Z., Shiri, I., Ghadimi-Daresajini, A., Farkhondeh, F., Ghaznavi, H., and Shakeri-Zadeh, A., Med. Phys., 2018, vol. 45, no. 9, pp. 4306–4314.

Zhao, L., Lu, L., Wang, A., Zhang, H., Huang, M., Wu, H., Xing, B., Wang, Zh., and Ji, R., J. Agric. Food Chem., 2020, vol. 68, no. 7, pp. 1935–1947.

Mohamed, E.A., Arch. Phytopathol. Plant Prot., 2019, vol. 52, nos. 17–18, pp. 1276–1288.

Ahmed, F., Javed, B., Razzaq, A., and Mashwani, Z., IET Nanobiotechnol., 2021, vol. 15, no. 1, pp. 68–78. https://doi.org/10.1049/nbt2.12002

Egorova, K.S. and Ananikov, V.P., Organometallics, 2017, vol. 36, no. 21, pp. 4071–4090. https://doi.org/10.1021/acs.organomet.7b00605

Phogat, N., Shadab, A.K., Shankar, Sh., Ansary, A.A., and Uddin, I., Adv. Mater. Lett., 2016, vol. 7, no. 1, pp. 3–12.

Guzmán, M.G., Dille, J., and Godet, S., Int. J. Mater. Metall. Eng., 2008, vol. 2, no. 7, pp. 100–107. https://doi.org/10.5281/zenodo.1062628

Gurusamy, V., Krishnamoorthy, R., Gopal, B., Veeraravagan, V., and Neelamegam, P., Inorg. Nano-Metal Chem., 2017, vol. 47, no. 5, pp. 761–767.

Saikova, S.V., Vorob’ev, S.A., Nikolaeva, R.B., and Mikhlin, Yu.L., Russ. J. Gen. Chem., 2010, vol. 80, no. 6, pp. 1122–1127.

Vanti, G.L., Masaphy, S.K., Mahantesh, S., and Nargund, V.B., Int. J. Biol. Macromol., 2020, vol. 156, pp. 1387–1395.

Cao, V.D., Nguyen, P.P., Khuong, V.Q., Nguyen, C.K., Nguyen, X.Ch., Dang, C.H., and Tran, N.Q., Bull. Korean Chem. Soc., 2014, vol. 35, no. 9, pp. 2645–2648. https://doi.org/10.5012/bkcs.2014.35.9.2645

Dong, X., Ji, X., Jing, J., Li, M., Li, J., and Yang, W., J. Phys. Chem., vol. 114, no. 5, pp. 2070–2074. https://doi.org/10.1021/jp909964k

Wojtysiak, S. and Kudelski, A., Colloids Surf. A Physicochem. Eng. Asp., 2012, vol. 410, pp. 45–51.

Pinero, S., Camero, S., and Blanco, S., J. Phys. Conf. Ser., 2016, vol. 755, no. 1, art. 011001. https://doi.org/10.1088/1742-6596/786/1/012020

Sreelekha, E., George, B., Shyam, A., Sajina, N., and Mathew, B., Bionanoscience, 2021, vol. 11, no. 2, pp. 489–496.

La Spina, R., Mehn, D., Fumagalli, F., Holland, M., Reniero, F., Rossi, F., and Gilliland, D., Nanomaterials, 2020, vol. 10, no. 10, p. 2031. https://doi.org/10.3390/nano10102031

Wang, J., Munir, A., and Zhou, H.S., Talanta, 2009, vol. 79, no. 1, pp. 72–76.

Storhoff, J.J., Elghanian, R., Mucic, R.C., Mirkin, C.A., and Letsinger, R.L., J. Am. Chem. Soc., 1998, vol. 120, no. 9, pp. 1959–1964.

Oliveira, J.P., Prado, A.R., Keijok, W.J., Ribeiro, M.R.N., Pontes, M.J., Nogueira, B.V., and Guimaraes, M.C.C., Arab. J. Chem., 2020, vol. 13, no. 1, pp. 216–226. https://doi.org/10.1016/j.arabjc.2017.04.003

Shankar, S. and Rhim, J.-W., Mater. Lett. Elsevier, 2014, vol. 132, pp. 307–311.

