Abstract

Biological systems mainly utilize chemical energy to fuel autonomous molecular motors, enabling the system to be driven out of equilibrium1. Taking inspiration from rotary motors such as the bacterial flagellar motor2 and adenosine triphosphate synthase3, and building on the success of light-powered unidirectional rotary molecular motors4,5,6, scientists have pursued the design of synthetic molecular motors solely driven by chemical energy7,8,9,10,11,12,13. However, designing artificial rotary molecular motors operating autonomously using a chemical fuel and simultaneously featuring the intrinsic structural design elements to allow full 360° unidirectional rotary motion like adenosine triphosphate synthase remains challenging. Here we show that a homochiral biaryl Motor-3, with three distinct stereochemical elements, is a rotary motor that undergoes repetitive and unidirectional 360° rotation of the two aryl groups around a single-bond axle driven by a chemical fuel. It undergoes sequential ester cyclization, helix inversion and ring opening, and up to 99% unidirectionality is realized over the autonomous rotary cycle. The molecular rotary motor can be operated in two modes: synchronized motion with pulses of a chemical fuel and acid–base oscillations; and autonomous motion in the presence of a chemical fuel under slightly basic aqueous conditions. This rotary motor design with intrinsic control over the direction of rotation, simple chemical fuelling for autonomous motion and near-perfect unidirectionality illustrates the potential for future generations of multicomponent machines to perform mechanical functions.

Similar content being viewed by others

Main

Molecular motors play a pivotal role in living systems, ranging from energy conversion, locomotion and intracellular transport, to signal transduction and vision14,15,16. In recent decades, remarkable progress has been made towards the design and applications of artificial molecular machines to enable mechanical functions such as motors, muscles, transporters or pumps17,18,19,20. The first light-driven rotary molecular motor based on an overcrowded alkene was reported in 1999 (ref.21), and at the same time 120° directional rotation, using a chemical-fuelled triptycene-based molecular ratchet, was demonstrated22. Since these pioneering studies, unidirectional rotation has been realized in a number of systems, including light-driven imine motors23, molecular motors based on an interlocked macrocycle24, hemithioindigo rotary motors25 and our chemical-driven unidirectional motors involving rotation about single bonds26,27,28. However, unlike power-stroke systems driven by light energy29,30,31,32,33,34,35, designing continuous and autonomous chemical-driven rotary motors in a unidirectional manner remains highly challenging, not least because the appropriate Gibbs-free-energy change for each state of rotation about a single bond and the activation energy, that is, the kinetics for each chemical step, should be precisely controlled with a single set of reactions. In 2016, an autonomous chemically driven molecular system based on a catenane with biased directionality involving a Brownian ratchet mechanism was reported36. However, suppressing random Brownian motion and designing an ATPase-like (ATP, adenosine triphosphate) autonomous molecular motor with the intrinsic capability of unidirectional rotation around an axle using a chemical fuel remains elusive. Our group designed chemically driven rotary molecular motors based on biaryl structures with formation of a transient bridge between the aryl groups, which facilitates atropisomeric conformational interconversion with high unidirectionality26,27,28; however, these systems require manipulation of protecting groups or sequential chemical steps and could not be operated autonomously. It should be noted that while we were preparing this manuscript, another group reported a related approach featuring an autonomous fuelled directional rotation about a single covalent bond37. Towards the design of fully autonomous rotary motors (Fig. 1), we reasoned that both the stereoselective cyclization and ring-opening reactions (bridge formation and cleavage in the biaryl system) to form the dominant kinetic products are essential to design continuously rotary molecular motors avoiding predominant random Brownian motion. The unidirectionality should be intrinsic to the system (like in ATPase) and is governed by the ratio of the rates of sequential reactions involved in clockwise and anticlockwise rotation.

