Abstract

It is of great significance for the engineering popularization of CO2-ECBM technology to evaluate the potential of CCUS source and sink and study the matching of pipeline network of deep unworkable seam. In this study, the deep unworkable seam was taken as the research object. Firstly, the evaluation method of CO2 storage potential in deep unworkable seam was discussed. Secondly, the CO2 storage potential was analyzed. Then, the matching research of CO2 source and sink was carried out, and the pipe network design was optimized. Finally, suggestions for the design of pipe network are put forward from the perspective of time and space scale. The results show that the average annual CO2 emissions of coal-fired power plants vary greatly, and the total emissions are 58.76 million tons. The CO2 storage potential in deep unworkable seam is huge with a total amount of 762 million tons, which can store CO2 for 12.97 years. During the 10-year period, the deep unworkable seam can store 587.6 million tons of CO2, and the cumulative length of pipeline is 251.61 km with requiring a cumulative capital of $ 4.26 × 1010. In the process of CO2 source-sink matching, the cumulative saving mileage of carbon sink is 98.75 km, and the cumulative saving cost is $ 25.669 billion with accounting for 39.25% and 60.26% of the total mileage and cost, respectively. Based on the three-step approach, the whole line of CO2 source and sink in Huainan coalfield can be completed by stages and regions, and all CO2 transportation and storage can be realized. CO2 pipelines include gas collection and distribution branch lines, intra-regional trunk lines, and interregional trunk lines. Based on the reasonable layout of CO2 pipelines, a variety of CCS applications can be simultaneously carried out, intra-regional and inter-regional CO2 transport network demonstrations can be built, and integrated business models of CO2 transport and storage can be simultaneously built on land and sea. The research results can provide reference for the evaluation of CO2 sequestration potential of China's coal bases, and lay a foundation for the deployment of CCUS clusters.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

CCUS stands for CO2 Capture, Utilization and Storage1. On the one hand, CCUS technology can reduce CO2 emissions in the atmosphere and reduce the concentration of greenhouse gases2,3. On the other hand, it can help industries with CO2 high-emission achieve low-carbon development and promote economic transformation4,5. Therefore, CCUS technology has broad application prospects in the field of global energy and environment. CO2 emissions from coal are the largest source of carbon emissions in China, and it will take a long time for China to transform its energy situation6,7. Therefore, based on CCUS technology, it is of profound significance to reduce CO2 emissions from coal, and can promote the realization of China's dual-carbon strategy.

CO2 geological sequestration, a core component of CCUS, is an effective way to achieve large-scale de-carbonization8,9. Scientific evaluation of CO2 storage potential in sedimentary basin and realization of source-sink matching are the basis of CCUS cluster deployment10,11. Major sedimentary basin in China have great potential for CO2 storage, and the storage forms are diverse12. However, due to the lack of unified methods for CO2 storage potential in sedimentary basin in China, the assessment of CO2 storage potential greatly varies13. The CO2 sequestration potential of geological body in China, such as oil and gas fields, deep unrecoverable seam, production and closed mines and goaf areas, is unclear and needs to be evaluated in detail.

Carbon emission sources in China's coal base are concentrated, and CO2 emission sources and CO2 storage sinks are highly overlapping14, which provides favorable conditions for CCUS cluster deployment. CCUS technology is the only way for coal base to achieve near zero for CO2 emission in the future, and the deployment of “Coal base + CCUS” cluster has scale and agglomeration effects15. The geographical proximity of CO2 sources and sinks can save more costs for CO2 transportation, and the geographical concentration of a large number of CO2 sources and sinks is also conducive to large-scale and clustered layout engineering practices. Geological body, such as deep unrecoverable seam, is the most typical forms of CO2 storage in coal bases16,17. However, its CO2 geological storage is still in the exploration stage, and there are few studies on its CO2 storage potential18. Therefore, it is necessary to establish potential assessment methods suitable for the characteristics of China’s coal bases.

The CO2 sequestration process can be simplified as the reverse process of the CBM extraction process, and its core mechanism is the dynamic process of CO2 adsorption and displacement of CBM19,20. Therefore, the mechanism of CO2 geological storage in unworkable seam is mainly about the mechanism of CO2 adsorption and desorption in coal seam21. The coal resource in Huainan and Huaibei coalfields account for 97.7% of the total resources in the province, and the distribution is concentrated22,23,24. Therefore, the Huainan coalfield is determined as the estimation coalfield for CO2 storage in this study. Due to the limitation of technical and geological conditions, the buried depth of coal mining in Anhui province is limited to less than 1000 m at present stage, and the coal seam with 1000–2000 m is the resource amount, which will be exploited in the next stage, and belongs to the deep unworkable seam at the present stage16, that is, the geological reserves with burial depth of 1000–2000 m are used to estimate the CO2 storage potential in Anhui province.

