Abstract

Future liability considerations and stringent regulatory requirements often lead the users to choose end product-driven processes. Over the last decade, high-rate novel reactors have emerged for wastewater treatment, ensuring high removal efficiencies. An example is jet loop reactors offering a number of advantages that could be even further improved by attaining thermophilic conditions. In this study, a respirometric analysis was employed in a thermophilic jet loop reactor for treating potato-processing wastewater in order to determine the kinetic and stoichiometric parameters. The kinetic parameters namely maximum specific growth rate (μmax), yield ratio (Y), decay coefficient (kd), and half saturation rate constant (Ks) were found to be 0.2 L/h, 0.71 g/g, 0.02 L/h, and 25.72 mg/L, respectively. Bacillus mojavensis, Gordonia paraffinivorans, Bacillus badius and Paenibacillus lactis strains were isolated from the thermophilic jet loop bioreactor. Considering the results, it is recommended that the estimation of kinetic and stoichiometric parameters in this system should preferentially be performed using respirometric techniques.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Combining environmental compliance with cost effectiveness calls for new approaches to wastewater treatment. With their efficiency in wastewater treatment and cost-effectiveness, jet loop bioreactors are now used as an alternative to conventional techniques for biological treatment [1, 2]. The prominent advantages of these high-rate reactors can be listed as possessing a simpler structure, easy operability, clearly defined flow regimes, improved dispersion impact, reduced power consumption and production of sludge, and the higher quality of treated water with the properties of reduced turbidity and higher mass transfer [2, 3]. Among these advantages, the achievement of high dissolved oxygen concentrations through turbulence generated in the reactor is of particular importance [4]. This results in higher efficiency for the biodegradation of organic pollutants particularly in high-strength wastewater [2]. All these features can be further improved by creating thermophilic conditions in this type of reactor.

As in thermophilic sludge digestion systems, thermophilic aerobic wastewater treatment has certain important features including faster biodegradation, pathogenic microorganism inactivation, and reduced production of sludge. An increase in biodegradation rates would also reduce the retention time required for organic matter decomposition, which would in turn lower capital costs. Increased degradation would also enhance the stability of the process by enabling the system to quickly recover from unexpected conditions. There are, however, certain disadvantages of thermophilic aerobic processes such as increased total cost in relation to aeration, poor settling characteristics, and foaming problems. In an earlier study, it was reported that the estimated oxygen requirements were 14% higher compared to traditional aerobic processes [5]. To overcome this problem, the authors recommended the use of aggressive aeration equipment and deeper tanks. The selection of the appropriate aeration equipment appears to be a crucial decision related to the design of the process [6]. Therefore, jet loop reactors with a high mass transfer capacity and high turbulence present as suitable media for thermophilic aerobic treatment. The above-mentioned characteristics of jet loop reactors make them promising candidates to perform respirometric measurements, taking relatively shorter time and being more cost effective than other kinetic methods to determine the kinetics and stoichiometric parameters of a biological treatment system [7].

This study aimed to determine the kinetic and stoichiometric parameters of a thermophilic jet loop reactor in treating potato-processing wastewater using in situ respirometric techniques. Although there are some publications in the literature on the kinetic studies of thermophilic aerobic systems by means of a respirometric analysis, the authors did not encounter any investigation on this subject using a thermophilic jet loop bioreactor.

MATERIALS AND METHODS

Wastewater source and characterisation. The wastewater used in this study was obtained from a factory that produces potato and maize chips and snacks. The factory produces around 400 m3 wastewater per day. Table 1 presents the characterisation of the raw wastewater obtained after the peeling and cutting processes. Through a pipe from the treatment plant connected to a submersible pump, 100 L barrels were filled with the wastewater and then transferred to the laboratory and maintained at a constant temperature of 4°C. Upon their arrival at the laboratory, the samples were filtered through a sieve of 60 mesh (Thermo Fisher Scientific, USA) and the measurements were performed immediately. All parameters, given in Table 1, were analysed according to American Public Health Association (APHA) [8].

