Abstract

Gelatin, derived from collagen, has both the mechanical properties required for tissue growth, as well the functional domains required for cell binding. In its natural state, gelatin derives its properties from a network of structured, intertwined, triple helical chains, which is stabilized by hydrogen bonds at temperatures below 37 °C. The mechanical properties of such a structure can be further controlled by additional enzymatic cross-linking. But, in contrast to simple polymer systems, the response to an imposed deformation is here determined by two competing factors: the establishment of the cross-linked mesh vs. the self-assembly of the fibrils into larger and stronger hierarchical structures. Therefore, properties deduced from the response to measurements such as rheology or swelling, are a combination of these two very different factors, hence a modeling is impossible unless more precise knowledge regarding the internal structure is available. The cryogenic-temperature scanning electron microscopy (cryo-SEM) was adopted to image the fully hydrated gelatin network in which distinct chain folding was observed at low densities, while cross-linked networks were observed at higher densities. Based on these images, a theoretical model which results in good agreement between the mesh sizes of both networks and their mechanical properties was developed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Gelatin is a naturally derived, easily accessible, and cheap material which was studied extensively in the last decade as it was used in numerous applications, ranging from food to tissue engineering1. Gelatin consists of cleaved collagen proteins which present a partially coiled, fibril like network at temperatures below 37 °C. The unique structure of gelatin arises due to a combination of Van der Waals interactions and hydrogen bonds which become unstable above 37 °C, when thermal fluctuations cause the chains to uncoil and form a homogeneous solution2,3. Therefore, in order to use gelatin as a structural component in a biocompatible scaffold, the network must be stabilized against dissolution at physiological temperatures4. This can be accomplished via enzymatic cross-linking, using Microbial Transglutaminase (MTG) which forms an iso-peptide bond between the amine groups of a lysine amino acid with the acyl group of a glutamine amino acid as seen on Fig. 1 Upon reaction with MTG in solution at temperatures higher than 37 °C, neighbor gelatin chains will be covalently bound to one another and will create a permanent network of gelatin strands5,6.

However, in such systems the duality in bonding nature creates a complicated system at room temperature, where the hydrogel strength derives from two different factors: the presence of stable covalently bonded gelatin strands competing with their natural tendency of re-coiling into fibrils7. In contrast to a simple cross-linked network, the interplay between these two structures determines the rheological response of complex structures such as gelatin or collagen. Unfortunately, these structures are hard to observe once the gel is dehydrated and often coated, and standard SEM microscopy cannot be applied to the swollen gel. Therefore, in order to directly observe these features we developed an imaging method of frozen fractured hydrogel samples by cryo-SEM microscopy7,8 where the obtained images were sufficiently detailed for direct comparison with theory.

Gelatin solution was synthetized by dissolving type A gelatin at a concentration of 10% (w/v) into deionized water, and heating the solution at 65 °C for 15 minutes until complete dissolution was obtained. We used two different concentrations of MTG enzyme to cross-link the hydrogels. High and low cross linking density formulations were prepared by adding 3.8 mg.ml−1 and 0.5 mg.ml−1 of MTG at 42 °C to the gelatin solution, and incubated for 24 hours at 37 °C to allow cross-linking to occur. The samples were kept tightly capped in order to avoid water evaporation and volume changes during the reaction. After 24 hours the gels were swollen at room temperature with excess water to reach equilibration of the network water-full porosities.

Rheology was first performed to assess the differences between the two gels in terms of mechanical properties7 (see Fig. 2a). The gels were then swollen at room temperature in water for 24 hours after cross linking in order to reach their equilibrated state. One can see that the moduli differ by approximately one order of magnitude at the cross-linking temperature and below (see Fig. 2a), which is not surprising, since it scales with the difference in MTG concentration responsible for the cross-linking reaction. The combination of hydrogen bonding and cross-linking density in determining the internal structure of the gels is illustrated above (see Fig. 2b,c). In these Figures we show that the structure of the gel is a compromise between a network formed by chemical cross-links, and the physical association between protein strands due to hydrogen bonding at temperatures below 37 °C. Thus, a highly ordered self-assembled lattice competes with the fluctuating random network produced by the cross-linking enzymes. At temperatures above 37 °C, the least cross linked gels exhibits a severe decrease of its elasticity parameter which is related to the instability of the hydrogen-bonded coiled natural structure of gelatin at these temperatures. This hypothesis is illustrated in Fig. 2 where one can see that for the softly cross-linked gel, the distance between cross-links is sufficiently large to allow, upon cooling, the self-assembly of the chain segments into the natural helical configuration which then co-exists at room temperature with the cross-linked network. Hence, the gel modulus below the self-assembly transition may be harder than expected, if only the degree of cross-linking was involved. In the case of the highly cross-linked gel, the chains are confined by the cross linking regions which prevents any other reorganization upon cooling. Therefore, this configuration would not show a significant change in modulus with temperature. Note that the rheology measurement alone is insufficient to determine the structure, and by this reason we performed cryo-SEM in the hope that we could actually image the lattice9.

