Abstract

Owing to a rapid growth in world trade and a large increase in the flow of containerized goods, sea container terminals play a vital role in globe-spanning supply chains. Container terminals should be able to handle large ships, with large call sizes within the shortest time possible, and at competitive rates. In response, terminal operators, shipping lines and port authorities are investing in new technologies to improve container handling and operational efficiency. Container terminals face challenging research problems that have received much attention from the academic community. The focus of this article is on highlighting recent developments in container terminals, which can be categorized into two areas: (i) innovative container terminal technologies and (ii) new OR directions and models for existing research areas. By choosing this focus, we complement existing reviews on container terminal operations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since the introduction of the container in April 1956, when Malcolm McLean moved fifty-eight 35-foot containers from Newark to Houston by a refitted oil tanker, container flows have increased continuously. According to the US Customs and Border Protection (2011) report, in 2011, about 108 million cargo containers were transported annually through seaports around the world, constituting the most critical component of global trade. Between 1990 and 2015, the total number of full containers shipped internationally is expected to grow from 28.7 million to 177.6 million (United Nations: ESCAP, 2007). A simple calculation shows that there are enough containers on the planet to build more than two 8-foot-high walls around the equator (Taggart, 1999).

Containerization has become the main driver for intermodal freight transport, which involves the transportation of freight in containers of standard dimensions (20 ft equivalent unit (1 TEU), 40 ft (2 TEU), 45 ft (high-cube)), using multiple modes of transportation such as ships, trucks, trains, or barges without any handling of the freight itself when changing modes (Crainic and Kim, 2007). Stuffing freight in containers reduces cargo handling, and thereby improves security, reduces damages and losses, and allows freight to be transported faster (Agerschou et al, 1983). In the chain of intercontinental transport, container terminals are of special importance since all containers pass through at least one of them during their drayage. Container terminals are the nodes where different modalities meet to transport containers.

Container terminals have received increasing attention from the academic community due to the opportunities and challenges they offer in research. A number of reviews have been published in the last decade, focusing on the use of operations research models for handling containers (Vis and De Koster, 2003; Steenken et al, 2004; Günther and Kim, 2005; Murty et al, 2005; Stahlbock and Voß, 2008a; Gorman et al, 2014). Parallel to this article, three focused reviews, focusing on seaside, transport and stackside storage operations have appeared (Carlo et al, 2013, 2014a, 2014b). However, this article provides an integrated view of container terminal operations, including gate operations and connections with the hinterland, based on recent literature published since 2008. We specifically focus on new technological developments and OR models. The scope of this study is limited to internal operations at a container terminal, as well as hinterland operations.

Container Terminal Operations

Container handling equipment includes quay cranes (QCs), yard cranes (YCs), automated guided vehicles (AGVs) and straddle carriers (SCs). These systems are shown in Figure 1(a)–(d), and are used to transship containers from ships to barges, trucks and trains, and vice versa. Other, newer, equipment is introduced in the next sections. Containers can be transshipped directly from one mode of transportation to another. Alternatively, containers can be stored for a certain period in a stack, before they are transferred to another mode. Material handling equipment used at a terminal is very expensive, regardless of whether it is automated or manned. The investment in a single modern container terminal can be as high as €1 billion or more and the payback period ranges between 15 and 30 years (Wiegmans et al, 2002; De Koster et al, 2009).

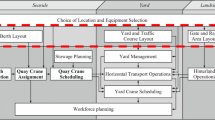

Sea container terminals are divided into several areas such as seaside, landside, stacking and internal transport areas that cater to seaside and landside operations (see Figure 2). At an automated container terminal, QCs load and unload containers from ships berthed along the quay at the seaside. QCs pick up or drop off containers on AGVs that transport containers from the seaside to the stacking area where YCs take over. Finally, SCs transport containers either between the YCs and trucks or between the YCs and trains at the landside. In more traditional container terminals, SCs are also used to stack containers.

Loading and unloading processes of containers at a typical container terminal (adapted from Meisel, 2009 and Brinkmann, 2010).

Containers are stacked in container stacks. Each stack consists of multiple rows, tiers and bays. Containers arrive or leave the terminal at the seaside or landside and spend a period of time in these stacks. Input/output (I/O) points are located at each stack end and a single YC is used to stack and retrieve containers in that stack. A container’s storage position within the container stack is mainly determined by the loading sequence onto the ships. This sequence depends on the container’s ship departure time, its port of destination and weight.

Obviously, containers have to be retrieved from the stack in the sequence of the departure of their corresponding ships. Furthermore, containers have to be loaded onto the ship in a reverse order of the sequence of destination. Containers with a later destination have to be loaded first. Finally, containers have to be loaded according to their weight. In order to ensure ship stability, heavier containers should be loaded before lighter ones. Many other practical constraints need to be considered while loading a ship (that is, dynamic stability, container sizes, containers with hazardous materials, reefer containers, and so on). However, some flexibility may be permitted in the yard while retrieving containers from the stack to load a ship, because multiple QCs load a ship in parallel, and vehicles can be rescheduled while bringing the containers. In addition, stacks constantly change due to pre-marshalling.

Latest Trends in Container Terminals

A large terminal handles millions of containers annually (Drewry, 2011). Container terminals in the Port of Rotterdam handled more than 11.6 million TEU in 2013 while those in Shanghai handled more than 33.8 million TEU in the same year (Port of Rotterdam Authority, 2014; Shanghai International Port Group, 2014). Because many containers have to be stacked temporarily, more land is needed for the related supply chain activities. Lack of space has driven container terminal operators to build higher container stacks. In addition, ships have grown larger over the past decades with larger call sizes at ports. The largest Post-Panamax ships can carry about 18 000 TEU, compared with the first-generation ships, which had a capacity of about 400 TEU. Shipyards are planning new ships of even larger sizes. Large ships can only berth in ports with adequate draft, at terminals with sufficiently wide gantry cranes, with adequate terminal material handling systems, and with adequate hinterland connections. This limits the number of ports of call and increases the drop size per terminal visited. Thus, larger ships spend more time in port than smaller ships. For instance, an 8000 TEU ship spends 24 per cent of its roundtrip time in port compared with 17 per cent for a 4000 TEU Panamax ship (Midoro et al, 2005). An idle 2000 TEU ship costs $20 000–$25 000 per day (Agarwal and Ergun, 2008). Container terminal managers are constantly looking for new technologies and methodologies to efficiently handle all the containers arriving and leaving their terminals.

In recent years, port authorities and companies in several countries have started to integrate supply chain and transportation activities in particular by extending the sea terminal gate into the hinterland (Iannone, 2012; Veenstra et al, 2012). Previously, integrated hinterland terminals were introduced as dry ports. Different firms in multimodal hinterland networks, such as terminal operators, freight forwarders, information service providers, infrastructure managers, shippers, and consignees, play a role. All these firms aim to contribute to a better performance of the overall supply chain. Terminal operators, for instance, are more and more involved in linking sea terminals with inland terminals. This enables them to better connect with shippers and receivers in the network. This change comes with serious and yet unexplored challenges, but it also provides one with opportunities to develop a sustainable and competitive advantage. The seamless flow of goods from seaports to locations far into the hinterland can prevent negative external effects from transport, such as congestion in seaports, or on motorways due to too much trucking.

In the subsequent sections of this article, we discuss recent papers studying these topics using operations research tools. In addition, we try to identify new and important topics which are still pristine and offer opportunities to operations researchers. We start with seaside operations in the next section, and then discuss internal transport and stack operations in two subsequent sections, respectively. Previous studies generally categorize papers related to container terminal operations into three groups: seaside, stacking area and landside (initially suggested by Steenken et al (2004) and Stahlbock and Voß (2008a)). We expand this framework to a seaside–stacking area–landside–hinterland framework. Owing to lack of space, pollution and long waiting times, integrated hinterland terminals have become an essential part of sea container terminals. Therefore, a survey on container terminal operations should include the recent developments and literature on hinterland operations. We do this in a Hinterland operations section. Each section, devoted to a specific container terminal process (seaside, transport, stacking area and hinterland), is composed of two subsections. We first discuss the new technologies and then we describe the new developments in OR models. Finally we draw conclusions.