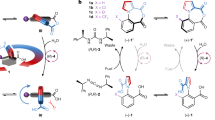

a, Structure and key features of the molecular motor. Key elements: stator and rotor, a carboxylic acid group and two hydroxyl groups to form the dynamic covalent ester bond, and two adjacent point chiral elements, which are used to control both the energy barrier of inversion and the unidirectionality of the motor. b, The potential energy diagram of the dynamic kinetic hydrolysis process in continuous rotation. ΔG°, the energy difference of kinetic product and thermodynamic product; ΔG‡, the energy barrier of inversion; ΔG1‡, the hydrolysis energy barrier of kinetic product; ΔG2‡, hydrolysis energy barrier of thermodynamic product; ΔΔG‡, the energy barrier difference between hydrolysis of kinetic product and thermodynamic product. c, Schematic representation of the continuously clockwise 360° rotary process of the molecular motor fuelled by chemical energy (green, the carboxylic acid group with two chiral centres at the rotor; red and blue, the hydroxyl groups at the stator). The chemical-fuelled cycle starts from the open state, and the carboxylic acid group (green) on the rotor reacts highly selectively with the right hydroxyl group (red) on the stator owing to the two adjacent stereocentres on the side chain (step 1). The high-energy intermediate undergoes relatively quickly helix inversion to the stable state with the rotor part flipping from back to front (step 2). Then the ring is opened by hydrolysis to the non-bridged biaryl state without back flipping (step 3). The remaining half cycle is achieved with the same sequence of steps (steps 4–6). The only difference is that the rotor forms a lactone with the other hydroxyl group (blue) at the stator (step 4) inducing the rotor flipping to the back side (step 5). d, Evolution of the structures of molecular motors designed and the ratios of kinetic/thermodynamic (K/T) products after cyclization and helix inversion.

To address these challenges, a family of biaryl molecular motors was designed. The structure and the essential operational features of the rotary molecular motor (Motor-3) are given in Fig. 1a. The clockwise 360° rotary process consists of six steps, including two cyclization steps (step 1 and step 4), two ring inversion steps (step 2 and step 5) and two ring-opening steps (step 3 and step 6; Fig. 1c). The upper ring (rotor) of the biaryl incorporates a carboxylic acid group at the side chain in the ortho position whereas the lower one (stator) adopts two phenolic groups. The rotation about the sp2–sp2 aryl bond is restricted because of the presence of three ortho functional groups to avoid random Brownian motion around the single bond without a fuel (Supplementary Fig. 12)38. Upon treatment with the fuel, an eight-membered ring lactone is formed and the intramolecular phenolic ester serves as a dynamic covalent bond motif28. Each cyclization (steps 1 and 4) is followed by a hydrolysis step (steps 3 and 6) to complete a full rotary cycle (Fig. 1c). The ester formation between the carboxyl group in the rotor aryl and one of the hydroxyl moieties in stator aryl is fuelled by the carbodiimide (N,N′-diisopropylcarbodiimide, DIC) to urea (N,N′-diisopropylurea, DIU) conversion, which facilitates the biaryl inversion. Key to the design, besides biaryl chirality, are two adjacent stereocentres present in the side chain to control both the cyclization and the inversion processes, respectively. Thus, the point-to-axis chirality induction strategy ensures the unidirectionality of both cyclization and ring-flipping processes.

The second principle used here is dynamic kinetic hydrolysis (steps 2 and 3) of the cyclic states. An ideal potential energy diagram is shown in Fig. 1b. When the molecular motor is operated under strong basic conditions, the selectivity of the ring-opening step is controlled by the ratio of unstable isomer to stable isomer (thermodynamic versus kinetic control), which is determined by the energy difference between two cyclic states (ΔG°). In other words, if khydrolysis > k′hydrolysis >> kinversion, the ratio of unstable isomer to stable isomer will be the selectivity of the ring-opening step corresponding to unidirectionality in synchronized stepwise motion (Fig. 1c). However, under slightly basic conditions, the hydrolysis speed slows down, and if kinversion >> khydrolysis > k′hydrolysis, the system follows the Curtin–Hammett principle39 and the unidirectionality is not solely dependent on the relative proportions of the interconverting cyclic diastereomers; it is controlled by the difference in energy barrier of the respective transition states ΔΔG‡ corresponding to khydrolysis/k′hydrolysis. This phenomenon resembles dynamic kinetic resolution in asymmetric catalysis, denoted dynamic kinetic hydrolysis. In the latter case, if ΔΔG‡ > ΔG°, the selectivity of the ring-opening step, and as a consequence directionality, would be amplified compared with the former situation.

To ensure continuous rotation along the biaryl C–C bond in Motor-3 when fuelled by chemical energy (Fig. 1c), all kinetic parameters are fine-tuned to ensure both cyclization and hydrolysis occur in the same reaction mixture and the molecular motor continuously rotates efficiently as long as the fuel is present. It should be emphasized that the working mechanism of the current molecular motor being kinetically driven resembles that of a second-generation light-driven molecular motor, albeit with a difference in energy input31,40.