In this study, the deep unworkable seam in Huainan coalfield was taken as the research object. Firstly, the evaluation method of CO2 storage potential in deep unworkable seam was discussed. Secondly, the CO2 geological storage potential was analyzed. Then, based on the lowest cost objective function and improved mileage saving method, the matching research of CO2 source and sink for CO2 geological storage was carried out, and the pipe network design was optimized. Finally, from the perspective of time and space scale, suggestions on the design of network planning of CCS source and sink are put forward in Huainan coalfield. The research innovations are described as follows: (1) Evaluation method of CO2 storage potential in deep unworkable seam is discussed; (2) Matching problem of CO2 source and sink is studied, and its pipe network design is optimized; (3) Design idea of network planning of CCS source and sink is systematically proposed. The results can provide reference for the evaluation of CO2 sequestration potential of coal bases in China, and lay a foundation for CCUS cluster deployment.

Geological setting and analysis method

Geological background of the study area

Based on regional structural analysis, the Huainan coalfield is located at the southern margin of North China Plate. In the west–east direction, the coal field boundary lies between the Kouziji-Nanzhaoji faults and the Xinchengkou-Changfeng faults. From north to south, the coalfield boundary lies between the Shangtangming-Longshan faults and Yingshang-Dingyuan faults (Fig. 1)25,26. The coalfield is a near east–west hedge tectonic basin with imbricate fan composed of nappe structures on both sides of the basin and simple synclinic structure in the interior (Fig. 1).

The coal-bearing strata are Taiyuan formation of upper Carboniferous series, Shanxi formation and Xiashihezi formation of lower Permian series, and Shangshihezi formation of upper Permian series, with a total thickness of about 900 m and about 40 layers of coal seams27,28. In the coal-bearing strata, there are 9–18 coal layers with a single layer thickness greater than 0.7 m on average, the maximum thickness is 12 m, and the total thickness is 23–36 m, which are distributed in Shanxi formation, Xiashihezi formation and lower part of Shangshihezi formation. In this study, the CO2 emission sources were 10 coal-fired power plants in the coalfield with numbered D1-D10, respectively. Deep unworkable seams are CO2 storage sinks, which are bounded by faults and numbered B1-B15, respectively (Fig. 1).

Evaluation method of CO2 geological storage potential

In deep unworkable seam, CO2 geological storage is mainly in adsorbed, dissolved and free states29, and adsorption storage is the main storage form of coal seam30. Considering the storage differences of different phase of CO2, the following potential assessment model of CO2 storage can be adopted16,31:

where \(M_{{{\text{CO}}_{2} }}\) is CO2 storage capacity, t; ρCO2 is the CO2 density, kg/m3; Mcoal is proved coal reserves, t; mab, md and mf are the stored quantity of CO2 adsorbed, dissolved and free states in coal per unit mass, m3/t.

In the unit mass coal, the storage potential of CO2 adsorbed state in deep unworkable seam can be characterized by the following formula16,31:

where P is the reservoir pressure, which is also CO2 adsorption pressure, MPa; Tc is CO2 critical temperature, K; Z is the CO2 compression coefficient; pc is CO2 critical pressure, MPa; T is the reservoir temperature, which also CO2 adsorption temperature, K; and mex is the CO2 excess adsorption amount per unit mass of coal, m3/t, which can be calculated using the following D-R adsorption model16,31:

where m0 is the maximum CO2 adsorption capacity of coal per unit mass tested by adsorption experiment, m3/t; ρf and ρa are the densities of free and adsorbed CO2 under the real temperature and pressure conditions, kg/m3; D is the adsorption constant, and k is the constant associated with Henry's Law.

In coal reservoir, CO2 density is a function of pressure and temperature, which can be expressed as ρf = f(p, T), and can be further characterized as follows16,31,32:

where δ = ρc/ρf is the CO2 reduced density; ρc is the CO2 critical density, kg/m3; τ = Tc/T is the reduced temperature; and ϕ(δ,τ) is the Helmholtz free energy, which can be controlled by temperature and density16,31,32:

where ϕo(δ, τ) is the Helmholtz free energy of ideal fluid, and ϕr(δ, τ) is the Helmholtz free energy of the residual fluid.

In deep unworkable seam, the storage potential of dissolved CO2 per unit mass of coal is a function of coal porosity, water saturation, coal density and CO2 solubility, which can be characterized as follows16,31:

where φ is the coal porosity, %; Sw is the water saturation, %; \(S_{{{\text{CO}}_{2} }}\) is the CO2 solubility, and ρcoal is the coal density, kg/m3.

According to Boyle-Mariotte law, the free CO2 storage potential per unit mass of coal in deep unworkable seam can be characterized as follows16,31:

where Sg is the gas saturation, %; P0 is the standard atmospheric pressure, MPa; T0 is the temperature under the standard condition, K; and ρvisual is the coal apparent density, kg/m3.

Construction of matching model of CO2 source-sink

CO2 source and sink matching

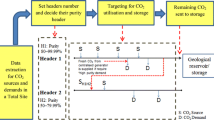

CO2 source-sink matching is the basis of CCUS cluster deployment and its pipe network design and construction, with the goal of minimizing CO2 transportation cost and maximizing carbon removal. Its essence is the optimization planning of CCUS cluster system33,34. Based on CO2 emission source, storage sink, storage geological process, transport network connecting source and sink and corresponding parameter data, the dynamic optimal matching between CO2 source and sink can be achieved in terms of target quantity, continuity and economic efficiency (Fig. 2).