Seaside Operations

Seaside operations planning consists of ship berthing operations (berth planning and quay crane scheduling), and loading and unloading of containers onto ships. Further, the stowage planning, where the sequence of loading and unloading containers in a ship is optimized, plays a critical role in seaside operations planning. In this section, we discuss technological advancements in QCs and also review some of the recent work on sea operations.

New Technologies

Recently, a new generation of fully automated (remote controlled) QCs has been developed. As shown in Figure 3(a)–(c), these QCs are equipped with two trolleys, each capable of handling two or even three TEUs at the same time. In some designs, QCs are equipped with shuttles on the boom to reduce the horizontal handling time, or with trolleys that can rotate 90 degrees, as respectively shown in Figure 3(d)–(e). In the section on stacking area operations, we discuss other designs in which QCs spread over an indented berth, or in which the QCs float on the water to build artificial temporary space.

New generation of QCs: (a) Double trolley QC (Source: Jordan, 1997); (b) QC with a double lifting trolley (Source: Jordan, 2002); (c) QC with a triple lifting trolley (Source: China Communications construction company, 2010); (d) QC with shuttles performing horizontal transport on the boom (Source: Giebel, 2003); (e) QC with 90 degrees rotating trolleys (Source: Jordan, 2002).

Since the new designs can be used more flexibly with higher capacity compared with traditional QCs, the existing models may have to be adapted to these new developments. For example, Xing et al (2012) analyse the problem of dispatching AGVs in container terminals equipped with tandem lift QCs, requiring two AGVs to be ready simultaneously to unload containers. The problem is formulated by a mixed-integer linear programming model and a decomposition method is used to solve the problem.

New terminal emulation systems that use terminal operating systems for input control allow dry testing of equipment control rules, remote quay crane control, as well as stack storage methods. For instance, Boer and Saanen (2012) developed an emulation tool – called CONTROLS (which stands for CONtainer TeRminal Optimised Logistics Simulation). All core processes in a terminal are supported by a TOS (Terminal Operations System), including quay side planning, vessel planning, yard planning, equipment control and gate management. Emulation allows the user to experiment with the real TOS without the risk of negatively affecting real operations.

OR Models

Quay crane and berth operations planning

When a ship arrives, several tactical and operational decisions are made such as allocating berthing space, berthing time, and assigning QCs to load and unload containers at minimum terminal cost and delay. The first problem is commonly known as the berth allocation problem (BAP). The optimal allocation of berths to incoming ships is very complex because of spatial constraints such as the draft requirement for ship berthing, ship size, space availability, and the distance between the berthing location to the stacks where the ship’s containers are stacked. The complexity of the problem is further increased due to temporal constraints (static versus dynamic arrival of ships). The second problem is related to assigning QCs to the ship. Modelling challenges, such as addressing the interference between QCs (which all move on a common rail) and improving crane productivity, make this problem interesting from both a research and a practical viewpoint. The third problem is scheduling QCs to unload or load containers from/to the ship by adhering to task precedence constraints. Until recently, the research community has mostly addressed these problems in isolation. However, due to interactions among the decisions, new algorithms and heuristic approaches have been developed to solve these problems within an integrated framework.

Figure 4 illustrates a berth plan with four ships. In this figure, the x and y axes denote the ship berthing time and the ship berthing space respectively. In Figure 4(b), the QCs are assigned to each ship. Note that QC 2 is reassigned from ship 1 to ship 2, after its process is complete.

Illustration of (a) the berth allocation problem and (b) the QC assignment problem (adapted from Bierwirth and Meisel, 2010).

We now discuss these problems in more detail and review the recent OR modelling contributions. For a comprehensive survey on berth allocation and QC scheduling problems including papers prior to 2010, see Bierwirth and Meisel (2010).

Berth allocation problem (BAP)

To minimize the sum of ship waiting and handling times (port stay times), optimization models have been developed by fixing the choice of spatial, temporal and handling time attributes. The spatial attribute denotes whether the quay area is partitioned into discrete or continuous berths (Buhrkal et al, 2011). The temporal attribute indicates the restriction imposed on the ship berthing time or departure time. Similarly, the handling time attribute indicates if this time is fixed or dependent on berthing position, QC assignment or QC schedules. Hansen et al (2008) solve the dynamic BAP problem by taking into account the service costs of ships depending on the berth they are assigned to, in addition to the handling times. The continuous dynamic BAP with both fixed and berth-position-dependent handling times has received considerable attention from researchers (Wang and Lim, 2007). Many other versions of the BAP have also been considered. Hendriks et al (2010) study a robust BAP in which cyclically calling ships have arrival time windows, instead of specific arrival times. They minimize the maximum amount of QC capacity required in different scenarios. In a later study, Hendriks et al (2012) work on a similar problem in which cyclically calling ships have to be processed in different terminals of the same port. They minimize the amount of inter-terminal movement, and balance the QC workload at different terminals and time periods. Xu et al (2012) study the BAP considering the water depth and tidal constraints. They model the problem in a static mode (all ships are available) and a dynamic one (ships arrive over time). They develop efficient heuristics to solve the problems. Nowadays, environmental issues are also considered in BAP models. Du et al (2011) develop an elaborate berth allocation strategy that also minimizes the fuel consumption by the vessel. The nonlinear intractability introduced by the consideration of fuel consumption is overcome by reformulating the original MINLP model as a mixed integer second-order cone programming (MISOCP) model.

QC assignment problem (QCAP)

After allocating a berth space to a ship, QCs are assigned to the ship such that crane productivity is maximized by reducing the number of QC setups and QC travel times. The two problems, QCAP and BAP, are closely interrelated, since once the QCs are allocated, the ship handling times are affected. In practice, the QCAP is solved using rules of thumb and has received little attention from researchers (Bierwirth and Meisel, 2010).

Giallombardo et al (2010) propose two formulations for combining the BAP and QCAP: a mixed-integer quadratic program and a linearization that reduces to a mixed-integer linear program. To solve the problem, they develop a heuristic that combines tabu search methods and mathematical programming techniques. Han et al (2010) consider a similar problem, but with stochastic ship arrival time and handling time. They formulate the problem as a mixed-integer programming model and solve it by a simulation-based Genetic Algorithm. Chang et al (2010) study the problem in a rolling horizon fashion. They solve the problem by a parallel genetic algorithm in combination with a heuristic algorithm.

QC scheduling problem (QCSP)

In terminal operations, QCs are typically the most constrained resources. Hence, optimal schedules can maximize throughput, and minimize ship handling time (ship makespan). Several constraints need to be satisfied during the schedule generation process, such as preventing crane crossovers (by structural constraints imposed on cranes and the crane trajectory), maintaining a minimum distance between cranes (neighbourhood constraint), time separation of containers that need to be stacked in the same location (job separation constraint), and ensuring that unloading transactions within a ship bay precede loading transactions (precedence constraint defined by the stowage plan). Multiple optimization formulations have been developed with variations in task attributes (single or multiple bays), crane attributes (initial and final positions of the cranes, operational time windows) and interference attributes. Recently, container reshuffling and stacking area attributes (congestion constraints) have also been included in the models (Choo et al, 2010; Meisel and Wichmann, 2010). Legato et al (2012) consider most of these constraints in a rich mixed-integer programming model. They solve the problem by a modified branch-and-bound algorithm which is based on the one developed by Bierwirth and Meisel (2009). Initial studies in this area generate QC schedules (unidirectional schedules) that consider non-crossing of cranes; that is, all QCs move in the same direction throughout the service. For instance, Lim et al (2007) generate unidirectional SC schedules for complete bays. They model the QCSP using constructs from an m-parallel crane scheduling problem and develop a backtracking algorithm based on dynamic programming that generates optimal QC schedules for average-size problems. Another stream of research allows the cranes to share the workload of bays, and develops optimal QC schedules for container groups. Lu et al (2012) consider such a problem and solve it by developing an efficient heuristic which has a polynomial computational complexity. Queuing network models are also used to study the QCSP (Canonaco et al, 2008). The solutions of such models are usually evaluated based on simulation. Meisel and Bierwirth (2011) develop a unified approach for evaluating the performance of different model classes and solution procedures.

