Abstract

This study aims to optimize and evaluate drug release kinetics of Modified-Release (MR) solid dosage form of Quetiapine Fumarate MR tablets by using the Artificial Neural Networks (ANNs). In training the neural network, the drug contents of Quetiapine Fumarate MR tablet such as Sodium Citrate, Eudragit® L100 55, Eudragit® L30 D55, Lactose Monohydrate, Dicalcium Phosphate (DCP), and Glyceryl Behenate were used as variable input data and Drug Substance Quetiapine Fumarate, Triethyl Citrate, and Magnesium Stearate were used as constant input data for the formulation of the tablet. The in-vitro dissolution profiles of Quetiapine Fumarate MR tablets at ten different time points were used as a target data. Several layers together build the neural network by connecting the input data with the output data via weights, these weights show importance of input nodes. The training process optimises the weights of the drug product excipients to achieve the desired drug release through the simulation process in MATLAB software. The percentage drug release of predicted formulation matched with the manufactured formulation using the similarity factor (f2), which evaluates network efficiency. The ANNs have enormous potential for rapidly optimizing pharmaceutical formulations with desirable performance characteristics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Drug release and dissolution are critical for the dosage forms like tablets, capsules, creams, ointments, and implants1. Modified-release (MR) dosage forms are designed to release the drug gradually and steadily over the prescribed duration, and ensures that the medication remains effective over a prolonged period, without causing any adverse effects or sudden spikes in the drug concentration in the body2,3. Several process and formulation variables are involved in the drug development process; the best combination of ingredients is found by using the multivariate optimization method4. The pharmaceutical industry is concentrating on developing new technologies for oral drugs at low-cost and at the minimal amount of time5. Currently, Pharmaceutical formulation development relies on trial-and-error techniques; the discovery, development and maintenance of this process require a lot of time, money, and labour6,7. However, with the right approach and resources, it is possible to streamline this process and make it more efficient. Reducing healthcare costs and increasing production of Active Pharmaceutical Ingredients (APIs) can be quite challenging for the pharmaceutical industry. To develop successful strategies for manufacturing the new drug product, the industry must determine the ideal formulations. Traditional methods such as Response Surface Method (RSM), Composite Experimental Design (CED). Shows challenges in the modelling of these interactions8. One of the challenges in modelling the drug formulation is understanding the relationships between process variables and unique pharmacological responses9. Pharmaceutical experts may develop crucial features of novel medications, such as higher absorption and controlled administration, through the formulation of drug compositions10. The drug release kinetics can be compared using the range of mathematical models including zero-order, first-order, Higuchi model, Hixson Crowell, quadratic, and Weibull models.11,12,13.

Sutariya et al.14 studied the benefits of ANNs in pharmaceutical research. ANNs ability to predict complex nonlinear interactions and combine experimental and evidence-based data makes them a valuable tool in solving complex problems15. ANNs make predictions, detects trends and, draws decisions on information previously stored in the network. Once trained, the network can predict outcomes for the untested data and gives the best possible result. These makes them ideal for dealing with formulation optimization challenges in the development of drug products16. ANNs used to optimise drug release characteristics by several authors as reported in the literature2,4,17,18,19.

As a universal approximator, Multilayer Perceptron (MLP) can approximate any nonlinear function with arbitrary accuracy when sufficient processing elements are provided. Prediction of drug release profiles can also be assumed as a function approximation problem and it is achieved by the MLP network. The drug components which meet the desired criteria of drug release can be determined using the Feedforward neural network in the MATLAB software20.

This study also compares the drug release characteristics of the predicted formulation of Quetiapine Fumarate MR tablets to the commercially available drugs using a similarity factor (f2). The present research highlights the importance of process and formulation variables in determining percentage drug release. This investigation extends the work on Linear Regression Model which also compares the drug release profiles13. The structure of the paper is as follows: Section "Preliminaries" presents the preliminaries. Section "Methodology" explains the process of ANNs in drug release kinetics with graphical presentation. In Section "Results" optimum excipient concentration of formulation and process variables on drug release profile is achieved by using MATLAB simulation network. Conclusion is discussed in Section "Conclusion".