The matching of CO2 source and sink is mainly based on the characteristics of large number, different types and scattered locations of CO2 emission sources (i.e., thermal power, steel, cement, chemical industry, etc.) and storage sinks (i.e., saltwater layer, CO2-ECBM, CO2-EOR, MCO2-ILU, CO2-SDR, etc.). Based on the discussion of constraint conditions and determination of objective function, the influence of regional geographical conditions, traffic, population density, transportation cost and transportation mode on CO2 transport between emission sources and storage sinks is fully considered in the CCUS system. The optimal matching of CO2 emission sources, storage sinks and transportation parameters was realized, so as to determine scientific and reasonable CO2 source and sink matching schemes (Fig. 2).

Objective functions

Based on the theory of network analysis in operations research, theoretical models of CO2 source-sink matching within CCUS technology can be constructed in Huainan coalfield by using the minimum support tree method. The construction of theoretical models should meet the following basic assumptions: (1) Source and sink with the lowest cost should be firstly matched; (2) Allow the matching of one source with multi sinks or one sink with multi sources; (3) Sequestration sink must meet the requirement of CCUS planning period.

In this study, the lowest total cost of matching of CO2 source-sink in CCS technology is taken as the objective function, namely:

where i refers to the ith CO2 source; j means the jth CO2 sink; m indicates the number of CO2 sources and the value is 10, and n indicates the number of CO2 sinks with the value of 15.

-

(1)

CO2 capture cost (i.e., CC)

Based on the analysis of the industrial sources report published by the National Energy Technology Laboratory of the United States, the average capture cost of CO2 source in coal-fired power plants is $ 64.35 /t30,35. Therefore, the capture cost of CO2 source in Huainan coalfield can be characterized as follows:

$$C_{C} = \sum\limits_{i = 1}^{m} {\sum\limits_{j = 1}^{n} {\omega_{ij} X_{ij} } }$$(9)where\(\omega_{ij}\) represents the CO2 capture cost in the i coal-fired power plant, $/t; and Xij represents CO2 transport amount from the i coal-fired power plant to the j sequestration sink, t.

-

(2)

CO2 transportation cost (i.e., CT)

CO2 transport is most common by pipeline, ship and tanker, and pipeline transportation is suitable for directional transportation with large capacity, long distance and stable load, which mainly includes construction cost and operation and maintenance cost. The operation and maintenance cost accounts for about 1.5% of the construction cost35, which can be calculated according to formula 10 and 11, respectively.

$$C_{T - j} = 9970 \times \sum\limits_{i = 1}^{m} {\sum\limits_{j = 1}^{n} {L^{1.13} X_{ij}^{0.35} } }$$(10)where L is the distance of pipeline transportation, km.

$$C_{T - y} = 0.015N \times 9970 \times \sum\limits_{i = 1}^{m} {\sum\limits_{j = 1}^{n} {L^{1.13} X_{ij}^{0.35} } }$$(11)where N represents the transportation cycle of the pipeline, year.

Therefore, CO2 transport cost can be characterized as follows:

$$C_{T} = (1 + 0.015N) \times 9970 \times \sum\limits_{i = 1}^{m} {\sum\limits_{j = 1}^{n} {L^{1.13} X_{ij}^{0.35} } }$$(12) -

(3)

CO2 sequestration cost (i.e., CS)

The cost of CO2 geological storage is closely related to the amount of CO2 storage and the type of storage site, and the average storage cost coefficient is $ 5.59 /t30,35. Therefore, the cost of CO2 geological storage in coal reservoir can be characterized as follows:

$$C_{S} = \sum\limits_{i = 1}^{m} {\sum\limits_{j = 1}^{n} {\varepsilon_{ij} X_{ij} } }$$(13)where\(\varepsilon_{ij}\) is the sequestration cost factor of transporting CO2 from coal-fired power plant i to sequestration sink j, $/t.

In summary, by substituting formulas (9), (12) and (13) into formula (8), the minimum objective function of total cost of CO2 source-sink matching in CCS technology can be obtained:

Constraint conditions

Based on the basic assumptions of theoretical model, in the planning process of matching pipe network of CO2 source-sink with CCS technology, the constraint conditions of the lowest total cost objective function are as follows:

-

(1)

The total amount of CO2 captured from all CO2 emission sources is equal to the total amount of pipeline transport, that is:

$$a_{i} = \sum\limits_{j = 1}^{n} {X_{ij} }$$(15)where ai is the CO2 capture amount of the ith coal-fired power plant.

-

(2)

The CO2 content transported by the pipeline to the storage site shall not exceed the storage capacity of the storage sink, that is:

$$b_{j} \ge \sum\limits_{i = 1}^{m} {X_{ij} }$$(16)where bj is the storage capacity of the jth storage sink.