To confirm the crucial role of two adjacent stereocentres in the benzyl and α-position to the carboxylic group, a series of model compounds (1, 2, 3 and Motor-1) were synthesized and the ratios of kinetic/thermodynamic (unstable/stable or abbreviated as K/T) isomers after cyclization (step 1) and helix inversion (step 2) were determined (Supplementary Sections 2 and 3). As shown in Fig. 1d, compound 1 with a single stereocentre at the benzylic position gave a high cyclization selectivity towards the kinetic isomer (K/T > 20/1) but a poor biaryl helix inversion ratio (K/T = 1/1.6). In contrast, compound 2 with a single stereocentre at the α-position to the carboxylic acid exhibited a poor cyclization selectivity (K/T = 1/1.9) but a good biaryl inversion ratio (K/T = 1/9.5). The above results clearly indicated that the stereocentre at the benzylic position and the one at the α-position of carboxylic acid were responsible for the stereocontrol in the cyclization and biaryl helix inversion, respectively. We reasoned that if two stereocentres with matched configuration were introduced, high selectivity in both the cyclization and the inversion processes might be achieved. To our delight, the syn-isomer (S,S′)-Motor-1 indeed showed high cyclization selectivity (K/T > 20/1) and a good helix inversion ratio (K/T = 1/4.1). In contrast, a high ratio (K/T = 1/15) of the thermodynamic product was obtained when the anti-isomer (R,S′)-3 was cyclized. Exploring the delicate balance of stereochemical elements, we found that Motor-2 with an –OH substituent at the benzylic position instead of –OMe compared with Motor-1 shows a marked decrease in the inversion barrier (standard free energy, Δ‡G° = 98.0 kJ mol−1; half-life, t1/2 = 4.7 h, 298.15 K; Supplementary Fig. 10). Further experimental details on the evaluation of the motors, that is, NMR spectra of the distinct isomers and single-crystal X-ray diffraction to establish their absolute configuration and conformational analysis, are given in Extended Data Figs. 1 and 2. To further improve the speed of the rotary molecular motor, an electron-rich and sterically more demanding t-Bu group was introduced to 4,4′-position of the biaryl (Motor-3) (ref.41). As a result, the Gibbs standard free energy of activation of Motor-3 was further decreased to 94.7 kJ mol−1 (t1/2 = 73 min, 298.15 K) and the helix inversion ratio was also improved to 10/1 (Supplementary Fig. 11).

To prove unequivocally that the chemically fuelled molecular motor undergoes stepwise 360° unidirectional rotation about the single bond, desymmetrization of lower ring (stator) is necessary to the distinguish isomers after each step (Fig. 2). Monobromination in the presence of chiral phosphoric acid catalyst of the stator of molecular Motor-1 provided Motor-Br with high stereoselectivity (diastereometric ratio (d.r.) > 25:1) (Supplementary Sections 2 and 7)42. The relative configuration of corresponding methyl ester Motor-Br-Me was determined by single-crystal diffraction analysis (Supplementary Fig. 22). The 360° rotary cycle of the molecular motor Motor-Br is shown in Fig. 2, and the individual steps studied by 1H NMR show all the distinct isomers during the unidirectional rotary cycle. In step 1, the lactonization of (S,S′,aR)-Motor-Br (where the superscript ‘a’ denotes the axial chirality) in the presence of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) is favoured to take place with the left hydroxyl rather than the right one on the stator. The stable isomer trans-Motor-Br-T was obtained by heating the unstable isomer trans-Motor-Br-K in deuterated chloroform (CDCl3) at 65 °C for 2 h and a good inversion ratio (K/T = 1/6.3) was observed. The 180° unidirectional rotation was accomplished after hydrolysis of trans-Motor-Br-K by lithium hydroxide (LiOH) to give (S,S′,aS)-Motor-Br—the atropisomer of (S,S′,aR)-Motor-Br. Accordingly, the remaining half cycle can be achieved with the same sequence of steps (Fig. 2; see also Supplementary Fig. 23 for full spectra). On the basis of these data, it is clear that the present chemically fuelled molecular motor indeed undergoes stepwise 360° unidirectional rotation as the sequential interconversion with excellent stereocontrol of all six isomers can be clearly identified by 1H NMR spectroscopy.

a, Six steps for 360° rotation of the Motor-Br. Step 1, EDC, triethylamine (Et3N), DCM, 0 °C, 77%; step 2, 65 °C in CDCl3, quantitative; step 3, LiOH, methanol (MeOH), H2O, room temperature (r.t.), 87%; step 4, EDC, Et3N, DCM, 0 °C, 72%; step 5, 65 °C in CDCl3, quantitative; step 6, LiOH, MeOH, H2O, r.t., 85%. b, Partial 1H NMR spectra of six isomers ((S,S′,aR)-Motor-Br, trans-Motor-Br-K, trans-Motor-Br-T, (S,S′,aS)-Motor-Br, cis-Motor-Br-K and cis-Motor-Br-T) in the rotary cycle of the molecular motor (where the superscript ‘a’ denotes the axial chirality). In steps 1 and 4, the appearance of minor diastereomers is due to helix inversion in the process of isolation. δ.