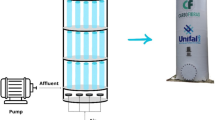

Equipment, instrumentation, and operational procedures. The fabricated bioreactor (Fig. 1) has an outer tube of cylindrical reactor and an inner tube of a draft channel both made of plexiglass having a conical bottom. The jet was created by the head through which wastewater and air were introduced at different ratios at the end of a nozzle [3, 9]. These reactors possess a liquid jet drive that allows circulation. Liquid is injected via a nozzle with a high velocity, resulting in a fine dispersion of liquid and gaseous phases [10]. The liquid and the gas inside the draft tube move downwards; then, after being reflected from the bottom of the reactor, the mixture rises up between the outer and inner tubes. At the upper end of the draft tube, through the sucking action, part of the fluid is recycled into the draft tube. This fact results in a homogeneous dispersion of bubbles and biomass created in the biological reaction [11]. The activated sludge taken from a domestic wastewater treatment plant was acclimated to thermophilic conditions during one month by increasing its temperature step by step to 45 ± 2°C in the jet loop bioreactor. The concentration of thermophilic biomass was kept as 450 ± 20 mg/L during the course of the experiments. An analysis of biomass concentration, mixed liquor suspended solids (MLSS), was carried out according to a standard method, namely STM 2540 D of APHA [8]. The temperature was kept constant at 45 ± 2°C throughout the experiments. The air and liquid flows were measured using flow meters (IFM Electronic GMBH, Germany). The pH was regularly measured by pH-meter (HACH-Lange, Germany) and found to vary between 7.4 and 7.6. Similarly, dissolved oxygen concentration (DO) was continually measured using an oxygen sensor (WTW Measurement Systems Inc., Germany). The raw data was transferred to Origin (Ver. 6.1) to generate respirograms.

Allylthiourea (ATU) was used to inhibit endogenous nitrification. 10 mg/L ATU was added to the reactor to avoid nitrification according to Orhon and Nazik [12].

Calculation of kinetic and stoichiometric parameters by respirometric methods. Determination of certain kinetic parameters of a process is important in establishing the mathematical model of a system. Therefore, in this study, the kinetic and stoichiometric parameters of the process were determined respirometrically. For a biological removal process, significant parameters are maximum specific growth rate (μmax), yield ratio (Y), decay coefficient (kd), and half saturation rate constant (Ks). The general stoichiometry between the organic substrates consumed and produced by the microorganisms is given as follows:

The first term of the right-hand side of the equation gives the growth rate of bacterial culture and the second represents endogenous decay.

In the literature, several approaches have been described to determine the kinetic parameters of an aerobic system [4, 13]. One of these approaches is the use of respirometric activity in which oxygen consumption is used as a surrogate measure of biodegradation. Since homogeneity of the amount of dissolved oxygen in the jet loop reactor used in this study was higher than in conventional activated sludge systems, a respirometric approach was chosen to analyse the kinetic parameters. The respirometric experiments were conducted according to Rós [14]. In the endogenous phase, when a given amount of substrate is added to a system, a change can be seen in the oxygen consumption. A respirogram can be obtained by plotting this change against time [14].

The non-linear state equations given below are based on Monod’s growth model [15] and demonstrate the dynamic behaviour of the process. According to the Monod model, the specific growth rate is calculated as follows:

Based on this equation, the state equation of a batch can be given as

To calculate the respirometric kinetic parameters, it is crucial to know the value of KLa (oxygen transfer coefficient) [16]. Therefore, KLa was experimentally determined as 0.28 L/min following a non-steady-state aeration process at 45 ± 2°C. This was achieved using Sigma Plot 9, a curve-fitting program, based on the non-linear least squares.

Additionally, in this study, the bacteria were identified by the 16s rDNA sequencing method as described by Taheri et al. [17].

RESULTS AND DISCUSSION

Mathematical models are often utilised to provide a better understanding cell culture systems. The Monod equation (Eq. (2)) is the most common model used to describe the impact of growth rate under substrate conditions. In addition, a respirometer is a very useful tool for the determination of bio-kinetic growth constants. Therefore, in this study, the kinetic (Ks, kd and μmax) and stoichiometric parameters (Y) that are necessary for the achievement of effective biological processes were determined by undertaking in situ respirometric experiments.

Determination of μ, μmax and Ks. Once the substrate is added to the activated sludge, the substrate respiration rate (re) is calculated based on Eq. (4) [14].

where C and Ce are dissolved oxygen concentrations (mg/L) under operating conditions and at the endogenous phase, respectively.