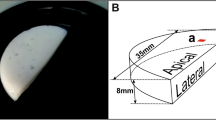

Both soft and hard hydrogels were synthetized following the same procedure as mentioned above. The samples were rapidly cooled and fractured from room temperature using the method developed by Talmon’s group8 and adapted to our system, as described in the supplementary material. Fast cooling minimized freezing expansion and preserved fine nanoscale details of the nanostructure by vitrifying the water swollen in the network, which can then be directly imaged by SEM at cryogenic temperatures, typically below −145 °C. The samples showed, as expected, unnoticeable geometrical expansion during the procedure. The images thus obtained are shown in Fig. 3, where we can see that both low and high MTG concentrations produce cross-linked structures which are swollen by the water phase. Scanning of the beam resulted in partial etching of the sample and lead to artificial reorganization of the hydrogels surfaces (see supplementary material Figures S4 and S5).

Comparison of the images in Fig. 3 clearly shows that the network mesh size is smaller when the cross-linking density is higher, as expected. The structure of the networks, though, is fundamentally different. The highly cross-linked network is composed of interconnected single strands of gelatin creating a mesh of an average size of ξobs.hard ≈ 342 ± 72 nm (see supplementary material Table S2). The network with the low cross linking density forms a much more complex structure composed of very large highly ordered fibers which branch at angles of approximately 120 ± 30 degrees (see supplementary material Table S3). Closer examination of the fibers (see insert in Fig. 3b) shows that each is composed of a secondary structure, with a well-defined banded pattern with a periodicity of 64 nm. This pattern is well known in collagen, where the molecules self-assemble in a staggered formation with period of 64 nm10. These large fibers are consistent with the model proposed above (Fig. 2b,c). The larger cross-linking period, of a mesh size ξobs.soft ≈ 873 ± 284 nm (see supplementary Table S2) is consistent with the lower cross-linking density, as shown. Upon cooling, the large spacing between cross-linking points allows the fiber sufficient mobility to rearrange into the characteristic fibril-like structure of collagen at T < 37 °C. The resulting fiber bundles are much stronger, and hence provide stiffness to the network resulting in the angular pattern shown.

Cross-linked polymer or protein gels are currently modeled using standard rubber elasticity theory (RET)11, which relates the mesh size, ξ, to the modulus, G′, with the well-known equation:

here NA is the Avogadro number, R is the perfect gas constant and T is the temperature.

Substituting the elastic modulus values obtained from the rheology measurements of the highly cross-linked gel at room temperature (Fig. 2a), into equation (1), we obtain that ξ ≈ 6.6 nm which is similar to the values previously quoted by numerous authors using RET analysis.

Swelling experiments can also be performed to evaluate the mesh size of semi-flexible polymeric networks12,13,14,15,16,17. In this case, the equilibrium stress in the network arises due to a solvent and the corresponding strain is derived by using the Flory-Rhener model18 which, in turn, is a modified form of RET which includes the polymer-solvent interaction. In order to compare with the values obtained from the equation (1), once cross-linked, the gels were swollen in deionized water. After recording the gels mass, gelatin volume fraction,  , in the network was derived as follows:

, in the network was derived as follows:

here ρp and ρs are the density of the polymer and of the solvent, respectively; Qm = Msw/Mp is the swelling ratio; and Msw and Mp are the masses of the swelled and dry samples, respectively.

The polymer volume fraction,  , can then be used to determine the molecular weight between crosslinks in a non-ionized gel with a Gaussian distribution of the polymer chains:

, can then be used to determine the molecular weight between crosslinks in a non-ionized gel with a Gaussian distribution of the polymer chains:

here  is the average molecular weight of the polymer, V1 is the molar volume of the solvent, χ1 is the Flory Huggins interaction parameter, and V is the specific volume of the polymer.

is the average molecular weight of the polymer, V1 is the molar volume of the solvent, χ1 is the Flory Huggins interaction parameter, and V is the specific volume of the polymer.