With the optimized motor design, that is, Motor-3 and stepwise 360° unidirectional rotation established, we next sought to synchronize the stepwise operation of the molecular motor (Fig. 3). Conditions were established to ensure that all the cyclization, biaryl-inversion and hydrolysis reactions took place sequentially in the reaction mixture with Motor-3. Initially, when EDC (2.0 equiv.) was added to a solution of Motor-3 in dichloromethane (DCM; 2.0 ml) and water (H2O; 3.0 ml), >80% carboxylic acid was converted to the kinetic isomer Motor-3-K within 5 min. However, high-performance liquid chromatography (HPLC) analysis indicated that about 30% of the kinetic isomer was converted to the stable isomer Motor-3-T owing to the low barrier of helix inversion (Fig. 3, (3)). Next, the system was acidified to about pH 2 by adding 20 μl concentrated hydrochloric acid (HCl), and after 5 h, >95% of the kinetic product (Motor-3-K) was converted to the thermodynamic isomer Motor-3-T. Then, the system was adjusted to about pH 13 by adding 2 mmol sodium hydroxide (NaOH), and the hydrolysis of Motor-3-T was completed in 20 min to give Motor-3 showing that unidirectional 180° rotary rotation was accomplished. The remaining half cycle was realized by operation of Motor-3 using the same reaction sequence mentioned above. As shown in Fig. 3 (6), after six steps Motor-3 fully restored to its initial state without any impurities observed. It is evident that Motor-3 can be operated in a synchronized 360° rotation manner by adding pulses of EDC as a chemical fuel under acid–base oscillations.

Reagents and conditions: Motor-3 (5 mg, 0.013 mmol), DCM (2.0 ml), H2O (3.0 ml), 25 °C (Supplementary Section 10, Agilent Pursuit XRs 5 C18 250 × 4.6 mm, 25 °C, 1.0 ml min−1, MeCN/H2O/HCOOH = 70/30/0.1, λ = 280 nm). (1) HPLC trace of the initial state of the Motor-3. (2) HPLC trace of the sample taken from the reaction mixture after cyclization for 5 min. (3) HPLC trace of the sample taken from the reaction mixture after inversion. (4) HPLC trace of the sample taken from the reaction mixture after hydrolysis. From (1) to (4), 180° rotation of the molecular motor has been achieved in a unidirectional manner. Then (5), (6) and (7) show the second half of the cycle to achieve full 360° unidirectional rotation. (i) EDC (40 mg, 0.21 mmol), 5 min; (ii) 20 μl concentrated HCl (c.HCl), 5 h; (iii) NaOH (80 mg, 2.0 mmol), 20 min; (iv) 75 μl c.HCl, EDC (40 mg, 0.21 mmol), 5 min; (v) 20 μl c.HCl, 5 h; (vi) NaOH (80 mg, 2.0 mmol), 20 min. λ, wavelength; EDU, 1-[3-(dimethylamino)propyl]-3-ethylurea); HCOOH, formic acid; MeCN, acetonitrile.

With the unequivocal proof of chemical-driven, sequential, synchronized and unidirectional steps comprising a full 360° rotary cycle, we next established the operation of the rotary molecular motor in a continuous, autonomous and unidirectional manner. We first investigated the hydrolysis rate of stable isomer (khydrolysis) and the unstable isomer (k′hydrolysis) of the cyclic states as in conditions of continuous rotation, if kinversion >> k′hydrolysis > khydrolysis, the system follows the Curtin–Hammett principle and the unidirectionality might be compromised (Fig. 4). Motor-1 was used to study the kinetics owing to its relatively high inversion barrier, which can avoid interconversion between the kinetic and the thermodynamic isomers during the hydrolysis process. Gratifying, the hydrolysis rate constant of the stable isomer is 47 times that of the unstable isomer (Fig. 4a and Supplementary Section 8). This means we can use this marked difference in hydrolysis rate to amplify the unidirectionality of the molecular motor according to the Curtin–Hammett principle if the kinetics follows kinversion ≥ khydrolysis > k′hydrolysis. Several experiments were performed with mixture of the methoxymethyl (MOM)-protected cyclic isomers (Motor-1-MOM-K/Motor-1-MOM-T = 4:1) to confirm this dynamic kinetic hydrolysis (Fig. 4b). When the hydrolysis reaction was executed in a mixture of 0.5 M tripotassium phosphate (K3PO4) aqueous solution, tert-butanol (t-BuOH) at 50 °C, the d.r. of the product was indeed improved to 21/1 compared with the ratio of reactant (4:1). In contrast, when the mixture of cyclic isomers was treated with LiOH as a control experiment, the d.r. of the product was equal to the d.r. of the starting material (4/1 to 4/1) (Supplementary Fig. 28), because the hydrolysis rates are much faster than the rate of inversion (khydrolysis > k′hydrolysis >> kinversion).