Preliminaries

Feedforward networks or multilayer preceptor (MLP)

Feedforward networks have one input layer, absent (0) or present (n) hidden layers, and one output layer. In a feedforward network, each neuron in one layer is exclusively directed toward the following layer, referred to as the output layer21. Multilayer network architecture is a special case of feedforward neural network. It consists of three layers: an input layer with vector length k, single or many hidden layers with m number of hidden neurons and an output layer with vector length n. For the development of artificial neural networks and the assessment of their accuracy, data was divided into three categories: training, validation, and test data set. The models were built using data from the training, testing, and validation sets, with 70% of the data belonging to the training set, 15% to the testing set, and 15% to the validation set. Data sets for training, testing, and validation were chosen at random by MATLAB software.

The effectiveness of the created network was evaluated using test datasets. It is essential to note that the test data was not made accessible to the network during training, that is they are the unseen data for the neural network. Figure 1 demonstrates fully connected architecture of a multilayer feedforward neural network with a single hidden layer. The network in Fig. 1 is described as a k-m-n network for simplicity because it consists of k input neurons, single hidden layer with m hidden neurons, and n output neurons.

Similarity factor (f2)

The similarity factor is adopted by USFDA22,23 and, is given by Moore and Flanner in 199624. A similarity factor is a logarithmic reciprocal square root transformation of the sum of squared errors. It compares the percentage dissolution of two curves to determine the similarity of two drug profiles13.

The similarity factor (f2) assumes the value 100 when the fit is perfect, and the value decreases when the profiles become more unsimilar. According to the guideline of FDA, the accepted range of f2 is between 50 and 10013,22,23.

Methodology

To access the drug release profile, ANN was employed as a part of simultaneous optimization method. The most effective drug release profile for the Quetiapine Fumarate MR tablet was found by analysing the similarity factor f2 with that of marketed available drug release profile.

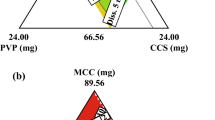

The composition of Sodium Citrate (\({x}_{1}\)), Eudragit® L100 55 (\({x}_{2}\)), Eudragit® L30 D55 (\({x}_{3}\)), Lactose Monohydrate (\({x}_{4}\)), DCP (x5) and Glyceryl Behenate (x6) was used as a formulation variable. Also, Drug Substance Quetiapine Fumarate, Triethyl Citrate and Magnesium Stearate were kept constant at 230.27, 1.5, and 4 respectively in the training of the network. The concentration of each of the drug content is in mg/tab. The drug content in each formulation is presented in Table 1. The tablet weight kept constant at 400 mg for all the formulations. All possible permutations of the formulation variables within the experimental domain were generated by fractional factorial design. For six variables \({x}_{1}\) to \({x}_{6}\), we get \({2}^{6-2}+1={2}^{4}+1=17\) formulations. All the input variables are simultaneously varied in this approach (See Table 1). The flow chart of manufacturing process is as given below (see Fig. 2).

Results

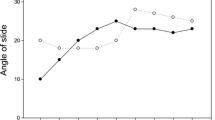

A formulator can better understand how process variables and formulation variables affect modified-release drug formulation by using conventional (statistical) method but it is time consuming method in creating and developing the modified-release drug formulation. This study found that the ANN model exhibited most suitable approach in checking the drug release similarity by optimizing the formulation variables. The results of the dissolution test for the formulations produced using the fractional factorial design is displayed in Fig. 3. These dissolution profiles were utilized for training, testing, and validating the neural network. The simulation network was processed by MATLAB code20. The formulation variable, Sodium Citrate (\({x}_{1}\)), Eudragit® L100 55 (\({x}_{2}\)), Eudragit® L30 D55 (\({x}_{3}\)), Lactose Monohydrate (\({x}_{4}\)), DCP (x5) and Glyceryl Behenate (x6) were used as input variables. The drug release profile at ten different time points were used as output. The dimension of input vector and target vector was 6 by 17 (6 variables and 17 samples) and 10 by 17 (10 variables and 17 samples) respectively. “The data set presented in the supplementary table S1 shows the partition of all seventeen formulations in three subsets”. There was total ten neurons in the hidden layer. The Levenberg–Marquardt algorithm was selected to train the network. In MATLAB, the function “trainlm” uses this algorithm for training feedforward neural networks. This algorithm updates weight and bias values during training the neural network. The simulation of trained network (different drug concentration of excipients) was processed when the mean square error is minimum and at this stage the regression coefficient was tending to one for all the trained data sets (see Fig. 4).