-

(3)

The amount of CO2 captured in all coal-fired power plants must not exceed the total capacity of all potential sequestration sinks, that is:

$$\sum\limits_{i = 1}^{m} {a_{i} } \le \sum\limits_{j = 1}^{n} {b_{j} }$$(17) -

(4)

Non-negative constraint: the pipeline of CO2 transport content is non-negative, that is:

$$X_{ij} > 0$$(18)

Optimization of matching pipe network of CO2 source-sink

The core idea of the mileage saving algorithm is to merge two transportation loops into one loop to reduce the transportation distance in the merging process, and keep cycling until the limit condition is reached, thus reducing the transportation cost. Specifically, three points, A, B and C, transport goods from A to B and C, where the distance from A to B is LAB (unit: km), the distance from A to C is LAC (unit: km), and the distance from B to C is LBC (unit: km), if the transportation from A to B and A to C is separately completed, the transportation distance is 2 × (LAB + LAC) with including the round trip process (Fig. 3a). If from A to B, then from B to C, and finally from C back to A, then the transport distance is LAB + LAC + LBC (Fig. 3a), then the distance saved is 2 × (LAB + LAC) − (LAB + LAC + LBC) = LAB + LAC − LBC > 0.

In CO2 source-sink matching, each sink is taken as the distribution center and distributed with the connected source points. The basic principle is similar to the mileage saving method, except that there is only a transportation network from the source to the sink, and there is no return pipeline. Based on this, the idea of mileage saving method is introduced in this study, and it is improved to meet the needs of CO2 source-sink matching and transportation network optimization. As shown in Fig. 3b, the CO2 emitted from points B and C is transported to the storage sink A for storage. The most direct way is from B to A, and then from C to A, with a transport distance of LAB + LAC (Fig. 3b). If it is transported from B to C and then from C to A or from C to B and then from B to A (Fig. 3b), the transport distance is LAC + LBC or LAB + LBC. LAB and LAC need to be compared to choose a route with a smaller distance for connection. If LBC < LAB/LAC, then LAB (LAC) − LBC is the savings; if LBC > LAB/LAC, then LAB/LAC − LBC is negative, which means no savings (Fig. 3b).

Results

CO2 source and sink characteristics

Characteristics of CO2 sources

In Huainan coalfield, CO2 emission sources are 10 coal-fired power plants within the coalfield, of which 9 have been put into operation, 1 has finished commissioning and plans to put into operation. According to the “Greenhouse Gas Emission Accounting Methods and Reporting Guidelines for Chinese Power Generation Enterprises (Trial)” and related methods, the carbon emission intensity of the coal-fired power plants was calculated, and on this basis, the average annual CO2 emissions of each coal-fired power plant were estimated. The installed capacity of China's coal-fired power plants is mainly 300 WM, 600 WM and 1000 WM, and the CO2 emission intensity of which is 0.845 t/MW/h, 0.807 t/MW/h and 0.768 t/MW/h, respectively, and in this study, the mean value is taken as the basis for estimation36,37. Based on the average annual power generation statistics of each power plant, the average annual CO2 emissions of each coal-fired power plant can be analyzed (Table 1).

As can be seen from Table 1, the average annual CO2 emissions of coal-fired power plants vary greatly with ranging from 0.36 million tons to 17.12 million tons. Among them, the average annual CO2 emissions of D7 power plant reach 17.12 million tons, accounting for about 30% of the total annual CO2 emissions. The total annual CO2 emissions of all coal-fired power plants are 58.76 million tons, which includes 5.28 million tons of emissions from the proposed D6 power plant (Table 1).

Assessment of CO2 sink

The core parameters of potential assessment of CO2 geological storage are mainly derived from engineering data, test data, experimental data and scientific research papers (Table 2)16,31,38,39. In this study, for deep unworkable seam in Huainan coalfield, the proved reserves with burial depth ≤ 1500 m are obtained from coal exploration, and the proved reserves with burial depth > 1500 m are predicted reserves by the resource management department. The geothermal gradient is 3.10 °C/100 m. When the depth of coal seam is less than 1000 m, the pressure gradient is 0.95 MPa/100 m. When the depth of coal seam is more than 1000 m, the pressure gradient is 1.08 MPa/100 m16,31. The core parameters of CO2 geological storage potential assessment can be detailed in Table 216,31,38,39.

The CO2 geological storage potential of deep unworkable seam in Huainan coalfield is huge, and the total amount is 762 million tons. The adsorbed, free and dissolved CO2 can be stored 685 million tons, 53 million tons and 24 million tons, respectively. The CO2 geological storage with adsorbed state in deep unworkable seam is the most dominant, accounting for 89.895% of the total storage. When the buried depth of coal seam is ≤ 1500 m and > 1500 m, the total CO2 geological storage is 253 million tons and 510 million tons, with accounting for 33.17% and 66.83% of the total storage, respectively. Regardless of the state in which CO2 is stored, the total amount of CO2 stored when the buried depth is greater than 1500 m is greater than that under the same state when the buried depth is less than 1500 m (Table 3).

When the buried depth of coal seam is > 1500 m and ≤ 1500 m, the proved coal reserves are 4.03 billion tons and 1.99 billion tons, respectively, with a ratio of 2.025. For the total amount of CO2 geologic storage and its adsorption, free and dissolved state, the ratio of coal seam buried depth > 1500 m and ≤ 1500 m is 2.016, 1.996, 2.312 and 2.000, respectively. The main reason why the ratio of total CO2 geological storage and total adsorption state is lower than 2.025 is that although the CO2 geological storage potential of deep unworkable seam is positively correlated with the proved coal reserves, the maximum CO2 adsorption capacity at the depth ≤ 1500 m is much higher than that at the depth > 1500 m. With the increase of burial depth, the reservoir pressure gradually increases, and the CO2 storage potential in free state in pore structure gradually increases, which will make the free CO2 ratio far greater than 2.025.