a, Determination of the hydrolysis rates of Motor-1-K and Motor-1-T. b, Dynamic kinetic hydrolysis experiment. Reagents and conditions: Motor-1-MOM-K (165 mg, 0.5 mmol), 0.5 M K3PO4 aqueous solution (5.0 ml), t-BuOH (5.0 ml), 50 °C, 72 h, 88%. Control experiment: Motor-1-MOM-K (165 mg, 0.5 mmol), 0.5 M LiOH aqueous solution (5.0 ml), t-BuOH (5.0 ml), 0 °C, 10 h, 92%. c, The continuous rotation of the molecular motor powered by chemical fuel (Supplementary Section 15). Reagents and conditions: Motor-3 (20 mg, 0.05 mmol), 2 M K3PO4 aqueous solution (5.0 ml), t-BuOH (3.0 ml), 1,4-dioxane (2.0 ml), DIC (2.0 mmol), HOBt (1.0 mmol), 35 °C. d, HPLC chromatograms of the samples taken from the reaction mixture during the continuous rotation of the Motor-3 from 0 h to 24 h (For analytical purposes, the carboxylic acid was converted to methyl carboxylate Motor-3-Me). c, concentration; c0, initial concentration.

In the present system, as we have proven that the molecular motor undergoes a 360° unidirectional stepwise rotation involving 6 distinct isomers, the molecular motor should exhibit the same properties in continuous rotation mode. However, conditions should be developed to ensure both hydrolysis and cyclization can take place in the same reaction mixture allowing the molecular motor to work in an efficient way, not compromising the unidirectional rotary cycle. Two principles guide us to establish the proper condition. (1) As the rotation speed and unidirectionality of molecular motor are dependent on a set of reaction rate constants (kcyclization, kinversion, k′hydrolysis and khydrolysis), the values of kcyclization and khydrolysis should be of a similar magnitude to kinversion to avoid that the rate-limiting step is far slower than the other steps. (2) To avoid the hydrolysis of the kinetic isomer, kinversion should be much larger than k′hydrolysis (kinversion > 100k′hydrolysis; Supplementary Section 12). On the basis of this analysis, we established the conditions that were compatible with both the cyclization and the hydrolysis process of Motor-3: 2 M aqueous K3PO4, t-BuOH and dioxane (5:3:2 v/v/v). Now the hydrolysis process can take place and meanwhile cyclization also occurs in the presence of DIC and 1-hydroxybenzotriazole (HOBt) in the same solvent mixture (Fig. 4c). With the optimized conditions for continuous rotation established, the reaction rate constant for helix inversion and the observed rate constants for cyclization and hydrolysis were determined at 35 °C (kinversion = 1.34 × 10−4 s−1, t1/2 = 86.1 min; kcyclization = 3.47 × 10−3 s−1, t1/2 = 33.3 min; khydrolysis = 7.28 × 10−5 s−1, t1/2 = 159 min), respectively (Supplementary Sections 12–14). In the presence of excess DIC, the hydrolysis is the slowest step and the rate-determining step in the rotatory cycle. These results clearly show that the rate constants meet the criteria we indicated above (Fig. 4).

A continuous rotation experiment was performed and the process was monitored by HPLC as shown in Fig. 4d. At the starting point, DIC and HOBt were added in one batch to a solution of Motor-3 in a mixed solvent of t-BuOH, dioxane and 2 M K3PO4 aqueous solution. Within 1 h, both cyclic isomers were detected, which can both be regarded as far-from-equilibrium states. From 4 h to 9 h, this out-of-equilibrium system reached a steady state, where the proportions of all isomers were roughly unchanged. From 9 h to 12 h, the observed cyclization rate decreased owing to the decreasing concentration of DIC, which led to the slightly decreased K/T ratio. Following the consumption of the chemical fuel (DIC) and thorough hydrolysis of cyclic isomers, this system turned back to its initial equilibrium state during 12 h to 24 h. The molecular motor will keep rotating if the amount of fuel is in excess to the motor. Finally, the hydrolysis rate of DIC (background reaction of fuel) was also determined (kdecomposition = 5.64 × 10−5 s−1, t1/2 = 204 min; Supplementary Section 11), which is much lower compared with kcyclization (3.47 × 10−3 s−1). This means the molecular motor is a good catalyst for decomposition of the fuel and, based on the rates, we can establish that 98% DIC is consumed in the early stages and the ratio drops as the concentration of the free acid form of Motor-3 decreased. Over the 360° autonomous unidirectional rotation, the unidirectionality is determined by the kinetics of three sets of highly selective cyclization, helix inversion and hydrolysis reactions, so the unidirectionality can be calculated as: (khydrolysis/k′hydrolysis)2 × (kinversion/k'inversion)2 × (kcyclization/k′cyclization)2 = 472 ×92 × 202 = 7.2 × 107/1, where kcyclization/k′cyclization is the ratio of K/T after cyclization and kinversion/k'inversion is the ratio of T/K after helix inversion.