The simulated network was used to predict the drug release profiles for the different concentration of drug contents. Also, the change in drug release profile is noted with the different drug concentration of excipients. The percentage drug release is then compared with the drug release of reference drug product. It was noted that, the similarity factor f2 is more than 80% for the proposed formulation and, is presented in the Table 2. “The calculation of f2 is found in the supplementary table S2 online.”

The steps involved in developing the ANN model is given below:

-

Step 1: Data Collection (Experimental data)

-

Step 2: Data preprocessing

-

Data cleaning (If any value I not available then put zero)

-

Data normalization

-

-

Step 3: Data Splitting

-

Training (70%)

-

Testing (15%)

-

Validation (15%)

-

-

Step 4: Design ANN model

-

Select ANN architecture

-

Define Input and Output Layers

-

Choose activation functions (TRANSIG, PURELIN)

-

-

Step 5: Training the model

-

Forward propagation

-

Compute loss

-

Backward propagation

-

Update weights

-

Iterate until convergence (train the network until regression coefficient becomes close to 1)

-

-

Step 6: Model validation

-

Validate the model on validation set

-

Tune hyperparameters (number of hidden layers, number of nodes in the hidden layer)

-

-

Step 7: Model evaluation

-

Evaluate model on test set

-

Analyse performance

-

-

Step 8: Optimization

-

Optimize release profile parameters

-

Use trained ANN for prediction

-

Simulate and optimize drug release

-

-

Step 9: Model deployment

Conclusion

We attempted building an ANN model to predict the impact of formulation excipients on drug release profiles. Various mathematical models are available to check drug release similarity of the dosage form. ANNs were used to find the combination of drug product excipients to predict the percentage drug release. The predicted percentage drug release is compared with the reference drug release using similarity factor (f2). Further, the optimal formulation predicted by ANN exhibited the best practice to check influence of drug product excipients on drug release from the tablet. With the recent development, k-nearest neighbor (KNN), Bayesian Algorithm, and Neuro ordinary differential equation can also be applicable in future, as it requires relatively small amount of data and indicates which variables are the most important and the direction that the future experiment should take.

Data availability

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- MR:

-

Modified Release

- ANNs:

-

Artificial Neural Networks

- DCP:

-

Dicalcium Phosphate

- APIs:

-

Active Pharmaceutical Ingredients

- RSM:

-

Response Surface Method

- CED:

-

Composite Experimental Design

- MLP:

-

Multilayer Perceptron

- FDA:

-

Food and Drug Administration

References

Paarakh, M. P., Jose, P. A., Setty, C. M. & Christoper, G. V. Release kinetics—concepts and applications. Int. J. Pharm. Res. Technol. https://doi.org/10.31838/ijprt/08.01.02 (2019).

Chaibva, F., Burton, M. & Walker, R. B. Optimization of salbutamol sulfate dissolution from sustained release matrix formulations using an artificial neural network. Pharmaceutics 2, 182–198. https://doi.org/10.3390/pharmaceutics2020182 (2010).

Sun, Y., Peng, Y., Chen, Y. & Shukla, A. J. Application of artificial neural networks in the design of controlled release drug delivery systems. Adv. Drug Deliv. Rev. 55(9), 1201–1215. https://doi.org/10.1016/s0169-409x(03)00119-4 (2003).

Das, P. J., Preuss, C., & Mazumder, B. Artificial neural network as helping tool for drug formulation and drug administration strategies. In Artificial Neural Network for Drug Design, Delivery and Disposition. pp. 263–276 (Elsevier, 2016). https://doi.org/10.1016/B978-0-12-801559-9.00013-2

Peng, Y. et al. Prediction of dissolution profiles of acetaminophen beads using artificial neural networks. Pharm. Dev. Technol. 11(3), 337–349. https://doi.org/10.1080/10837450600769744 (2006).

Bannigan, P. et al. Machine learning directed drug formulation development. Adv. Drug Deliv. Rev. 175, 113806. https://doi.org/10.1016/j.addr.2021.05.016 (2021).

Deb, P. K., Omar, A., Mohammed. A., Prasad, R. M., & Rakesh, T. Applications of computers in pharmaceutical product formulation. pp. 665–703 (2018). https://doi.org/10.1016/B978-0-12-814421-3.00019-1

Takayama, K., Fujikawa, M., Obata, Y. & Morishita, M. Neural network-based optimization of drug formulations. Adv. Drug Deliv. Rev. 55(9), 1217–1231. https://doi.org/10.1016/s0169-409x(03)00120-0 (2003).