Matching characteristics of CO2 source-sink

Plane distribution characteristics of CO2 sinks

The total CO2 storage potential of deep unworkable seam in Huainan coalfield is 762 million tons (Table 3). For the average annual CO2 emissions of the 10 coal-fired power plants, it can be stored for 12.97 years. The deep unworkable seam is the most potential body for CO2 storage in Huainan coalfield. The unrecoverable coal seam with buried depth ≤ 1500 m can meet the CO2 geological storage requirements of coal-fired power plants for 4.31 years. Considering the technical challenges and implementation costs of CO2 storage in coal seam with different burial depths, the unworkable coal seam with burial depths ≤ 1500 m should be the main target reservoir for the implementation of CO2-ECBM technology in the next five years.

With fault structure as the boundary, the deep unworkable seam can be divided into 15 CO2 storage blocks, and the comparative analysis of the plane distribution of CO2 storage sinks can be carried out according to the plane area size (Fig. 4). The main blocks of CO2 geological storage are B9, B12, B8 and B5, and their sealable stocks are 124 million tons, 114 million tons, 97 million tons and 85 million tons, respectively, among which the largest two blocks, B9 and B12, can store the CO2 emissions of 10 coal-fired power plants for nearly four years. The four blocks with larger area are also the main blocks of the CO2 source-sink matching.

Matching characteristics of CO2 source-sink

According to the preliminary potential assessment analysis, for the average annual CO2 emissions of the 10 coal-fired power plants in Huainan coalfield, the deep unworkable seam can be stored for 12.97 years. Therefore, in this study, the matching study of CO2 source-sink was conducted based on the cumulative CO2 emissions of 10 coal-fired power plants in Huainan coalfield in 10 years for deep unworkable seam (Fig. 5).

Based on the matching results of CO2 source and sink during the 10-year cycle in Huainan coalfield, it can be seen that the coal-fired power plant of D1 can be mainly stored in blocks of B2, B3, B4 and B7, with the stored stocks of 20.2 million tons, 19.7 million tons, 30.9 million tons and 10.8 million tons, respectively. Coal-power plant of D2 is mainly stored in block of B5, and the stored stock is 3.6 million tons. The coal-power plant of D3 is mainly stored in blocks of B7 and B10, with a stored stock of 25.8 million tons and 51 million tons, respectively. Coal-fired power plant of D4 is mainly stored in blocks of B8 and B9, with a storage capacity of 10.9 million tons and 12.3 million tons, respectively. Coal-fired power plant of D5 is mainly stored in block of B9, with a stored stock of 58.9 million tons. Coal-fired power plant of D6 is mainly stored in block of B9, and the stored stock is 52.8 million tons. Coal-fired power plant of D7 is mainly stored in blocks of B8, B12 and B14, with stored stocks of 61.1 million tons, 58.3 million tons and 51.8 million tons, respectively. Coal-fired power plant of D8 is mainly stored in block B8, with a stored stock of 15.5 million tons. Coal-fired power plant of D9 is mainly stored in block of B13, and the stored stock is 48.2 million tons. The coal-fired power plant of D10 is mainly stored in block of B12, with a stored stock of 56.0 million tons (Fig. 5). During the 10-year cycle, the CO2 in deep unworkable seam can be stored up to 587.6 million tons, and the cumulative planned pipeline is 251.61 km, which will require a cumulative capital of $ 4.26 × 1010.

Discussions

Optimization of matching pipe network of CO2 source-sink

Analysis of matching pipe network of CO2 source-sink

Based on the analysis of matching pipe network of CO2 source-sink in deep unworkable seam, it can be seen that the transportation routes of pipelines of 9, 4, 16, 5 and 8 are relatively long, which accounts for 53.65% of the total transportation route length (Fig. 6). Because the transportation cost is proportional to the route, it is important to optimize the line length of pipelines of 9, 4, 16, 5 and 8 to reduce the total cost.

Based on the analysis of CO2 storage and transport costs and their proportion in deep unworkable seam, it can be seen that the transport costs of blocks of 8, 7, 12 and 13 are the highest, which accounts for 36.96%, 14.01%, 11.60% and 11.86% of the total CO2 storage and transport costs, respectively. The transportation cost of four CO2 storage sinks accounted for 74.43% of the total cost. Therefore, blocks of 8, 7, 12 and 13 of deep unworkable seam will be the focus of optimization of matching pipe network of CO2 source-sink. Blocks of 1, 6, 11 and 15 do not need to bear CO2 geological storage for the time being, which can be used as alternative blocks for CO2 storage (Figs. 5 and 7).

Optimization of matching pipe network of CO2 source-sink

Based on the improved mileage saving method, the optimization results of matching pipe network of CO2 source-sink in deep unworkable seam can be obtained (Fig. 8).The unchanged pipe network paths are D1–B4, D1–B7, D3–B10, D4–B8, D4–B9 and D7–B13 (Fig. 8), and the routes among other source-sink take the minimum total transportation cost as the objective function, and the pipe network optimization is carried out according to the constraints of the emission source and the storage capacity (Fig. 8).