In conclusion, we have developed an autonomous unidirectional rotary molecular motor fuelled by chemical energy, taking advantage of intrinsic chiral elements in a system that is mainly governed by kinetics distinct from the systems operating through a small bias to mainly Brownian motion. Although still far from the rotary speeds of our light-powered motors operating in the nanosecond regime, we expect that the design principles shown here will be compatible with several other chemical transformations and fuels and probably facilitate the development of chemical powered rotary motors for a wide range of machine-like functions.

Data availability

Details on the procedures, characterization and references, including spectra of new compounds and compounds made using the reported method, are available in Supplementary Information. Crystallographic data for (S,S')-Motor-1-Me, (R,S')-3-Me, Motor-1-K, Motor-1-T-MOM and Motor-Br-Me can be obtained free of charge from www.ccdc.cam.ac.uk under CCDC deposition numbers 2170186, 2170187, 2170188, 2170189 and 2170190.

Change history

22 December 2022

Editor’s Note: Readers are alerted that the authors have discovered that the motion of molecular motor reported in this paper appears to be very sensitive to pH change, which occurs during fuel consumption. A further editorial response will follow the based on the investigation of this issue.

10 July 2023

This article has been retracted. Please see the Retraction Notice for more detail: https://doi.org/10.1038/s41586-023-06380-2

References

Saper, G. & Hess, H. Synthetic systems powered by biological molecular motors. Chem. Rev. 120, 288–309 (2020).

Sowa, Y. et al. Direct observation of steps in rotation of the bacterial flagellar motor. Nature 437, 916–919 (2005).

Boyer, P. D. The ATP synthase—a splendid molecular machine. Annu. Rev. Biochem. 66, 717–749 (1997).

Wang, J. & Feringa, B. L. Dynamic control of chiral space in a catalytic asymmetric reaction using a molecular motor. Science 331, 1429–1432 (2011).

Roke, D., Wezenberg, S. J. & Feringa, B. L. Molecular rotary motors: unidirectional motion around double bonds. Proc. Natl Acad. Sci. USA 115, 9423–9431 (2018).

Browne, W. R. & Feringa, B. L. Making molecular machines work. Nat. Nanotechnol. 1, 25–35 (2006).

Kelly, T. R. et al. Progress toward a rationally designed, chemically powered rotary molecular motor. J. Am. Chem. Soc. 129, 376–386 (2007).

Anelli, P. L., Spencer, N. & Stoddart, J. F. A molecular shuttle. J. Am. Chem. Soc. 113, 5131–5133 (1991).

Badjić, J. D., Balzani, V., Credi, A., Silvi, S. & Stoddart, J. F. A molecular elevator. Science 303, 1845–1849 (2004).

Cárdenas, D. J., Livoreil, A. & Sauvage, J.-P. Redox control of the ring-gliding motion in a Cu-complexed catenane: a process involving three distinct geometries. J. Am. Chem. Soc. 118, 11980–11981 (1996).

Jiménez, M. C., Dietrich-Buchecker, C. & Sauvage, J.-P. Towards synthetic molecular muscles: contraction and stretching of a linear rotaxane dimer. Angew. Chem. Int. Ed. 39, 3284–3287 (2000).

Silvi, S., Venturi, M. & Credi, A. Artificial molecular shuttles: from concepts to devices. J. Mater. Chem. 19, 2279–2294 (2009).

Stevens, A. M. & Richards, C. J. A metallocene molecular gear. Tetrahedron Lett. 38, 7805–7808 (1997).

Geeves, M. A. & Holmes, K. C. Structural mechanism of muscle contraction. Annu. Rev. Biophys. 68, 687–728 (1999).

Hua, W., Chung, J. & Gelles, J. Distinguishing inchworm and hand-over-hand processive kinesin movement by neck rotation measurements. Science 295, 844–848 (2002).

Vale, R. D. The molecular motor toolbox for intracellular transport. Cell 112, 467–480 (2003).