Finally, we have to consider the gelatin strands persistence length as well as its contour length to calculate the mesh size of the fully cross-linked network:

here  is the calculated average molecular weight between two neighbor crosslinks; Mr is the molecular weight of the repeating unit; l0 is the length of the bond along the polymer backbone which can be derived from the arithmetic mean of one C-C bond and two C-N bonds to be about 1.4 Å19, Cn is the characteristic ratio of the polymer which can be calculated as:

is the calculated average molecular weight between two neighbor crosslinks; Mr is the molecular weight of the repeating unit; l0 is the length of the bond along the polymer backbone which can be derived from the arithmetic mean of one C-C bond and two C-N bonds to be about 1.4 Å19, Cn is the characteristic ratio of the polymer which can be calculated as:

where lper is the persistence length of the gelatin, and ls is the linear segment length, here ls = l0.

From this equation (5) we obtain that ξ ≈ 21.3 ± 0.22 nm, (See supplementary material Table S1).

In our case, we can directly compare this value with the microscopic image, and we find that, even though it is three times larger than the RET value, it still underestimates the actual value by one order of magnitude. Indeed, RET assumes that the mesh is composed of fully flexible polymer chains interconnected by tetragonal junction types. On the other hand, the Flory-Rhener model is only accurate in the case of perfectly distributed polymer chains composing the cross-linked network with swelling behavior depending on the equilibrium between thermodynamic compatibility of the polymers and the solvent, and retractile force due to extensive stretching of the network cross-links20. Swelling experiments provide an increased value for the mesh size estimation, but it remains still under-estimated18,21 (Fig. 3a). In a bio polymeric system that presents bundles or coiled secondary structures the higher rigidity of the segments between the cross-linked junctions needs to be considered22.

In general, the elastic modulus, G′, of a network consisting of effective springs with effective elastic constant, kef, can be estimated as:

here ξ0 is the network mesh size.

The partially cross-linked network can be considered as an arrangement of large gelatin bundles interconnected by individual gelatin strands (see Fig. 4a).

Assuming that the bundles are hard elements (no stretching and no bending of the fibrils are possible), and the tie molecules are semi-flexible and non-stretchable, we have to conclude that the system stretching can only occur due to a straightening of α angle between the connecting tie molecules (see Fig. 4b).

The straightening of the tie molecules under external action (stretched force, Fext) can be considered as an elongation of a spring with effective elastic constant, kef, in accordance with the Hook’s law: Fext = kefδL. The effective elastic constant of the spring presenting a tie molecule, is a function of the bending rigidity, a, which determines the persistence length, lper ∝ a/kBT. In the case of semi-flexible gelatin sub-chains, the effective elastic constant, kef, can be calculated similarly to calculations of Treolard et al., derived for PS polymer chains23:

k1 being the elastic constant of the chain along the polymer backbone direction and ka the one across that direction. Here we can assume that k1 is very large, and <sin2(α/2)> is not too small, we can omit the first term in equation (7), so the effective elastic constant, kef, can be estimated as:

here n = lef/lper is the amount of “zigzag’s”, and <sin2(α/2)> = 0.75 (see supplementary material Table S3).

The angular deformation constant, kα, used in the Treloar et al. paper23, is also related to the rigidity parameter, a. Indeed, according to Treloar et al., the potential energy, U, for an angular deformation of amount δα is:

At the same time, the bending energy, Eb, of an isotropic macromolecule is

here  characterize the change in monomer orientations (in two directions, perpendicular to the local chain orientation) along the chain, l0 is the monomer unit length.

characterize the change in monomer orientations (in two directions, perpendicular to the local chain orientation) along the chain, l0 is the monomer unit length.

Therefore, the bending energy per one monomer,  , is

, is

so, we can conclude that

In the case of a system where the coiled structure of gelatin tends to be minimal we have:  therefore using Equation 8 combined with Equation 6 we have,

therefore using Equation 8 combined with Equation 6 we have,  . In the case of a fully cross-linked network (see Fig. 3a) we can hypothesize that the cross-linking mechanism prevents coiled fibrils formation, hence the observed network tends to exhibit almost only thin, semi-flexible chains. Rheology experiments performed on the gel to evaluate its elastic modulus G′24, can then be used to compare the calculated value for the mesh size of such a network with the one observed with cryo-SEM. Using G′ = 9100 Pa, we obtain a value for the network mesh size of ξmodel.hard = 2 × 102 nm, which is in good agreement with the experimental data, ξobs.hard = 3.4 ± 0.7 × 102 nm.