Stowage planning

To achieve economies of scale and better ship utilization, ships sail from one port to another (up to 20 ports) through a fixed route. At each port, thousands of containers may be loaded, unloaded or repositioned. Although such container movement plans reduce the transportation cost per container, it poses a difficult operational problem known as the container stowage problem (CSP). A stowage plan includes the placement of a container at a ship slot described by a combination of the row number, bay number and tier number. The objectives of a good stowage plan are to minimize handling time, ensure stability, obey ship stress limits and maximize QC utilization. Several constraints have to be taken into account, such as container size, weight, height, port of unloading and container type (reefer, danger class). The complexity of developing high-quality stowage plans has further increased with the launching of mega-ships with a carrying capacity of 18 000 TEU or more (for instance, see Maersk’s Triple E series plan, Maersk Line, 2011).

Wilson and Roach (2000) classify the methodologies developed for addressing the CSP into five categories: (1) simulation based upon probability, (2) heuristic driven, (3) mathematical modelling, (4) rule-based expert systems and (5) decision support systems. They also indicate that the existing solution methods either relax some of the important constraints or do not generate high-quality solutions in a short time (see also Avriel et al, 2000). Further, existing exact models do not scale beyond very small feeder ships.

To deal with the complexity of the CSP, successful studies decompose the problem hierarchically into a multi-port master planning phase and a slot planning phase (Delgado et al, 2012). In the first phase (Master planning), the hatch-overstowage and crane utilization measures are optimized by determining the number of 20 ft and 40 ft containers that need to be stowed in a location. The integer programming model, which is shown to be NP-hard, is solved using a relaxed MIP formulation. The second phase (slot planning) refines the master plan by assigning the containers associated with each location to a specific slot in that location. A constraint-based local search (CBLS) approach is used to solve the optimization problem.

Other potential research topics for quay and berth planning include: (1) joint continuous/discrete quay berthing and QC planning with uncertainties in arrival and inhomogeneous QCs (think of cranes of different sizes or specializations, for example, barges); (2) different objective functions, not just minimization of total berthing time, but also minimization of violation of agreed (contracted) time windows; (3) berth planning with cooperating QCs; and (4) berth planning and QC scheduling with mixed vessel types of different priorities, including barges. All these topics have until now hardly been studied.

Internal Transport Operations

The internal seaside transport process connects the seaside and the stacking. Vehicles are used both in the unloading process by transporting containers from seaside to the stacking areas and in the loading process by transporting containers from the stacking area to the seaside area.

Internal transport vehicles have varying degrees of automation and functionalities. We first review different types of vehicles. We then examine vehicle guide path types. The guide path has a significant impact on vehicle travel times and overall throughput performance. Further, we present innovations in information and communication technologies, such as vehicle tracking and tracing, that can help to improve coordination among vehicles. We then classify the different design decisions that affect vehicle transport performance, and discuss how OR tools can be deployed to analyse and to improve internal transport performance.

New Technologies

Types of vehicles

Internal transport vehicles can be broadly classified into two categories: human-controlled and automated systems. Further, depending on the vehicle and crane transfer interface, the vehicles are classified as coupled (C) or decoupled (DC). Trailer-trucks and SCs are manual transport vehicles used in several container terminals in Asia (such as JNPT, India, and Northport, Malaysia). Automated lifting vehicles (ALVs) and AGVs are used in automated container terminals such as the Patrick container terminal in Australia, the ECT container terminal in Rotterdam and the container terminal in Nagoya. Lift AGVs (L-AGVs) are a recent innovation in the AGV family, which will be deployed at the new APM terminal at Maasvlakte II, Rotterdam (Gottwald Port Technology GmbH, 2012). We briefly describe these internal transport vehicles below.

Automated lifting vehicles (DC)

These automated SCs, also known as ALVs, decouple the container handling process between the seaside and the stacking area (Figure 5(a)). Owing to their self-lifting capability, they are used in the unloading process, and pick up the containers from one of the several buffer lanes located beneath the QCs and transport them to the YC buffer locations. The new ALVs can lift up to two containers at a time.

New internal transport vehicles: (a) Automated lifting vehicle; (b) L-AGV (Source: Gottwald port technology GmbH, 2012).

Lift-automated guided vehicles (C/DC)

Lift-automated guided vehicles (L-AGVs) decouple the transport of containers to the stacking area processes (Figure 5(b)). The L-AGV is an AGV with electrically operated lifting platforms. These enable the vehicle to raise its load and deposit it independently and automatically on handover racks in the stacking crane interface zone and to pick up containers from those racks. Gottwald Port Technology GmbH (2012) claims that fleet size can be considerably reduced as a result of the increased working frequency; the overall number of vehicles required to service each QC can be reduced by up to 50 per cent compared with conventional AGVs.

L-AGVs and ALVs operate in a very similar way; they both transport containers and use decoupled interfaces at the stack and quay side. However, ALVs can also stack containers, while L-AGVs cannot.

Vehicle guide-path types

Automated vehicles travel along guide-paths in the yard area. Two types of guide-path networks are typically found: closed-loop and cross-lane. The closed-loop guide-path is composed of several large circular guide-paths for vehicles to follow (see Figure 6(a)–(b)). While a uni-directional closed loop travel path allows a simplified control of vehicles, it may increase vehicle travel time due to long travel distances. To reduce vehicle travel time, most automated terminals now use guide-path networks with multiple cross-lanes (see Figure 6(c)–(d)). A cross-lane path is composed of parallel travel paths with several big, small or mixed (both big and small) crossings. In cross-lane guide-paths, a vehicle adopts the shortest travel path (using shortcut paths) from the quay buffer lane to the stack buffer lane and vice versa. Hence, cross-lane guide-path networks can significantly reduce AGV travel distances, but the complexity of controlling traffic (and hence, chance of blocking) at the intersections of paths increases.

Vehicle coordination and tracking

Better coordination and real-time control of AGVs has multiple benefits for internal transport operations. A smaller fleet size can be used, and (empty) travel times can be reduced. Further, it allows one to deal with inherent operational variability in the system. Real-time resource status information obtained by automatic context capturing devices such as sensor networks may be used by the terminal operators to re-plan the schedule. Today, several techniques exist for vehicle tracking and tracing, including the use of transponders, laser scanners, or GPS in combination with RFID. Ngai et al (2011) develop an intelligent context-aware prototype for resource tracking at container terminals. Ting et al (2012) discuss the feasibility of applying RFID for vehicle tracking purposes. Hu et al (2011) discuss RFID-related tracking solutions for orderly balancing and seamlessly connecting different operational processes at the terminal gate.

OR Models

Internal transport management

Optimization formulations have been developed to determine optimal fleet size and to decide on vehicle routing and operation schedules. Jeon et al (2011) adopt a Q-learning technique to determine the shortest-time routes for internal transport using AGVs. Note that their approach also considers the expected waiting times that result from vehicle interference and the shortest-path travel times, to determine the optimal routes. Vis and Roodbergen (2009) consider the problem of scheduling SCs to process container storage and retrieval requests in the yard area. The two components of the problem are assigning transport requests to the vehicles and scheduling these requests for each vehicle. By using a combination of a graph-theoretic and dynamic programming approach, they solve the problem to optimality. Nguyen and Kim (2009) develop a mixed integer model for a terminal which uses ALVs to handle containers at the seaside. The objective is to minimize the total travel time of the ALVs and the total delays of QCs. They transform constraints regarding the buffer space under the QCs to time window constraints and propose a heuristic algorithm to solve the model.

Analytical models based on queuing theory have been also put to practice to study internal transport management. Kang et al (2008) develop a cyclic queue model of container unloading operations that provides a steady-state throughput measure and can estimate the optimal fleet (cranes and trucks) size. The model assumes exponentially distributed service times in order to obtain closed-form analytical results. They also develop a Markovian decision problem (MDP) model that can dynamically allocate a transport fleet based on general service time distributions. Finally, through simulations, researchers have evaluated design choices and operational policies. Petering (2010) develops a simulation model to study the real-time dual-load yard truck control in a transshipment terminal.