Based on the optimization results of matching pipe network of CO2 source-sink in Huainan coalfield, it can be seen that the accumulated mileage saved is 98.75 km, and the accumulated cost saved is $ 25.669 billion, which accounts for 39.25% and 60.26% of the total mileage and cost of pipeline, respectively (Table 4). Among them, the mileage and cost savings of 13 and 14 blocks in deep unworkable seam are more obvious, which accounts for 10.43% and 10.10% of the total mileage and 16.20% and 16.01% of the total cost, respectively (Table 4).

Planning and design of matching pipe network of CO2 source-sink

Pipeline network planning on a time scale

By analyzing the optimization results of matching pipe network of CO2 source-sink in Huainan coalfield and the amount of CO2 transported by each pipe network line, it can be seen that the entire pipe network is centrally distributed in the east and west regions, and it is obvious that the transport amount of the eastern pipe network is significantly greater than that of the western one (Fig. 9). The thicker the lines of the route, the greater the traffic amount (Fig. 9). The planning and design of matching pipe network of CO2 source-sink should refer to the thickness of the transportation line, that is, the amount of CO2 transported (Figs. 10, 11, 12). The planning and design of matching pipe network of CO2 source-sink in Huainan coalfield is proposed in accordance with three steps:

First step: It is recommended to preferentially plan the pipeline route of D9–D8–D7–B12–D6–D4–B8 in the eastern region, and the D3–B10 and D1–B4 in the western region. This planned pipeline can effectively connect the coal-fired power plants of D9, D8, D7, D6 and D4, and unworkable blocks of B12, B8, B10 and B4 of Huainan coalfield (Fig. 10). At this step, the total amount of CO2 that can be transported by the pipeline network is 6.65 billion tons, and the total amount of CO2 that can be stored is 2.27 billion tons, which accounts for 56.99% and 38.74% of the total transportation and storage stock of CO2, respectively.

Second step: It is recommended to further plan the pipeline lines of D10–D9, D7–B13, D7–B14, D4–B9, D5–B9, B10–B7, and B4–B3–B2, which can further effectively connect the deep unworkable seam in the east, middle and west areas (Fig. 11). After the pipeline network planning at this step, the total amount of CO2 transported can be 10.345 billion tons, and the total amount of CO2 stored can be 5.84 billion tons, which accounts for 88.66% and 99.39% of the total CO2 transport and storage, respectively.

Third step: Complete the design of all remaining pipelines to connect the deep unworkable seam in the east and west of the study area. It is suggested to add the design of B3 and B4 pipelines, so as to run through all CO2 emission sources and CO2 storage sinks in Huainan coalfield, so as to realize all CO2 transportation and geological storage (Fig. 12).

Pipeline network planning at the spatial scale

In this study, the location of each point in deep unworkable seam is determined by taking the center location of each region (Fig. 1), but in the actual well location layout, the regional center location is often not the only consideration. Therefore, the analysis of the type of CCS pipeline within each region and the planning of CCS pipeline network between each region are very important (Fig. 13).

According to the location and use of CO2 pipelines in the pipe network, CO2 pipelines can be defined as the following four types (Fig. 13): (1) Gas collection branch, that is, the pipeline that communicates CO2 source and transfer point, and the transport phase is determined according to its economy; (2) Distribution branch, that is, the pipeline from the end of the communication pipeline to the carbon sequestration point; (3) Intra-regional trunk lines, that is, trunk pipelines from the transfer point to the carbon sequestration point in the region; (4) Interregional trunk lines, that is, shared pipelines connecting regions. As far as Huainan coalfield is concerned, in terms of spatial scale, priority should be given to planning intra-regional pipe networks in various regions within unworkable seam bounded by faults, that is, the pipe networks in various regions within B1–B15 (Fig. 13).

Whether it is a small area of Huainan coalfield or the whole large area of China, the CCS pipe network layout should follow the following ideas. First of all, small-scale carbon sources in the region should be transferred to main pipelines through gas collection branch lines, and commercial CO2 pipeline demonstration projects can be built. Secondly, the collection and distribution pipelines of regional carbon sources can be planned within the basin to form a backbone sharing pipeline, and a variety of CCS carbon sequestration applications can be simultaneously carried out to build an interregional transport network demonstration. Then, for areas that do not have the conditions for storage, inter-regional trunk pipelines should be built to gradually form a cross-regional carbon network on land to fully meet the matching transport of source and sink. Offshore CO2 storage resources should be developed, suitable coastal injection points should be selected, marine transport pipelines and ship transport should be simultaneously carried out, and integrated business models of transport and storage based on land and sea should be built (Fig. 13).