Erbas-Cakmak, S., Leigh, D. A., McTernan, C. T. & Nussbaumer, A. L. Artificial molecular machines. Chem. Rev. 115, 10081–10206 (2015).

van Dijk, L. et al. Molecular machines for catalysis. Nat. Rev. Chem. 2, 0117 (2018).

Aprahamian, I. The future of molecular machines. ACS Cent. Sci. 6, 347–358 (2020).

Astumian, R. D. Kinetic asymmetry allows macromolecular catalysts to drive an information ratchet. Nat. Commun. 10, 3837 (2019).

Koumura, N., Zijlstra, R. W. J., van Delden, R. A., Harada, N. & Feringa, B. L. Light-driven monodirectional molecular rotor. Nature 401, 152–155 (1999).

Kelly, T. R., De Silva, H. & Silva, R. A. Unidirectional rotary motion in a molecular system. Nature 401, 150–152 (1999).

Greb, L. & Lehn, J.-M. Light-driven molecular motors: imines as four-step or two-step unidirectional rotors. J. Am. Chem. Soc. 136, 13114–13117 (2014).

Erbas-Cakmak, S. et al. Rotary and linear molecular motors driven by pulses of a chemical fuel. Science 358, 340–343 (2017).

Bach, N. N., Josef, V., Maid, H. & Dube, H. Active mechanical threading by a molecular motor. Angew. Chem. Int. Ed. 61, e202201882 (2022).

Fletcher, S. P., Dumur, F., Pollard, M. M. & Feringa, B. L. A reversible, unidirectional molecular rotary motor driven by chemical energy. Science 310, 80–82 (2005).

Collins, B. S. L., Kistemaker, J. C. M., Otten, E. & Feringa, B. L. A chemically powered unidirectional rotary molecular motor based on a palladium redox cycle. Nat. Chem. 8, 860–866 (2016).

Zhang, Y. et al. A chemically driven rotary molecular motor based on reversible lactone formation with perfect unidirectionality. Chem 6, 2420–2429 (2020).

Corra, S. et al. Artificial supramolecular pumps powered by light. Chem. Eur. J. 27, 11076–11083 (2021).

Guentner, M. et al. Sunlight-powered kHz rotation of a hemithioindigo-based molecular motor. Nat. Commun. 6, 8406 (2015).

Koumura, N., Geertsema, E. M., van Gelder, M. B., Meetsma, A. & Feringa, B. L. Second generation light-driven molecular motors. Unidirectional rotation controlled by a single stereogenic center with near-perfect photoequilibria and acceleration of the speed of rotation by structural modification. J. Am. Chem. Soc. 124, 5037–5051 (2002).

Lubbe, A. S. et al. Photoswitching of DNA hybridization using a molecular motor. J. Am. Chem. Soc. 140, 5069–5076 (2018).

Pooler, D. R. S., Lubbe, A. S., Crespi, S. & Feringa, B. L. Designing light-driven rotary molecular motors. Chem. Sci. 12, 14964–14986 (2021).

Štacko, P. et al. Locked synchronous rotor motion in a molecular motor. Science 356, 964–968 (2017).

Zhao, D., van Leeuwen, T., Cheng, J. & Feringa, B. L. Dynamic control of chirality and self-assembly of double-stranded helicates with light. Nat. Chem. 9, 250–256 (2016).

Wilson, M. R. et al. An autonomous chemically fuelled small-molecule motor. Nature 534, 235–240 (2016).

Borsley, S., Kreidt, E., Leigh, D. A. & Roberts, B. M. W. Autonomous fuelled directional rotation about a covalent single bond. Nature 604, 80–85 (2022).

Bringmann, G. et al. Atroposelective synthesis of axially chiral biaryl compounds. Angew. Chem. Int. Ed. 44, 5384–5427 (2005).

Seeman, J. I. The Curtin–Hammett principle and the Winstein–Holness equation: new definition and recent extensions to classical concepts. J. Chem. Educ. 63, 42–48 (1986).

Koumura, N., Geertsema, E. M., Meetsma, A. & Feringa, B. L. Light-driven molecular rotor: unidirectional rotation controlled by a single stereogenic center. J. Am. Chem. Soc. 122, 12005–12006 (2000).

Aikawa, K., Miyazaki, Y. & Mikami, K. Stable axial chirality in metal complexes bearing 4,4′-substituted BIPHEPs: application to catalytic asymmetric carbon–carbon bond-forming reactions. Bull. Chem. Soc. Jpn 85, 201–208 (2012).

