Abstract

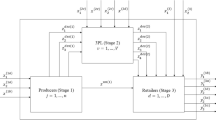

Designing a supply chain network (SCN) is an important issue for organizations in competitive markets. In this paper, a novel robust SCN that considers the efficiencies and costs simultaneously is proposed. In order to estimate the efficiency of the producers and distributors, data envelopment analysis (DEA) model is incorporated into SCN. Moreover, to handle the uncertainty in data, a scenario-based robust optimization approach is applied. The proposed model finds out the efficient location of producers and distributors and determines the amount of purchases from each supplier in uncertain conditions. To illustrate the application of the proposed model, a numerical example is solved and results are analyzed.

Similar content being viewed by others

References

Alirezaee MR and Afsharian M (2007). A complete ranking of DMUs using restrictions in DEA models. Applied Mathematics and Computation 189(2): 1551–1559.

Altiparmak F, Gen M, Lin L and Karaoglan I (2009). A steady-state genetic algorithm for multi-product supply chain network design. Computers & Industrial Engineering 56(2): 521–537.

Altiparmak F, Gen M, Lin L and Paksoy T (2006). A genetic algorithm approach for multi-objective optimization of supply chain networks. Computers & Industrial Engineering 51(1): 196–215.

Baghalian A, Rezapour S and Farahani RZ (2013). Robust supply chain network design with service level against disruptions and demand uncertainties: A real-life case. European Journal of Operational Research 227(1): 199–215.

Bal H, Orkcu H and Celebioğlu S (2008). A new method based on the dispersion of weights in data envelopment analysis. Computers & Industrial Engineering 54(3): 502–512.

Bala K (2014). Supply chain management: Some issues and challenges a review. International Journal of Current Engineering and Technology 4(2): 947–953.

Castillo-Villar KK, Smith NR and Herbert-Acero JF (2014). Design and optimization of capacitated supply chain networks including quality measures. Mathematical Problems in Engineering 2014: 1–7.

Chan FTS, Chung SH and Wadhwa S (2004). A hybrid genetic algorithm for production and distribution. Omega 33(4): 345–355.

Charnes A, Cooper WWand Rhodes E (1978). Measuring the efficiency of decision making units. European Journal of Operational Research 2(6): 429–444.

Chen C, Lee W (2004) Multi-objective optimization of multi-echelon supply chain networks with uncertain product demands and prices. Computers and Chemical Engineering 28(6–7):1131–1144

Chen Y, Liang L and Yang F (2006). A DEA game model approach to supply chain efficiency. Annals of Operations Research 145(1): 5–13.

Chopra S and Meindl P (2004). Supply Chain Management: Strategy, Planning and Operation. Pearson Prentice Hall: Upper Saddle River, NJ.

Correia I, Melo T and Saldanha-da-Gama F (2013). Comparing classical performance measures for a multi-period, two-echelon supply chain network design problem with sizing decisions. Computers & Industrial Engineering 64(1): 366–380.

Dimitrov S and SuttonW (2009). Promoting symmetric weight selection in data envelopment analysis: A penalty function approach. European Journal of Operational Research 200(1): 281–288.

Dullaert W, Bräysy O, Goetschalckx M, Raa B and Center A (2007). Supply chain (re) design: Support for managerial and policy decisions. European Journal of Transport and Infrastructure Research 7(2): 73–92.

Erol I and Ferrell Jr WG (2004). A methodology to support decision making across the supply chain of an industrial distributor. International Journal of Production Economics 89(2): 119–129.

Fleischmann M, Beullens P, Bloemhof-Ruwaard JM and Wassenhove LN (2001). The impact of product recovery on logistics network design. Production and Operations Management 10(2): 156–173.

Gan M, Li Z and Chen S (2014). On the transformation mechanism for formulating a multiproduct two-layer supply chain network design problem as a network flow model. Mathematical Problems in Engineering. doi:10.1155/2014/480127.

Ganeshan R and Harrison TP (1995). An introduction to supply chain management, department of management sciences and information systems, 303 beam business building. Penn State University, University Park.

Georgiadis MC, Tsiakis P, Longinidis P and Sofioglou MK (2011). Optimal design of supply chain networks under uncertain transient demand variations. Omega 39(3): 254–272.

Guillén G, Mele FD, Bagajewicz MJ, Espuna A and Puigjaner L (2005). Multi objective supply chain design under uncertainty. Chemical Engineering Science 60(6): 1535–1553.

Klimberg RK and Ratick SJ (2008). Modeling data envelopment analysis (DEA) efficient location/allocation decisions. Computers & Operations Research 35(2): 457–474.

Leung SC, Tsang SO, Ng WL and Wu Y (2007). A robust optimization model for multi-site production planning problem in an uncertain environment. European Journal of Operational Research 181(1): 224–238.

Liang L, Yang F, Cook WD and Zhu J (2006). DEA models for supply chain efficiency evaluation. Annals of Operations Research 145(1): 35–49.

Listeş O (2007). A generic stochastic model for supply-and-return network design. Computers & Operations Research 34(2): 417–442.