. In the case of a fully cross-linked network (see Fig. 3a) we can hypothesize that the cross-linking mechanism prevents coiled fibrils formation, hence the observed network tends to exhibit almost only thin, semi-flexible chains. Rheology experiments performed on the gel to evaluate its elastic modulus G′24, can then be used to compare the calculated value for the mesh size of such a network with the one observed with cryo-SEM. Using G′ = 9100 Pa, we obtain a value for the network mesh size of ξmodel.hard = 2 × 102 nm, which is in good agreement with the experimental data, ξobs.hard = 3.4 ± 0.7 × 102 nm.

In the case of a network mostly composed of coiled fibrils which are not flexible, the effective length of the flexible region would be greatly reduced. The minimum value required to form a bend would be at least two persistence length of the uncoiled flexible chains interconnecting the larger bundles (see Fig. 3b). The persistence length of gelatin is known to be of 2.7 nm25, and lef = 5.4 nm. Substituting this value into equation (13) above and using the experimental value obtained for the lightly cross linked gel, G′ = 7800 Pa obtained at 25 °C, we obtain, an upper limit for the mesh size of ξmodel.soft ~ 3.7 μm. The mesh size approximated from Fig. 3b (see supplementary section Table S2) is ξobs,soft ~ 0.9 ± 0.3 μm. This is consistent with this model considering that the flexible region would be on average slightly longer experimentally.

In conclusion we have shown that the ability to directly image the internal network structure of a hydrogel using cryo-SEM, has enabled us to develop an analytical model which incoporates both the semi-flexible chain strucutre as well as the supra-molecular organization in the thermomechanical response functions of complex biological networks.

Additional Information

How to cite this article: Marmorat, C. et al. Cryo-Imaging of Hydrogels Supermolecular Structure. Sci. Rep. 6, 25495; doi: 10.1038/srep25495 (2016).

References

Zavan, B., Cortivo, R. & Abatangelo, G. In Hydrogels Ch. 1, 1–8 (Springer Milan, 2009).

Pauling, L. & Corey, R. In Fortschritte der Chemie Organischer Naturstoffe/Progress in the Chemistry of Organic Natural Products/Progrés dans la Chimie des Substances Organiques Naturelles Vol. 11 Fortschritte der Chemie Organischer Naturstoffe/Progress in the Chemistry of Organic Natural Products / Progrés dans la Chimie des Substances Organiques Naturelles (ed L. Ƶechmeister ) Ch. 5, 180–239 (Springer Vienna, 1954).

Rich, A. & Crick, F. H. C. The Structure of Collagen. Nature 176, 915–916 (1955).

McDermott, M. K., Chen, T., Williams, C. M., Markley, K. M. & Payne, G. F. Mechanical properties of biomimetic tissue adhesive based on the microbial transglutaminase-catalyzed crosslinking of gelatin. Biomacromolecules 5, 1270–1279, 10.1021/bm034529a (2004).

Yung, C. W. et al. Transglutaminase crosslinked gelatin as a tissue engineering scaffold. Journal of Biomedical Materials Research Part A 83A, 1039–1046, 10.1002/jbm.a.31431 (2007).

Heck, T., Faccio, G., Richter, M. & Thöny-Meyer, L. Enzyme-catalyzed protein crosslinking. Applied Microbiology and Biotechnology 97, 461–475, 10.1007/s00253-012-4569-z (2013).

Xing, Q. et al. Increasing Mechanical Strength of Gelatin Hydrogels by Divalent Metal Ion Removal. Scientific Reports 4, 4706, 10.1038/srep04706 (2014).

Issman, L. & Talmon, Y. Cryo-SEM specimen preparation under controlled temperature and concentration conditions. Journal of Microscopy 246, 60–69, 10.1111/j.1365-2818.2011.03587.x (2012).

Rahbani, J., Behzad, A. R., Khashab, N. M. & Al-Ghoul, M. Characterization of internal structure of hydrated agar and gelatin matrices by cryo-SEM. ELECTROPHORESIS 34, 405–408, 10.1002/elps.201200434 (2013).

Fang, M. & Holl, M. M. B. Variation in type I collagen fibril nanomorphology: the significance and origin. BoneKEy Rep 2, 10.1038/bonekey.2013.128 (2013).

Welzel, P. B. et al. Modulating Biofunctional starPEG Heparin Hydrogels by Varying Size and Ratio of the Constituents. Polymers 3, 10.3390/polym3010602 (2011).