Xiong, J., Wang, Y., Xue, Q., and Wu, X., Green Chem, 2011, vol. 13, no. 4, p. 900.

Pham, N.-D., Duong, M.-M., Le, M.-V., Hoang, H.A., and Pham, L-K.-O., Comptes Rendus Chim., 2019, vol. 22, nos. 11–12, pp. 786–793. https://doi.org/10.1016/j.crci.2019.10.007

Zain, N.M., Stapley, A.G.F., and Shama, G., Carbohydr. Res., 2014, vol. 112, pp. 195–202.

Torras, M. and Roig, A., ACS Omega, 2020, vol. 5, no. 11, pp. 5731–5738.

Ramyadevi, J., Jeyasubramanian, K., Marikani, A., Rajakumar, G., and Rahuman, A.A., Mater. Lett. Elsevier, 2012, vol. 71, pp. 114–116.

Chieng, B.W. and Loo, Y.Y., Mater. Lett., 2012, vol. 73, pp. 78–82.

Fiévet, F., Ammar-Merah, S., Brayner, R., Chau, F., Giraud, M., Mammeri, F., Peron, J., Piquemal, J.-Y., Sicard, L., and Viau, G., Chem. Soc. Rev. R. Soc. Chem., 2018, vol. 47, no. 14, pp. 5187–5233.

Viljoen, E.L., Thabede, P.M., Moloto, M.J., Mubiayi, K.P., and Dikiza, B.W., Dig. J. Nanomater. Biostruct., 2019, vol. 14, no. 4, pp. 1131–1137.

Ahamed, M., Alhadlaq, H.A., Khan, M.A.M., Karuppiah, P., and Al-Dhabi, N.A., J. Nanomater., 2014, vol. 2014, pp. 1–4.

Garcia-Hernandez, L., Flores-Saldivar, J.A., Ramirez Ortega, P., Flores Guerrero, M.U., ECS Trans., 2021, vol. 101, no. 1, pp. 131–138.

Subashini, K., Prakash, S., and Sujatha, V., Mater. Res. Express., 2020, vol. 7, no. 11, art. 115308. https://doi.org/10.1088/2053-1591/abc979

Nazar, N., Bibi, I., Kamal, S., Iqbal, M., Nouren, S., Jilani, K., Umair, M., and Ata, S., Int. J. Biol. Macromol., 2018, vol. 106, pp. 1203–1210.

Yaqub, A., Malkani, N., Shabbir, A., Ditta, S.A., Tanvir, F., Ali, S., Naz, M., Kazmi, S.A.R., and Ullah, R., Curr. Microbiol. Springer US, 2020, vol. 77, no. 9, pp. 2287–2299.

Tiwari, N., Pandit, R., Gaikwad, S., Gade, A., and Rai, M., IET Nanobiotechnol., 2017, vol. 11, no. 2, pp. 205–211. https://doi.org/10.1049/iet-nbt.2016.0003

Shende, S., Rathod, D., Gade, A., and Rai, M., IET Nanobiotechnol., 2017, vol. 11, no. 7, pp. 773–781. https://doi.org/10.1049/iet-nbt.2016.0179

Jamkhande, P.G., Ghule, N.W., Bamer, A.H., and Kalaskar, M.G., J. Drug Deliv. Sci. Technol., 2019, vol. 53, art. 101174.

Worthington, K.L.S., Adamcakova-Dodd, A., Wongrakpanich, A., Mudunkotuwa, I.A., Mapuskar, K.A., Joshi, V.B., Allan Guymon, C., Spitz, D.R., Grassian, V.H., Thorne, P.S., and Salem, A.K., Nanotecnology, 2013, vol. 24, art. 395101.

Elrahman, A.A. and Mansour, F.R., J. Drug Deliv. Sci. Technol., 2019, vol. 52, pp. 702–712.