The re values obtained are then divided by the mean biomass concentration, X, to calculate the Re values representing μ. Likewise, Remax refers to μmax.

Therefore, by adding different volumes of wastewater, the μ values can be changed until reaching μmax value. To achieve the μmax value, an adequate amount of the substrate should be added and several trials should be performed in the reactor [14].

Once the endogenous phase was reached, the amount of dissolved oxygen was kept constant through constant aeration. A known volume (0.1, 0.2, 0.3, 0.4 and 0.5 L) of the substrate taken from the same container maintained at 4°C was added to the reactor. Figures 2 and 3 present the resulting respirograms and re diagrams, respectively. The additions of 0.1, 0.2, and 0.3 L were found to be insufficient; therefore, the higher volumes of substrate (0.4 and 0.5 L) were added and very similar μmax values were obtained. The calculated μmax values were considered as the μmax value of the system, which was 0.2 L/h. In previous studies, the μmax values for the thermophilic treatment processes ranged from 0.1 to 0.25 L/h, indicating that the μmax value found in this study was consistent with those reported in the literature [18].

Ks, the half saturation constant, was calculated using Monod’s linearized model (Eq. (2)). As known, Ks, which indicated the affinity of microorganisms to substrate [19] and is easily obtained based on the slope of 1/S versus 1/μ plot. The Ks value was determined as 25.72 mg/L, which shows that the potato-processing wastewater was easily biodegraded by thermophilic microorganisms.

Determination of kd. During the experiments, the air supply to the activated sludge in the reactor was cut off to prevent air leakage to the reactor. As reported in a previous study [20], 4 h was found to be sufficient to achieve endogenous respiration. After the endogenous phase was attained, the air supply to the reactor was cut off again. It is important to note that longer aeration periods would result in a logarithmic curve, indicating that multiple endogenous respiration rates can be obtained for specific systems [20]. Over time, there would also be a decrease in the kd value. The endogenous oxygen uptake rate was calculated based on the linear section of the curve of time-dependent DO concentration as follows [21]:

The Rs value was calculated based on the slope of the linear graph corresponding to approximately 1 h immediately after cutting off the air supply (Fig. 4). Then, the specific endogenous oxygen uptake rate was determined by the following equation:

where Rs refers to the kd value.

The decay rate, kd, has been reported to vary between 0.01 and 0.03 L/h for the systems treating industrial wastewaters [18]. Therefore, it can be said that the kd value of 0.02 L/h found in this study was in agreement with the literature values. It has been suggested that microorganisms exposed to higher temperatures cannot maintain membrane integrity; therefore, decay rates may increase with the increasing temperature [21].

Determination of Y. To calculate Y (yield coefficient), the following equation was used as proposed by Rós [14]:

where A indicates the area of the respirogram belonging to μmax in Fig. 2.

The Y values differ based on the type of microorganism, the degree of oxidation of organic matter in the substrate and the decay rate. High Y value of 0.71 g/g obtained in this study, indicate that the conversion of substrate to biomass is favourable owing to the nature of thermophilic jet-loop reactors. Thermodynamically, the Y values are obtained as a result of the balance between the Gibbs free energy generated by organic matter oxidation using the oxygen present in the system and the formation of new biomass [22]. It has been reported that the Gibbs energy released is slightly affected by 15% with the increased temperature in the transition from mesophilic to thermophilic conditions [22].

In the literature, there is limited data regarding the demonstration of microbial diversity through thermophilic aerobic wastewater treatment [6]. Some studies have isolated cultures from thermophilic aerobic reactors but only found Bacillus [23] and Bacillus-like [23] organisms. Similar results were obtained in this study. Bacillus mojavensis, Gordonia paraffinivorans, Bacillus badius and Paenibacillus lactis strains were isolated from the jet loop bioreactor used.

CONCLUSIONS

In this study, alternative industrial wastewater treatment processes with a potential for enhanced removal of organic matter were investigated. The effectiveness of these processes can be further improved by combining the advantages of thermophilic conditions with a jet loop reactor. For this purpose, a jet loop reactor was used in this study under thermophilic conditions. The efficacy of bioreactors is known to be affected by changes in various parameters throughout the procedure. Therefore, to evaluate the performance of these reactors, it is important to determine the biodegradation kinetics. The kinetic parameters of the system used in this study were determined by in situ respirometric analysis due to the properties of the jet loop reactor. According to the results, the kinetic parameters μmax, kd, and Ks were 0.2, 0.02, and 25.72 mg/L, respectively and the stoichiometric parameter Y was 0.71 g/g.