Lin, C.-C. & Metters, A. T. Hydrogels in controlled release formulations: Network design and mathematical modeling. Advanced Drug Delivery Reviews 58, 1379–1408, doi: http://dx.doi.org/10.1016/j.addr.2006.09.004 (2006).

Mason, M. N., Metters, A. T., Bowman, C. N. & Anseth, K. S. Predicting Controlled-Release Behavior of Degradable PLA-b-PEG-b-PLA Hydrogels. Macromolecules 34, 4630–4635, 10.1021/ma010025y (2001).

Canal, T. & Peppas, N. A. Correlation between mesh size and equilibrium degree of swelling of polymeric networks. Journal of Biomedical Materials Research 23, 1183–1193, 10.1002/jbm.820231007 (1989).

Peppas, N. A., Keys, K. B., Torres-Lugo, M. & Lowman, A. M. Poly(ethylene glycol)-containing hydrogels in drug delivery. Journal of Controlled Release 62, 81–87, doi: http://dx.doi.org/10.1016/S0168-3659(99)00027-9 (1999).

Amsden, B. Solute Diffusion within Hydrogels. Mechanisms and Models. Macromolecules 31, 8382–8395, 10.1021/ma980765f (1998).

Cruise, G. M., Scharp, D. S. & Hubbell, J. A. Characterization of permeability and network structure of interfacially photopolymerized poly(ethylene glycol) diacrylate hydrogels. Biomaterials 19, 1287–1294, doi: http://dx.doi.org/10.1016/S0142-9612(98)00025-8 (1998).

Flory, P. J. & Rehner, J. Statistical Mechanics of Cross‐Linked Polymer Networks II. Swelling. The Journal of Chemical Physics 11, 521–526, doi: http://dx.doi.org/10.1063/1.1723792 (1943).

Ma, S. et al. Monodisperse collagen-gelatin beads as potential platforms for 3D cell culturing. Journal of Materials Chemistry B 1, 5128–5136, 10.1039/C3TB20851F (2013).

Cai, S. & Suo, Z. Mechanics and chemical thermodynamics of phase transition in temperature-sensitive hydrogels. Journal of the Mechanics and Physics of Solids 59, 2259–2278, doi: http://dx.doi.org/10.1016/j.jmps.2011.08.008 (2011).

Flory, P. J. & Rehner, J. Statistical Mechanics of Cross‐Linked Polymer Networks I. Rubberlike Elasticity. The Journal of Chemical Physics 11, 512–520, doi: http://dx.doi.org/10.1063/1.1723791 (1943).

MacKintosh, F. C., Käs, J. & Janmey, P. A. Elasticity of Semiflexible Biopolymer Networks. Physical Review Letters 75, 4425–4428 (1995).

Treloar, L. R. G. Calculations of elastic moduli of polymer crystals: I. Polyethylene and nylon 66. Polymer 1, 95–103, doi: http://dx.doi.org/10.1016/0032-3861(60)90012-4 (1960).

Meyvis, T. K. L. et al. A comparison between the use of dynamic mechanical analysis and oscillatory shear rheometry for the characterisation of hydrogels. International Journal of Pharmaceutics 244, 163–168, doi: http://dx.doi.org/10.1016/S0378-5173(02)00328-9 (2002).

Mohanty, B. & Bohidar, H. B. Microscopic structure of gelatin coacervates. International Journal of Biological Macromolecules 36, 39–46, doi: http://dx.doi.org/10.1016/j.ijbiomac. 2005.03.012 (2005).

Acknowledgements

We greatfully acknowledge the support of the National Science Foundation (NSF grant INSPIRE#1344267). We would also like to thank Judith Schmidt, of the Technion Israel Insititue of Technology for her tremendous help in electron microscopy, and Maho Koga of Ward Melville High School, for network image analysis.

Author information

Authors and Affiliations

Contributions

C.M. and M.R. wrote the main manuscript text, N.K. and Y.T. prepared Figure 3 and supplementary material related to cryo-imaging techniques. A.A. and E.Z. prepared Figure 4 and the modeling of the observed networks structures. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Marmorat, C., Arinstein, A., Koifman, N. et al. Cryo-Imaging of Hydrogels Supermolecular Structure. Sci Rep 6, 25495 (2016). https://doi.org/10.1038/srep25495

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep25495

- Springer Nature Limited

This article is cited by

-

On the Molecular Level Cavitation in Soft Gelatin Hydrogel

Scientific Reports (2020)

-

Inferring spatial variations of microstructural properties from macroscopic mechanical response

Biomechanics and Modeling in Mechanobiology (2017)