Colbourn, E. A. & Rowe, R. C. Novel approaches to neural and evolutionary computing in pharmaceutical formulation: Challenges and new possibilities. Future Med. Chem. 1(4), 713–726. https://doi.org/10.4155/fmc.09.57 (2009).

Mohs, R. C. & Greig, N. H. Drug discovery and development: Role of basic biological research. Alzheimer’s & Dement. 3(4), 651–657. https://doi.org/10.1016/j.trci.2017.10.005 (2017).

Brahmankar, D. M. & Jaiswal, S. B. Biopharmaceutics and pharmacokinetics: A treatise. Vallabh Prakashan (2005).

Higuchi, T. Mechanism of sustained-action medication. Theoretical analysis of rate of release of solid drugs dispersed in solid matrices. J. Pharm. Sci. 52, 1145–1149 (1963).

Sheth, T. S. & Acharya, F. Optimizing similarity factor of in vitro drug release profile for development of early stage formulation of drug using linear regression model. J. Math. Ind. https://doi.org/10.1186/s13362-021-00104-9 (2021).

Sutariyaa, V., Grosheva, A., Sadanab, P., Bhatiab, D. & Pathak, Y. Artificial neural network in drug delivery and pharmaceutical research. Open Bioinform. J. 7, 49–62. https://doi.org/10.2174/1875036201307010049 (2013).

Teja, T. B. et al. Role of Artificial Neural Networks in Pharmaceutical Sciences. J. Young Pharm. https://doi.org/10.5530/jyp.2022.14.2 (2022).

Agatonovic-Kustrin, S. & Beresford, R. Basic concepts of artificial neural network (ANN) modeling and its application in pharmaceutical research. J. Pharm. Biomed. Anal. 22(5), 717–727. https://doi.org/10.1016/S0731-7085(99)00272-1 (2000).

Ibrić, S., Djuriš, J., Parojčić, J. & Djurić, Z. Artificial neural networks in evaluation and optimization of modified release solid dosage forms. Pharmaceutics 4(4), 532–550. https://doi.org/10.3390/pharmaceutics4040531 (2012).

Khan, A. M. et al. Artificial neural network (ANN) approach to predict an optimized pH-dependent mesalamine matrix tablet; Drug Design. Dev. Therapy 14, 2435. https://doi.org/10.2147/DDDT.S244016 (2020).

Manda, A., Walker, R. B. & Khamanga, S. M. M. An artificial neural network approach to predict the effects of formulation and process variables on prednisone release from a multipartite system. Pharmaceutics 11(3), 109. https://doi.org/10.3390/pharmaceutics11030109 (2019).

The Math Works, Inc. (2015): MATLAB version: 8. 5. 0. 197613 (R2015a), https://www.mathworks.com

Kriesel, D., (2007): A brief introduction to neural networks, available at http://www.dkriesel.com

FDA Guidance for Industry: Modified Release Solid Oral Dosage Forms, Scale-Up and Post-Approval Changes (SUPAC-MR): Chemistry, Manufacturing and Controls, In Vitro Dissolution Testing and In Vivo Bioequivalence Documentation. US Food and Drug Administration, Rockville, MD, USA, (1997).

FDA Guidance for Industry: Waiver of in vivo bioavailability and bioequivalence studies for immediate-release solid oral dosage forms based on a biopharmaceutics classification System, U.S. Department of Health and Human Services, Food and Drug Administration, Center for Drug Evaluation and Research (CDER), (2017).

Moore, J. W. & Flanner, H. H. Mathematical comparison of dissolution profiles. Pharm. Technol. 20(6), 64–74 (1996).

Acknowledgements

The authors would like to thank School of Pharmacy, Parul University, Vadodara, Gujarat for the data.

Author information

Authors and Affiliations

Contributions

T.S.S. and F.S. contributed to design and implementation of the research. T.S.S. performed the ANN simulation and the numerical calculations for the suggested experiments. F.S. developed the theoretical framework. T.S.S. took the initiative in writing the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sheth, T.S., Acharya, F. Optimization and evaluation of modified release solid dosage forms using artificial neural network. Sci Rep 14, 16358 (2024). https://doi.org/10.1038/s41598-024-67274-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-67274-5

- Springer Nature Limited