Gate operations planning

Terminal gates are the decoupling points of internal and external transport. Gate management is important, since the massive number of containers arriving and leaving terminals at the landside creates congestion. Many trucks and trains show up at the terminal gates for inland container transport. Trains have fixed schedules which are set externally. Violating these time windows is costly and container terminal operators prioritize trains so they can be easily loaded and unloaded to leave the yard. On the other hand, trucks are a more flexible, more efficient mode in door-to-door service for containers, but they bring higher cost (Wang and Yun, 2013). Modelling truck scheduling problems and their interaction with container terminal operations offers interesting challenges for researchers.

Long queues of trucks at terminals lead to delays and cause emissions, congestion and high costs. In the past several years, a growing number of studies have addressed truck congestion. One of the solutions is to carefully manage truck arrival times, using an appointment system in which a terminal operator announces the time periods that trucks can enter the terminal. Huynh and Walton (2008) develop a model to determine the maximum number of trucks a terminal can accept per time window. Huynh and Walton (2011) extend this model by additionally scheduling the trucks. Namboothiri and Erera (2008) study how a terminal appointment system affects the management of a fleet of trucks providing container pickup and delivery services to a terminal. The objective is to minimize transportation costs. Chen and Yang (2010) propose a ship-dependent time window optimization method, which involves partitioning truck entries into groups serving a specific ship and assigning different time windows to the groups. They use an integer programming model to optimize the position and the length of each time window and develop a genetic algorithm heuristic to solve the problem. Chen et al (2013) use several metaheuristic methods to solve the problem. Unlike the other studies, Lang and Veenstra (2010) consider congestion at the seaside. They develop a quantitative arrival scheduling simulation (centrally controlled by the terminal) to determine the optimal approach speed for the arriving vessels. Their cost function includes both fuel and delay costs.

Besides mixed-integer programming models, some studies use conventional stationary queuing models to analyse the gate system at container terminals (Guan and Liu, 2009; Kim, 2009). However, stationary queuing models should not be used to analyse a queuing system that is non-stationary in nature. The gate system at a container terminal is typically non-stationary, because the truck arrival rate varies from hour to hour and the gate service rate may change over time (Guan and Liu, 2009). Therefore, Chen et al (2011b) propose a two-phase approach to find a desirable pattern of time varying tolls that leads to an optimal truck arrival pattern, by combining a fluid-based queuing and a toll pricing model.

In general, terminal appointment systems have mixed performance. For example, Giuliano and O’Brien (2007) report on unsuccessful application of a terminal appointment system at the Ports of Los Angeles and Long Beach. As a result, in addition to a gate appointment system, the OR community should find new solutions to the gate congestion problem at terminals. Over the past decades, truck scheduling and storage allocation in port operations have been studied extensively as two separate sub-problems. However, from the operational point of view, they are highly interdependent. Researchers might find better solutions when studying the two problems together. Van Asperen et al (2011) have conducted a simulation experiment to evaluate the impact of truck announcement time on online stacking rules. The longer the announcement period, the better the performance of the stacking rules is. Similarly, Borgman et al (2010) use simulation to compare the effect of different stacking rules on the number of reshuffles. They use given container departure times to minimize the number of reshuffles. Zhao and Goodchild (2010) assess how truck arrival information can be used to reduce the number of reshuffles when containers are retrieved to be loaded on the truck. The results demonstrate that significant container re-handle reductions can be achieved by using the truck arrival sequence obtained from the terminal appointment system, even if the sequence information does not cover all the trucks.

In addition to trucks, trains are also handled at terminals. However, the literature on train transportation focuses mainly on scheduling and routing trains outside the terminal, which is outside the scope of this review (see, for example, Cordeau et al, 1998; Newman and Yano, 2000; Yano and Newman, 2001; Almotairi et al, 2011; Wang and Yun, 2011; Woxenius and Bergqvist, 2011; Leachman and Jula, 2012). On the other hand, a handful of papers discuss train loading and unloading operational problems. Most of these papers focus on handling trains at transshipment yards which are designed to move containers from trains to trucks and vice versa, which is again outside the scope of this review (see, for example, Jaehn, 2013).

Potential research topics for internal transport operations include: (1) studying the impact of new vehicle types such as Lift-AGVs on the terminal throughput capacity for loading and unloading operations; and (2) studying the effect of the number of buffer positions at the quay side on the vehicle throughput capacity.

Stacking Area Operations

The stacking area is one of the most important areas at a container terminal, since almost every container spends a period of time there. In the past, container terminals used traditional container handling equipment such as SCs and reach stackers to stack and retrieve containers in the stacking area. However, these types of equipment cannot serve the huge number of containers that nowadays arrive and leave terminals. Today, most large new sea terminals use YCs to handle containers in the stacking area. Therefore, we focus on YC operations in the following sections.

New Technologies

Yard cranes

New container terminals use two or three YCs per stack lane to retrieve and stack containers, as shown in Figure 7(a)–(c) (Li et al, 2009; Vis and Carlo, 2010; Li et al, 2012). Depending on the design of the stacks and YCs, the YCs can or cannot pass each other. There is a fixed safety distance between YCs during stacking operations. Twin lifting QCs have been used in automated container terminals for several years. However, YCs with twin lifting capabilities have only been introduced recently. Zhu et al (2010) study a new type of YC designed by Shanghai Zhenhua Heavy Industries that can lift two 40 ft containers at a time (see Figure 7(d)).

Twin, double, triple and twin lifting YCs on a container stack: (a) Passing double YCs (Source: Vis and Carlo, 2010); (b) Non-passing double YCs also known as twin YCs (Source: NauticExpo, 2012); (c) Triple YCs (Source: Dorndorf and Schneider, 2010); (d) Twin lifting YC (Source: Zhu et al, 2010).

New container terminal layouts and stacking systems

In new automated container terminals, containers are generally stacked in container stacks which can be perpendicular or parallel to the quay. Obviously, the size of the stacks, their number and the type of container handling equipment can be different. Many papers have recently studied the effect of these layout variables on the performance of the terminal. Kim et al (2008) develop an integer programming model to determine the layout type, the outline of the yard, and the numbers of vertical and horizontal aisles. Wiese et al (2011) develop a decision support model for the design of yard layouts of SC-based terminals. However, the dominant methodology in such papers is discrete event simulation because it is difficult to capture all elements and find an optimal solution. Petering and Murty (2009) develop a simulation model for a transshipment yard. They find out that in order to keep QCs busy and minimize the makespan of ships, the block length should be limited between 56 and 72 TEU. Furthermore, the movements of the YC should be restricted to one block. Petering (2011) extended the simulation study to include decision support for yard capacity, fleet composition, truck substitutability and scalability issues. Kemme (2012) develops a simulation study to evaluate the effects of four Rail-mounted gantry (RMG) crane systems and 385 yard block layouts, differing in block length, width and height, on the yard and terminal performance. Lee and Kim (2013) compare two terminal layouts that differ in the orientation of the stack blocks with respect to the quay: a perpendicular layout and a parallel layout. They consider different cost factors including the construction cost of the ground space, the fixed overhead cost of YCs, and the operating costs of YCs and transporters. The effect of various design parameters on the throughput capacity and storage space capacity of the designs is evaluated. Both optimization and analytical models are proposed to analyse optimal parallel stack layouts. For example, Lee and Kim (2010) propose optimization models to determine the stack block size at a container terminal based on different objective function such as minimizing the weighted expected YC cycle time for various operations subject to the minimum block storage capacity provided, and minimizing the weighted expected truck waiting time for various operations subject to the minimum block storage capacity provided. On the other hand, Roy et al (2014) use an integrated analytical model for the seaside operations to obtain the optimal parallel stack layout.