Melo MT, Nickel S and Saldanha-Da-Gama F (2009). Facility location and supply chain management—A review. European Journal of Operational Research 196(2): 401–412.

Melo MT, Nickel S and Saldanha-da-Gama F (2006). Dynamic multi-commodity capacitated facility location: A mathematical modeling framework for strategic supply chain planning. Computers and Operations Research 33(1): 181–208.

Melo MT, Nickel S and Saldanha-da-Gama F (2012). A tabu search heuristic for redesigning a multi-echelon supply chain network over a planning horizon. International Journal of Production Economics 136(1): 218–230.

Mirzapour Al-E-Hashem SMJ, Malekly H and Aryanezhad MB (2011). A multi-objective robust optimization model for multi-product multi-site aggregate production planning in a supply chain under uncertainty. International Journal of Production Economics 134(1): 28–42.

Moheb-Alizadeh H, Rasouli SM and Tavakkoli-Moghaddam R (2011). The use of multi-criteria data envelopment analysis (MCDEA) for location—Allocation problems in a fuzzy environment. Expert Systems with Applications 38(5): 5687–5695.

Mulvey JM and Ruszczynski A (1995). A new scenario decomposition method for large-scale stochastic optimization. Operations Research 43(3): 477–490.

Mulvey JM, Vanderbei RJ and Zenios SA (1995). Robust optimization of large-scale systems. Operations Research 43(2): 264–281.

Pan F and Nagi R (2013). Multi-echelon supply chain network design in agile manufacturing. Omega 41(6): 969–983.

Parmigiani A, Klassen RD and Russo MV (2011). Efficiency meets accountability: Performance implications of supply chain configuration, control, and capabilities. Journal of Operations Management 29(3): 212–223.

Pattanamekar P, Kim C, Park D and Lee K (2011). Technical efficiency analysis of shippers using DEA. Journal of Advanced Transportation 45(3): 161–172.

Pierce NA and Giles MB (1997). Preconditioned multi grid methods for compressible flow calculations on stretched meshes. Journal of Computational Physics 136(2): 425–445.

Pishvaee MS, Rabbani M and Torabi SA (2011). A robust optimization approach to closed-loop supply chain network design under uncertainty. Applied Mathematical Modeling 35(2): 637–649.

Pishvaee MS, Razmi J and Torabi SA (2012). Robust possibilistic programming for socially responsible supply chain network design: A new approach. Fuzzy Sets and Systems 206(November): 1–20.

Pishvaee MS and Torabi SA (2010). A possibilistic programming approach for closed-loop supply chain network design under uncertainty. Fuzzy Sets and Systems 161(20): 2668–2683.

Porembski M, Breitenstein K and Alpar P (2005). Visualizing efficiency and reference relations in data envelopment analysis with an application to the branches of a German bank. Journal of Productivity Analysis 23(2): 203–221.

Sabri EH and Beamon BM (2000). A multi-objective approach to simultaneous strategic and operational planning in supply chain design. Omega 28(5): 581–598.

Sahraeian R, Bashiri M and Ramezani M (2010). A stochastic multi-product, multi-stage supply chain design considering products waiting time in the queue. In: International Conference of Industrial Engineering and Operations Management, Dhaka, Bangladesh.

Salema MIG, Barbosa-Povoa AP and Novais AQ (2007). An optimization model for the design of a capacitated multi-product reverse logistics network with uncertainty. European Journal of Operational Research 179(3): 1063–1077.

Sarrico CS and Dyson RG (2004). Restricting virtual weights in data envelopment analysis. European Journal of Operational Research 159(1): 17–34.

Seuring S (2013). A review of modeling approaches for sustainable supply chain management. Decision Support Systems 54(4): 1513–1520.

Shen Z (2007). Integrated supply chain design models: A survey and future research directions. Journal of Industrial and Management Optimization 3(1): 1–27.

Thomas P, ChanY, Lehmkuhl L and Nixon W (2002). Obnoxious-facility location and data envelopment analysis: A combined distance-based formulation. European Journal of Operation Research 141(3): 495–514.

Van der Plas C, Tervonen T and Dekker R (2012). Evaluation of scalarization methods and NSGA-II/SPEA2 genetic algorithms for multi-objective optimization of green supply chain design. Econometric Institute Research Papers 24:1–22.

Wang YM, Luo Y and Liang L (2009). Ranking decision making units by imposing a minimum weight restriction in the data envelopment analysis. Journal of Computational and Applied Mathematics 223(1): 469–484.

Yu CS and Li HL (2000). A robust optimization model for stochastic logistic problems. International Journal of Production Economics 64(1–3): 385–397.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Omrani, H., Adabi, F. & Adabi, N. Designing an efficient supply chain network with uncertain data: a robust optimization—data envelopment analysis approach. J Oper Res Soc 68, 816–828 (2017). https://doi.org/10.1057/jors.2016.42

Published:

Issue Date:

DOI: https://doi.org/10.1057/jors.2016.42