Shavandi, A., Saeedi, P., Ali, M.A., and Jalalvandi, E., Funct. Polysaccharides Biomed. Appl., 2019, pp. 267–304. https://doi.org/10.1016/B978-0-08-102555-0.00008-X

Yugay, Y.A., Usoltseva, R.V., Silant’ev, V.E., Egorova, A.E., Karabtsov, A.A., Kumeiko, V.V., Ermakova, S.P., Bulgakov, V.P., and Shkryl, Y.N., Carbohydr. Res., 2020, vol. 245, p. 116547.

Kou, S., Peters, L.M., and Mucalo, M.R., Int. J. Biol. Macromol., 2021, vol. 169, pp. 85–94. https://doi.org/10.1016/j.ijbiomac.2020.12.005

Jiang, T., James, R., Kumbar, S.G., and Laurencin, C.T., Natural and Synthetic Biomedical Polymers, Kumbar, S., Laurencin, C., and Deng, M., Elsevier, 2014, pp. 91–113.

Choi, C., Nam, J.-P., and Nah, J.-W., J. Industr. Eng. Chem., 2016, vol. 33, pp. 1–10.

Mikhailov, S.N. and Varlamov, V.P., Khitozan (Chitosan), Skryabin, K.G., Mikhailov, S.N., and Varlamov, V.P., Eds., Moscow: Bioengineering Tsentr Ross. Akad. Nauk, 2013, pp. 5–17.

Wang, W., Xue, C., and Mao, X., Int. J. Biol. Macromol., 2020, vol. 164, pp. 4532–4546.

Wei, D., Sun, W., Qian, W., Ye, Y., and Ma, X., Carbohydr. Res., 2009, vol. 344, no. 17, pp. 2375–2382.

Long, Y., Ran, X., Zhang, L., Guo, Q., Yang, T., Gao, J., Cheng, H., Cheng, T., Shi, C., and Su, Y., Mater. Lett., 2013, vol. 112, pp. 101–104.

Chen, K., Shen, Z., Luo, J., Wang, X., and Sun, R., Appl. Surf. Sci., 2015, vol. 351, pp. 466–473.

Mendoza, G., Regiel-Futyra, A., Andreu, V., Sebastian, V., Kyziol, A., Stochel, G., and Arruebo, M., ACS Appl. Mater. Interfaces, 2017, vol. 9, no. 21, pp. 17693–17701. https://doi.org/10.1021/acsami.6b15123

Raghavendra, G.M., Jung, J., Kim, D., Varaprasad, K., and Seo, J., Carbohydr. Res., 2016, vol. 152, pp. 558–565.

Chang, T.Y., Chen, C.C., Cheng, K.M., Chin, C.Y., Chen, Y.H., Chen, X.A., Sun, J.R., Young, J.J., and Chiueh, T.S., Colloids Surf. B. Biointerfaces, 2017, vol. 155, pp. 61–70. https://doi.org/10.1016/j.colsurfb.2017.03.054

Dananjaya, S.H.S., Erandani, W.K.C.U., Kim, C.-H., Nikapitiya, C., Lee, J., and De Zoysa, M., Int. J. Biol. Macromol., 2017, vol. 105, pp. 478–488.

Elshaarawy, R.F.M., Ismail, L.A., Alfaifi, M.Y., Rizk, M.A., Eltamany, E.E., and Janiak, C., Int. J. Biol. Macromol., 2020, vol. 152, pp. 709–717.

Funding

The reported study was funded by RFBR, project no. 19-33-90011.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest. This article does not contain any studies involving animals or human participants performed by any of the authors.

Additional information

Translated by G. Levit

Rights and permissions

About this article

Cite this article

Lyalina, T.S., Lunkov, A.P. & Varlamov, V.P. Obtaining of Metal Nanoparticles Using Reducing Agents and Chitosan. Appl Biochem Microbiol 58, 97–104 (2022). https://doi.org/10.1134/S0003683822020132

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0003683822020132