In all the papers discussed so far, containers are loaded and unloaded by QCs from only one side of the ship. At a terminal with an indented berth, containers can be loaded and unloaded from the ship at both sides (see Figure 8(a)). Some of these terminals have special QCs spreading over the indented berth (see Figure 8(b)). Furthermore, terminal operators can use floating QCs to load or unload containers from both sides of the ship (see Figure 8(c)). Chen et al (2011a) develop an integer programming model to schedule QCs loading and unloading containers at such an indented berth. They propose a Tabu search to solve the problem. Vis and Van Anholt (2010) develop a simulation model for a similar setting. They argue that an indented berth results in more flexibility. If all equipment is scheduled properly, an indented berth can lead to shorter makespan of the ship. However, the QCs can be used less flexibly compared with conventional quays, as they cannot easily move to other quay positions. In addition, using many cranes per ship may lead to a low productivity per crane, due to blocking from two sides of the ship, as well as by losing the advantages offered these days by the larger hold hatches. It may therefore be difficult to financially justify such operations. Recently, Imai et al (2013) studied terminals with different indented berth designs servicing both feeders and mega-ships where mega-ships have priority to feeders. They conclude that a linear berth performs better in terms of reducing the handling time of feeders. On the other hand, an indented berth design, where ships can enter from one side and exit from the other, performs better in terms of reducing the handling time of mega-ships.

Different indented berth designs: (a) Indented berth with QCs at both sides (Source: Young, 2012); (b) QC spreading over an indented berth (Source: Jordan, 1997); (c) Floating QCs (Source: Jordan, 2002).

Another layout suggested to increase performance is to add a chassis exchange terminal to a terminal or a group of terminals (Dekker et al, 2012b). In such a terminal, containers are stored on a chassis and can rapidly be moved by terminal trucks. This reduces congestion at the main terminals, as external trucks are handled elsewhere. During the night, import containers are collected from the terminal and loaded on chassis. During the day, these chassis are exchanged with chassis loaded with export containers. Since trucks can quickly charge or discharge chassis, the capacity of the terminal increases substantially. However, Guan and Liu (2009) argue that due to land requirements, more feasibility studies are necessary to justify its application.

Reviewing the literature on warehouse layout design reveals that in order to obtain more flexibility and a higher performance, designs in which stacks and transfer lines are diagonal to the quay, or in which stacks are divided into smaller stacks with different sizes and I/O points in the middle should be studied (Gue and Meller, 2009; Gue et al, 2012; Öztürkoģlu et al, 2012). In warehouses, such new layouts have achieved a reduction in vehicle travel time of up to 20 per cent (Öztürkoģlu et al, 2012). Recently, container terminal managers have started to adopt new stacking systems stemming from warehouse literature, such as rack-based compact storage, or overhead grid rail systems. Ez-Indus of South Korea has built a prototype of an ultra-high container warehouse (UCW) system (see Figure 9(a)). The UCW is a high-rise rack-based automatic system that can theoretically save 90 per cent of the space by stacking containers up to 50 tiers high. Containers are delivered to the UCW where they are placed on shuttles. These take containers into the UCW elevator which takes them to a slot in the rack. Shuttles can also be used to transfer containers between the seaside and land side, as shown in Figure 9(b). These shuttles can move containers to the UCW or to the traditional container stacks. In the overhead grid system shown in Figure 9(c), containers can be handled using the cranes hanging from the overhead grid. The new systems impact the entire terminal operations and may result in a higher terminal efficiency. However, the cost of implementing such systems is very high, as terminals deal with large and heavy containers compared with small and light totes in a warehouse. The question is therefore whether such systems can become profitable in the long term.

New stacking systems: (a) Ultra-high container ware house system (Source: Ez-lndus, 2012); (b) Shuttle system (Source: Zhu et al, 2010); (c) Overhead grid rail system (Source: Kosmatopoulos et al, 2002).

OR Models

Yard crane operations planning

At a container terminal, YCs move retrieval containers from the block to the input and output (I/O) points, and move storage containers from the I/O points to the block. Owing to the huge number of containers handled at terminals, YCs often deal with a queue of containers waiting to be stacked or retrieved. It is therefore important to minimize the makespan and total delay time of all requests to be carried out by a YC, by optimally sequencing them. In the following, we review some of the recent OR models developed for scheduling YCs.

Yard crane scheduling

In general, YCs can be classified into two types: RMG cranes and rubber-tired gantry (RTG) cranes. RTG cranes are manned and can move freely from one stack to another. RMG cranes can be automated or manned, and their movements are limited to one or a few adjacent stacks in a row. Automated RMG cranes are sometimes called automated stacking cranes (ASCs), according to Stahlbock and Voß (2008b). A survey by Wiese et al (2010) using the data of 114 container terminals, worldwide, shows that 63.2 per cent of all terminals use YCs for stacking. In Asia, this is 75.5 per cent.

Most of the papers dealing with YC scheduling do not specify any special type of YC (that is, manual or automated RMG or RTG crane), and as such the models and solution methods developed are applicable to all sorts of YC. However, the assumptions considered often show that the models are more suitable for a special type of crane and usually need to be modified for another type of crane. Table 1 summarizes recent integer programming models (other than the ones mentioned in Stahlbock and Voß, 2008a) on YC scheduling including the objective functions and constraints considered. We try to indicate the type of crane considered based on the constraints mentioned in the papers.

Recently, Sharif and Huynh (2012) employed agent-based models to formulate the YC scheduling problem. Agent-based models can dynamically adapt to real-time truck arrivals, making them better suited for real-life operations. Vidal and Huynh (2010) also use an agent-based approach to schedule YCs with a specific focus on assessing the impact of different crane service strategies on drayage operations. In their work, they model the cranes as utility maximizing agents and develop a set of utility functions to determine the order in which individual containers are handled. Finally, Petering et al (2009) develop a simulation model for real-time YC control in transshipment terminals.

Scheduling two or three YCs dedicated to a stack

In the previous section, we focused on papers in which each stack has a single YC or in which stacks share YCs. We now review papers in which stacks with double or triple YCs are considered.

Li et al (2009) introduce a discrete time model to schedule twin YCs carrying out storage and retrieval requests in a single stack. The YCs cannot pass each other and must be separated by a safety distance. The requests have different due times and the objective is to minimize a weighted combination of earliness and lateness of all requests, compared with their due times. They introduce a rolling horizon algorithm in which a horizon of a specific length is defined, and all requests falling within this horizon are considered and optimized by CPLEX. The horizon is updated whenever all its requests have been scheduled. In a recent paper, Li et al (2012) extend the model to a continuous time model. The results show a significant improvement compared with a previous discrete model. Gharehgozli et al (2014a) also schedule twin YCs for a large number of requests using adaptive-large neighbourhood search. Park et al (2010) consider container rehandling (see the stacking area operations section) in their mixed-integer programming model used for scheduling twin YCs in a rolling horizon mode. Containers that have to be rehandled are considered as independent requests and are assigned to any idle YC. This approach results in balancing the workload of YCs and reducing the waiting times of trucks and AGVs. Vis and Carlo (2010) consider a double YC problem in which the YCs can pass each other but cannot work on the same bay simultaneously. In their problem, requests do not have any due time and can be scheduled in any sequence. They formulate the problem as a continuous time model and minimize the makespan of the YCs. They solve it by a simulated annealing algorithm and use the single-row method proposed by Vis (2006) to compute a lower bound. Cao et al (2008) propose an integer model for a similar problem. They develop two heuristics and a simulated annealing algorithm to solve the problem. Stahlbock and Voß (2010) perform a simulation study to investigate to what extent double YCs can help to improve container terminal efficiency. They evaluate different online algorithms for sequencing and scheduling requests. The experiments are based upon real-world scenarios (from the Container Terminal Altenwerder, CTA, Hamburg, Germany).

Recently, Container Terminal Altenwerder (CTA) in the Port of Hamburg installed three cranes per stack to handle stacking operations (Dorndorf and Schneider, 2010). Two cranes are smaller so that the larger crane can pass. Dorndorf and Schneider (2010) model the scheduling problem of these cranes as an integer programming model. The objective is to maximize the productivity of the crane system under peak load while preventing delays in the transport of import and export containers. They solve the problem in a rolling horizon scheme using a beam search method. The results show that the method performs better than nearest neighbour and first-come-first-served request selection heuristics by more than 20 per cent.