Conclusions

In this study, the deep unworkable seam in Huainan coalfield was taken as the research object. Firstly, the evaluation method of CO2 storage potential in deep unworkable seam was discussed. Secondly, the CO2 geological storage potential was analyzed. Then, the matching research of CO2 source and sink for CO2 geological storage was carried out, and the pipe network design was optimized. Finally, suggestions on the design of network planning of CCS source and sink are put forward in Huainan coalfield. The main conclusions are as follows:

-

(1)

The total annual CO2 emissions of each coal-fired power plant are 58.76 million tons, and the average annual CO2 emissions of each coal-fired power plant vary greatly with ranging from 0.356 million tons to 17.12 million tons. The CO2 geological storage potential of deep unworkable seam is huge, and the total amount is 762 million tons. It can store 685 million tons, 53 million tons and 24 million tons of CO2 in adsorbed, free and dissolved states, respectively. For the average annual CO2 emissions of coal-fired power plants, deep unworkable seam can be stored for 12.97 years. During the 10-year period, the deep unworkable coal seam can store 587.6 million tons, and the cumulative planning pipeline is 251.61 km, requiring a cumulative capital of $ 4.26 × 1010.

-

(2)

The main blocks of CO2 geological storage are B9, B12, B8 and B5, with stored stocks of 124 million tons, 114 million tons, 97 million tons and 85 million tons, respectively. The matching of CO2 source and sink saved 98.75 km, and saved $ 25.67 billion, accounting for 39.25% and 60.26% of the total mileage and cost, respectively. The mileage and cost savings in 13 and 14 blocks are more obvious, which accounts for 10.43%, 10.10% and 16.20% and 16.01% of the total mileage and cost, respectively.

-

(3)

Based on the three-step approach, the whole line of CO2 emission sources and CO2 storage sinks in Huainan coalfield can be completed by stages and regions, and all CO2 transportation and storage can be realized. CO2 pipelines include gas collection branch lines, gas distribution branch lines, intra-regional trunk lines, and interregional trunk lines. Based on the reasonable layout of various types of CO2 pipelines, a variety of CCS carbon sequestration applications can be simultaneously carried out, the intra-regional and inter-regional network demonstration for CO2 transport can be built, and integrated business models of CO2 transport and storage can be built simultaneously on land and sea.

Data availability

All data generated or analysed during this study are included in this published article (Please refer to the manuscript that has been uploaded).

References

Kong, H. et al. The development path of direct coal liquefaction system under carbon neutrality target: Coupling green hydrogen or CCUS technology. Appl. Enegry 347, 121451 (2023).

Wang, X. et al. Research on CCUS business model and policy incentives for coal-fired power plants in China. Int. J. Greenh. Gas Control 125, 103871 (2023).

Wang, F. et al. Carbon emission reduction accounting method for a CCUS-EOR project. Pet. Explor. Dev. 50(4), 989–1000 (2023).

Han, J. et al. Coal-fired power plant CCUS project comprehensive benefit evaluation and forecasting model study. J. Clean. Prod. 385, 135657 (2022).

Fan, J. et al. Modelling plant-level abatement costs and effects of incentive policies for coal-fired power generation retrofitted with CCUS. Energ Policy 165, 112959 (2022).

Xu, S. et al. Repowering coal power in China by nuclear energy-implementation strategy and potential. Energies 15(3), 1072 (2022).

Tian, Y. et al. Evolution dynamic of intelligent construction strategy of coal mine enterprises in China. Heliyon 8(10), e10933 (2022).

Zhan, J. et al. Suitability evaluation of CO2 geological sequestration based on unascertained measurement. Arab. J. Sci. Eng. 47(9), 11453–11467 (2022).

Hou, L. et al. Self-sealing of caprocks during CO2 geological sequestration. Energy 252, 124064 (2022).

Sun, L. & Chen, W. Impact of carbon tax on CCUS source-sink matching: Finding from the improved China CCS DSS. J. Clean Prod. 333, 130027 (2022).

Fan, J. et al. Near-term CO2 storage potential for coal-fired power plants in China: A county-level source-sink matching assessment. Appl. Energy 279, 115878 (2020).

Li, Y. et al. Grading evaluation and ranking of CO2 sequestration capacity in place (CSCIP) in China’s major oil basins: Theoretical, effective, practical and CCUS-EOR. ACTA Geol. Sin.-Engl. 97(3), 873–888 (2023).

Ming, X. et al. Thin-film dawsonite in Jurassic coal measure strata of the Yaojie coalfield, Minhe Basin, China: A natural analogue for mineral carbon storage in wet supercritical CO2. Int. J. Coal Geol. 180, 83–99 (2017).

Fan, J. et al. Carbon reduction potential of China’s coal-fired power plants based on a CCUS source-sink matching model. Resour. Conserv. Recycl. 168, 105320 (2021).

Liu, S. et al. Emission reduction path for coal-based enterprises via carbon capture, geological utilization, and storage: China energy group. Energy 273, 127222 (2023).

Liu, S. et al. Evaluation of carbon dioxide geological sequestration potential in coal mining area. Int. J. Greenh. Gas. Control 122, 103814 (2023).

Wang, F. et al. Mechanism of supercritical CO2 on the chemical structure and composition of high-rank coals with different damage degrees. Fuel 344, 128027 (2023).

Omotilewa, O. et al. Evaluation of enhanced coalbed methane recovery and carbon dioxide sequestration potential in high volatile bituminous coal. Gas Sci. Eng. 91, 103979 (2021).

Liu, X. et al. Mechanistic insight into the optimal recovery efficiency of CBM in sub-bituminous coal through molecular simulation. Fuel 266, 117137 (2020).