REFERENCES

Guttormsen, K.G. and Carlson, D.A., Current Practice in Potato Processing Waste Treatment, Water Pollution Research Series, Report no. DAST-14, Washington DC, 1969.

Waste Treatment in Food Processing Industry, Wang, L.K., Hung, Y.T., Lo, H.H., and Yapijakis, C., Eds., London: CRC, 2006, pp. 193–254.

Farizoglu, B. and Keskinler, B., J. Membrane Sci., 2006, vol. 279, pp. 578–587.

Ince, M., Yildiz, F., Onkal Engin, G., Engin, S.N., and Keskinler, B., J. Hazard. Mater., 2008, vol. 153, pp. 991–998.

Surucu, G.A., Chian, E.S.K., and Engelbrecht, R.S., Biotech. Bioeng., 1975, vol. 11, pp. 1639–1662.

Lapara, T.M. and Alleman, J.E., Wat. Res., 1999, vol. 33, pp. 895–908.

Mahendraker, V. and Viraraghavan, T., J. Environ. Sci. Health, 1995, vol. A30, pp. 713–734.

APHA, Standard Methods for the Examination of Water and Wastewater, 21st ed., Washington, DC: American Public Health Association, 2005.

Dutta, N.N., and Raghavan, K.V., Chem. Eng. J., 1987, vol. 36, pp. 111–121.

Salehi, Z., Sohrabi, M., Kaghazchi, T., and Bonakdarpour, B., Proc. Biochem., 2005, vol. 40, pp. 2455–2460.

Farizoglu, B., Keskinler, B., Yildiz, E., and Nuhoglu, A., Proc. Biochem., 2004, vol. 39, pp. 2283–2291.

Orhon, D. and Nazik, A., Modelling of Activated Sludge Systems, Lancaster, USA: Technomic Publ. Co. Inc., 1994.

Spanjers, H., Olsson, G., and Klapwijk, A., Wat. Res., 1994, vol. 28, pp. 1571–1583.

Rós, M., Respirometry of Activated Sludge, Pennsylvania, USA: Technomic Publ. Co. Inc., 1993.

Kovarova-Kovar, K. and Egli, T., Microbiol. Mol. Biol. R., 1998, vol. 62, pp. 646–666.

Rós, M., and Dular, M., Wat. Sci. Technol., 1992, vol. 26, pp. 2535–2538.

Taheri, E., Khiadani, M.H., Amin, M.M., Nikaeen, A.H., and Hassanzadeh, A., Biores. Technol., 2012, vol. 111, pp. 21–26.

Couillard, D., Gariepy, S., and Tran, F.T., Wat. Res., 1989, vol. 79, pp. 573–579.

Setiadi, T. and Fairus, S., Wat. Sci. Technol., 2003, vol. 48, pp. 111–117.

Suschka, J. and Ferreira, E., Wat. Res., 1986, vol. 20, pp. 137–144.

Konopka, A., Zakharova, T., and La Para, T.M., J. Ind. Microbiol. Biotech., 1999, vol. 23, pp. 127–132.

Vogelaar, J.C.T., Van Lier, J.B., Klapwijk, B., De Vries, M.C., and Lettinga, G., App. Microbiol. Biotech., 2002, vol. 59, pp. 105–111.

Surucu, G.A., Chian, E.S.K., and Engelbrecht, R.S., J. Wat. Poll. Cont. Fed., 1976, vol. 48, pp. 669–679.

Funding

This study was financially supported by The Scientific and Technological Research Council of Turkey (TUBITAK, grant number 110Y134).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest. This article does not contain any studies involving animals or human participants performed by any of the authors.

Rights and permissions

About this article

Cite this article

İnce, M., İnce, E. & Topaloğlu, A. In Situ Respirometric Kinetic Analysis of a Thermophilic Jet Loop Bioreactor. Appl Biochem Microbiol 56, 743–747 (2020). https://doi.org/10.1134/S000368382006006X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S000368382006006X