Minimizing container reshuffling

New technologies and methods for managing the stacking area of container terminals reduce container throughput time. However, a discussion about improving the efficiency of container stacking would be incomplete without considering container reshuffling. A reshuffle is an unwanted movement of a container stacked on top of the one which has to be retrieved (De Castillo and Daganzo, 1993; Kim et al, 2000; Caserta and Voß, 2009b). Reshuffling is time consuming and it increases a ship’s berthing time. Few systems, such as the UCW discussed above, allow direct access to all containers. However, not much technological innovation can be seen in this regard. On the other hand, many new methods have been designed to reduce or avoid reshuffling. Papers dealing with container reshuffling study three main subjects: (1) pre-marshalling, (2) relocating methods while retrieving containers and (3) stacking methods.

The common objective in all these papers is to reduce the number of reshuffles.

Pre-marshalling

Some researchers focus on how to reduce the number of reshuffles by pre-marshalling containers in a way that fits the ship’s stowage plans. Pre-marshalling is the repositioning of containers of the stack so that no, or few, reshuffles are needed when containers are loaded onto the ships. Lee and Hsu (2007) propose an integer programming model for a container pre-marshalling problem preventing reshuffles. They develop a multi-commodity network flow model for obtaining a plan on how to pre-marshal containers stacked in a single bay and solve it by replacing some of the constraints and relaxing others. They also propose a simple heuristic for large-scale problems. Lee and Chao (2009) develop a neighbourhood-based heuristic model to pre-marshal containers of a single bay of a container stack in order to find a desirable final layout. Caserta and Voß (2009b) propose a dynamic programming model to pre-marshal containers of a single bay. In order to quickly find the solution, they propose a corridor method. In this local search method, a pre-marshalled container of a specific pile can only be stacked in a corridor which consists of the next few predecessor or successor piles of the bay with a specific limit on the number of empty locations. Expósito-Izquierdo et al (2012) develop an instance generator that creates instances with varying degrees of difficulty. The difficulty of the instances is determined based on the occupancy rate and the percentage of containers with high priority that are located below those with low priority. Bortfeldt and Forster (2012) propose a tree-based heuristic to solve the pre-marshalling problem. In the tree search procedure, the nodes of the tree represent layouts. The root node corresponds to the initial layout and each leaf node corresponds to a final layout. Finally, Huang and Lin (2012) work on two different types of container pre-marshalling problems, and develop two heuristics to solve them. They obtain better solutions than the solutions present in the literature (that is, Lee and Hsu, 2007) in a shorter time.

Relocating

The problem of minimizing the number of reshuffles of a container stack while containers are retrieved is called the block (stack) relocation problem (BRP), which is proven to be NP hard by Caserta et al (2012). Given a retrieval sequence of containers in the BRP, the decision is where to locate reshuffled containers to obtain the minimum number of reshuffles when all containers in the retrieval sequence are retrieved. Caserta et al (2011) formulate the problem as a dynamic programming (DP) model and use a corridor method similar to the one proposed by Caserta and Voß (2009b) to solve it. Since the quality of the solution depends on the length and height of the corridor, in two later papers, Caserta and Voß (2009a) and Caserta and Voß (2009c) incorporate heuristic algorithms to tune these variables. Caserta et al (2009) propose a greedy heuristic algorithm to solve the BRP. In their heuristic, a reshuffled container will be stacked either in a pile which is empty or in a pile of containers that have lower retrieval priority. If such a pile is not available, the container will be stacked in a pile of containers that have a retrieval time nearest to the container that has to be stacked. Forster and Bortfeldt (2012) propose a tree search algorithm similar to the one developed by Bortfeldt and Forster (2012) for the pre-marshalling problem. However, they use a finer move classification scheme, different rules for branching and bounding, and require an additional greedy heuristic. Finally, Lee and Lee (2010) consider a multi-bay generalization of the BRP and describe a solution approach that combines heuristics with integer programs.

Stacking

Although pre-marshalling and relocating help to minimize the number of reshuffles while containers are retrieved, a good stacking policy significantly decreases the handling effort in later stages. Some papers focus on how to avoid reshuffling by proposing methods to properly locate incoming containers in a container stack. Dekker et al (2007) investigate different stacking policies, using simulation based on real data. They allocate containers to the stack based on the container’s expected duration of stay. Kim and Park (2003) also propose a heuristic algorithm based on the container’s duration of stay to locate export containers. Kim et al (2000) propose a stochastic DP model for determining storage positions of export containers in a single bay of a stack. To avoid solving a time-consuming DP model for each incoming container, they build decision trees, using the optimal solutions of the DP model. The trees decide where to store an incoming container. The validity of the recursive function of the DP model is proven by Zhang et al (2010). Their method is adapted to handle large realistic stacks by Gharehgozli et al (2014c). Saurì and Martin (2011) propose three new strategies to stack import containers. They also develop a model to compute the expected number of reshuffles based on the container arrival times. They compare their strategies based on different criteria including the size of terminals and container traffic. Yu and Qi (2013) consider a similar problem. They propose two models of which one is used to allocate import containers to the stack after they are unloaded from a ship, and the other one is used to pre-marshal containers. Through simulation, they validate the models and find out that segregating the space and pre-marshalling enhance the efficiency of the terminal in terms of reducing truck waiting times. Finally, Casey and Kozan (2012) develop a dynamic mixed integer programming model to determine where to stack containers while others are retrieved in each period. The objective is to minimize the total amount of time that containers are stacked in the block. Several constraints are developed to calculate the amount of required time for reshuffling, loading and unloading containers from the equipment systems handling the containers.

Other potential research topics for stack side operations include: (1) understanding the impact of multiple stack cranes on interference delays, and (2) studying how the stack crane scheduling can be done to minimize delays in both seaside and landside operations.

Hinterland Operations

Large deep-sea terminals face many challenges such as congestion, delays and pollution. This has driven container terminals to transform their supply chains to increase their competitiveness and robustness (Heinrich and Betts, 2003; Vervest and Li, 2009). By closely collaborating with hinterland terminals, deep-sea terminals can balance flows and workload more efficiently over time. As a result, not all the value adding activities, such as container inspection and container delivery to end customers, need to be done at deep-sea terminals, but it can be relegated to hinterland terminals.

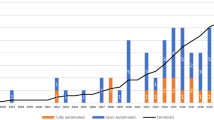

New technologies

Close cooperation of deep-sea and hinterland terminals is a recent development, caused by the substantial increase of the number of containers handled (Van Klink and Van den Berg, 1998; Heaver et al, 2001; Notteboom and Winkelmans, 2001; Notteboom, 2002; Robinson, 2002; Roso et al, 2009). At first, the goal was to increase terminal capacity by adding dry ports to the network of main deep-sea terminals. During the last decade, the amount of authority delegated to these hinterland terminals has increased. Veenstra et al (2012) describe an example project in Rotterdam that integrates supply and transportation by extending the sea terminal gate into the hinterland. An extended gate is an inland intermodal terminal directly connected to the seaport terminal(s) with high capacity transport mean(s), where customers can leave or pick up their containers as if directly at a seaport (including customs and security inspections), and where the seaport terminal operator can choose to control the flow of containers between the terminals. Iannone (2012) empirically studies a similar example in the Campania region in Southern Italy.

OR models

Network configurations give rise to several strategic and operational challenges such as information sharing, modal split, inter-terminal transportation, repositioning of empty containers, asset light solutions and barge operations which were not a matter of concern previously. We discuss these topics in more detail below. Owing to their novelty, the operations research-related literature on this topic is still limited, providing opportunities for future research.