Li, Y. et al. Variation in permeability during CO2-CH4 displacement in coal seams: Part 1-Experimental insights. Fuel 263, 116666 (2020).

Li, J. et al. Simulation of adsorption-desorption behavior in coal seam gas reservoirs at the molecular level: A comprehensive review. Energy Fuel 34(3), 2619–2642 (2020).

Hou, H. et al. Pore structure characterization of middle- and high-ranked coal reservoirs in northern China. AAPG Bull. 107(2), 213–241 (2023).

Liu, H. et al. Insight into difference in high-pressure adsorption-desorption of CO2 and CH4 from low permeability coal seam of Huainan-Huaibei coalfield, China. J. Environ. Chem. Eng. 16(6), 108846 (2022).

Yu, K. et al. Influence of sedimentary environment on the brittleness of coal-bearing shale: Evidence from geochemistry and micropetrology. J. Petrol. Sci. Eng. 185, 106603 (2020).

Wang, G. et al. Pore structure characteristics of coal-bearing shale using fluid invasion methods: A case study in the Huainan-Huaibei Coalfield in China. Mar. Pet. Geol. 62, 1–13 (2015).

Fang, H. et al. Numerical analysis of permeability rebound and recovery evolution with THM multi-physical field models during CBM extraction in crushed soft coal with low permeability and its indicative significance to CO2 geological sequestration. Energy 262, 125395 (2023).

Xiong, S., Lu, J. & Qin, Y. Prediction of coal-bearing strata characteristics using multi-component seismic data-a case study of Guqiao coalmine in China. Arab. J. Geosci. 11(15), 408 (2018).

Zhang, K. et al. Experimental study on the influence of effective stress on the adsorption-desorption behavior of tectonically deformed coal compared with primary undeformed coal in Huainan coalfield, China[J]. Energies 15(18), 6501 (2022).

Wang, M. et al. Current research into the use of supercritical CO2 technology in shale gas exploitation. Int. J. Min. Sci. Technol. 29(5), 739–744 (2019).

Zhu, Q. et al. Optimal matching between CO2 sources in Jiangsu province and sinks in Subei-Southern South Yellow Sea basin, China. Greenh. Gase 9(1), 95–105 (2019).

Xu, H. et al. CO2 storage capacity of anthracite coal in deep burial depth conditions and its potential uncertainty analysis: A case study of the No. 3 coal seam in the Zhengzhuang Block in Qinshui Basin, China. Geosci. J. 25(5), 715–729 (2021).

Span, R. & Wagner, W. A new equation of state for Carbon dioxide covering the fluid region from the triple—point temperature to 1100 K at pressures up to 800 MPa. J. Phys. Chem. Ref. Data 25(6), 1509–1596 (1996).

Wang, J. Optimal Design of CCUS Source Sink Matching Pipe Network for Coal Fired Power Plants in North China (Chengdu University of Technology, Chengdu, 2021).

Sang, S. et al. Research progress on technical basis of synergy between CO2 geological storage potential and energy resources. J. China Coal Soc. 48(7), 2700–2716 (2023) (in Chinese with English abstract).

Mo, H., Liu, S. & Sang, S. Matching of CO2 geological sequestration source and sink for industrial fixed emission source in Subei-Southern Yellow Sea Basin. Geol. Rev. 69(S1), 128–130 (2023) (in Chinese with English abstract).

Liu, M. et al. Assessing the cost reduction potential of CCUS cluster projects of coal-fired plants in Guangdong province in China. Front. Earth Sci. 17(3), 844–855 (2023).

Kong, H. et al. The development path of direct coal liquefaction system under carbon neutrality target: Coupling green hydrogen or CCUS technology. Appl. Energy 347, 121451 (2023).

Huang, D., Hou, X. & Wu, Y. The mechanism and capacity evaluation on CO2 sequestration in antiquated coal mine gob. Environ. Eng. 32(S1), 1076–1080 (2014) (in Chinese with English abstract).

Sun, W., Zhang, E. & Wu, H. An analysis of production potential of residual CBM in Huainan mining area. Coal Geol. China 22(12), 24–28 (2010) (in Chinese with English abstract).

Acknowledgements

We would like to express our gratitude to the anonymous reviewers for offering their constructive suggestions and comments which improved this manuscript in many aspects. This work was financially supported by the Natural Science Research Project of Anhui Educational Committee (2023AH040154), the Anhui Provincial Natural Science Foundation (2308085Y30), the Anhui Provincial Key Research and Development Project (2023z04020001), the National Natural Science Foundation of China (No. 42102217; 42277483), and the University Synergy Innovation Program of Anhui Province (No. GXXT-2021-018).

Author information

Authors and Affiliations

Contributions

H.F. and S.S.: The conception and design of the study, revising it critically for important intellectual content, final approval of the version to be submitted. H.F. and Y.W.: Drafting the article. J.G. and H.L.: Drawing of all figures. H.F. and Z.W.: Collection and analysis of the field data. S.Y.: Derivation of mathematical models.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Fang, H., Wang, Y., Sang, S. et al. Potential assessment of CO2 source/sink and its matching research during CCS process of deep unworkable seam. Sci Rep 14, 17206 (2024). https://doi.org/10.1038/s41598-024-67968-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-67968-w

- Springer Nature Limited