Mori, K. et al. Enantioselective synthesis of multisubstituted biaryl skeleton by chiral phosphoric acid catalyzed desymmetrization/kinetic resolution sequence. J. Am. Chem. Soc. 135, 3964–3970 (2013).

Acknowledgements

We are grateful for the support of this work by the National Natural Science Foundation of China (21971267), the Fundamental Research Funds for the Central Universities, Sun Yat-sen University (22lgqb34) and the programme for Guangdong Introducing Innovative and Entrepreneurial Teams (2017ZT07C069). B.L.F. acknowledges financial support from the European Research Council (ERC; advanced grant number 694345 to B.L.F.) and the Dutch Ministry of Education, Culture and Science (Gravitation programme number 024.001.035).

Author information

Authors and Affiliations

Contributions

D.Z., K.M., Y.Z. and B.L.F. conceived the project. K.M., Y.Z., Z.D. and X.M. carried out the synthesis and characterized the motion of the molecular motor. K.M. and Y.Y. performed all XRD measurements and structural analysis. D.Z. and B.L.F. guided the research; K.M., Y.Z., D.Z. and B.L.F wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks He Tian and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article has been retracted. Please see the retraction notice for more detail: https://doi.org/10.1038/s41586-023-06380-2

Extended data figures and tables

Extended Data Fig. 1 Single-crystal structures of 3-Me, Motor-1-Me, Motor-1-K and MOM-derived thermodynamic product (Motor-1-T-MOM).

(a) The absolute configuration of molecular motors was unambiguously established by single-crystal X-ray diffraction as well (Here, the S or R denotes the configuration of the chiral centre at the α position of carboxylic acid group, S’ or R’ denotes the configuration of the chiral centre of the benzyl position). Single crystal X-ray diffraction experiments of the corresponding methyl esters 3-Me and Motor-1-Me were performed to gain insight into the relationship between configurations and cyclization selectivity. The results indicated the orientation of the carboxylic group is key to realize high selectivity of cyclization. Viewed along the biaryl C–C bond (the axle of rotation), the carboxylic group in (S,S’)-syn-isomer−1 favours bridge formation with the hydroxyl group on the right of the stator aryl to generate exclusively the kinetic isomer. However, the methyl group at the α-position of the carboxylic group in (R,S’)-anti-isomer 3 blocked the carboxylic group from reacting with hydroxyl group on the right side of the stator aryl and therefore cyclized with the left hydroxyl group to give dominantly a thermodynamic isomer. (b) Single-crystal X-Ray diffraction of Motor-1-K and MOM-protected Motor-1-T-MOM confirmed that the rotational direction of Motor-1 was clockwise. It is interesting to note the favoured tub-shaped conformation of the eight-membered ring in Motor-1-T and Motor-1-K. In Motor-1-K, the methyl group adopts a pseudoaxial orientation while the methoxy group is located in a pseudoequatorial position. However, in the case of Motor-1-T, the methoxy group is in a pseudoaxial orientation and the methyl group adopts a pseudoequatorial position. The eight-membered ring flipping can be explained by Winstein–Holness A value which is used to describe the conformational preference of an equatorial compared to an axial substituent in a substituted cyclohexane. As the A value of a methyl group (1.7 kcal/mol) is larger than the A value of a methoxy group (0.6 kcal/mol), the methyl group has a strong tendency for the equatorial position which also drives the helix inversion of the biaryl and the conversion of Motor-1-K to Motor-1-T (P to M).

Extended Data Fig. 2 1H NMR spectra of three stations of Motor-1.

1H NMR spectra of three states (Motor-1, Motor-1-K, Motor-1-T) during the 180° unidirectional rotation. In the first step, Motor-1 was cyclized to give a high-energy isomer Motor-1-K in the presence of the fuel EDC in DCM at 0 °C and this is the only energy input step in the half cycle of rotation. Motor-1-K unstable isomer then underwent an energetic downhill helix inversion to yield the Motor-1-T with a final ratio of T/K = 4/1. Analysis of the kinetic data provided the Gibbs free energy of activation Δ‡G° = 103.6 kJ/mol (t1/2 = 45 h at 298.15 K) (Supplementary Fig. 9).

Supplementary information

Supplementary Information

This Supplementary Information file contains 17 sections and includes 40 figures and 5 tables.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mo, K., Zhang, Y., Dong, Z. et al. RETRACTED ARTICLE: Intrinsically unidirectional chemically fuelled rotary molecular motors. Nature 609, 293–298 (2022). https://doi.org/10.1038/s41586-022-05033-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-022-05033-0

- Springer Nature Limited

This article is cited by

-

A catenane that is topologically achiral despite being composed of oriented rings

Nature Chemistry (2023)