Information sharing

One of the crucial conditions for the development of efficient networks is the availability of reliable information on containers (arrival, departure times, content and modes of final transport). Terminal operators usually possess estimated arrival and departure times. More exact information is needed though, to better stack containers; minimize internal travel time to the proper pick up points; and avoid tardiness or earliness of loading and unloading different means of transport. Some examples were discussed in the previous sections (see, for example, Borgman et al, 2010; Van Asperen et al, 2011). Douma et al (2009) propose a decentralized multi-agent system to align barge operators with terminal operations. They compare their approach with a central approach, where a trusted party coordinates the activities of all barges and terminals. The results indicate that, in spite of the limited information available, their approach performs quite well compared with the central approach. In their later study, Douma et al (2011a) examine the effect of different degrees of cooperativeness on the efficiency of the barge handling process.

Modal split and service network design

One of the most important challenges in a container handling and transport network is the modal split. Besides ships, terminal operators deploy trucks, trains and barges to transport containers. Barges and trains have less negative environmental and societal impact than road transport. However, compared with trucks, barges and trains usually have longer transit times, and do not connect directly to any final destination (Groothedde et al, 2005). Port authorities are strongly urging container terminals to adopt more environmentally friendly modes of transport. For example, the Port of Rotterdam needs to move from the current truck/barge/rail split of 45/40/15 to 35/45/20 per cent by 2035 (Port of Rotterdam Authority, 2012; Veenstra et al, 2012). Synchromodal transport connections (that is, connections where multiple transport modes can be used on different legs of the transport path and where switching between modes is possible) can be instrumental in achieving this.

Over time, seaport terminals are being integrated with inland terminals, by means of frequent services of high capacity transport modes such as river vessels (barges) and trains. The multi-modal transport operators typically face three interrelated decisions: (1) determine which inland terminals can act as extended gates of the seaport terminal, (2) determine capacity of the transport modes and frequency of service, and (3) set prices for the transport services on the network (Ypsilantis and Zuidwijk, 2013). Van Riessen et al (2013) propose an integer-programming model for the design of such networks. The model uses a combination of a path-based formulation and a minimum flow network formulation that penalizes overdue deliveries and combines both self-operated and subcontracted services. Sharypova et al (2012) address the minimum cost service network design problem by developing a continuous-time mixed-integer linear programming model. Using this model, they are able to accurately determine transportation events and the number of containers to be transshipped by vehicles. Ypsilantis and Zuidwijk (2013) propose a bi-level programming model to jointly obtain the design and price of extended gate network services for profit maximization.

Inter-terminal transportation

Inter-terminal transportation is the movement of containers between close-by terminals (by sea, rail, or otherwise), often in the same port area. When developing new terminals and container ports, the movement of containers between terminals has to be taken into consideration. Previous work in the area of design and evaluation of inter-terminal transportation commonly deals with simulation (see, for example, Ottjes et al, 2007). Recent work uses optimization methods to study the problem. Tierney et al (2013) develop a model combining vehicle flows and multi-commodity container flows for inter-terminal movements. They solve the model to optimality using real data from the Port of Hamburg, Germany, and the Maasvlakte 1 & 2 area of the Port of Rotterdam, the Netherlands. Lee et al (2012) develop a mixed-integer programming model for assigning ships to terminals within a terminal hub and allocating corresponding containers. The objective function minimizes the total inter-terminal and intra-terminal handling costs. They develop a two-level heuristic algorithm to solve the problem. Minimizing intra-terminal handling costs is also considered in the BAP problem studied by Hendriks et al (2012).

Barge transportation

During the past decades, truck transport has been the dominant mode of inland transportation compared with train and barge. To reduce pressure on road infrastructure as well as to reduce greenhouse gas emissions, port authorities aim for a modal shift from road to barge or train. For a country with easy access to waterways, barge transport is a competitive alternative to road and rail transport due to its ability to offer cheap and reliable transport services. One of the crucial conditions for successful barge freight transportation is the alignment of terminal and barge operators. The barge handling problem (BHP) consists of routing and scheduling barges to visit different terminals in a port. A centralized decision-making method, where a trusted party coordinates the activities of all barges and terminals, is unacceptable by both terminal and barge operators. Generally, they are not willing to share information, wanting to be autonomous. Therefore, online decentralized decision-making methods are much more suitable in this case. To achieve this goal, Douma et al (2009) model the problem using agent-based planning systems and compare their approach with a central approach. The results indicate that, in spite of the limited information available, their approach performs quite well compared with the central approach. The authors extend this idea in their later studies (Douma et al, 2011a, 2011b). The insights from these studies are currently embedded in a project entitled barge terminal multi-agent network (BATMAN) which will be implemented in the Port of Rotterdam (Mes, 2012). Despite the intriguing findings and clear contributions, the present studies do not yet capture all aspects of such operations in practice, leaving room for further study.

Conclusions

During the last decade, container terminals have witnessed rapid developments that have led to the design of more automated, responsive, cost and energy-efficient, and secure terminals. Operations research models encompassing new constraints and objective functions, needed by such advancements, are required to efficiently manage container terminals. The operations research community needs to revisit and update the previous studies on container terminal operations. This article discusses the new developments in container terminal technologies and OR models, and reviews the related literature. Although the study is limited to container handling operations performed inside a terminal, this article shows that there is a substantial body of research on the related topics and there is enough room for further research.

References

Agarwal, R. and Ergun, Ö. (2008) Ship scheduling and network design for cargo routing in liner shipping. Transportation Science 42 (2): 175–196.

Agerschou, H. et al (1983) Planning and Design of Ports and Marine Terminals. Chichester, UK: John Wiley and Sons.

Almotairi, B., Flodén, J., Stefansson, G. and Woxenius, J. (2011) Information flows supporting hinterland transportation by rail: Applications in Sweden. Research in Transportation Economics 33 (1): 15–24.

Avriel, M., Penn, M. and Shpirer, N. (2000) Container ship stowage problem: Complexity and connection to the coloring of circle graphs. Discrete Applied Mathematics 103 (1–3): 271–279.

Bierwirth, C. and Meisel, F. (2009) A fast heuristic for quay crane scheduling with interference con straints. Journal of Scheduling 12 (4): 345–360.

Bierwirth, C. and Meisel, F. (2010) A survey of berth allocation and quay crane scheduling problems in container terminals. European Journal of Operational Research 202 (3): 615–627.

Boer, C.A. and Saanen, Y.A. (2012) Improving container terminal efficiency through emulation. Journal of Simulation 6 (2012): 267–278.

Borgman, B., Van Asperen, E. and Dekker, R. (2010) Online rules for container stacking. OR Spectrum 32 (3): 687–716.

Bortfeldt, A. and Forster, F. (2012) A tree search procedure for the container pre-marshalling problem. European Journal of Operational Research 217 (3): 531–540.

Brinkmann, B. (2010) Operations Systems of Container Terminals: A Compendious Overview. Berlin/Heidelberg, Germany: Springer, pp. 25–39.

Buhrkal, K., Zuglian, S., Ropke, S., Larsen, J. and Lusby, R. (2011) Models for the discrete berth al location problem: A computational comparison. Transportation Research Part E: Logistics and Transportation Review 47 (4): 461–473.

Canonaco, P., Legato, P., Rina, M.M. and Musmanno, R. (2008) A queuing network model for the management of berth crane operations. Computers & Operations Research 35 (8): 2432–2446.

Cao, Z., Lee, D.H. and Meng, Q. (2008) Deployment strategies of double-rail-mounted gantry crane systems for loading outbound containers in container terminals. International Journal of Production Economics 115 (1): 221–228.

Carlo, H.J., Iris, F.A. and Vis, K.J.R. (2014a) Storage yard operations in container terminals: Literature overview, trends, and research directions. European Journal of Operational Research 235 (2): 412–430.

Carlo, H.J., Iris, F.A. and Vis, K.J.R. (2014b) Transport operations in container terminals: Literature overview, trends, research directions and classification scheme. European Journal of Operational Research 236 (1): 1–13.

Carlo, H.J., Iris, F.A. and Vis, K.J.R. (2013) Seaside operations in container terminals: Literature overview, trends, and research directions. Flexible Services and Manufacturing Journal 1–39, doi: 10.1007/s10696-013-9178-3.

Caserta, M., Schwarze, S. and Voß, S. (2009) A new binary description of the blocks relocation problem and benefits in a look ahead heuristic. In: C. Cotta and P. Cowling (eds.) Evolutionary Computation in Combinatorial Optimization, Lecture Notes in Computer Science. Vol. 5482. Berlin/Heidelberg, Germany: Springer, pp. 37–48.

Caserta, M., Schwarze, S. and Voß, S. (2012) A mathematical formulation and complexity considerations for the blocks relocation problem. European Journal of Operational Research 219 (1): 96–104.

Caserta, M. and Voß, S. (2009a) A cooperative strategy for guiding the corridor method. In: N. Krasnogor, M. Melian-Batista, J. Perez, J. Moreno-Vega and D. Pelta (eds.) Nature Inspired Cooperative Strategies for Optimization (NICSO 2008), Studies in Computational Intelligence. Vol. 236. Berlin/Heidelberg, Germany: Springer, pp. 273–286.

Caserta, M. and Voß, S. (2009b) A corridor method-based algorithm for the pre-marshalling problem. In: M. Giacobini et al (eds.) Applications of Evolutionary Computing, Lecture Notes in Computer Science. Vol. 5484 Berlin/Heidelberg: Springer, pp. 788–797.

Caserta, M. and Voß, S. (2009c) Corridor selection and fine tuning for the corridor method. In: T. Stutzle (ed.) Learning and Intelligent Optimization, Lecture Notes in Computer Science. Vol. 5851. Berlin/Heidelberg, Germany: Springer, pp. 163–175.

Caserta, M., Voß, S. and Sniedovich, M. (2011) Applying the corridor method to a blocks relocation problem. OR Spectrum 33 (4): 915–929.

Casey, B. and Kozan, E. (2012) Optimising container storage processes at multimodal terminals. Journal of the Operational Research Society 63 (8): 1126–1142.

Chang, D., Jiang, Z., Yan, W. and He, J. (2010) Integrating berth allocation and quay crane assignments. Transportation Research Part E: Logistics and Transportation Review 46 (6): 975–990.

Chang, D., Jiang, Z., Yan, W. and He, J. (2011) Developing a dynamic rolling-horizon decision strategy for yard crane scheduling. Advanced Engineering Informatics 25 (3): 485–494.

Chen, G., Govindan, K. and Yang, Z. (2013) Managing truck arrivals with time windows to alleviate gate congestion at container terminals. International Journal of Production Economics 141 (1): 179–188.

Chen, L. and Langevin, A. (2011) Multiple yard cranes scheduling for loading operations in a container terminal. Engineering Optimization 43 (11): 1205–1221.

Chen, G. and Yang, Z. (2010) Optimizing time windows for managing export container arrivals at Chinese container terminals. Maritime Economics & Logistics 12 (1): 111–126.

Chen, J.H., Lee, D.H. and Cao, J.X. (2011a) Heuristics for quay crane scheduling at indented berth. Transportation Research Part E: Logistics and Transportation Review 47 (6): 1005–1020.

Chen, X., Zhou, X. and List, G.F. (2011b) Using time-varying tolls to optimize truck arrivals at ports. Transportation Research Part E: Logistics and Transportation Review 47 (6): 965–982.

Cheung, R.K., Li, C.L. and Lin, W. (2002) Interblock crane deployment in container terminals. Transportation Science 36 (1): 79–93.

China Communications construction company. (2010) Three-container spreader. http://en.ccccltd.cn/business/heavymachinerymanufactory/201011/t20101112_1549.html, accessed 4 April 2012.

Choo, S., Klabjan, D. and Simchi-Levi, D. (2010) Multiship crane sequencing with yard congestion constraints. Transportation Science 44 (1): 98–115.

Cordeau, J.F., Toth, P. and Vigo, D. (1998) A survey of optimization models for train routing and scheduling. Transportation Science 32 (4): 380–404.

Crainic, G.T. and Kim, K.H. (2007) Chapter 8 intermodal transportation. In: C. Barnhart and G. Laporte (eds.) Transportation, Handbooks in Operations Research and Management Science. Vol. 14. Elsevier, pp. 467–537.

De Castillo, B. and Daganzo, C.F. (1993) Handling strategies for import containers at marine terminals. Transportation Research Part B: Methodological 27 (2): 151–166.

De Koster, R., Balk, B.M. and Van Nus, W.T.I. (2009) On using DEA for benchmarking container terminals. International Journal of Operations & Production Management 29 (11): 1140–1155.

Dekker, R., Van der Heide, S., Van Asperen, E. and Ypsilantis, P. (2012b) A chassis exchange terminal to reduce truck congestion at container terminals. Flexible Services and Manufacturing Journal 25 (4): 528–542.

Dekker, R., Voogd, P. and Asperen, E. (2007) Advanced methods for container stacking. In: K.H. Kim and H.O. Günther (eds.) Container Terminals and Cargo Systems. Berlin/Heidelberg, Germany: Springer, pp. 131–154.

Delgado, A., Jensen, R.M., Janstrup, K., Rose, T.H. and Andersen, K.H. (2012) A constraint programming model for fast optimal stowage of container vessel bays. European Journal of Operational Research 220 (1): 251–261.

Dorndorf, U. and Schneider, F. (2010) Scheduling automated triple cross-over stacking cranes in a container yard. OR Spectrum 32 (3): 617–632.

Douma, A., Schutten, M. and Schuur, P. (2009) Waiting profiles: An efficient protocol for enabling distributed planning of container barge rotations along terminals in the port of rotterdam. Transportation Research Part C: Emerging Technologies 17 (2): 133–148.

Douma, A., Schuur, P. and Jagerman, R. (2011a) Degrees of terminal cooperativeness and the efficiency of the barge handling process. Expert Systems with Applications 38 (4): 3580–3589.

Douma, A., Schuur, P. and Schutten, M. (2011b) Aligning barge and terminal operations using service time profiles. Flexible Services and Manufacturing Journal 23 (4): 385–421.

Drewry. (2011) Container Forecaster. London: Drewery Publications.

Du, Y., Chen, Q., Quan, X., Long, L. and Fung, R.Y.K. (2011) Berth allocation considering fuel consumption and vessel emissions. Transportation Research Part E: Logistics and Transportation Review 47 (6): 1021–1037.

Europe Container Terminals (ECT). (2012) from ECT: http://www.ect.nl/imagegallery/pages/Gallery.aspx, accessed 4 April 2012.

Expósito-Izquierdo, C., Melian-Batista, B. and Moreno-Vega, M. (2012) Pre-marshalling problem: Heuristic solution method and instances generator. Expert Systems with Applications 39 (9): 8337–8349.

Ez-Indus. (2012) Ultra high container warehouse system. http://www.ezindus.com/emain.php?page=emenu2&sub=eez_m2, accessed 4 April 2012.

Forster, F. and Bortfeldt, A. (2012) A tree search procedure for the container relocation problem. Computers & OR 39 (2): 299–309.

Froyland, G., Koch, T., Megow, N., Duane, E. and Wren, H. (2008) Optimizing the landside operation of a container terminal. OR Spectrum 30 (1): 53–75.

Gharehgozli, A.H., Laporte, G., Yu, Y. and de Koster, R. (2014a) Scheduling twin yard cranes in a container block. Transportation Science. pp. 1–20 ISSN 0041-1655 (print) ISSN 1526-5447 (online), http://dx.doi.org/10.1287/trsc.2014.0533.

Gharehgozli, A.H., Yu, Y., de Koster, R. and Udding, J.T. (2014b) An exact method for scheduling a yard crane. European Journal of Operational Research 235 (2): 431–447.

Gharehgozli, A.H., Yu, Y., de Koster, R. and Udding, J.T. (2014c) A decision-tree stacking heuristic for large scale reshuffling problems at a container yard. International Journal of Production Research 52 (9): 2592–2611.

Giallombardo, G., Moccia, L., Salani, M. and Vacca, I. (2010) Modeling and solving the tactical berth-allocation problem. Transportation Research Part B: Methodological 44 (2): 232–245.

Giebel, F.G. (2003) Massareductie op de horizontale transportwagen van de carrier crane. http://wbmttt.tudelft.nl/rapport/6820e.htm, accessed 4 April 2012.